Abstract

The abbreviation “nano-Calphad” stands for “Calculation of Phase Diagrams for nano-systems.” Nano-systems contain at least one phase or at least one interface layer (film, complexion) with at least one of its dimensions being below 100 nm. The essential task of nano-Calphad is to introduce correctly the surface term into the equation for the Gibbs energy. In view of the controversy between the Kelvin and Gibbs equations, even this task does not have an obvious solution (in the present paper, the Gibbs method is preferred). However, there are many further questions to be addressed when the Calphad method is converted into the nano-Calphad method. This paper attempts to give an as full as possible list of all those problems, such as: (i) the definition of a new, independent thermodynamic variable, (ii) the extended phase rule, (iii) the curvature dependence of the interfacial energies, (iv) the dependence of interfacial energies on the separation between interfaces (including the problem of surface melting), (v) the role of the shapes and relative arrangement of phases, (vi) the role of the substrate (if such exists), and (vii) the role of segregation, taking into account its effect on the mass balance within multi-component nano-phases and its surface phase transition and complexion. It is also shown that the well-known meaning of the tie line in binary two-phase fields is lost in nano-systems. The issues related to the size limits of materials thermodynamics and the need for a more complete databanks on molar volumes and interfacial energies are discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The Calphad (=calculation of phase diagrams) method to calculate phase diagrams has become a vital part of materials science and engineering since the 1970s [1–3]. Traditionally, the Calphad method deals with macroscopic systems containing phases with all sizes above 100 nm. In this size range, the size dependence of the molar integral Gibbs energy of a phase is negligible; thus the results of the Calphad calculations are independent of the size of the system and phases.

Since the 1990s, the science and engineering of nano-materials have been strengthening both in the number of papers and in market value (see recent papers [4–16]). It is well known that nano-systems containing phases (or at least a surface film) with at least one of the dimensions being below 100 nm have different properties from those of macro-systems, including their phase equilibria (see experiments [17–46]). It is expected that phase diagrams for nano-systems will gradually become a vital part of materials nanotechnology.

There have already been a considerable number of papers devoted to the construction of phase diagrams for nano-systems [17, 21, 29, 37, 38, 42, 46–99]. However, those 60 papers usually reflect a limited number of aspects on how the phase diagrams for macro- and nano-systems differ. The goal of the present paper is to collect all such features and to work out a generic algorithm to calculate nano-phase diagrams. This sub-branch of Calphad is suggested to be called here as “nano-Calphad”. By definition, it is the Calphad method which is applied to systems containing at least one phase (or interface region, complexion) with at least one dimension below 100 nm. In other words, the nano-Calphad concept takes into account the size dependence of the molar Gibbs energy, through its surface term.

A short summary of the Calphad method

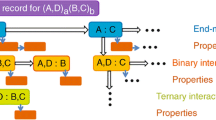

Before introducing differences between the Calphad and the nano-Calphad method, let us shortly define the basic features of the Calphad concept. Calphad searches the relationship between state variables and the equilibrium state of matter in a given system using computers instead of empirical measurements (Fig. 1) [100].

Systems are 3-dimensional parts of the universe under study, and contain a given amount of matter \( n \) (mole). Systems contain a P number of phases denoted as \( \Upphi \) (=\( \alpha \) or \( \beta \), etc.). A phase \( \Upphi \) is a 3-dimensional part of the system, being uniform throughout, both chemically and physically. Phases are separated from each other by interfaces. Each phase contains a certain amount of matter \( n_{\Upphi } \) and is characterized by its phase fraction \( y_{\Upphi } \), defined as: \( y_{\Upphi } \equiv n_{\Upphi } /n \) (with the relationship between them: \( \sum\limits_{\Upphi } {y_{\Upphi } } = 1 \)). Systems contain a C number of components, denoted as i (=A or B, etc.). In the simplest definition of materials science (to be used here), components are the elements. The amount of component i in the system is n i ; the average mole fraction of component i in the system is defined as: \( x_{i} \equiv n_{i} /n \) (with the relationship between them: \( \sum\limits_{i} {x_{i} } = 1 \)). All phases of the system contain the same components. The amount of component i in phase \( \Upphi \) is denoted as: \( n_{i(\Upphi )} \), and the mole fraction of component i in phase \( \Upphi \) is defined as: \( x_{i(\Upphi )} \equiv n_{i(\Upphi )} /n_{\Upphi } \) (with the relationship between them: \( \sum\limits_{i} {x_{i(\Upphi )} } = 1 \)).

If the system is in constant gravitational, electromagnetic, etc., fields, one needs to define the number of components (C) and the identity of the components i. Then, for macroscopic systems there are C + 1 independent state variables (see Fig. 1): pressure (p), temperature (T), and the average mole fractions of (C − 1) components (x i ). These state variables determine the equilibrium state, characterized by the following quantities (see Fig. 1): the number of phases (P) being in equilibrium, their identity (\( \Upphi \)), their equilibrium phase fractions (\( y_{\Upphi } \)) and the equilibrium composition of each phase (\( x_{i(\Upphi )} \)). The relationship between the state variables and the equilibrium state can be established empirically, through measurements. For C = 84 (there are 84 stable elements in nature), there are 85 independent state variables. If each is considered with only 100 different values (in fact a much higher resolution is needed), there are 10085 different combinations of state variables in nature to be measured. If each member of mankind living today measures every day one relationship between the state variables and equilibrium state (which is a highly optimistic assumption), the time needed to establish the empirical databank of the above given size is more than 10158 years, being much longer than the time passed since Big Bang (1010 years). Thus, the establishment of the full empirical databank for materials equilibrium is a mission impossible.

This situation calls for a practical, but theoretically well-established solution, called the Calphad method, which is based on thermodynamics of Gibbs [101]. The Calphad method has two tasks. In step 1 (see Fig. 1), the relationship between the molar Gibbs energy of each possible phase (\( G_{\Upphi } \), J/mol) should be established as function of state variables (T, p, \( x_{i(\Upphi )} \)). If appropriate models are used (which enable reasonable interpolations and extrapolations), it takes much less effort to get this relationship for all phases, than to measure empirically the equilibrium states for all possible combinations of state variables. This relationship can be written in five terms:

where \( G_{\Upphi }^{\rm o} \) (J/mol) is the Gibbs energy of the mechanical mixture:

where \( G_{i(\Upphi )}^{\text{o}} \) (J/mol) is the standard Gibbs energy of pure component i in non-magnetic, strain-free state of phase \( \Upphi \), which is described as a function of p and T. For metallic elements in condensed state, the databank of Dinsdale [102] is widely used, describing \( G_{i(\Upphi )}^{\text{o}} \) by polynomials of temperature at standard pressure. These polynomials are derived from the following relationship:

where \( U_{i(\Upphi )}^{\text{o}} \), \( V_{i(\Upphi )}^{\text{o}} \), \( S_{i(\Upphi )}^{\text{o}} \), \( H_{i(\Upphi )}^{\text{o}} \) are the standard molar inner energy (J/mol), volume (m3/mol), entropy (J/mol K), and enthalpy (J/mol) of component i in phase \( \Upphi \), respectively (all dependent on p and T). The term \( \Updelta G_{\Upphi }^{\text{id}} \) (J/mol) of Eq. (1a) is the Gibbs energy change due to the transition from the mechanical mixture to the ideal solution:

where R = 8.3145 J/mol K, the universal gas constant. The term \( \Updelta G_{\Upphi }^{\text{E}} \) (J/mol) of Eq. (1a) is the Gibbs energy change due to the transition from the ideal solution to the real solution. For a binary solution A–B, the Redlich–Kister equation [103] is usually used:

where L j (J/mol) is the interaction energy of jth order (valid for the given A–B solution of the given \( \Upphi \) phase), being pressure and temperature dependent. Its temperature dependence is usually described by a semi-empirical linear equation:

where h j (J/mol) and s j (J/mol K) are the enthalpy and entropy terms of the jth order interaction energy, taken as constants, while \( \tau_{j} \) (K) is their ratio. However, the extrapolation of this linear equation often leads to high-temperature artifacts [104, 105]. This is because, the linear equation contradicts the recently proposed 4th law of thermodynamics [106], which is based on earlier work of Lupis and Elliot [107]. One of the equations obeying the 4th law is [105]:

where h j (J/mol) is the enthalpy part of the jth interaction energy at T = 0 K, and \( \tau_{j} \) (K) is the temperature at which L j would cross zero if described by an oversimplified linear Eq. (1f). Equation (1g) guarantees that any real solution \( \Upphi \) will gradually approach the state of the ideal solution with increasing temperature, in accordance with the 4th law of thermodynamics. It should be mentioned that Eq. (1g) can lead to a low-temperature artifact, if instead of running the full Calphad optimization, 4(!) parameters are found from 3(!) measured points of a phase diagram [108]. In contrary to this, in all systems for which full Calphad optimization has been carried out so far, it has been shown that Eq. (1g) indeed removes all high-temperature artifacts without introducing any low-temperature artifact [109–122].

