Abstract

We report the synthesis of flexible, hydrophobic, and oleophilic silica aerogels through a two-step acid–base sol–gel reaction followed by supercritical drying, in which methyltriethoxysilane (MTES) is used as a precursor, ethanol (EtOH) as a solvent, and hydrochloric acid (HCl) and ammonia (NH3·H2O) as catalysts. At the optimal molar ratio of MTES:EtOH:H2O:HCl:NH3·H2O is 1:18:3.5:1.44 × 10−4:1.2, MTES-based silica aerogels show the minimum density of 0.046 g/cm3 and the maximum compression ratio of 80 % with 15.09 kPa stress. They are superhydrophobic with a water contact angle of 157° and thermally stable up to 350 °C. We also find that they show the excellent adsorption for ethanol with a ratio of 1400 %.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Silica aerogels are a highly porous material derived from a silica gel, in which the liquid phase confined in three-dimensional (3D) porous silica networks is replaced with a gas phase [1, 2]. Due to their low density, low thermal conductivity, high porosity, and large surface area, silica aerogels have gained tremendous interests as catalyst supports [3], light-weight thermal insulators [4], absorbents [5], and drug delivery systems [6]. Tetraethylorthosilane (TEOS) [7, 8] is a traditional precursor for the synthesis of silica aerogels through sol–gel process. However, the TEOS-based silica aerogels are fragile and show strong moisture absorption due to the presence of hydrophilic Si–OH groups on the silica networks [9], which limit their potential applications in a number of fields [10]. The flexible and hydrophobic properties of silica aerogels are extremely important for their long-term applications.

Recently, progresses have been made in improving the strength and toughness of silica aerogels by integrating high-strength fibers in the silica aerogels [11] or cross-linking of silica aerogels with polymers [12]. Although these methods are effective in improving the strength and toughness of silica aerogels, further surface modification is required to improve their hydrophobic property [13]. It has been shown that silica aerogels made of methyltrimethoxysilane (MTMS) [14, 15] and methyltriethoxysilane (MTES) [16, 17] precursors are flexible and hydrophobic due to the presence of non-polar methyl terminated groups on the three-dimensional (3D) porous silica networks. Hydrophobic aerogels are great promise in the removal of oil from water for oil spill cleanup [18].

Herein, we study the effect of solvent and catalysts on the flexibility and hydrophobicity of silica aerogels made of MTES precursor through a two-step acid–base sol–gel reaction [19], in which ethanol (EtOH) is used as a solvent, hydrochloric acid (HCl) and ammonia (NH3·H2O) are as catalysts. At the optimal molar ratio of MTES:EtOH:H2O:HCl:NH3·H2O is 1:18:3.5:1.44 × 10−4:1.2, the MTES-based silica aerogels show the minimum density of 0.046 g/cm3 and the maximum compression ratio of 80 %. The MTES-based silica aerogels are superhydrophobic with a water contact angle of 157° and show the excellent uptaking capacity of ethanol with an adsorption ratio of 1400 %. The flexible, hydrophobic, and oleophilic MTES-based silica aerogels are thermally stable up to 350 °C.

Experimental

MTES, EtOH, HCl, and NH3·H2O were obtained from Sinopharm Chemical Reagent (Shanghai, China). All chemicals were used without further purification. In our experiments, the silica gels were synthesized by MTES as a precursor, EtOH as a solvent, and HCl and NH3·H2O as acid–base catalysts in two steps. Firstly, MTES precursor was diluted with EtOH and H2O, followed by the addition of 0.01 mol/L HCl alcohol solution (acidic catalyst). The mixed solution was placed at room temperature for the hydrolysis of MTES. Secondly, after 18 h, 10 mol/L NH3·H2O alcohol solution (basic catalyst) was added to the mixed solution to accelerate condensation reactions. Table 1 shows the specific molar ratios of MTES:EtOH:H2O:HCl:NH3·H2O to create various samples in this work. The resultant sol was stirred for 20 min and transferred to airtight glass tubes. The gelation took place after 5–16 h. The gels were then aged in an EtOH bath for 2 days to remove water confined in gel networks. Finally, the MTES-based aerogels were obtained by the supercritical drying (at 260 °C and 10 MPa).

