Abstract

The synthesis and characterization of a series of polyalkylthiophenes-containing electron-rich thienothiophene (donor heteroaromatic bicycle) and electron-deficient benzothiadiazole (acceptor heteroaromatic bicycle) block have been reported. The polymers are synthesized by Stille cross-coupling reaction and are found to be having high molecular weight with number-average molecular weight in the range of 7.1 × 104–5.7 × 104. The photo-physical, electro-chemical, and electroluminescent (EL) properties of the polymers are investigated in detail. The optical band gap of the polymers is found to be in the range of 1.53–1.54 eV. These new polymers are luminescent in nature and showed red photoluminescence in chloroform solution (722–740 nm) as well as in thin film (781–786 nm). Ionization potential for these polymers is calculated and falling in the range of 5.23–5.33 eV. Polymer light emitting diodes with configuration ITO/PDOT:PSS/polymer/BCP/Alq3/LiF/Al have been fabricated, and a deep red emission is observed. The EL maxima of polymers are found to be in the range of 750–760 nm with threshold voltages around 4.0–5.5 V. The fabricated devices show luminescence around 40 cd/m2 at current density of 100 mA/cm2 with maximum value of 580–810 cd/m2 at 11 V.

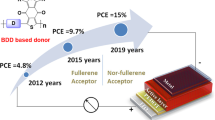

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Semiconducting π-conjugated polymers are being extensively investigated as the active materials in polymer light emitting diodes (PLEDs) and polymer solar cells [1–9]. In recent years, preparation of alternating conjugated polymers with varying the nature of the co-monomers affords novel means to design materials with improved functional properties that cannot be attained by the corresponding homopolymers [10, 11]. As an example, copolymers with alternating electron rich and electron deficient monomers may result a good highest occupied molecular orbital (HOMO) and lowest unoccupied molecular orbital (LUMO) alterations to bring the air stability of the polymers with red shifting the absorption band and decreasing the band gap [12–14].

The electro-active and photo-active materials, generally used for the organic light emitting diodes are based on molecules such as thiophene, pyrrole, phenylene, fluorenes, carbazoles, and various other fused rings [15–19]. Among the fused ring molecules, thienothiaphene is one of the most investigated molecule has received considerable attention in recent years [20–22]. The homo- and copolymers of thienothiophene-based polymers have been used as conducting materials in various optoelectronic devices like organic thin film transistors (OTFTs), organic photovoltaics (OPVs) etc. [23–25]. However, a least attention has been given for using the thienothiophene-based polymers for PLEDs [26]. This is because, even though the rigid and planar structure of the fused ring in the backbone facilitates the intermolecular charge hopping and charge carrier mobility by lowering the reorganization energy, still the intermolecular interaction and aggregation can quench the fluorescence in solid state making it a bad choice of materials for this purpose.

Generally, thienothiaphene-based polythiophenes are predominately hole transporting materials. When these polymers are used in device structure, creates an imbalance in electron transport results the charge recombination near polymer/cathode interface, leads in lowering of EL efficiency due to quenching of excitons by the metal electrode. Therefore, to achieve high quantum efficiency LEDs using the polymer, it is also necessary to have balanced charge injection and transport of both holes and electrons in the emissive material. The common strategy to construct such types of polymers is the incorporation of electron donor and acceptor units in the polymeric backbone [27, 28]. Among various n-type monomers, benzothiadiazole is an attractive heterocyclic compound having a strong electron affinity [29]. Benzothiadiazole derivatives are known to be strongly fluorescent dyes exhibiting low lying HOMO energy level [30]. Because of such unique opto-electronic properties, benzothiadiazole-containing polymers and oligomers are vastly used in various applications like light emitting diodes [31, 32], liquid crystal displays [33], two photon absorption [34], and organic solar cells [35, 36].

In this paper, we report the synthesis and electroluminescent (EL) properties of a series of polyalkylthiophenes containing alternatively thienothiophene and benzothiadiazole moiety in the main chain. The polymers were synthesized by Stille cross-coupling reaction which ensured achievement of well-defined molecular structure. The optical and electrochemical properties of the copolymers are systematically described. To achieve good electroluminescence efficiency and to avoid electrode (cathode) quenching due to unbalanced electron and hole mobility, an additional hole blocking and electron transporting layers were incorporated into the device structure to confine the emission zone in emissive layer. Electroluminescent devices with configuration ITO/PDOT:PSS/polymer/BCP/Alq3/LiF/Al were fabricated, and a deep red electroluminescence was observed on application of suitable voltage.