The excess Gibbs energy term is more complicated for ternary and multi-component systems (for details see [2, 3]). In addition to the formal Redlich–Kister polynomials, there are many other solution models (for details see [2, 3, 123]). The term \( \Updelta G_{\Upphi }^{\text{magn}} \) (J/mol) of Eq. (1a) is the Gibbs energy change due to the transition from a non-magnetic state to a magnetic state if such exists (for details see [2, 3, 124]). The term \( \Updelta G_{\Upphi }^{\text{strain}} \) (J/mol) of Eq. (1a) is the Gibbs energy change due to the transition from a strain-free state to a state under strain [74, 91, 125], also being a function of the interface thickness. Equation (1a–1g) are written for a one-sublattice phase. There are many phases in nature (especially the compound phases) that contain two, or several sub-lattices, having more difficult mathematical description (for details see [2, 3, 126, 127]).

Equation (1a–1g) are written for the integral Gibbs energy of phase \( \Upphi \). The components of this phase have their own partial Gibbs energies denoted as \( G_{i(\Upphi )} \). The average values of all partial Gibbs energies of the phase equal the integral Gibbs energy of the phase:

The partial Gibbs energies can be found from the integral Gibbs energy as:

Now, let us suppose that step 1 of the Calphad method is fulfilled, i.e., the full databank of \( G_{\Upphi } = f(p,T,x_{i(\Upphi )} ) \) is known. Having Eq. (1i), the full databank of \( G_{i(\Upphi )} = f(p,T,x_{i(\Upphi )} ) \) is also known. Now, let us proceed to step 2 of the Calphad method (Fig. 1) and see how the parameters of the equilibrium state can be calculated from the known Gibbs energy functions. The major rule is that the equilibrium state is the one (to be selected from the list of all possible states) which provides the absolute minimum value for the molar Gibbs energy of the system [101]:

The total Gibbs energy of the system (G, J/mol) is written as an average of the integral Gibbs energies of its phases:

where \( y_{\Upphi } \) is the phase fraction of phase \( \Upphi \) (for its definition see above). In the simplest case P = 1, so \( x_{i(\Upphi )} = x_{i} \), \( y_{\Upphi } = 1 \) and \( G = G_{\Upphi } \). In the case of P = 1, the \( G_{\Upphi } \) functions of all possible phases \( \Upphi \) at given values of state variables (p, T, x i ) should be compared to each other to select the equilibrium phase in accordance with Eq. (1j). In addition, all possible two-phase mixtures (\( \alpha + \beta \)) should also be considered, with the following condition of heterogeneous equilibrium to be fulfilled for each component i [101]:

Not only 2-phase, but all multi-phase combinations should be checked for the minimum of total Gibbs energy. Fortunately, the number of co-existing phases is limited by the phase rule of Gibbs [101]:

Equation (1m) follows from the equality of the possible number of Eq. (1l) (=\( C \cdot (P - 1) \)) and the number of all independent concentrations and other state variables (=\( 2 + P \cdot (C - 1) \)). Equation (1m) defines the allowed interval (\( 1 \le P \le C + 2 \)) for the number of phases that can co-exist in equilibrium. For example, Eq. (1m) provides P max = 3 for one-component systems, allowing the existence of well-known triple points in one-component phase diagrams, but excluding the existence of quaternary points.

Although not needed for the Calphad calculations but useful in the interpretation of phase diagrams, let us also write the equation for the degrees of freedom (F) defined as: \( F \equiv P_{\max } - P \). Substituting Eq. (1m) into this equation [101]:

The degree of freedom is the number of state variables that can be changed independently without changing the quality of the equilibrium state. The quality of the equilibrium state is kept unchanged, if parameters P, \( \Upphi \) and \( y_{\Upphi } \) are not changed. In other words, the composition of the phases (\( x_{i(\Upphi )} \)) is not a qualitative, only a quantitative measure of the equilibrium state (see Fig. 1).

Now, let us suppose that in a C-component system a mixture of P phases is formed, in agreement with the phase rule, i.e., supposing \( P \le C + 2 \). Then, according to Fig. 1, (P − 1) independent values of phase fractions \( y_{\Upphi } \) and \( P \cdot (C - 1) \) independent values of compositions \( x_{i(\Upphi )} \) should be found by the Calphad method. Thus, the total number of independent unknowns is (\( P \cdot C - 1 \)). To find these unknowns, we have \( C \cdot (P - 1) \) equations of the Eq. (1l) type and additionally (C − 1) equations of material balance as follows:

Thus, the total number of independent equations is (\( P \cdot C - 1 \)), which is the same as the total number of independent unknowns. Thus, the Calphad method is always capable of finding the parameters of the equilibrium state, supposing that the phase rule is obeyed.

For the particular case of a 2-component, 2-phase system (C = 2, P = 2), the equilibrium compositions of the two phases (\( x_{{\rm{B}}(\alpha )} \) and \( x_{{\rm{B}}(\beta )} \)) can be found from the two independent equations of the (1l) type (\( G_{{\rm{A}}(\alpha )} = G_{{\rm{A}}(\beta )} \) and \( G_{{\rm{B}}(\alpha )} = G_{{\rm{B}}(\beta )} \)), without using the mass balance Eq. (1o). Thus, at any average mole fraction of \( x_{{\rm{B}}(\alpha )} < x_{{\rm{B}}} < x_{{\rm{B}}(\beta )} \) the equilibrium mole fractions (\( x_{{\rm{B}}(\alpha )} \) and \( x_{{\rm{B}}(\beta )} \)) will be identical, and independent of the actual value of \( x_{{\rm{B}}} \). The latter will determine only the phase fraction \( y_{\beta } \) through the mass balance Eq. (1o). That is why, in the T-x B section (drawn at fixed p) of macroscopic binary phase diagrams, a tie line can be constructed within each two-phase region, along which the equilibrium values of \( x_{{\rm{B}}(\alpha )} \) and \( x_{{\rm{B}}(\beta )} \) will not depend on x B. This point is highlighted here, because this property of the tie lines will be lost in nano-Calphad (see below).

Finally, it should be recognized that in Fig. 1 and above an idealized picture is shown, supposing that all Gibbs energy functions can be independently measured and modeled (step 1) with an accuracy requested for phase diagram calculations (step 2). Unfortunately, it is not the case. The measured phase diagrams are also needed for better results of step 1, and hence steps 1–2 are treated together. This procedure is called “optimization” or “assessment” [2, 3]. Although great efforts are being made in many Calphad groups worldwide, the creation of the 84-component, contradiction-free thermodynamic databank is very far. The goal to create this full databank is further complicated by the fact that in addition to the constant flow of new measured results and new assessments, there is also a constant flow of new ideas expressed in better model equations. Sometimes it makes the situation frustrating; with the acceptance of each new model equation, any group working on Calphad assessments has to start building its databank from zero, instead of building the existing one further. This situation sometimes postpones the acceptance of new model equations by the Calphad community.

As a conclusion to this short introduction to the Calphad method, let us remind that the Calphad method is independent of the size and of the arrangement of phases, simply because the Calphad method works entirely with bulk Gibbs energies and neglects any surface or interface interaction between the phases. Now, let us consider step by step what modifications should be introduced in the Calphad method to convert it into the nano-Calphad method.

On a new, independent state variable for nano-systems

In the majority of nano-phase diagram calculations (except [66, 128]), the resulting phase diagram is shown at given radius or diameter of the system. However, the size of a condensed system is not an independent state variable. This is because, for a given amount of material its size depends on the molar volume, while the molar volume of any phase is a function of other state variables (temperature, pressure, composition). Therefore, size (radius or diameter) should not be used as independent state variable.

In the present paper, the number of atoms in the system (N) is selected as a new independent state variable, supposing that only condensed phases are considered in the system. It is supposed that the condensed phases are surrounded by a large vapor phase, keeping equilibrium with each other, but not exchanging atoms with each other.

If a gas/vapor phase is also considered as part of a nano-system, then the new independent variable should be N/V, i.e., the ratio of the total number of atoms in the system (N) to the available volume for the system (V, m3). In this case, the volume V should be larger than needed for the condensed phase of the largest molar volume, supposing that all atoms are in this phase (thus the N/V ratio should not give limitations to the free formation of condensed phases). In the following part of this paper, only condensed nano-systems will be considered for simplicity.

The above selected new, independent state variable will be independent of all other independent state variables. Thus, the full list of state variables for condensed nano-systems will be: pressure (p), temperature (T), average composition of the system (\( x_{i} \)), and the total number of atoms in the system (N), providing (C + 2) independent state variables in a C-component system.

The number of atoms in the system and its actual size can be converted into each other, if other state variables are known; so the molar volume is fixed and also the shapes of the phases are known. In this paper, in addition to N, the radius r (m) also will be sometimes used, especially for the purposes of comparison with previous equations in the literature.

It should be recognized that the same choice (N) was done earlier by Wautelet et al. [66] and later by the author [128].

The extended phase rule for nano-systems

It should be reminded that “2” in Eqs. (1m, 1n) for the phase rule is the number of non-concentration state variables, p and T. As shown above, the number of such state variables is increased by one (the number of atoms, N) for nano-systems. Therefore, the extended phase rule of Gibbs for nano-systems is written as (for a detailed derivation, see [128]):

As follows from Eq. (2a), even for 1-component systems (C = 1): P max = 4, i.e., in addition to the well-known triple points, a quaternary point also might appear in 1-component nano-phase diagrams. Such a quaternary point was predicted for the one-component phase diagram of thallium, at fixed values of all state variables of N, p, T [128]).

