Abstract

It has often been claimed that the equilibrium moisture content (EMC) of wood is controlled by the available hydroxyl group content and their accessibility, but this has not been proven. In the present study, the accessibility of the hydroxyl groups were analysed by deuterium exchange in a dynamic vapour sorption apparatus, and generally poor correlation with the EMC and hydroxyl group accessibility was found. Therefore, the role of the accessibility of wood hydroxyl groups in relation to exerting sole influence on the EMC is disputable. It is concluded that there has to be an additional mechanism to exercise control over the EMC in addition to hydroxyl group accessibility.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

When wood is placed in an atmosphere containing moisture, it will adsorb or desorb moisture until it attains equilibrium moisture content (EMC). By determining EMC at different values of atmospheric relative humidity (RH) at constant temperature, a sorption isotherm is obtained. Wood, in common with cellulosic and lignocellulosic materials, exhibits a characteristic sigmoidal sorption isotherm. It has been often claimed that the equilibrium moisture content (EMC) is controlled by the available hydroxyl group content and their accessibility [1, 2], but this has not been proven. It is difficult to explain the supposed importance of OH content with this behaviour, and other factors would be expected to exert an influence. Water present in the cell wall exerts a swelling pressure, which is resisted by the cell wall matrix. Equilibrium can therefore be viewed as a balance of these two forces. The question that arises is either which model is correct, or is there a mixed mechanism involving mechanical restraint in combination with OH accessibility controlling sorption behaviour.

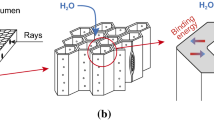

Several methods [3, 4] such as chemical wood modification and thermal modification have been developed to decrease the hygroscopicity of wood and therefore reduce unpreferable properties (dimensional instability, susceptibility to microbiological attack, etc.). With the latter method, wood material is kept in an elevated temperature (usually in excess of 160 °C) in a controlled manner for certain time period. During thermal modification, the mass of the wood material decreases because of the thermal degradation in the wood cell wall polymers: cellulose, lignin and hemicelluloses. The cellulose polymer in the microfibrils is embedded in a complex matrix of lignin and hemicellulose, with the lignin resisting compressive forces and the hemicelluloses acting as interfacial coupling agents between the cellulosic reinforcement and the lignin-rich matrix. The interior of the cellulose microfibrils is not accessible to water [5] and the lignin has a much lower OH to C ratio than the polysaccharide components. The hemicelluloses are the most thermally labile wood polymer and are also the most hydrophilic of these polymers; hence, their degradation results in a reduced hygroscopicity.

Recently, Borrega and Kärenlampi [6] showed that the hygroscopicity of wood decreased in proportion to the mass loss as a result of thermal modification. Surprisingly, the measured EMCs of modified wood showed that the reduction in hygroscopicity was due not only to the loss of hydrophilic hemicellulose, but also to the influence of another mechanism. Suchy et al. [7, 8] hypothesized that this mechanism relates to the irreversible aggregation of cellulose microfibrils and irreversible stiffening of the hemicelluloses/lignin matrix during the drying of the green wood. Moreover, Kato and Cameron [9] suggested that during the thermal modification process, irreversible creation of new hydrogen bonds take place in the amorphous regions of cellulose and hemicelluloses. This phenomenon (also known as “hornification”) is well known in the pulp and paper literature, where it is described as a decrease of water retention value (WRV) of pulp fibres due to structural changes in the cell wall during drying [10]. Hornification is a complex process which has been proposed to be based upon several mechanisms, such as irreversible cell wall nanopore closure, microfibril aggregation, irreversible hydrogen bond formation, etc. [9, 11].

The hygroscopicity of the wood can be determined by the dynamic vapour sorption (DVS) technique, which reveals accurately the sorption kinetics behaviour and sorption isotherms [12]. The accessibility of primary sorption sites in the wood ultrastructure can be measured with hydrogen–deuterium exchange also using such an apparatus. Deuterium exchange is a well-established method to determine the hydroxyl group accessibility either spectroscopically [5, 7, 8, 13–15] or gravimetrically [16–19].