Experimental

Materials

High purity chemicals used in this study were purchased from Sigma Aldrich. Tetrahydrofuran (THF) was distilled over sodium ketyl radical under nitrogen atmosphere. Anhydrous chlorobenzene was purchased from Aldrich. All other solvents were purified and dried using the standard procedures prior to use.

Synthesis of monomers

The monomers 4,7-bis(5-bromo-4-alkylthiophen-2-yl)benzo[c][1,2,5]thiadiazole (3a–3c) and 2,5-bis[3-alkyl-5-(trimethylstannyl)thiophen-2-yl]thieno[3,2-b]thiophene (7a–7c) were synthesized according to literature procedure [12, 37].

General procedure for the synthesis of 4,7-bis(5-bromo-4-alkylthiophen-2-yl)benzo[c][1,2,5]thiadiazole (3a–3c)

4,7-Bis(4-alkylthiophen-2-yl)benzo[c][1,2,5]thiadiazole (0.3 mmol) (alkyl chain with –C12H25, –C14H29 or –C16H33) was dissolved in chloroform (50 mL). The solution was cooled to 0 °C, and NBS (6.15 mmol) was added to the solution in portions at same temperature (0 °C) in dark. Subsequently, the solution was warmed to room temperature and stirred overnight. 50 mL of water was added to the reaction mixture. The organic layer was separated, dried over anhydrous MgSO4 and evaporated. The crude material was purified by column chromatography (silica gel) using hexane and CHCl3 (90:10) as eluent to obtain dark red solids.

4,7-Bis(5-bromo-4-dodecylthiophen-2-yl)benzo[c][1,2,5]thiadiazole (3a)

1H NMR (300 MHz, CDCl3): δ 7.73 (s, 2H), 7.68 (s, 2H), 2.61 (t, 4H), 1.65 (q, 4H), 1.25–1.34 (m, 36H), 0.86 (t, 6H). 13C NMR (75 MHz, CDCl3): δ 152.12, 143.03, 138.47, 128.02, 125.17, 124.66, 111.60, 31.94, 29.69, 29.46, 29.37, 22.70, 14.12.

4,7-Bis(5-bromo-4-tetradecylthiophen-2-yl)benzo[c][1,2,5]thiadiazole (3b)

1H NMR (300 MHz, CDCl3,): δ 7.75 (s, 2H), 7.72 (s, 2H), 2.62 (t, 4H), 1.65 (q, 4H), 1.24–1.34 (m, 44H), 0.86 (t, 6H). 13C NMR (75 MHz, CDCl3): δ 152.12, 143.03, 138.48, 128.03, 125.18, 124.67, 111.60, 31.94, 29.70, 29.46, 29.37, 22.70, 14.12.

4,7-Bis(5-bromo-4-hexadecylthiophen-2-yl)benzo[c][1,2,5]thiadiazole (3c)

1H NMR (CDCl3, 300 MHz): δ 7.74 (s, 2H), 7.70 (s, 2H), 2.62 (t, 4H), 1.65 (q, 4H), 1.24–1.34 (m, 52H), 0.86 (t, 6H). 13C NMR (CDCl3, 75 MHz): δ 152.12, 143.03, 138.48, 128.02, 125.17, 124.65, 111.60, 31.94, 29.71, 29.46, 29.38, 22.70, 14.12.

General procedure for the synthesis of 2,5-bis[3-alkyl-5-(trimethylstannyl)thiophen-2-yl]thieno[3,2-b]thiophenes (7a–7c)

2,5-Bis(5-bromo-3-alkyl-2-yl)thieno[3,2-b]thiophene (1.25 mmol) (alkyl chain with –C12H25, –C14H29 or –C16H33) was dissolved in 80 mL of dry THF under a nitrogen atmosphere The solution was cooled to −78 °C, and BuLi (1.7 mL of 1.6 M solution in hexane) was added drop wise. The mixture was stirred at the same temperature for an additional 1.5 h. Then 2.87 mmol of Me3SnCl in THF (5 mL) was added drop wise to the reaction mixture, and subsequently, the whole mixture was allowed to stir at room temperature overnight. The solvent was evaporated, the crude material was dissolved in chloroform (50 mL), and the organic layer was washed with water. The organic layer was collected, dried over MgSO4 (anhydrous), and evaporated in vacuo to get a brown sticky liquid. Hot methanol (15 mL) was added to the crude and it was kept in a refrigerator for 1 h. The methanol layer was poured out, and the sticky compound was dried under a high vacuum to obtain the compound as a yellow brown solid.