Although the present author has not found Eqs. (2a, 2b) in the nano-Calphad literature [17–99] prior to the paper [128], there are papers mentioning that constructing and understanding phase diagrams for nano-systems differ qualitatively (and not only quantitatively as usually presented) from the usual phase diagrams [64, 66, 72, 76].

The extended equation for the integral molar Gibbs energy of nano-phases

The integral molar Gibbs energy of nano-phases will be a function of the following variables: \( G_{\Upphi } = f(p,T,x_{i(\Upphi )} ,N_{\Upphi } ) \) where \( N_{\Upphi } \) is the number of atoms in the given condensed phase \( \Upphi \), calculated as: \( N_{\Upphi } = y_{\Upphi } \cdot N \). The major reason why the Gibbs energy is size dependent is the high specific surface area of nano-phases (see below). Therefore, Eq. (1a) will be extended with a new surface term (\( \Updelta G_{\Upphi }^{{\rm{surf}}} \), J/mol), being the molar Gibbs energy change between the macroscopic and nano-phases:

The surface term of Eq. (3a) will be a function of all state variables \( \Updelta G_{\Upphi }^{{\rm{surf}}} = f(p,T,x_{i(\Upphi )} ,N_{\Upphi } ) \). However in the first approximation, this will be the only term being a function of \( N_{\Upphi } \). In other words, all the other terms of Eq. (3a) remain the same as known for macroscopic phases of Eq. (1a) at given values of \( p,T,x_{i(\Upphi )} \) and at \( N_{\Upphi } \to \infty \).

After Gibbs [101], the molar Gibbs energy of the surface can be written as:

where N Av is the Avogadro number (\( 6.02 \cdot 10^{23} \) mol−1), \( A_{\Upphi ,{\rm{abs}}} \) is the absolute surface area (m2) of phase \( \Upphi \), \( \sigma_{\Upphi /{\rm{s}}} \) is the interfacial energy (J/m2) between phase \( \Upphi \) and the surrounding phase (denoted as “s”). The following relationship is valid between the number of atoms in a phase (\( N_{\Upphi } \)), its absolute volume (\( V_{\Upphi ,{\rm{abs}}} \), m3), and its molar volume (\( V_{\Upphi } \), m3/mol): \( N_{\Upphi } \cdot V_{\Upphi } = N_{{\rm{Av}}} \cdot V_{\Upphi ,{\rm{abs}}} \). Substituting this equation into Eq. (3b), another version of Eq. (3b) is found:

where \( A_{\Upphi ,{\rm{spec}}} \) is the specific surface area (m2/m3 = m−1) of phase \( \Upphi \), defined as:

As follows from Eq. (3c), the surface term of the Gibbs energy is proportional to the specific surface area of the phase, which depends not only on the number of atoms in the phase but also on the shape of the phase. This gives rise to an additional problem of nano-Calphad: the equilibrium shape and arrangement of phases should be found from Eq. (1j) (see below).

Let us specify Eq. (3c) for a thin film of thickness d, surrounded by two parallel phases \( \alpha \) and \( \beta \). The specific surface area of one side of a thin film is written as: \( A_{\Upphi ,{\rm{spec}}} = A_{\Upphi ,{\rm{abs}}} /\left( {d \cdot {\rm{A}}_{\Upphi ,{\rm{abs}}} } \right) = d^{ - 1} \). Substituting this equation into Eq. (3c), and taking into account the two sides of the thin film, the surface term of its Gibbs energy is obtained:

For comparison, the surface term of the Gibbs energy for a sphere of radius r:

where \( 3/r = A_{\Upphi ,{\text{spec}}} \) is the specific surface area of a sphere of radius r, being the ratio of its surface area (\( 4 \cdot \pi \cdot r^{2} \)) to its volume (\( 4 \cdot \pi \cdot r^{3} /3 \)).

As follows from Eq. (3c), the nano-effect is due to the large specific surface area of the nano-phase. This is in contrast to the common belief in the materials science literature claiming that the nano-effect is due to the curvature of the nano-phase. This misbelief originates from the Kelvin equation [47]. Kelvin used the Laplace equation in his derivation. The Laplace pressure describes the inner pressure within a phase of a curved interface. For a spherical 1-component phase of radius r, the Laplace pressure is written as [129]:

where p o is the outer pressure, usually taken as the standard pressure. Now, let us consider the equations for the Gibbs energy with a surface term and that for a standard Gibbs energy for one-component phases:

Let us substitute Eq. (4a) into Eq. (4b) and express the surface term by taking into account Eq. (4c):

Equation (4d) is valid for 1-component phases. For a more general case of solutions, Eq. (4d) becomes:

Comparing Eqs. (4e) to (3f) one can see that the two differ in a numerical coefficient (2 vs. 3). This difference in the numerical coefficients of Eqs. (3f, 4e) is a sign of a qualitative difference between the approaches of Gibbs and Kelvin, as both Eqs. (3f, 4e) cannot be correct at the same time. The present author cannot find any fault in the logic of Gibbs. However, there are at least two faults of logic in the derivation of Eq. (4e), the way how the Kelvin equation is derived today:

-

i.

although mathematically everything is correct in the above derivation, there is a physical fault: the inner pressure of Eq. (4a) should not be substituted for the state variable p (outer pressure) of Eq. (4b).

-

ii.

the Laplace pressure of Eq. (4a) can be derived from the equation of the Gibbs energy including its surface term Eqs. (3a, 3c) (see [130, 131]), and so there is no sense in substituting the result back into the same equation.

Due to the above, Eq. (4e) and all its consequences are incorrect. Those consequences are far-reaching: the Kelvin equation for the vapor pressure above a nano-droplet, the Gibbs–Thomson equation for a melting point of a nano-crystal, and the Ostwald–Freundlich equation for the solubility of the nano-crystal (sometimes called also the Gibbs–Thomson equation) should all be corrected, as shown below.

At this point, it should be noted that in the minority of papers [56, 72–74, 91, 97] the correct Eqs. (3c–3f) are used. The incorrect Eq. (4e) and its consequences (the Kelvin equation, the Gibbs–Thomson equation, and the Ostwald–Freundlich equation) are common in the literature of chemistry and its derived sciences, such as biology, metallurgy, and materials. Why the physics community prefers the Gibbs equation to the Kelvin equation is probably connected with the importance of thin films in physics. Thin films by definition do not have curvatures, so from the Kelvin equation (4e) it seems that they do not have a surface term of their Gibbs energies. Thus, based on the Kelvin equation, all of their thermodynamic properties are expected to be independent of the thickness of the thin film, being in contradiction with observations [17, 18]. On the other hand, Eq. (3e) obtained after Gibbs is in accordance with the experiments.

The corrected Kelvin equation

The original Kelvin equation provides the equilibrium vapor pressure (p, Pa) around a spherical droplet of radius r [47]:

where p o is the vapor pressure (Pa) above a flat liquid surface (\( r \to \infty \)). Equation (5a) is in full accordance with Eq. (4e), although Eq. (4e) was derived later from Eq. (5a) using the thermodynamics of Gibbs. If Eq. (3c) is used instead of Eq. (4e) for the surface term of the Gibbs energy, the corrected Kelvin equation can be obtained (for details see [132]):

For a particular case of a spherical droplet of radius r, Eq. (5b) simplifies to [132]:

The corrected Gibbs–Thomson equation

The Gibbs–Thomson equation was published neither by Gibbs, nor by W. Thomson (=Lord Kelvin), rather by J.J. Thomson [48]. It is an extension of the Kelvin equation for the case of the melting point (T m, K) of a spherical nano-crystal of radius r (neglecting the molar volume change upon melting):

where \( T_{\rm m}^{\rm o} \) is the melting point (K) of a large crystal (\( r \to \infty \)), \( \Updelta_{\rm m} S \) is the melting entropy (J/mol K). If Eq. (3c) is used instead of Eq. (4e) for the surface term of the Gibbs energy, the corrected Gibbs–Thomson equation can be obtained (for details see [132]):

For a particular case of a spherical crystal of radius r, Eq. (6b) simplifies to [132]:

It should be mentioned that Eqs. (6a–6c) are valid for a solid crystal embedded in a liquid matrix [17, 53] and if the temperature dependence of parameters \( \sigma_{\rm{sl}} \), \( \Updelta_{\rm m} S \) and \( V_{\rm s} \) are neglected. In a formal treatment, when the solid and liquid phases are treated separately (not in contact with each other), the term of \( \sigma_{\rm{sl}} \cdot V_{\rm s} \) of all Eqs. (6a–6c) should be replaced by the term \( \left( {\sigma_{\rm{sg}} \cdot V_{\rm s} - \sigma_{\lg } \cdot V_{\rm l} } \right) \) [22, 50, 52, 56, 59, 72, 74]. This replacement usually does not change the numerical results considerably, due to the validity of the approximated equalities \( V_{\rm s} \cong V_{\rm l} \) and \( \sigma_{\rm{sl}} \cong \sigma_{\rm{sg}} - \sigma_{\lg } \).