The bulk density (ρ = m/V) of MTES-based silica aerogels was calculated from the mass (m) to volume ratio (V). The mass was measured by an electronic balance with 0.01 mg accuracy. The dimension was measured using calipers with 0.01 mm accuracy. The flexibility of MTES-based silica aerogels was defined by the compression ratio (S = ΔL/L), where ΔL is the largest length change with stress and L is the original length. The uniaxial compression tests were performed by KDII-0.01 testing machine (Shenzhen Kaiqiangli Testing Instruments, Shenzhen, China), equipped with two flat-surface compression stages and 100 N load cells. The cylindrical samples with 12 × 12 × 20 mm size were used. The contact angle of water droplets on MTES-based silica aerogels was measured with a JC2000A contact angle analyzer (Shanghai Advanced Photoelectric Technology, Shanghai, China). Thermo gravimetric and differential thermal analyses (TGA/DTA, STA 409 EP/DIL 404, Netzsch, Selb, Germany) were conducted from room temperature to 800 °C at a rate of 10 °C/min under air flow. The chemical composition of MTES-based silica aerogels was characterized with Fourier transform-infrared spectroscopy (FT-IR, Avatar 360, Thermo Nicolet, Madison, WI, USA). The microstructure of MTES-based aerogels was characterized using scanning electron microscopy (SEM, LEO1530, Germany LEO electron, Oberkochen, Germany).

Results and discussion

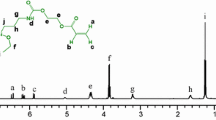

Figure 1 shows a two-step acid–base catalyzed process for preparing flexible and hydrophobic silica gels. MTES was partially hydrolyzed in water under acidic condition, and then condensed into silica network under basic condition. Compared to TEOS-based aerogels, the MTES-based aerogels are hydrophobic with a lower cross-linking density and higher deformability due to one non-hydrolysable, hydrophobic methyl group present. It has been known that the microstructures of silica aerogels are primarily controlled by the molar ratio of reactants [15]. MTES-based silica aerogels were synthesized at three molar ratios of H2O, HCl, and NH3·H2O. Orthogonal tests were used to assess their flexibilities. Table 1 shows the result of a L9 (34) orthogonal array with nine combinations was applied. The optimal result via the ANOVA analysis [20] reveals that MTES-based silica aerogels synthesized at the MTES:H2O:HCl:NH3·H2O molar ratio of 1:3.5:1.44 × 10−4:1.2 have the maximum flexibility.

Furthermore, we studied the effect of EtOH solvent on the flexibility of MTES-based silica aerogels, in which the molar ratio of EtOH and MTES was varied from 8 to 20, while the molar ratio of MTES:H2O:HCl:NH3·H2O was kept at 1:3.5:1.44 × 10−4:1.2. We find that the gelation time increases with the increase of the molar ratio of EtOH and MTES from 8 to 20. This is due to the fact that the high dilution of MTES molecules in EtOH solvent would slow down the hydrolysis and condensation reaction. Simultaneously, the high dilution of MTES molecules in EtOH solvent reduces silica contents, leading to the lower density of the silica aerogels. As can be seen in Fig. 2, the densities of MTES-based silica aerogels decrease from 0.082 to 0.046 g/cm3 with the increase of the molar ratio of EtOH and MTES from 8 to 18. However, a slight increase in the density of MTES-based silica aerogels is observed when the molar ratio increase from 18 to 20. In this molar ratio range, the resultant silica network becomes weaker, resulting in the increase of volume shrinkages during drying. When the molar ratio is increased to 22, there is no gel formation observed. In addition, the compression ratio of MTES-based silica aerogels increases from 15.40 to 80.00 % as the increase of the molar ratio from 8 to 18 (Fig. 3). When the molar ratio is increased to 20, a slight decrease in the compression ratio is noticed. From Figs. 2 and 3, we conclude that the minimum density (0.046 g/cm3) and the maximum flexibility (80.00 %) of MTES-based silica aerogels can be obtained at the MTES:EtOH:H2O:HCl:NH3·H2O molar ratio of 1:18:3.5:1.44 × 10−4:1.2.