2,5-Bis[3-dodecyl-5-(trimethylstannyl)thiophen-2-yl]thieno[3,2-b]thiophene (7a)

1H NMR (300 MHz, CDCl3): δ 7.20 (s, 2H), 7.02 (s, 2H), 2.78 (t, 4H), 1.64 (q, 4H), 1.24–1.37 (m, 36H), 0.86 (t, 6H), 0.37 (s, 18H). 13C NMR (75 MHz, CDCl3): δ 141.30, 139.16, 138.37, 137.81, 137.17, 136.57, 117.48, 31.97, 30.98, 30.83, 29.73, 29.51, 29.40, 29.21, 22.73, 14.15, 8.18.

2,5-Bis[3-tetradecyl-5-(trimethylstannyl)thiophen-2-yl]thieno[3,2-b]thiophene (7b)

1H NMR (300 MHz, CDCl3): δ 7.21 (s, 2H), 7.00 (s, 2H), 2.79 (t, 4H), 1.62 (q, 4H), 1.23–1.37 (m, 44H), 0.86 (t, 6H), 0.38 (s, 18H). 13C NMR (75 MHz, CDCl3): δ 141.30, 139.17, 138.38, 137.81, 137.18, 136.58, 117.48, 31.97, 30.98, 30.84, 29.71, 29.52, 29.40, 29.21, 22.73, 14.16, 8.18.

2,5-Bis[3-hexadecyl-5-(trimethylstannyl)thiophen-2-yl]thieno[3,2-b]thiophene (7c)

1H NMR (300 MHz, CDCl3): δ 7.20 (s, 2H), 7.01 (s, 2H), 2.79 (t, 4H), 1.63 (q, 4H), 1.24–1.38 (m, 52H), 0.87 (t, 6H), 0.38 (s, 18H). 13C NMR (75 MHz, CDCl3): δ 141.29, 139.17, 138.37, 137.82, 137.17, 136.59, 117.48, 31.97, 30.99, 30.84, 29.75, 29.53, 29.41, 29.22, 22.74, 14.16, 8.18.

Representative example of polymerization

To a Schlenk, flask was added the compound 3a (0.37 mmol), compound 7a (0.37 mmol) and CuO (0.37 mmol) with anhydrous chlorobenzene (10 mL) under nitrogen. The flask was degassed for 10 min, and then Pd2(dba)3 (3 mol%) and (o-tol)3P (6 mol%) were added. The reaction mixture was stirred for 72 h at 140 °C. After cooling to room temperature, the resulting mixture was poured into 100 mL of methanol. The precipitate was recovered by filtration, and the resulting crude polymers were extracted by Soxhlet apparatus with methanol and hexane for 12 h each and finally with chloroform to collect the polymer. The chloroform was evaporated and dried over vacuum to afford polymer as black powders.

Poly{4-(4-dodecyl-5-(4-dodecyl-5-(2-(3-dodecylthiophen-2-yl)thieno[3,2-b]thiophen-5-yl)thiophen-2-yl)thiophen-2-yl)-7-(4-dodecylthiophen-2-yl)benzo[c][1,2,5]thiadiazole} (PTTBz-C12)

Monomer 3a and 7a are used for polymerization. Yield: 69 %. Molecular weight (GPC, THF): M n = 57000. M w/M n = 3.7. Decomposition temperature (T d) (TGA, 5 % wt. loss): 410 °C. FTIR (KBr, cm−1): 2922, 2851, 1642, 1570, 1486, 1460, 1382, 1263, 1175, 1072, 862, 822, 719.

Poly{4-(4-tetradecyl-5-(4-tetradecyl-5-(2-(3-tetradecylthiophen-2-yl)thieno[3,2-b]thiophen-5-yl)thiophen-2-yl)thiophen-2-yl)-7-(4-tetradecylthiophen-2-yl)benzo[c][1,2,5]thiadiazole} (PTTBz-C14)

Monomer 3b and 7b are used for polymerization. Yield: 66 %, Molecular weight (GPC, THF): M n = 59500. M w/M n = 3.3. Decomposition temperature (T d) (TGA, 5 % wt. loss): 410 °C. FTIR (KBr, cm−1): 2922, 2851, 1631, 1487, 1462, 1384, 1270, 1166, 1017, 863, 795, 711.