The corrected Ostwald–Freundlich equation

The Ostwald–Freundlich equation (being also the extension of the Kelvin equation) is due to Freundlich and it provides the equilibrium solubility (\( x_{\rm{ A(l)}} \)) of a spherical solid phase A(\( \alpha \)) of radius \( r \) in a large liquid solution (l), supposing ideal behavior in the liquid solution [51]:

where \( x_{\rm{ A(l)}}^{\rm o} \) is the solubility of the large crystal (\( r \to \infty \)). To add to the confusion, Eq. (7a) is also called the “Gibbs–Thomson” equation in some papers, as it is related to Eqs. (5a–6a). If Eq. (3c) is used instead of Eq. (4e) for the surface term of the Gibbs energy, the corrected Ostwald–Freundlich equation can be obtained (for details see [133]):

For a particular case of a spherical crystal of radius r, Eq. (7b) simplifies to [133]:

For a historical reason, let us mention that Eq. (7c) was already published in 1900 by Ostwald [49], using the same original ideas of Gibbs as being used in the present paper [101]. However, Eq. (7c) of Ostwald was later “corrected” by Freundlich [51], and this mistakenly corrected equation is called today (quite ironically) the Ostwald–Freundlich equation. The corrected back Eq. (7c) is suggested to be referred to in the future as “the Ostwald equation.”

The curvature dependence of the interfacial energies

For precise calculations, the curvature dependence of the interfacial energy should be taken into account. It was also Gibbs who derived a curvature-dependent equation for surface tension [101]. However, he did it not for the purposes of nano-Calphad, rather to make sure that measurements performed on sub-millimeter objects do not affect the results of measured surface tension values (they do not). This subject received renewed attention only after the work of Tolman [134]. The most general equation for the curvature dependence of the interfacial energy of a spherical phase of radius \( r \) is written as:

where \( \sigma_{\alpha /\beta } \) is the curvature-dependent interfacial energy (J/m2), \( \sigma_{\alpha /\beta }^{\rm o} \) is the interfacial energy (J/m2) at the limit of \( r \to \infty \), and δ is the distance (m) from the surface of tension to the dividing surface for which the superficial density of the particle vanishes (its value is proportional to the intermolecular, or interatomic distance). The Tolman equation has been discussed and improved in the literature [135–148]. Although there is no final choice made in the present paper between different approaches [134–148], it is stressed that this question should be addressed in all papers dealing with curved nano-phases. This aspect of phase equilibrium calculations has already been taken into account in some papers [60, 149, 150].

It is worth to mention that in deriving Eq. (8a), Gibbs used the Laplace pressure described by Eq. (4a). This is the third reason why the Laplace pressure should not be used to derive the Kelvin Eq. (4e). Finally, let us mention that the difference shown above between the Ostwald and the Freundlich equations is partly compensated if the curvature dependence of the interfacial energy is taken into account, as shown in [133]. As a further example, let us write here the modified version of Eq. (6c), taking into account the curvature dependence of the interfacial energy (note a possible replacement of the term \( \sigma_{\rm{sl}} \cdot V_{\rm s} \) by the term \( \left( {\sigma_{\rm{sg}} \cdot V_{\rm s} - \sigma_{\lg } \cdot V_{\rm l} } \right) \) depending on the situation—see explanation after Eq. (6c)):

Equation (8b) provides somewhat lower melting point depression values for small particle sizes compared to Eq. (6c), and thus it partly compensates the difference between Eqs. (6a, 6c).

The dependence of interfacial energies on the separation between interfaces

If there is more than one phase in a nano-system, usually the separation between different interfaces will also be below 100 nm. At this distance, the so-called interfacial adhesion force acts between the phases, first described by Derjaguin [151], de Boer [152], and Hamaker [153] (see also recent books on the subject [154, 155]). This interfacial adhesion force arises because the interfacial energies of neighboring interfaces affect each other from a small distance [130, 131].

Let us consider two phases α and β in a larger phase γ, with two parallel α/γ and β/γ interfaces, with a distance (separation) of z (m) between them. If phases α and β are close enough to each other (yet not touching each other) the molecules/atoms along their opposing interfaces will generate some change in the energetic states of each other. In other words, the α/γ and β/γ interfacial energies will become functions of separation z. In order to find this relationship, let us first define the boundary conditions:

-

i.

at infinite separation (z → ∞), the interfacial energies have their standard, z-independent values: \( \sigma_{\alpha /\gamma } (\infty ) = \sigma_{\alpha /\gamma } \), \( \sigma_{\beta /\gamma } (\infty ) = \sigma_{\beta /\gamma } \),

-

ii.

at zero separation (z = 0), the two particles touch each other and so the sum of their interfacial energies becomes the interfacial energy of the α/β interface: \( \sigma_{\alpha /\gamma } (0) + \sigma_{\beta /\gamma } (0) = \sigma_{\alpha /\beta } \). Formally, this can be divided into two parts as: \( \sigma_{\alpha /\gamma } (0) = p \cdot \sigma_{\alpha /\beta } \) and \( \sigma_{\beta /\gamma } (0) = (1 - p) \cdot \sigma_{\alpha /\beta } \) with parameter 0 < p < 1 (for simplicity, parameter p can be taken as p = 0.5).

Then, one can write the following general equations:

The above boundary conditions can be translated into the boundary conditions for function f(z): (i) at infinite separation (z → ∞): f(z) = 0, and (ii) at zero separation (z = 0): f(z) = 1. Depending on the type of cohesion energy within phase \( \gamma \), two types of f(z) functions are used, both obeying the above boundary conditions:

where \( \xi \) is the interaction length (m), being several times the atomic diameter in phase \( \gamma \). Equation (9c) is used for phases with van-der-Waals interaction between the molecules [130, 131] in agreement with the van-der-Waals type interfacial adhesion force [151–155], while Eq. (9d) is used for metallic phases with short range interaction [59].

As an example, let us apply Eqs. (9a, 9b, 9d) to the case of a thin liquid layer, covering a solid surface in a gas (vapor) environment (Fig. 2b). The sum of the two interfacial energies is written by adding Eqs. (9a, 9b) and substituting Eq. (9d):

Equation (9e) allows the prediction of surface melting, schematically shown in Fig. 2. The total Gibbs energy change per unit area (J/m2) accompanying surface melting can be written as the sum of the bulk term and of the surface term as follows, if the T-dependence of the melting entropy is neglected:

If \( T < T_{\rm m}^{\rm o} \) (i.e., below the macroscopic melting point), the value of the z-dependent Gibbs energy change upon melting passes through a minimum as function of z in accordance with Eq. (9g), if \( \Updelta \sigma > 0 \). This minimum corresponds to the equilibrium thickness of the molten surface layer, as shown in Fig. 3. The equation for the equilibrium thickness of the melting layer z eq (m) follows if Eq. (9g) is substituted into the mathematical condition of the minimum point (\( d\Updelta_{\rm m} G(z)/dz = 0 \)) and the resulting equation is solved for z, denoted as zeq:

Dependence of the melting Gibbs energy per unit area on the thickness of the thin liquid film of Fig. 2b, calculated by Eq. (9g) (parameters: \( T_{\rm m}^{\rm o} - T \) = 10 K, \( \Updelta_{\rm m} {S^{\rm o}} \) = 10 J/mol K, \( V_{\rm s}^{\rm o} = 10^{ - 5} \) m3/mol, \( \Updelta \sigma \) = 0.1 J/m2, \( \xi \) = 1 nm)

The temperature dependence of z eq is shown in Fig. 4. As follows from Eq. (9h), surface melting below the melting point takes place only if \( \Updelta \sigma > 0 \) and only in a limited temperature range, in the proximity of the melting point. The “proximity” can be calculated from the condition of \( z_{\rm{eq}} \ge \xi \) by the equation: \( \left( {T_{\rm m}^{\rm o} - T} \right) \le \Updelta \sigma \cdot V_{\rm s}^{\rm o} /(e \cdot \xi \cdot \Updelta_{\rm m} S) \) (with e = 2.718…). With parameter values of Fig. 4 “proximity of the melting point” means \( \left( {T_{\rm m}^{\rm o} - T} \right) \le 37 \) K, i.e., 1000 K \( \ge T \ge \) 963 K—see Fig. 4.

Dependence of the equilibrium thickness of the liquid layer on a solid substrate as function of temperature, calculated by Eq. (9h) (parameters: \( T_{\rm m}^{\rm o} \) = 1000 K, \( \Updelta_{\rm m} S^{\rm o} \) = 10 J/mol K, \( V_{\rm s}^{\rm o} = 10^{ - 5} \) m3/mol, \( \Updelta \sigma \) = 0.1 J/m2, \( \xi \) = 1 nm)

The phenomenon of surface melting has been known for a long time (for a review see [156]). Its influence on melting of nano-particles is discussed in [59, 157–160] (note: the terms “surface melting” and “melting point depression of nano-particles” are only related to each other, but not equivalent to each other). Not only surface melting, but also the formation of amorphous thin films can be explained by a similar formalism [91, 161–163]. The effect of strain has a high importance in this subject through its influence on interfacial energies [91, 163, 164]. A similar formalism is applicable also for grain boundary pre-melting [165].