Figure 4a shows the pictures of MTES-based silica aerogels which is compressed to 80 % of their original length. After releasing the stress, the silica aerogels recover completely. The compression and recovery process of MTES-based silica aerogels can be repeated many times. Figure 4b shows the maximum possible bending of MTES-based silica without cracks. Further, exact mechanical properties of MTES-based silica aerogels were measured by a universal testing machine. Figure 5 shows plots of compressive strain–stress for the aerogels at the set strain (ε) maxima of 80 % and shows a linear elastic region at ε < 20 %, followed by densification regions at ε > 20 % [21]. At ε = 80 %, the maximal stress was measured to be 15.09 kPa, illustrating that the aerogels are quite soft material. Moreover, the aerogels recovered their original size rapidly and almost completely, while the unloading curves return to zero at ε = 0 of all strains, corresponding to the experimental observation in Fig. 4. The flexibility of MTES-based silica aerogels is a result of the formation of 3D silica networks with the CH3 terminal group. Figure 6 shows SEM images of MTES-based silica aerogels formed at the molar ratio of MTES:EtOH is 1:14, 1:18, and 1:20, respectively. The MTES-based silica aerogels have branched microstructures, in which silica aggregates interconnect to form a porous network. We noticed that the pore size in the network structure becomes larger when the molar ratio of MTES:EtOH increases from 1:14 to 1:18, while pore sizes have slightly reduced when the molar ratio increases from 1:18 to 1:20. The network structure with large pore size and strong skeleton could avoid the easily damage under stress and hence more flexible, as well as the dense network with smaller particles and pore sizes diminished the flexibility [16]. The SEM images conform to the regularity of compression with the increase of ethanol solvent.

MTES-based silica aerogels are hydrophobic. Like sacred lotus leaves and water strider’s legs, water droplets can roll off the surface of the MTES-based silica aerogels without wetting (Fig. 7a). The hydrophobicity of the MTES-based silica aerogels remains unchanged after being washed with running tap water for several minutes (Fig. 7b). Compared to the conventional cleaning sponge made from polyurethane microfibers which sinks in water, the MTES-based aerogels can float on the surface of water due to their low density and hydrophobic nature (Fig. 7c). If we push the MTES-based silica aerogels in water, the interface between the aerogels and the water is formed due to the formation of an air film on the surface of hydrophobic silica aerogels (Fig. 7d). The thickness of the air film is about 1.3 mm.

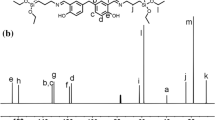

The water contact angle of MTES-based silica aerogels was measured by a static method, in which a water droplet is ejected from a syringe and a MTES-based silica aerogel film is then moved up to make the contact with the water droplet (Fig. 8). We find that a 3 μL water droplet cannot be released to the surface of the silica aerogel film even when it is squeezed into an ellipse. Until the water volume increasing to 10 μL, the successful release of water droplets could be observed, however, the water droplets roll away on the surface of silica aerogel films immediately. After several attempts, the static water contact angle of 10 μL water droplet is ~157°, indicating the superhydrophobicity of the MTES-based silica aerogels. It is known that the wettability of a surface is determined by its chemical composition and geometrical structures [22]. The peaks of 1270 and 849 cm−1 in FT-IR spectrum (Fig. 12) are associated with the stretching of the Si-CH3 bond and the presence of CH3 groups at the surface of the silica networks lowers the surface energy making the MTES-based silica aerogels exhibit fairly good water repellency. Moreover, the surface roughness could be obtained by tuning the microstructures of the sol–gels through control of hydrolysis and condensation reactions [23]. The MTES-based silica aerogels via sol–gel method are shown 3D porous network structure in Fig. 6.

The oleophilicity of MTES-based silica aerogels is also studied. Water droplets on MTES-based silica aerogels maintain a spherical shape, while ethanol droplets are absorbed totally [24]. Thus they can only allow organic compounds entering their pores and inhibit the entry of water, showing selectivity [25]. By placing a small piece of MTES-based aerogels on the surface of hexane-water mixtures, as expected, the hydrophobic and oleophilic aerogels separated hexane (labeled with Oil Red O) from the water surface completely after a few seconds, and then floating on the water (Fig. 9). The hexane was removed from the mixture after putting the aerogels out. The absorption efficiency of MTES-based aerogels for ethanol was estimated by measuring the adsorption ratio, which is defined as the ratio of the absorbed ethanol weight and the pristine aerogels weight. We found that the ethanol adsorption ratio can reach to as high as 1400 % and remain unchanged even after 10 adsorption–desorption process cycles (Fig. 10), in which desorption was carried out by drying the MTES-based silica aerogels in an oven at 60 °C for 2 h. With the advantages of high adsorption efficiency, selectivity, and excellent recyclability, the MTES-based silica aerogels could be a promising absorbent material.