Poly{4-(4-hexadecyl-5-(4-hexadecyl-5-(2-(3-hexadecylthiophen-2-yl)thieno[3,2-b]thiophen-5-yl)thiophen-2-yl)thiophen-2-yl)-7-(4-hexadecylthiophen-2-yl)benzo[c][1,2,5]thiadiazole} (PTTBz-C16)

Monomer 3c and 7c are used for polymerization. Yield: 61 %. Molecular weight (GPC, THF): M n = 71000. M w/M n = 3.2. Decomposition temperature (T d) (TGA, 5 % wt. loss): 390 °C. FTIR (KBr, cm−1): 2922, 2851, 1630, 1484, 1465, 1386, 1272, 1164, 1002, 865, 792, 715.

Materials analysis

Number-average and weight-average molecular weight of the polymers were determined by using a Waters 2690 separations module apparatus and a Waters 2487 dual λ absorbance detector, with chloroform as the eluent and polystyrene as standards. Thermo gravimetric analysis (TGA) was carried out in a Hi-Res TGA 2950, TA instrument with a heating rate of 10 °C/min under N2 atmosphere. 1H NMR spectra were recorded on a Bruker Avance 300 MHz spectrometer. Fourier transform infrared (FT-IR) spectra were obtained from Jasco 4200 FT-IR spectrometer. UV–Vis absorption spectra were recorded on a Varian Cary 5000 spectrometer in chloroform solution and polymer thin films cast onto a cover glass slide. PL spectra were recorded on a Fluorolog Jobin spectrophotometer (Yvon-Horiba, Model-3-11). Cyclic voltammetry was carried out on Auto lab PGSTAT 100 using a three-electrode cell. A platinum plate was used as working electrode and a platinum wire as counter electrode. An Ag/Ag+ electrode (Ag in a 0.01 mol/L of AgNO3) was used as the reference electrode. An anhydrous 0.1 M solution of tetrabutylammonium-tetrafluoroborate (Bu4N+BF4 −) in acetonitrile purged with nitrogen was used as supporting electrolyte. All the solvents were dried and purified using the standard purification techniques.

Device fabrication and characterizations

Indium-tin oxide(ITO)-coated glass substrate with a sheet resistance ~20 Ω/cm2 was used as anode. The substrate was patterned and cleaned using deionized water, acetone, trichloroethylene, and isopropyl alcohol sequentially for 20 min each using an ultrasonic bath and dried in vacuum oven. The poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate) (PEDOT:PSS) as hole transport layer and synthesized polymer as emitting layer were deposited on the pre-cleaned substrate sequentially using spin coating technique. A layer of 2,9-dimethyl 4,7-diphenyl-1,10-phenanthroline (BCP) as a hole and exciton blocking layer (HBL) maintaining a layer thickness of 60 Å and tris(8-hydroxyquinolinato)aluminum (Alq3) with a layer thickness of 280 Å as electron transport layer were deposited under high vacuum (1 × 10−5 torr) at a deposition rate of 0.1 Å/s. The thicknesses of the deposited films were monitored in situ by quartz crystal monitor. Finally, a cathode comprising 10 Å lithium fluoride and 1000 Å aluminum was sequentially deposited onto the substrate to complete the device structure. The EL spectra were recorded with a high resolution spectrometer (Ocean Optics HR-2000CG UV-NIR). The current density–voltage–luminescence (J–V–L) characteristics were measured with a luminance meter (LMT l-1009) interfaced with a Keithley 2400 programmable voltage–current digital source meter. All the measurements were performed at room temperature under ambient atmosphere, without any encapsulation.