The role of the shapes and relative arrangement of phases

Some examples of arrangements and shapes of two phases in the same two-phase system are shown in Fig. 5. As was mentioned above, the classical Calphad method does not make any difference between these situations, for the reason that it works only with bulk Gibbs energies. However, to apply Eqs. (3a, 3c, 3d) correctly, the shapes and arrangements of all phases in a system should be pre-defined. Moreover, Eqs. (3c, 3d) should be extended to take into account different interfaces surrounding the same phase, as:

where \( A_{\Upphi /{\text{s, spec}}} \) is the partial specific interfacial area (m2/m3 = m−1) of phase \( \Upphi \) along its contact with a given surrounding phase s (taking into account a number of such different surrounding phases), defined as:

where \( A_{\Upphi /{\text{s, abs}}} \) is the absolute interfacial area (m2) of phase \( \Upphi \) along its contact with a given surrounding phase s.

The shape and the relative arrangement of phases are not known a priori. When calculating phase diagrams for nano-systems, all possible shapes and arrangements for phases should be analyzed and the equilibrium shapes and arrangement of the phases will be the one which corresponds to the total minimum value of the Gibbs energy described by Eq. (1j).

It should be noted that the importance of the shape and arrangement of phases has been recognized since the work of Reiss and Wilson [52]. Since then, this effect was taken into account in about 20 % of nano-Calphad papers [42, 53, 57, 59, 64, 66, 73, 76, 89, 90].

The role of the substrate

In the majority of phase diagram calculations performed for nano-systems so far, the nano-system virtually levitates in space, having no contact with any other substrate. Although this is certainly one of the possibilities, it is of real scientific and technical interest what will happen if nano-phase \( \beta \) surrounded by phase \( \alpha \) comes into contact with a foreign substrate \( \gamma \). As follows from Fig. 6, the interfacial areas of different interfaces are different in subfigures of Fig. 6, thus the energetic states of nano-phase \( \beta \) will also be different. We can presume that the presence of a wettable substrate \( \gamma \) will stabilize the wetting nano-phase \( \beta \).

In this situation, the same Eqs. (10a, 10b) should be used instead of Eqs. (3c, 3d). An example is Eq. (3e) describing the total surface term of a thin film surrounded by two large parallel phases. The situation described in this and previous chapters are very similar. The difference is that the macroscopic phase \( \gamma \) of Fig. 6 might not be considered as part of the nano-system, for simplicity. However, if this phase \( \gamma \) is in thermodynamic equilibrium with phases \( \alpha \) and \( \beta \), then its influence on the final equilibrium can be taken into account using Eqs (10a, 10b).

Let us mention that there are several papers [84, 96, 166–168] in which the effect of the substrate has been taken into account in nano-Calphad calculations.

The role of segregation

If phase \( \Upphi \) consists of C components (with C > 1), the composition of each interface is generally different from that of the bulk, which is called segregation (it can be positive or negative). Segregation is one of the ways to decrease the total interfacial energy of a phase. Thus, the influence of segregation on the interfacial energy and on the total equilibrium in nano-systems should be taken into account. Although it can be done through the original Gibbs adsorption equation [101], it is more convenient to use the Butler equation [169]:

The partial interfacial energies \( \sigma_{i(\Upphi /{\rm s})} \) (J/m2) are written as [170]:

where \( \sigma_{i(\Upphi /{\rm s})}^{\rm o} \) is the interfacial energy (J/m2) of the \( \Upphi /{\rm s} \) interface of pure component i of phase \( \Upphi \), \( f \) is a geometrical constant depending on the structures of both the bulk and the interface, taken equal for liquid metal/vapor interfaces \( f \cong 1.00 \) [171], \( x_{i(\Upphi /{\rm s})} \) is the mole fraction of component i at the \( \Upphi /{\rm s} \) interface, \( x_{i(\Upphi )}^{\rm b} \) is the mole fraction of component i of the bulk of phase \( \Upphi \) (excluding its surface/interface regions), \( \beta \) is the ratio of surface bonds to bulk bonds, taken equal for liquid metal/vapor interfaces \( \beta \cong 9/11 \) [171], \( \Updelta G_{i(\Upphi )}^{\rm E} \) is the bulk partial excess Gibbs energy of component i (J/mol) described by Eqs. (1e, 1f), being a function of temperature and bulk composition (\( x_{i(\Upphi )}^{\rm b} \)), \( \Updelta G_{i(\Upphi /{\rm s})}^{\rm E} \) is the interfacial partial excess Gibbs energy of component i (J/mol) described by the same Eqs. (1e, 1f) using the same parameters, but being a function of temperature and surface composition \( x_{i(\Upphi /{\rm s})} \). The material balance equations are written as:

where \( x_{i(\Upphi )} \) is the average mole fraction of component i of phase \( \Upphi \), N Φ is the number of atoms in phase \( \Upphi \), N b(Φ) is the number of atoms in the bulk of phase \( \Upphi \), while N Φ/s is the number of atoms at the Φ/s interface. The latter two quantities are written as:

A simplified version of Eqs. (11a–11d) with \( x_{i(\Upphi )}^{\rm b} = x_{i(\Upphi )} \) has been proven to describe correctly the concentration dependence of surface tension of bulk liquid metallic alloys [172–185]. The same method has been extended from the liquid/vapor surface to the liquid/liquid [186] and solid/solid [187] interfaces, thus it can be generalized to any interface. The same simplified Eqs. (11a–11d) with \( x_{i(\Upphi )}^{\rm b} = x_{i(\Upphi )} \)were used in calculations of phase diagrams for nano-systems by Tanaka et al. [67, 68, 79, 94] and later by other groups [42, 77, 96, 97].

The full set of Eqs. (11a–11h) is suggested here for the first time. It is superior to the simplified set of Eqs. (11a–11d) with \( x_{i(\Upphi )}^{\rm b} = x_{i(\Upphi )} \) as it takes into account the material balance limitations upon segregation from a nano-phase. Although the necessity to do so was already mentioned by Wautelet et al. [66], to the best knowledge of the author this idea has not been implemented into the nano-Calphad algorithm so far. According to the full set of Eqs. (11a–11h) for nano-phases, the bulk composition \( x_{i(\Upphi )}^{\rm b} \) is usually not identical to the average composition \( x_{i(\Upphi )} \)of the phase (\( x_{i(\Upphi )}^{\rm b} \ne x_{i(\Upphi )} \)), due to the interplay between the segregation and the limited number of segregating atoms in the nano-phase.

For C components and s interfaces we have \( s \cdot (C - 1) \) equations of type (11a) and (C − 1) equations of type (11e), i.e., together (\( s \cdot C - s + C - 1 \)) equations. On the other hand, we have (C − 1) unknowns of \( x_{i(\Upphi )}^{\rm b} \) type and \( s \cdot (C - 1) \) unknowns of \( x_{i(\Upphi /{\rm s})} \) type at given values of \( x_{i(\Upphi )} \), p, T, \( N_{\Upphi } \) and \( A_{\Upphi {\rm{/{\text{s, abs}}}}} \). Thus, the number of unknowns (\( s \cdot C - s + C - 1 \)) equals the number of equations, i.e., the solution can be found in a unique way. Substituting the unknowns \( x_{i(\Upphi )}^{\rm b} \) and \( x_{i(\Upphi )} \) into Eqs. (11b), the partial interfacial energies of all the components can be found at all interfaces, which leads to the interfacial energy at each interface, in agreement with Eq. (11a).

An interesting feature of the Butler equation has been found recently [188–190] for the systems with positive excess Gibbs energy values, becoming partly immiscible below a certain bulk critical temperature. In a limited interval of composition and temperature, Eqs. (11a–11d) lead to 3 mathematical solutions for the surface composition instead of one, among which only the mathematical solution with the minimum surface tension has a physical sense. However, at a given temperature (below a certain surface critical temperature) there is one special bulk composition at which the surface tension values of two mathematical solutions with two different surface compositions coincide: this is a first order surface phase transition (SPT). When the bulk composition exceeds the SPT composition of a surface-active component, a nano-layer rich in the surface-active component is formed on the top of the bulk liquid solution.

This phenomenon was predicted independently in the same year by Cahn [191] and Helms [192], although experimental evidence existed before [193]. Since then, the SPT phenomenon has been proven to exist both theoretically and experimentally along surfaces [194–213] and also along inner interfaces [214–216], including dislocations [217] and grain boundaries [218–226]. This surface or interface nano-layer is not a new phase. It is rather an interface film, or an adsorbed layer, sometimes called “complexion” [227–232]. Complexions can be modeled by the combination of Eqs. (9–11).

The summary for the nano-Calphad concept

Let us consider a C-component-condensed nano-system with the following state variables (Fig. 7): total N atoms at pressure p and temperature T, with (C − 1) components of average mole fractions of \( x_{i} \), in contact with a given (equilibrium) substrate material (there can be several substrates and one of them can be an equilibrium vapor phase). One should find the equilibrium state of the system, including the following independent parameters: the number of equilibrium phases (P), their identity (\( \Upphi \)), their phase fractions (\( y_{\Upphi } \)), average compositions (\( x_{i(\Upphi )} \)), and also their shapes and relative arrangement.