Recently, an alternative mechanism for explaining the reduction in EMC with increasing levels of thermal modification has been presented [12]. This posits that the EMC of the wood is solely determined by the cell wall modulus. As water molecules enter the cell wall, they exert a swelling pressure, which is resisted by the cell wall polymers as well as by restraint on the cell wall exerted by the surrounding wood substance in bulk wood samples (not the case with wood flour). Energy is expended in swelling the cell wall, and the EMC is the point where the free energy of the water/swollen cell wall is balanced by the free energy of the atmospheric water vapour. Thermal degradation of the hemicelluloses and possibly the amorphous cellulose, coupled with increased cross-linking of the lignin, would result in an increase in the cell wall matrix modulus and thereby a reduction in EMC at a given RH (note that this does not necessarily translate to an increase in the global modulus of the wood, since degradation can also lead to a decoupling between individual cells potentially resulting in a decrease in modulus [4]). On the basis of the parallel exponential kinetics (PEK) model, which has been used to determine the cell wall moisture content at infinite time, the cell wall modulus comprises two components: a modulus associated with the fast sorption process, and a modulus associated with the slow sorption process [20]. The purpose of this study was to examine the change in accessible OH content due to thermal modification and examine whether such a reduction was the sole determinant influencing the EMC. This is the first such study reported in the scientific literature.

Materials and methods

Two tropical hardwood species, acacia (Acacia mangium) and sesendok (Endospermum malaccense), were selected in this study. The specimens were thermally modified in dry conditions at 180, 200 and 220 °C for 1, 2 or 3 h, before being milled to form fine particles (20 mesh). The water sorption isotherms of unmodified and modified wood species were analysed using a DVS (dynamic vapour sorption) Intrinsic apparatus (Surface Measurement Systems, London, UK). Full details of the sample preparation, thermal modification and measurements of the sorption isotherms are presented by Jalaludin et al. [21, 22].

A typical isotherm as an example is presented in Fig. 1, which shows sorption isotherms of the untreated and thermally modified (220 °C, 3 h) acacia wood. It is seen that the thermally modified wood shows a dramatic reduction in EMC compared with the untreated wood. An earlier study [21] shows all the sorption isotherms in detail.

The accessibility of the hydroxyl groups were analysed by deuterium exchange in the DVS apparatus. The DVS reservoir was filled with D2O rather than with deionised water. Approximately 10–20 mg of milled wood particles (20 mesh) was placed in the sample pan, and it was preconditioned at 0 % relative humidity (RH) of deuterium oxide (D2O) and nitrogen (flow rate 200 cm3 s−1) at a temperature of 25 °C to remove any adsorbed water molecules. Six adsorption–desorption (RH 0–90 %) cycles were conducted, and the dry mass increase due to deuterium exchange was calculated. The DVS apparatus maintained a constant RH until the sample moisture content change per minute (dm/dt) was less than 0.002 % per minute over a 10-min period to ensure the equilibrium in each RH step. An example of a D2O exchange cycle is presented in Fig. 2. The DVS apparatus achieved a RH of 80–85 % in the example illustrated, but it was enough to reach all accessible OH-groups, as evidenced by the stable mass change obtained in the dry masses of the later cycles. Moreover, an earlier study [13] has found out that OH-groups accessibility did not change above 60 % RH during deuterium exchange. More details of this experimental technique have been given elsewhere [23]. The accessibility was calculated from the difference between the initial dry weight of the sample and the dry weight after the sixth cycle, when the weight did not change anymore. It was found that the major weight change was accomplished already in the first cycle, and the difference is pointed out as a dashed line in Fig. 2.