Results and discussion

Polymer synthesis and thermal properties

The two different set of monomers (3a–c and 7a–c) with different alkyl chain lengths [–C12H25 (a), –C14H29 (b), –C16H33 (c)] used for the polymerizations were synthesized by the reported procedure (Scheme 1). The monomers were then subjected to a Stille polymerization utilizing Pd2(dba)3, (o-tol)3P, and CuO in chlorobenzene to obtain Polymers PTTBz-C12, PTTBz-C14, and PTTBz-C16, respectively (Scheme 2). The polymerization reactions were preceded smoothly, and good yield of the polymers was obtained after purifications. Since it is well known that in palladium (0) mediated synthesis of poly(phenylenes), concentration of the macro monomers plays an important role [38], the polymerizations were done in a concentrated solution. The resulting polymers obtained as a black-purple solid showed good solubility in most of the chlorinated solvents, toluene and THF (maximum solubility was found to be 20–30 mg/mL solvent). The synthesized polymers were characterized by FTIR, TGA, and GPC analysis, and their results are introduced in experimental section. The molecular weight of the polymers was determined using gel permeation chromatography (GPC) calibrated with polystyrene standards. GPC showed that the polymers have slightly broad molecular weight distribution (Table 1). Using THF as the eluent and polystyrene as the standards, the GPC data demonstrate that the number-average molecular weight (M n) of the polymers was found to be in the range of 57 × 103–71 × 103 g/mol. The polydispersity index (M w/M n) of the polymers was found to be in the range of 3.2–3.7. It is important to note that similar thienothiophene-based polymers containing thiazolothiazole molecules synthesized by our group possessed a molecular weight of 15000–16500 with a limited solubility only in chlorobenzene and o-dichlorobenzene [37]. The thermal properties of the polymers investigated by TGA are shown in Fig. 1 and summarized in Table 1. The polymers exhibited good thermal stability with thermal decomposition temperature (T d) ~400 °C with 5 % weight loss. The results indicate that the introduction of benzothiodiazole moiety in the main chain enhances the thermal stability than other similar thienothiophene-based polymer [37].

Optical properties

The optical absorption spectra of the polymers were measured in chloroform solution as well as in solid thin films. The spectroscopic data of the polymers are summarized in Table 2. In solution, the polymers showed two distinct absorption peaks: one between 408 and 422 nm and the other at 549–570 nm. Thin films of the copolymers were spin coated on glass substrate from their solution in chloroform. In solid state, the polymers showed two absorption peaks, one at 456–470 nm and the other at 626–648 nm (Fig. 2). UV–Vis absorption spectrum of the polymers shows similar feature in solid and solution state. However, both the higher and lower energy peaks were red-shifted by ~50 and ~70 nm from the solution to the film. The red-shift indicates the higher co-planarity of the polymer and the enhanced intermolecular electronic interactions in the solid state. The optical band gap of the polymers has been calculated from the onset of the optical absorption in thin film (~800 nm) and found to be in the range of 1.53–1.54 eV.

Photoluminescence (PL) data for the polymers in solution as well as thin films are summarized in Table 2. The thin film of the polymer sample was spin coated on glass substrate from the chloroform solution and allowed to evaporate slowly to get a uniform film. PL were then recorded upon excitation at the wavelength of the absorption maxima. The PL spectra of the polymers appear around 722–740 nm in solution. In solid film, the PL was observed at 778–786 nm (Fig. 3). The PL spectra obtained for the thin films of the polymers show red-shift in relation to the solution counterpart, as shown in Table 2. The red shifting of the polymer PL is due to the molecular aggregation.

Electrochemical properties

The electrochemical characteristics of polymer thin films coated on Pt electrode were studied by cyclic voltammetry in a 0.1 M tetrabutyl-ammoniumtetrafluoroborate solution in acetonitrile at a scan rate of 100 mV/s, and the results are summarized in Table 2. The oxidation peak of the polymers became sharper, while the side chain of the polymers increased (Fig. 4). This could be due to the faster movement of the charge in polymer matrix due increasing in inter polymeric distance. All the polymers exhibited a quasi-reversible oxidation process. The onset oxidation potential (E ox,onset) of the polymers was found to be in the range of 0.5–0.6 V, which is higher as compared to the (E ox,onset) of pure polythienothiophene. The high E ox of the current set of polymers is attributed to the presence of electron deficient benzothiadiazole unit. As the molecular weight (and thus conjugation length) of polymers was found to increase with increasing the side chain length, the E ox of the polymers also follows the same trend. This behavior could be due to decreasing in the effective conjugation by increasing in the side chain length. The HOMO of the polymer is estimated from the onset potential of oxidation by considering the energy level of the reference ferrocene/ferrocenium (Fc/Fc+) redox couple and found to possess between 5.23 and 5.33 eV. This higher level of HOMO prohibits the formation of adverse exciplexes in association with the hole transporting materials. The LUMO levels of the polymers were estimated from the HOMO values and the values of optical band gap. The LUMO values of the polymers were calculated to be in the range of 3.70–3.79 eV.