TG–DTA experiments [26] were performed to investigate the thermal stability of MTES-based silica aerogels. Figure 11 shows that the TG–DTA curves of MTES-based aerogels obtained in the temperature range from 25 to 800 °C. There is a small amount of heat loss in the temperature range from 25 to 350 °C in the DTA curve and hardly any weight loss in the TG curve. Then a sharp decline in the weight is observed in the temperature range from 350 to 550 °C in the TG cure, the weight loss is about 12 %, with an exothermic peak at 500 °C in the DTA curve. To better understand the effect of temperature on the structure or properties of MTES-based aerogels, the aerogels were heated in a tube furnace at 100, 300, 500, and 700 °C for 8 h, respectively. We observed that the samples treated at 500 and 700 °C can be broken by hand easily, indicating that the aerogels lose their elastic nature at high temperature. Chemical reactions are responsible for this change, which is evidence from the FT-IR spectra of MTES-based silica aerogels treated at different temperatures (Fig. 12). It can be also seen that the Si–O–Si bonds indicated by the double peaks located at 1134 and 1035 cm−1disappears when temperature is above 300 °C and the Si–O stretching at 1079 cm−1and the O–Si–O stretching at 500 cm−1 were observed. In addition, the peak at ~1270 cm−1, which represents the stretching of Si-CH3 groups, gradually decreases with the increase of temperature and finally disappears at 500 °C that correlate well with the mass loss data shown in the TG curve. We place the silica aerogels treated at different temperatures into water to confirm the thermal stability of hydrophobic MTES-based silica aerogels (Fig. 13). The silica aerogels heated at temperatures below 300 °C float on the surface of water. While the aerogels treated at 500 and 700 °C sink to the bottom of water. This suggests that the aerogels treated at temperatures above 500 °C become hydrophilic due to the oxidation of the terminated CH3 groups on the silica networks.

Conclusions

Light, flexible, hydrophobic, and oleophilic silica aerogels have been synthesized through a two-step acid–base sol–gel reaction followed by supercritical drying, in which MTES is used as a precursor, EtOH as a solvent, HCl and NH3·H2O as catalysts. Under the optimal MTES:EtOH:H2O:HCl:NH3·H2O molar ratio of 1:18:3.5:1.44 × 10−4:1.2, MTES-based silica aerogels show the minimum density of 0.046 g/cm3 and the maximal stress was measured to be 15.09 kPa at the set strain (ε) of 80 %. They are superhydrophobic with a water contact angle of 157° and oleophilic with an ethanol adsorption ratio of 1400 %. The TGA and FT-IR measurements show that the MTES-based silica aerogels are stable up to 350 °C. The MTES-based aerogels have potential for the efficient removal for oil from water.

References

Soleimani Dorcheh A, Abbasi M (2008) Silica aerogel; synthesis, properties and characterization. J Mater Process Tech 199(1):10–26

Pierre AC, Pajonk GM (2002) Chemistry of aerogels and their applications. Chem Rev 102(11):4243–4266

Yu KMK, Yeung CM, Thompsett D, Tsang SC (2003) Aerogel-coated metal nanoparticle colloids as novel entities for the synthesis of defined supported metal catalysts. J Phys Chem B 107(19):4515–4526

Koebel M, Rigacci A, Achard P (2012) Aerogel-based thermal superinsulation: an overview. J Sol–Gel Sci Technol 63(3):315–339

Štandeker S, Novak Z, Knez Ž (2007) Adsorption of toxic organic compounds from water with hydrophobic silica aerogels. J Colloid Interf Sci 310(2):362–368

Guenther U, Smirnova I, Neubert R (2008) Hydrophilic silica aerogels as dermal drug delivery systems: dithranol as a model drug. Eur J Pharm Biopharm 69(3):935–942

Bhagat SD, Hirashima H, Rao AV (2007) Low density TEOS based silica aerogels using methanol solvent. J Mater Sci 42(9):3207–3214. doi:10.1007/s10853-006-1366-z

Gurav JL, Rao AV, Nadargi D, Park H-H (2010) Ambient pressure dried TEOS-based silica aerogels: good absorbents of organic liquids. J Mater Sci 45(2):503–510. doi:10.1007/s10853-009-3968-8

Tan S, Xie Q, Lu X, Zhao N, Zhang X, Xu J (2008) One step preparation of superhydrophobic polymeric surface with polystyrene under ambient atmosphere. J Colloid Interf Sci 322(1):1–5