Chemical compositions of untreated and thermally modified wood were evaluated from the milled wood meal (60 mesh). The extractives were removed according to Tappi standard [24] before determination of holocellulose, α-cellulose and lignin, which were determined according to a previous study [25] and Tappi standards [26] and [27], respectively. Two replicates were measured from each sample and averaged.

Results and discussion

The accessibility of the hydroxyl groups of acacia (n = 3–4) and sesendok (n = 3–4) are presented in Fig. 3. The OH accessibility values of untreated acacia and sesendok wood were 8.1 and 7.5 mmol g−1, respectively, which is in agreement with the literature values [13, 14]. Thermal degradation of polymeric components resulted in the reduction of the accessible OH groups in the modified samples for both species as was seen in an earlier study [14] on Styrax tonkinensis wood, measured using NMR spectroscopy. In this study, the response was unclear. The accessibility of acacia increased, when modified at 180 °C for the first 2 h, which then decreased. It is possible that degradation of the cell wall results in an increase in cell wall-accessible OH content due to internal stresses generating microcracks. Thermally modified acacia at a temperature of 220 °C showed entirely unexpected results wherein there was a substantial (up to 70 %) reduction in accessible cell wall OH content compared with sesendok.

The unexpected results mentioned above could possibly be attributed to high degradation of the thermally labile hemicelluloses, but this was not seen in an earlier study [14]. Moreover, the EMC at RH 95 % from sorption isotherms [21] of the samples and accessibility of the OH groups are compared in Fig. 4b. The degradation of thermally labile components and associated OH groups during thermal modification is believed to decrease the EMC and accessibility of OH groups. In the present study, it is shown that there is rather a poor correlation. The chemical compositions of the unmodified and thermally modified wood are presented in Table 1. The relative cellulose content of thermally modified acacia was increased and hemicelluloses (pentosan + hexosan) decreased as expected; however, the relative lignin content is relatively stable after different modifications, whereas thermally modified sesendok behaves differently. There was a large increase in relative lignin content, a reduction in hemicelluloses (except at a modification temperature of 180 °C and time of 3 h) and a non-uniform decrease of relative cellulose content. However, the number of theoretical OH groups in moles per gram can be estimated by Eq. 1 proposed by Rowell [2] and Hill [4]:

where composition—% of cellulose (A), hemicelluloses hexosan (B) and pentosan (C) and lignin (D) are known. The crystalline proportion of cellulose is assumed to be inaccessible, and therefore the hydroxyl groups of cellulose are corrected by the crystallinity index of 50 %. The crystallinity index (CI) is based on preliminary study by X-ray diffraction (XRD) technique, which showed an averaged CI of 50 %. The XRD technique was not suitable for these studies, because the results showed high variation in CI for reasons that we were not able to explain. Earlier studies [28, 29] have been also found out high variation in CI for A. mangium 46 and 68 %, respectively, using XRD technique. However, an earlier study showed that thermal modification in dry conditions induced a decrease in the CI, rather than an increase that could be observed when the wood is modified in a steam atmosphere [30]. An increase in the CI can be explained by increased mobility of the cellulose chains in the presence of moisture and high temperature. The theoretical OH group contents were calculated and compared with the accessible OH groups. Figure 4a shows again the unexpected behaviour of modified acacia at 220 °C (group of three squares on the left), and poor correlation between the theoretical and experimental data. Nevertheless, even though the crystallinity index is averaged, it is not able to explain the results, because the cellulose proportion is rather low. If the crystallinity index would have increased by 10 % units, then the theoretical accessibility of OH groups would have decreased approximately by 6 %, according Eq. 1. If the EMC of the wood was controlled by accessible hydroxyl group contents alone, then a more uniform correlation would have been expected (Fig. 4b). Therefore, more information is needed to explain this phenomenon.