Electroluminescence properties

Multi layer PLEDs having configuration, glass:ITO/PEDOT:PSS/polymer/BCP/Alq3/LiF/Al have been fabricated as shown in Fig. 5b. The schematic energy level diagram of PLED device structures used in this study has been shown in Fig. 5a. The energy level and HOMO–LUMO values of PEDOT:PSS, BCP, and Alq3 have been taken from the literature [39, 40]. From the energy level diagram of the fabricated device (Fig. 5a), the charge carrier recombination and emitting zone should be localized at the polymer/BCP interface. The barrier for holes is estimated from the HOMO level of polymers (5.23–5.33 eV) and BCP (6.4 eV) to be 1.17–1.07 eV. This means that the holes, which pass over the polymer layer can be obstructed at the interface of polymer/BCP effectively, resulting into limiting the recombination zone in emissive layer (polymer layer). At the same time, there are no barriers for electrons coming from cathode, thus, if more holes can arrive and be accumulated at this interface, it should be beneficial to their recombination with injecting electrons. From the energy level diagrams, it can be clearly seen that BCP and Alq3 layers act as good hole blocking and electron transporting layers, respectively. Hence, all devices showed a bright red emission when appropriate positive bias was applied with EL spectra ranging from 650 to 900 nm (Fig. 6). The main peak of the observed EL maxima was centered at 760, 753, and 750 nm for PTTBz-C12, PTTBz-C14, and PTTBz-C16, respectively (Table 2). Throughout the series of the polymers, the EL spectra show a slight blue shift with increase in side chain length. This could be attributed to increase in band gap resulting from decreased net conjugation length due to polymer chain twisting. In most case the EL spectra of the polymers were found to be blue shifted as compared to the corresponding PL spectra. This phenomenon was also observed in polymers containing thiazolothiazole polymers [34].

Figure 7 show the voltage–luminescence (V–L) and current density–voltage (J–V) (inset) curves of the devices having synthesized polymers as emissive materials and showed a typical diode characteristic. When a forward bias was applied, the increase of current as well as luminescent intensity was observed for the polymer devices. The turn-on voltages were found to be 4.0, 4.0, and 5.5 V for the PTTBz-C12, PTTBz-C14, and PTTBz-C16 device, and the maximum luminescences were 581, 688, and 813 cd/m2, respectively. The comparatively inferior device performance could be due to the strong intermolecular interaction and aggregate formation of the polymers, which quench fluorescence in solid state. However, we also believe that the luminescence of these polymers can be improved by material and device optimization.

Conclusion

We have synthesized a series of high molecular weight polyalkylthiophenes containing an electron-rich thienothiophene and electron-deficient benzothiodiazole block in the main chain. The optical and electrochemical characterizations reveal that all the polymers have low band gap with HOMO and LUMO energy levels ranging from 5.23 to 5.33 eV and 3.70 to 3.79 eV, respectively. When used in EL devices, these polymers shown a deep red emission with a maxima ranging from 750 to 760 nm in ITO/PDOT:PSS/Polymer/BCP/Alq3/LiF/Al device configuration. A highest luminescence of 813 cd/m2 has also been realized. These interesting optoelectronic properties also render them promising materials for OPV application.

References

Dang MT, Hirsch L, Wantz G, Wuest JD (2013) Controlling the morphology and performance of bulk heterojunctions in solar cells. Lessons learned from the benchmark poly(3-hexylthiophene):[6,6]-phenyl-C61-butyric acid methyl ester system. Chem Rev 113:3734–3765

Yang C, Song H-S, Liu D-B (2013) Pure blue light-emitting fluorene-based conjugated polymer with excellent thermal, photophysical, and electroluminescent properties. J Mater Sci 48:6719–6727. doi:10.1007/s10853-013-7473-8

Dkhila SB, Bourguiga R, Davenas J, Cornu D (2012) Influence of the polymer matrix on the efficiency of hybrid solar cells based on silicon nanowires. Mater Sci Eng B 177:173–179

Grimsdale AC, Chan KL, Martin RE, Jokisz PG, Holmes AB (2009) Synthesis of light-emitting conjugated polymers for applications in electroluminescent devices. Chem Rev 109:897–1091

Cheng Y-J, Yang S-H, Hsu C-S (2009) Synthesis of conjugated polymers for organic solar cell applications. Chem Rev 109:5868–5923

Forrest SR, Thompson ME (2007) Introduction: organic electronics and optoelectronics. Chem Rev 107:923–925

Sondergaard RR, Hosel M, Krebs FC (2013) Roll-to-roll fabrication of large area functional organic materials. J Polym Sci B 51:16–34