Similar to the Calphad method, all possible combinations of phases should be considered and their total Gibbs energies should be compared using Eq. (1j) to find the equilibrium state with a minimum total Gibbs energy. The maximum number of phases in equilibrium should be in agreement with Eq. (2a) (without taking into account the macroscopic equilibrium substrates, or the equilibrium large vapor phase). Within each phase combination studied, different shapes and arrangement of phases should be separately studied, including their arrangement to the substrates(s) if such are present (see Figs. 5, 6). Within each combination of phases, Eq. (1j) is used to find the most probable shapes and arrangements of phases ensuring the minimum of the total Gibbs energy. For systems with more than one component, the bulk partial and integral Gibbs energies of all phases should be expressed in terms of \( x_{i(\Upphi )}^{\rm b} \), being the result of the interplay between segregation and the limited number of atoms (molecules) within a given nano-phase. This is so even if the final result can be written in terms of the average composition of the phases (\( x_{i(\Upphi )} \)). Using this framework, the equilibrium state can always be found.

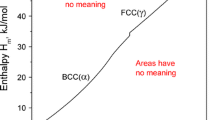

It is worth to discuss the difference between macro- and nano-systems for 2-component, 2-phase systems (C = 2, P = 2). As it was shown above, the tie line is valid in 2-phase regions of binary phase diagrams for macro-systems (Fig. 8). However, due to the complexity of the algorithm shown above, the equilibrium values of \( x_{{\rm B}(\alpha )} \) and \( x_{{\rm B}(\beta )} \) cannot be found in an independent way from \( y_{\beta } \). In other words, these three quantities (\( x_{{\rm B}(\alpha )} \), \( x_{{\rm B}(\beta )} \) and \( y_{\beta } \)) will be interconnected, and thus all three of them will have different values if x B gradually changes within the same two-phase region. It means that the meaning of the tie line within two-phase regions of binary nano-phase diagrams is lost. It also means that the way how phase diagrams for nano-systems are constructed and the way how they are interpreted, should also be different from that we are used to for phase diagrams of macro-systems. It should be noted that the same conclusion was reached earlier [64, 66, 72, 76, 82].

A schematic of a tie line in a two-phase field of a binary phase diagram. For macro-systems, the equilibrium compositions of the two phases (\( x_{\rm {B}(\alpha )} \) and \( x_{\rm{B}(\beta )} \)) are independent of the actual average composition of the alloy x B within the interval of \( x_{\rm{B}(\alpha )} \le x_{\rm B} \le x_{{\rm B}(\beta )} \). In nano-systems this constancy is not valid, as the equilibrium compositions \( x_{{\rm B}(\alpha )} \) and \( x_{{\rm B}(\beta )} \) are functions of the average composition x B

In addition to phases, the appearance and thickness of adsorbed layers (called also adsorbed films, thin films, surface melted layers or complexions) also can be predicted using the concept described here (see Sects. 7 and 10). These complexions can radically change the properties of the system, promising high industrial potential [59, 91, 188–232]. These complexions can exist at the surface/interface of both macroscopic and nano-phases. Thus even in a seemingly macro-systems, the role of nano-thin complexions sometimes can play an unexpected and important role.

Some additional remarks

One of the constant questions with the equilibrium of nano-systems is that thermodynamics is a statistical science, so it should have a certain size limit. Indeed, the obvious size limit is N Φ = 1 atom for a vapor phase. For a condensed phase, at least 33 = 27 atoms are needed to ensure “structure” of a phase.

Another aspect of this size problem is that the smaller number of atoms the system has, the larger is the effect of fluctuations. In other words, the result of the equilibrium calculation can be still meaningful as an average state but with small N, the system can fluctuate between two or several states of similar total Gibbs energy.

Finally, it should be mentioned that for the successful calculation of phase diagrams for nano-systems, the existing databank for the bulk Gibbs energies of phases should be enlarged by the corresponding databanks on molar volumes and interfacial energies. Especially the latest is far from being completed, despite the efforts of the HTC (high-temperature capillarity) community (see [233] and the present special issue).

Conclusions

The “nano-Calphad” concept has been introduced here, being an extension of the Calphad method for systems containing at least one phase (or at least one interface film, complexion) with at least one of its dimensions being below 100 nm. First, a “classical” Calphad method is summarized for reference.

It is shown that instead of a widely used radius (diameter) of a system, a number of atoms should be used as a new, independent state variable for nano-systems. As a consequence, the phase rule of Gibbs should be extended, allowing more phases to co-exist in equilibrium (thus, a quaternary point is predicted in one-component phase diagrams). The Kelvin equation is shown to be based on an erroneous derivation. Instead, a Gibbs equation is suggested here to describe the surface term of the Gibbs energy. As a consequence, nano-effects are due to high specific surface area and not due to the high curvature of the phases. Thus, the Kelvin equation (for vapor pressure), the Gibbs–Thomson equation (for melting point), and the Ostwald–Freundlich equation (for solubility) are corrected.

The dependence of interfacial energies on both the curvature of the interface and its separation from other interfaces is discussed. The latter is useful to predict the equilibrium thickness of surface (and interface) liquid and amorphous layers. In phases (both macro- and nano-) with more than one-component, segregation of components to the surfaces and interfaces is taken into account using the Butler equation. The usual formalism is extended here to take into account the material balance limitations due to the interplay between segregation and a limited number of segregating atoms in nano-phases. It is shown that surface phase transition (SPT) can be predicted using the same formalism. This can explain the existence of adsorbed films, interfacial layers, and complexions.

In contrary to Calphad, the results of nano-Calphad depend on the shapes and relative arrangement of phases, and also on the presence of substrates (even if the substrate is not a part of the nano-system). It is shown that the meaning of tie lines within the Calphad method is lost within the framework of nano-Calphad. This (and the extended phase rule) makes it necessary to re-think the way how we present and interpret nano-phase diagrams in the future.

References

Kaufman L, Bernstein H (1970) Computer Calculation of phase diagrams (with special reference to refractory metals). Academic Press, NY

Saunders N, Miodownik AP (1998) CALPHAD, a comprehensive guide. Pergamon, New York

Lukas HL, Fries SG, Sundman B (2007) Computational thermodynamics. The Calphad method. Cambridge University Press, Cambridge

Lee HJ (2012) J Mater Sci 47:5114

Kachi M, Sakamoto W, Ichida M, Wada T, Ando H, Yogo T (2012) J Mater Sci 47:5128

Vijayan PP, Puglia D, Jyotishkumar P, Kenny JM, Thomas S (2012) J Mater Sci 47:5241

Liu XQ, Wang Y, Yang W, Liu ZY, Luo Y, Xie BH, Yang MB (2012) J Mater Sci 47:4620

Sharma M, Bijwe J (2012) J Mater Sci 47:4928

Wang CJ, Wang Y, Cheng YL, Huang WZ, Khan ZS, Fan XZ, Wang Y, Zou BL, Cao XQ (2012) J Mater Sci 47:4392

Perusko D, Petrovic S, Kovac J, Stojanovic Z, Panjan M, Obradovic M, Milosavljevic M (2012) J Mater Sci 47:4488

Vasu K, Krishna MG, Padmanabhan KA (2012) J Mater Sci 47:3522

Brandes MC, Kovarik L, Miller MK, Mills MJ (2012) J Mater Sci 47:3913

Tiwari S, Bijwe J, Panier S (2012) J Mater Sci 47:2891

Yang Y, Xu DG, Zhang KL (2012) J Mater Sci 47:1296

Land G, Stephan D (2012) J Mater Sci 47:1011

Braga NA, Baldan MR, Ferreira NG (2012) J Mater Sci 47:23

Takagi M (1954) J. Phys. Soc. Jpn. 9:359

Pocza JF, Barna A, Barna PB (1969) J Vac Sci Technol 6:472

Coombes CJ (1972) J Phys F Metal Phys 2:441

Buffat Ph, Borel JP (1976) Phys. Rev. A 13:2287

Allen GL, Gile WW, Jesser WA (1980) Acta Metall. 28:1695

Jackson CL, McKenna GB (1990) J Chem Phys 93:9002

Moore KI, Zhang DL, Cantor B (1990) Acta Metall. Mater. 38:1327

Zhang DL, Cantor B (1991) Acta Metall. Mater. 39:1595

Abe YR, Holzer JC, Johnson WL (1992) Mater. Res. Soc. Symp. Proc. 238:721

Sheng HW, Ren G, Peng LM, Hu ZQ, Lu K (1996) Phil Mag Lett 73:179

Chattopadhyay K, Goswami R (1997) Prog. Mater Sci. 42:287

Goswiami R, Chattopadhyay K, Ryder PL (1998) Acta Mater. 46:4257

Peters KF, Cohen JB, Chung YW (1998) Phys Rev B 57:13430

Jin ZH, Lu K (1999) Nanostruct. Mater. 12:369

Gabrisch H, Kjeldgaard L, Johnson E, Dahmen U (2001) Acta Mater. 49:4259

Johnson E, Johansen A, Dahmen U, Chen S, Fujii T (2001) Mater. Sci. Eng., A 304–306:187

Cherginets VL, Deineka TG, Demirskaya OV, Rebrova TR (2002) J. Electroanal. Chem. 531:171