Conclusions

In this study, the accessibility of the thermally modified wood hydroxyl groups were analysed by deuterium exchange in the DVS apparatus—and poor correlation with the EMC, hydroxyl groups accessibility, and theoretical hydroxyl group content were found. If the moisture content of wood would be controlled by accessible hydroxyl group contents alone, then a more uniform correlation would have been expected. Therefore, the role of the accessibility of wood hydroxyl groups in relation to controlling the moisture content exclusively is disputed, and therefore, there has to be additional mechanism that exercises control over the EMC.

References

Skaar C (1972) Water in wood. Syracuse University Press, New York

Rowell RM (1980) Wood Sci 13:102

Stamm AJ, Tarkow H (1946) J Phys Chem 51:493

Hill CAS (2006) Wood modification—chemical, thermal and other processes. Wiley, Chichester

Hofstetter K, Hinterstoisser B, Salmén L (2006) Cellulose 13:131

Borrega M, Kärenlampi PP (2010) Eur J Wood Prod 68:233

Suchy M, Kontturi E, Vuorinen T (2010) Biomacromolecules 11:2161

Suchy M, Virtanen J, Kontturi E, Vuorinen T (2010) Biomacromolecules 11:515

Kato KL, Cameron RE (1999) Cellulose 6:23

Laivins GV, Scallan AM (1993) Products of papermaking. Transactions of the 10th fundamental research symposium. Pira International, Oxford, p 1235

Fernandez Diniz JMB, Gil MH, Castro JAAM (2004) Wood Sci Technol 37:489

Hill CAS, Ramsay J, Keating B, Laine K, Rautkari L, Hughes M, Constant B (2012) J Mater Sci 47:3191

Taniguchi T, Harada H, Nakato K (1978) Nature 272:23

Phuong LX, Takayama M, Shida S, Matsumoto Y, Aoyagi T (2007) Holzforschung 61:488

Fernandez AN, Thomas LH, Altaner CM, Callow P, Forsyth T, Apperley DC, Kennedy CJ, Jarvis MC (2011) Proc Natl Acad Sci USA 108:E1195

Frilette VJ, Hanle J, Mark H (1948) J Am Chem Soc 70:1107

Morrison JL (1960) Nature 185:160

Sepal O, Mason SG (1961) Can J Chem 39:1934

Sepal O, Mason SG (1961) Can J Chem 39:1944

Hill CAS, Keating BA, Jalaludin Z, Mahrdt E (2012) Holzforschung 66:35

Jalaludin Z, Hill CAS, Xie Y, Samsi HW, Husain H, Awang K, Curling SF (2010) J Mater Sci Eng 5:194

Jalaludin Z, Hill CAS, Samsi HW, Husain H, Xie Y (2010) Holzforschung 64:763

Lee K-Y, Quero F, Blaker JJ, Hill CAS, Eichhorn SJ, Bismarck A (2011) Cellulose 18:595

Tappi standard (2000) T 204 cm-97, Solvent extractives of wood and pulp. TAPPI, Atlanta, GA

Wise LE, Murphy M, D’Addieco AA (1946) Pap Trade J 122:35

Tappi standard (1994) T 203 om-93, Alpha-, Beta- and Gamma-cellulose in pulp. TAPPI, Atlanta, GA

Tappi standard (1994) T 222 om-88, Acid-insoluble lignin in wood and pulp. TAPPI, Atlanta, GA

Kaida R, Kaku T, Baba K, Oyadomari M, Watanabe T, Hartati S, Sudarmonowati E, Hayashi T (2009) J Wood Sci 55:381

Pinto PC, Evtuguin DV, Neto CP (2005) J Agric Food Chem 53:7856

Dwianto W, Takana F, Inoue M, Norimoto M (1996) Wood Res 83:47

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rautkari, L., Hill, C.A.S., Curling, S. et al. What is the role of the accessibility of wood hydroxyl groups in controlling moisture content?. J Mater Sci 48, 6352–6356 (2013). https://doi.org/10.1007/s10853-013-7434-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7434-2