Lanzi M, DiNicola FP, Livi M, Paganin L, Cappelli F, Pierini F (2013) Synthesis and characterization of conjugated polymers for the obtainment of conductive patterns through laser tracing. J Mater Sci 48:3877–3893. doi:10.1007/s10853-013-7204-1

Lanzi M, Paganin L, Errani F (2012) Synthesis, characterization and photovoltaic properties of a new thiophene-based double-cable polymer with pendent fullerene group. Polymer 53:2134–2145

Chen CH, Hsieh CH, Dubosc M, Cheng YJ, Hsu CS (2010) Synthesis and characterization of bridged bithiophene-based conjugated polymers for photovoltaic applications: acceptor strength and ternary blends. Macromolecules 43:697–708

Palai AK, Mishra SP, Kumar A, Srivastava R, Kamalasanan MN, Patri M (2010) Synthesis and characterization of red-emitting poly(aryleneethynylene)s based on 2,5-bis(2-ethylhexyl)-3,6-di(thiophen-2-yl)pyrrolo[3,4-c]pyrrole-1,4(2h,5h)-dione (DPP). Macromol Chem Phys 211:1043–1053

Liu J, Zhang R, Sauve G, Kowalewski T, McCullough RD (2008) Highly disordered polymer field effect transistors: N-alkyl dithieno[3,2-b:2′,3′-d]pyrrole based copolymers with surprisingly high charge carrier mobilities. J Am Chem Soc 130:13167–13176

Hwang YJ, Kim FS, Xin H, Jenekhe SA (2012) New thienothiadiazole-based conjugated copolymers for electronics and optoelectronics. Macromolecules 45:3732–3739

Mishra SP, Palai AK, Srivastava R, Kamalasanan MN, Patri M (2009) Dithieno[3,2-b:2′,3′-d]pyrrole–alkylthiophene–benzo[c][1,2,5]thiadiazole-based highly stable and low band gap polymers for polymer light-emitting diodes. J Polym Sci Part A 47:6514–6525

Intemann JJ, Hellerich ES, Tlach BC, Ewan MD, Barnes CA, Bhuwalka A, Cai M, Shinar J, Shinar R, Jeffries-EL M (2012) Altering the conjugation pathway for improved performance of benzobisoxazole-based polymer guest emitters in polymer light-emitting diodes. Macromolecules 45:6888–6897

Tamura K, Shiotsuki M, Kobayashi N, Masuda T, Sanda F (2009) Synthesis and properties of conjugated polymers containing 3,9- and 2,9-linked carbazole units in the main chain. J Polym Sci Part A 47:3506–3517

Blouin N, Leclerc M (2008) Poly(2,7-carbazole)s: structure−property relationships. Acc Chem Res 41:1110–1119

Ogawa K, Rasmussen SC (2006) N-Functionalized poly(dithieno[3,2-b:2‘,3‘-d]pyrrole)s: highly fluorescent materials with reduced band gaps. Macromolecules 39:1771–1778

Shahid M, Ashraf RS, Klemm E, Sensfuss S (2006) Synthesis and properties of novel low-band-gap thienopyrazine-based poly(heteroarylenevinylene)s. Macromolecules 39:7844–7853

Poelking C, Cho E, Malafeev A, Ivanov V, Kremer K, Risko C, Brédas J-L, Andrienko D (2013) Characterization of charge-carrier transport in semicrystalline polymers: electronic couplings site energies and charge-carrier dynamics in poly(bithiophene-alt-thienothiophene) [PBTTT]. J Phys Chem C 117:1633–1640

Bijleveld JC, Verstrijden RAM, Wienk MM, Janssen RAJ (2011) Copolymer of diketopyrrolopyrole and thienothiophene for photovaltaic cells. J Mater Chem 21:9224

McCulloch I, Heeney M, Chabinyc ML, DeLongchamp D, Kline RJ, Colle M, Duffy W, Fischer D, Gundlach D, Hamadani B, Hamilton R, Richter L, Salleo A, Shkunov M, Sparrowe D, Tierney S, Zhang W (2009) Semiconducting thienothiophene copolymers: design, synthesis, morphology, and performance in thin-film organic transistors. Adv Mater 21:1091–1109

Murphy AR, Frechet JMJ (2007) Organic semiconducting oligomers for use in thin film transistors. Chem Rev 107:1066–1096

Biniek L, Chochos CL, Leclerc N, Hadziioannou G, Kallitsis JK, Bechara R, Leveque P, Heiser T (2009) Thienothiophene-alt-for photovoltaic applications: design, synthesis, material characterization and device performances. J Mater Chem 19:4946–4951