Yasuda H, Mori H (2002) J. Cryst. Growth 237–239:234

Zhao DS, Zhao M, Jiang Q (2002) Diamond Relat Mater 11:234

Rosner H, Scheer P, Weismuller J, Wilde G (2003) Phil Mag Lett 83:511

Lee JG, Mori H (2004) Phil. Mag. 84:2675

Wunderlich B (2005) Thermochim. Acta 432:127

Freitas JCC, Nunes E, Passamani EC, Larica C, Kellermann G, Craievich AF (2006) Acta Mater. 54:5095

Rosner H, Wilde G (2006) Scripta Mater. 55:119

Sun J, Simon SL (2007) Thermochim. Acta 463:32

Braidy N, Purdy GR, Botton GA (2008) Acta Mater. 56:5972

Lee J, Lee J, Tanaka T, Mori H (2009) Nanotechnology 20:475706

Zou C, Gao Y, Yang B, Zhai Q (2010) J Mater Sci: Electron Mater 21:868

Bao TT, Kim Y, Lee JH, Lee JG (2010) Mater. Trans. 51:2145

Le HH, Osswald K, Ilisch S, Hoang XT, Heinrich G, Radusch HJ (2012) J Mater Sci 47:4270

Thomson W (1871) Phil. Mag. 42:448

Thomson JJ (1888) Application of dynamics to physics and chemistry. Macmillan, London

Ostwald W (1900) Z. Phys. Chem. 34:495

Pawlow P (1908) Z. Phys. Chem. 55:545

Freundlich H (1909) Kolloidchemie. Akademischer Veralg, Leipzig

Reiss H, Wilson IB (1948) J. Colloid Sci. 3:551

Hanszen KJ (1960) Z Phys 157:523

Wagner C (1961) Z. Elektrochem. 65:581

Greenwood GW (1969) J Mater Sci 4:320

Couchman PR, Jesser WA (1977) Nature 269:481

Spaepen F, Turnbull D (1979) Scr. Metall. 13:149

Weismuller J (1993) Nanostruct. Mater. 3:261

Kofman R, Cheyssac P, Aouaj A, Lereah Y, Deuscher D, Ben-David T, Penisson JM, Bourret A (1994) Surf. Sci. 303:231

Shi FG (1994) J. Mater. Res. 9:1307

Badmos AY, Bhadeshia HK (1997) Metall. Mater. Trans. A 28:2189

Qian M, Lim LC (1998) Scr Mater 39:1451

Weismuller J, Ehrhardt H (1998) Phys. Rev. Lett. 81:1114

Jesser WA, Shiflet GJ, Allen GL, Crawford JL (1999) Mater Res Innovat 2:211

Jiang Q, Shi HX, Zhao M (1999) J Chem Phys 11:2176

Wautelet M, Dauchot JP, Hecq M (2000) Nanotechnology 11:6

Tanaka T, Hara S (2001) Z. Metallkd. 92:467

Tanaka T, Hara S (2001) Z. Metallkd. 92:1236

Hillert M, Argen J (2002) Acta Mater. 50:2429

Liang LH, Liu D, Jiang Q (2003) Nanotechnology 14:438

Samsonov VM, Malkov OA (2004) Central Eur J Phys 2:90

Weissmuller J, Bunzel P, Wilde G (2004) Scripta Mater. 51:813

Shirinayan AS, Gusak AM (2004) Phil. Mag. 84:579

Shi Z, Wynblatt P, Srinivasan SG (2004) Acta Mater. 52:2305

Lee J, Lee J, Tanaka T, Mori H, Penttilá K (2005) JOM 57:56

Shirinyan AS, Gusak AM, Wautelet M (2005) Acta Mater. 53:5025

Liu XJ, Wang CP, Jiang JZ, Ohnuma I, Kainuma R, Ishida K (2005) Int J Mod Phys B 19:2645

Wang CX, Yang GW (2005) Mater. Sci. Eng., R 49:157

Qiao Z, Cao Z, Tanaka T (2006) Rare Met. 25:512

Jiang Q, Chen ZP (2006) Carbon 44:79

Koukkari P, Pajarre R, Hack K (2007) Int. J. Mater. Res. 98:926

Wilde G, Bunzel P, Rosner H, Weissmuller J (2007) J Alloys Compd 434–435:286

Shahandeh S, Arami H, Sadrnezhaad SK (2007) J Mater Sci 42:9440

Lee J, Tanaka T, Lee J, Mori H (2007) Calphad 31:105

Leteiller P, Mayaffre A, Turmine M (2007) J Colloids Interf Sci 314:604

Letellier P, Mayaffre A, Turmine M (2007) Phys Rev B 76:045428

Shahandeh S, Nategh S (2007) Mater. Sci. Eng., A 443:178

Shchekin AK, Rusanov AI (2008) J Chem Phys 129:154116

McCue SW, Wu B, Hill JM (2009) IMA J Appl Mathem 74:439

Guisbiers G, Buchaillot L (2009) Phys. Lett. A 374:305

Jeurgens LPH, Wang Z, Mittemeijer EJ (2009) Int. J. Mater. Res. 100:1281

Sommer F, Singh RN, Mittemeijer EJ (2009) J Alloys Compd 467:142

Kim DH, Kim HY, Ryu JH, Lee HM (2009) Phys. Chem. Chem. Phys. 11:5079

Lee J, Park J, Tanaka T (2009) Calphad 33:377

Nanda KK (2009) Pramana J Phys 72:617

Eichhammer Y, Heyns M, Moelans N (2011) Calphad 35:173

Garzel G, Janczak-Rusch J, Zabdyr L (2012) Calphad 36:52

Ivas T, Grundy AN, Povoden-Karadeniz E, Gauckler LJ (2012) Calphad 36:57

Byshkin M, Hou M (2012) J Mater Sci 47:5784

Kaptay G (2011) Equilibrium of materials of macro-, micro- and nano-sized systems. Raszter, Miskolc (in Hungarian)

Gibbs JW (1875–1878) Trans Conn Acad Arts Sci 3:108, 343

Dinsdale AT (1991) Calphad 15:317

Redlich O, Kister AT (1948) Ind. Eng. Chem. 40:345

Chen SL, Daniel S, Zhang F, Chang YA, Oates WA, Schmid-Fetzer R (2001) J Phase Equilib 22:373

Kaptay G (2004) Calphad 28:115

Kaptay G (2012) Metall. Mater. Trans. A 43:531

Lupis CHP, Elliot JF (1966) Trans Metal Soc AIME 236:130

Schmid-Fetzer R, Andersson D, Chevalier PY, Eleno L, Fabrichnaya O, Kattner UR, Sundman B, Wang C, Watson A, Zabdyr L, Zinkevich M (2007) Calphad 31:38

Arroyave R, Liu YK (2006) Calphad 30:1

Guo C, Du Z, Li C (2008) Calphad 32:177

Ran H, Du Z, Guo C, Li C (2008) J Alloys Compd 464:127

Gao Y, Guo C, Li C, Cui S, Du Z (2009) J Alloys Compd 479:148

Li M, Guo C, Li C, Du Z (2009) J Alloys Compd 481:283

Yuan X, Sun W, Du Y, Zhao D, Yang H (2009) Calphad 33:673

Zhan CY, Wang W, Tang ZL, Nie ZR (2009) Mater. Sci. Forum 610–613:674

Guo C, Li C, Du Z (2009) J Alloys Compd 492:122

Wang W, Guo CP, Li CR, Du ZM (2010) Int. J. Mater. Res. 101:1339

Niu C, Liu M, Li C, Du Z, Guo C (2010) Calphad 34:428

Sheng SH, Zhang RF, Veprek S (2011) Acta Mater. 59:297

Tang Y, Yuan X, Du Y (2011) JMM 37:1

Sheng SH, Zhang RF, Veprek S (2011) Acta Mater. 59:3498

Tang Y, Du Y, Zhang L, Yuan X, Kaptay G (2012) Thermochim. Acta 527:131

Bale CW, Pelton AD (1983) Metall. Trans. B 14:77

Hillert M, Jarl M (1978) Calphad 2:227

Sekerka RF, Cahn JW (2004) Acta Mater. 52:1663

Hillert M, Staffansson LL (1970) Acta Chem. Scand. 24:3618

Sundman B, Agren J (1981) J. Phys. Chem. Solids 42:297

Kaptay G (2010) J. Nanosci. Nanotechnol. 10:8164

de Laplace PS (1806) Mechanique Celeste, Supplement to Book 10. Durat, Paris

Kaptay G (2005) J Mater Sci 40:2125

Kaptay G (2012) J. Dispersion Sci. Technol. 33:130

Kaptay G (2012) J. Nanosci. Nanotechnol. 12:2625

Kaptay G (2012) Int J Pharmaceut 430:253

Tolman RC (1949) J Chem Phys 17:333

Buff FP (1951) J Chem Phys 19:1591

Sinanoglu O (1981) J Chem Phys 75:463

Bartell LS (1987) J. Phys. Chem. 91:5985

Kopga K, Zeng XC (1998) J Chem Phys 109:4063

Jiang Q, Zhao DS, Zhao M (2001) Acta Mater. 49:3143

Samsonov VM, Sdobnyakov NY, Bazulev AN (2004) Colloids Surf A 239:113

Lu HM, Jiang Q (2005) Langmuir 21:779

Blokhuis EM, Kuipers J (2006) J Chem Phys 124:074701

Yaghmaee MS, Shokri B (2007) Smart Mater. Struct. 16:349

Jiang Q, Lu HM (2008) Surf Sci Rep 63:427

Sonderegger B, Kozeschnik E (2009) Scripta Mater. 60:635

Protasova LN, Rebrov EV, Ismagilov ZR, Schouten JC (2009) Microporous Mesoporous Mater 123:243