Du A, Zhou B, Zhang Z, Shen J (2013) A special material or a new state of matter: a review and reconsideration of the aerogel. Mater 6(3):941–968

Fidalgo A, Farinha JPS, Martinho JM, Ilharco LM (2013) Flexible hybrid aerogels prepared under subcritical conditions. J Mater Chem A 1(39):12044–12052

Mulik S, Sotiriou-Leventis C, Churu G, Lu H, Leventis N (2008) Cross-linking 3D assemblies of nanoparticles into mechanically strong aerogels by surface-initiated free-radical polymerization. Chem Mater 20(15):5035–5046

Ingale S, Wagh P, Tripathi A, Kamble V, Kumar R, Gupta SC (2011) Physico-chemical properties of silica aerogels prepared from TMOS/MTMS mixtures. J Porous Mater 18(5):567–572

Hegde ND, Rao AV (2007) Physical properties of methyltrimethoxysilane based elastic silica aerogels prepared by the two-stage sol–gel process. J Mater Sci 42(16):6965–6971. doi:10.1007/s10853-006-1409-5

Dong H, Brennan JD (2006) Macroporous monolithic methylsilsesquioxanes prepared by a two-step acid/acid processing method. Chem Mater 18(17):4176–4182

Nadargi DY, Latthe SS, Hirashima H, Rao AV (2009) Studies on rheological properties of methyltriethoxysilane (MTES) based flexible superhydrophobic silica aerogels. Microporous Mesoporous Mater 117(3):617–626

Cui S, Liu Y, Fan MH, Cooper AT, Lin BL, Liu XY, Han GF, Shen XD (2011) Temperature dependent microstructure of MTES modified hydrophobic silica aerogels. Mater Lett 65(4):606–609

Rao AV, Hegde ND, Hirashima H (2007) Absorption and desorption of organic liquids in elastic superhydrophobic silica aerogels. J Colloid Interf Sci 305(1):124–132

Choi DG, Yang SM (2003) Effect of two-step sol–gel reaction on the mesoporous silica structure. J Colloid Interf Sci 261(1):127–132

Chen G, Chen BW, Liu TS, Mei Y, Ren HB, Bi YT, Luo X, Zhang L (2012) The synthesis and characterization of germanium oxide aerogel. J Non Cryst Solids 358(23):3322–3326

Gui X, Wei J, Wang K, Cao A, Zhu H, Jia Y, Shu Q, Wu D (2009) Carbon nanotube sponges. Adv Mater 22(5):617–621

Li XM, Reinhoudt D, Crego-Calama M (2007) What do we need for a superhydrophobic surface? A review on the recent progress in the preparation of superhydrophobic surfaces. Chem Soc Rev 36(8):1350–1368

Hsieh CT, Cheng YS, Hsu SM, Lin JY (2010) Water and oil repellency of flexible silica-coated polymeric substrates. Appl Surf Sci 256(16):4867–4872

Yang H, Pi P, Cai ZQ, Wen X, Wang X, Cheng J, Yang ZR (2010) Facile preparation of super-hydrophobic and super-oleophilic silica film on stainless steel mesh via sol–gel process. Appl Surf Sci 256(13):4095–4102

Qin G, Yao Y, Wei W, Zhang T (2013) Preparation of hydrophobic granular silica aerogels and adsorption of phenol from water. Appl Surf Sci 280:806–811

Bhagat SD, Oh CS, Kim YH, Ahn YS, Yeo JG (2007) Methyltrimethoxysilane based monolithic silica aerogels via ambient pressure drying. Microporous Mesoporous Mater 100(1):350–355

Acknowledgements

Financial support from the Natural Science Foundation of China (51175444), the Fundamental Research Funds for the Central Universities (Xiamen University, 2011121002), the Aviation Science Foundation of China (2013ZD68009), New Century Excellent Talents in Fujian Province University (2013), the Natural Science Foundation of Fujian Province of China (2014J01206), Xiamen Municipal Bureau of Science and Technology (3502Z20143009), and Shenzhen City Science and Technology Innovation Committee (JCYJ20120618155425009) is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, Y., Wu, X., Guo, D. et al. Preparation of flexible, hydrophobic, and oleophilic silica aerogels based on a methyltriethoxysilane precursor. J Mater Sci 49, 7715–7722 (2014). https://doi.org/10.1007/s10853-014-8480-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8480-0