Biniek L, Chochos CL, Hadziioannou G, Leclerc N, Leveque P, Heiser T (2010) Electronic properties and photovoltaic performances of a series of oligothiophene copolymers incorporating both thieno[3,2-b]thiophene and 2,1,3-benzothiadiazole moieties. Macromol Rapid Commun 31:651–656

Lim E, Jung B-J, Lee J, Shim H-K, Lee J-I, Yang YS, DoL M (2005) Thin-film morphologies and solution-processable field-effect transistor behavior of a fluorene−thieno[3,2-b]thiophene-based conjugated copolymer. Macromolecules 38:4531–4535

Beaupre S, Leclerc M (2002) Fluorene-based copolymers for red-light-emitting diodes. Adv Funct Mater 12:192–196

Muller CD, Falcou A, Reckefuss N, Rojahn M, Wiederhirn V, Rudati P, Frohne H, Nuyken O, Becker H, Meerholz K (2003) Multi-colour organic light-emitting displays by solution processing. Nature 421:829–833

Johnson JR, Rotenberg DH, Ketcham R, Thiazolothiazoles II (1970) Parent heterocycle and its carboxylic and amino derivatives. J Am Chem Soc 92:4046–4050

Wen S, Pei J, Zhou Y, Li P, Xue L, Li Y, Xu B, Tian W (2009) Synthesis of 4,7-diphenyl-2,1,3-benzothiadiazole-based copolymers and their photovoltaic applications. Macromolecules 42:4977–4984

Wang J-L, Zhou Y, Li Y, Pei J (2009) Solution-processable gradient red-emitting π-conjugated dendrimers based on benzothiadiazole as core: synthesis, characterization, and device performances. J Org Chem 74:7449–7456

Liu J, Bu L, Dong J, Zhou Q, Geng Y, Ma D, Wang L, Jing X, Wang F (2007) Green light-emitting polyfluorenes with improved color purity incorporated with 4,7-diphenyl-2,1,3-benzothiadiazole moieties. J Mater Chem 17:2832–2838

Zhang X, Gorohmaru H, Kadowaki M, Kobayashi T, Ishi-iT Thiemann T, Mataka S (2004) Benzo-2,1,3-thiadiazole-based, highly dichroic fluorescent dyes for fluorescent host–guest liquid crystal displays. J Mater Chem 14:1901–1904

Kato S-I, Matsumoto T, Shigeiwa M, Gorohmaru H, Maeda S, Ishi-i T, Mataka S (2006) Novel 2,1,3-benzothiadiazole-based red-fluorescent dyes with enhanced two-photon absorption cross-sections. Chem Eur J 12:2303–2317

Karakus M, Apaydin DH, Yildin DE, Toppare L (2012) Benzotriazole and benzothiadiazole containing conjugated copolymers for organic solar cells. Polymer 53:1198–1202

Pei J, Wen S, Zhou Y, Dong Q, Liu Z, Zhang J, Tian WA (2011) low band gap donor–acceptor containing fluorene and benzothiadiazole units: synthesis and photovoltaic properties. New J Chem 35:385–393

Mishra SP, Palai AK, Srivastava R, Kamalasanan MN, Patri M (2010) Highly air-stable thieno[3,2-b]thiophene-thiophene-thiazolo[5,4-d]thiazole-based polymers for light-emitting diodes. Macromol Chem Phys 211:1890–1899

Marsitzky D, Vestberg R, Blainey P, Tang BT, Hawker CJ, Carter KR (2001) Self-encapsulation of poly-2,7-fluorenes in a dendrimer matrix. J Am Chem Soc 123:6965–6972

Kumar A, Srivastava R, Bawa SS, Singh D, Singh K, Chauhan G, Singh I, Kamalasanan MN (2010) Synthesis, characterization and luminescent properties of terbium complexes. J Lumin 130:1516–1520

Xue S, Yao L, Liu S, Gu C, Shen F, Li W, Zheng H, Wu H, Ma Y (2012) Simultaneous enhancement of the carrier mobility and luminous efficiency through thermal annealing a molecular glass material and device. J Mater Chem 22:21502–21506

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Palai, A.K., Kumar, A., Shashidhara, K. et al. Polyalkylthiophene-containing electron donor and acceptor heteroaromatic bicycles: synthesis, photo-physical, and electroluminescent properties. J Mater Sci 49, 2456–2464 (2014). https://doi.org/10.1007/s10853-013-7921-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7921-5