Freitas M, Costa DIG, Caral AA, Gomes AR, Mercury JMR (2009) Mater Res 12:101

Zhang H, Chen B, Banfield JF (2009) Phys. Chem. Chem. Phys. 11:2553

Alymov MI, Shorshorov MK (1999) Nanostruct. Mater. 12:365

Lu HM, Ding DN, Cao ZH, Tang SC, Meng XK (2007) J. Phys. Chem. C 111:12914

Derjaguin B (1934) Kolloid Z 69:155

de Boer JH (1936) Trans. Faraday Soc. 32:10

Hamaker HC (1937) Physica 10:1058

Israelachvili JN (1992) Intermolacular and surface forces. Academic Press, London

Butt H-N, Graf K, Kappl M (2003) Physics and chemistry of interfaces. Wiley, Weinheim

Tartaglio U, Zykova-Timan T, Ercolessi F, Tosatti E (2005) Phys. Rep. 411:291

Vanfleet RR, Mochel JM (1995) Surf. Sci. 341:40

Sakai H (1996) Surf. Sci. 351:285

Kofman R, Cheyssac P, Lereah Y, Stella A (1999) Eur. Phys. J. D 9:441

Müller P, Kern R (2003) Surf. Sci. 529:59

Benedictus R, Bottger A, Mittemeijer AJ (1996) Phys Rev B 54:9109

Luo J, Chang Y-M (2000) Acta Mater. 48:4501

Reichel F, Jeurgens LPH, Mittemeier EJ (2006) Phys Rev B 74:144103

Tartaglino U, Tosatti E (2003) Surf. Sci. 532–535:623

Mellenthin J, Karma A, Plapp M (2008) Phys Rev B 78:184110

Luo EZ, Cai Q, Chung WF, Altman MS (1996) Appl. Surf. Sci. 92:331

Sondergard E, Kofman R, Cheyssac P, Celestini F, Ben David T, Lereah Y (1997) Surf Sci 388:L1115

Shibuta Y, Suzuki T (2010) Chem. Phys. Lett. 486:137

Butler JAV (1932) Proc Roy Soc A135:348

Hoar TP, Melford DA (1957) Trans Farad Soc 53:315

Kaptay G (2008) Mater Sci Eng A 495:19 (corrigendum: 2009, 501:255)

Monma K, Suto H (1961) J Jpn Inst Met 25:143

Overbury SH, Bertrand PA, Somorjai GA (1975) Chem. Rev. 75:547

Speiser R, Poirier DR, Yeum K (1987) Scripta Metall 21:687

Tanaka T, Hack K, Hara S (1999) MRS Bull. 24:45

Moser Z, Gasior W, Pstrus J (2001) J Phase Equilib 22:254

Picha R, Vrestal J, Kroupa A (2004) Calphad 28:141

Kucharski M, Fima P (2004) Arch. Metall. Mater. 49:565

Lee J, Shimoda W, Tanaka T (2005) Meas. Sci. Technol. 16:438

Brillo J, Egry I (2005) J Mater Sci 40:2213

Kucharski M, Fima P (2005) Monat Chem 136:1841

Brillo J, Plevachuk Y, Egry I (2010) J Mater Sci 45:5150

Terzieff P (2010) Phys B Condens Matter 405:2668

Fima P (2011) Surf. Sci. 257:3265

Gancarz T, Moser Z, Gasior W, Pstrus J, Henein H (2011) Int. J. Thermophys. 32:1210

Kaptay G (2008) Calphad 32:338

Kaptay G (2012) Acta Mater (in press)

Kaptay G (2005) Calphad 29:56 (Erratum see 29:262)

Mekler C, Kaptay G (2008) Mater. Sci. Eng., A 495:65

Sandor T, Mekler C, Dobranszky J, Kaptay G (2012) Metal Mater Trans A. doi:10.1007/s11661-012-1367-2

Cahn JW (1977) J Chem Phys 66:3667

Helms CR (1977) Surf. Sci. 69:689

Shelton JC, Patil HR, Blakely JM (1974) Surf. Sci. 43:493

Moldover MR, Cahn JW (1980) Science 207:1073

de Gennes PG (1985) Rev Mod Phys 57:827

Wynblatt P, Liu Y (1992) J Vaccum Sci Technol 10:2709

Cheng WC, Chatain D, Wynblatt P (1995) Surf. Sci. 327:501

Chatain D, Wynblatt P (1996) Surf. Sci. 345:85

Wynblatt P, Saul A, Chatain D (1998) Acta Mater. 46:2337

Freyland W (1999) J Non-Cryst Solids 250–252:199

Wynblatt P (2000) Acta Mater. 48:4439

Bonn D, Ross D (2001) Rep. Prog. Phys. 64:1085

Nattland D, Turchanin A, Freyland W (2002) J Non-Cryst Solids 312–314:464

Freyland W, Ayyad AH, Mechdiev I (2003) J. Phys.: Condens. Matter 15:S151

Dogel S, Nattland D, Freyland W (2004) Thin Solid Films 455–456:380

Ishizaki H, Akiyama T, Nakamura K, Shiraishi K, Taguchi A, Ito T (2005) Appl. Surf. Sci. 244:186

Matsubara H, Aratono M, Wilkinson KM, Bain CD (2006) Langmuir 22:982

Luo J (2007) Crit. Rev. Solid State Mater. Sci. 32:67

Luo J, Chiang Z-M (2008) Ann Rev Mater Res 38:227

Bonn D, Eggers J, Indekeu J, Meunier J, Rolley E (2009) Rev Mod Phys 81:739

Indekeu JO (2010) Phys. A 389:4332

Kaban I, Curiotte S, Chatain D, Hoyers W (2010) Acta Mater. 58:3406

Freyland W (2011) Coulombic Fluids 168:5

Ohmasa Y, Kajihara Y, Kohno H, Hiejima Y, Yao M (1999) J Non-Cryst Solids 250–252:209

Staroske S, Freyland W, Nattland D (2001) J Chem Phys 115:7669

Baram M, Chatain D, Kaplan WD (2011) Science 332:206

Ma N, Shen C, Dregia SA, Wang Y (2006) Metall. Mater. Trans. A 37:1773

Rabkin EI, Semenov VN, Shvindlerman LS, Straumal BB (1991) Acta Metall. Mater. 39:627

Straumal B, Gust W, Molodov D (1994) J Phase Equil 15:386

Chang LS, Rabkin E, Straumal BB, Baretzky B, Gust W (1999) Acta Mater. 47:4041

Ludwig W, Pereiro-López E, Bellet D (2005) Acta Mater. 53:151

Luo J, Gupta VK, Yoon DH, Meyer HMIII (2005) Appl. Phys. Lett. 87:231902

Tang M, Carter WC, Cannon RM (2006) Phys. Rev. Lett. 97:075502

Straumal BB, Baretzky B, Kogtenkova OA, Straumal AB, Sidorenko AS (2010) J Mater Sci 45:2057

Straumal BB, Kogtenkova OA, Protasova SG, Zięba P, Czeppe T, Baretzky B, Valiev RZ (2011) J Mater Sci 46:4243

Straumal BB, Kucheev YO, Efron LI, Petelin AL, Majumdar JD, Manna I (2012) J. Mater. Eng. Perform. 21:667

Dillon SJ, Tang M, Carter WC, Harmer MP (2007) Acta Mater. 55:6208

Dillon SJ, Harmer MP (2008) J. Eur. Ceram. Soc. 28:1485

Carter WC, Baram M, Drozdov M, Kaplan WD (2010) Scripta Mater. 62:894

Shi X, Luo J (2011) Phys Rev B 84:014105

Luo J, Cheng H, Asl KM, Kiely CJ, Harmer MP (2011) Science 333:1730

Meltzman H, Mordehai D, Kaplan WD (2012) Acta Mater. 60:4359

Eustathopoulos N, Nicholas MG, Drevet B (1999) Wettability at high temperatures. Pergamon, London

Acknowledgements

This paper summarizes the current state of understanding of the subject by the author, being developed since 2006 when the BAY-NANO Research Institute on Nanotechnology was established by him in Miskolc, Hungary. Financial support is acknowledged to the NAP-NANO project (NKTH, Hungary), to OTKA grant K101781 (Hungarian Academy of Sciences) and to the TAMOP-4.2.1.B-10/2/KONV-2010-0001 project with support by the European Union and the European Social Fund. The discussions with MHF Sluiter (Delft University of Technology), J Janczak Rusch (EMPA) and T Tanaka (JWRI) are highly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kaptay, G. Nano-Calphad: extension of the Calphad method to systems with nano-phases and complexions. J Mater Sci 47, 8320–8335 (2012). https://doi.org/10.1007/s10853-012-6772-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6772-9