Abstract

Y2O2S:Eu3+ nanobelts were successfully prepared via electrospinning method and sulfurization process using the as-prepared Y2O3:Eu3+ nanobelts and sulfur powders as sulfur source by a double-crucible method for the first time. X-ray diffraction analysis indicated that the Y2O2S:Eu3+ nanobelts were pure hexagonal in structure with space group P \( \bar{3} \) m1. Scanning electron microscope images showed that the width and thickness of the Y2O2S:Eu3+ nanobelts were ca. 6.7 μm and 125 nm, respectively. Under the excitation of 325-nm ultraviolet light, Y2O2S:Eu3+ nanobelts exhibited red emissions of predominant peaks at 628 and 618 nm, which are attributed to the 5D0 → 7F2 transition of the Eu3+ ions. It was found that the optimum doping concentration of Eu3+ ions in the Y2O2S: Eu3+ nanobelts was 3 %. Compared with bulk particle, Eu3+–O2−/S2− charge transfer bands (260 and 325 nm) of the Y2O2S:Eu3+ nanobelts showed a blue-shift significantly. The formation mechanism of the Y2O2S: Eu3+ nanobelts was also proposed. This new sulfurization technique is of great importance, not only to inherit the morphology of rare earth oxides but also to fabricate pure-phase rare earth oxysulfides at low temperature compared with conventional sulfurization method.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

As a group of important wide-gap (4.6–4.8 eV) semiconductor materials, rare earth oxysulfides with high chemical and thermal stability have been extensively used as optical functional materials [1, 2], owing to their high absorption of light and efficient energy transfer. Among these materials, rare earth ions-activated lanthanide oxysulfides have become a very important family of inorganic phosphor materials [3], especially for Y2O2S:Eu3+, one of the most efficient phosphors [4] that have wide applications in the fields of color television tubes, field emission display, and long-lasting phosphorescence. Recently, a large number of fabrication methods have already been employed to prepare micro- and nanosized Y2O2S:Eu3+, such as hydrothermal and solvothermal method [5], solid-sate reaction method [6, 7], combustion method [8, 9], microwave-heating method [10, 11], etc. These methods led to produce Y2O2S:Eu3+ nanoparticles [12], nanotubes, nanowires, nanorods [13], and nanoflowers [14]. However, rare earth oxysulfides nanobelts were limited. Therefore, fabrication of rare earth oxysulfides nanobelts is a meaningful subject of study.

Conventionally, RE2O2S:Ln3+ (RE = Y, La, Gd; Ln = Eu, Tb) luminescent bulk materials were prepared by the calcination of the mixture of rare earth oxides [10, 11] or oxalate compounds [15, 16] or carbonates [17, 18], sulfur powders, and flux (Na2CO3, Mg2CO3·4 Mg(OH)2·5H2O, TiO2) at above 1,100 °C for 2 h in a reduced or protective atmosphere. In this way, the as-prepared bulk materials often have irregular morphology and cannot inherit the peculiar morphologies of rare earth oxide precursors because sulfur powders and flux will melt and destruct the morphologies of rare earth oxides. Therefore, it is difficult to obtain rare earth oxysulfide nanobelts via the conventional sulfurization method using rare earth oxide nanobelt as a precursor.

Electrospinning is a simple, convenient, and versatile technique to prepare long fibers with diameters ranging from tens of nanometers up to micrometers, including rare earth oxyfluoride nanofibers [19], rare earth oxide, and composite oxide nanofibers and nanobelts [20–23]. However, to the best of our knowledge, there have been no reports on the preparation of rare earth oxysulfides nanobelts by electrospinning combined with sulfurization technique.

In this paper, Y2O2S:Eu3+ nanobelts were fabricated through the sulfurization of the relevant Y2O3:Eu3+ nanobelts which were prepared by the calcination of the electrospun belts of PVP/[Y(NO3)3 + Eu(NO3)3] composites. A sulfurization mechanism for the Y2O2S:Eu3+ nanobelts was proposed. Finally, we investigated the photoluminescence properties of the Y2O2S:Eu3+ nanobelts. This synthetic route is also suitable for fabricating other rare earth oxysulfide nanomaterials.

Experimental section

Chemicals

Polyvinyl pyrrolidone (PVP) (Mw = 90,000, AR), yttrium oxide (Y2O3) (99.99 %), and europium oxide (Eu2O3) (99.99 %) were purchased from Kemiou Chemical Co. Ltd. N,N-Dimethylformamide (DMF, AR) was bought from Tiantai Chemical Co. Ltd. Nitric acid (AR) and sulfur(AR) were purchased from Beihua Fine Chemical Co. Ltd. All chemicals were directly used as received without further purification.

Preparation of PVP/[Y(NO3)3 + Eu(NO3)3] composite nanobelts via electrospinning

Y2O2S:x % Eu3+ [x = 1,3,5,7, x stands for molar ratio of Eu3+ to (Eu3+ + Y3+)] were prepared by an electrospinning method combined with sulfurization technique. In a typical procedure of preparing Y2O2S:3 %Eu3+, rare earth nitrates were first prepared by dissolving 0.0382 g of Eu2O3 and 0.7913 g of Y2O3 in dilute HNO3 (1:1, volume ratio) at elevated temperatures. Then, 13.9128 g of DMF was added into the rare earth nitrates, and a clear DMF solution was formed. Finally, 4 g of PVP was added into the above solution under stirring for 4 h to form homogeneous transparent precursor solution. In the precursor solution, the mass ratios of rare earth nitrates, DMF, and PVP were equal to 10:70:20. Subsequently, the precursor solution was electrospun at room temperature under a positive high voltage of 8 kV, the distance between the capillary tip and the collector (Al foil) was fixed to 15 cm, and relative humidity was 60 ~ 80 %. PVP/[Y(NO3)3 + Eu(NO3)3] composite nanobelts were obtained on the collector with the evaporation of DMF.

Preparation of Y2O3:Eu3+ nanobelts

The as-prepared PVP/[Y(NO3)3 + Eu(NO3)3] composite nanobelts were annealed at 700 °C for 8 h with a heating rate of 1 °C/min. Then, the calcination temperature was decreased to 200 °C at a rate of 1 °C/min. Finally, samples were down to room temperature naturally and Y2O3:Eu3+ nanobelts were obtained.

Fabrication of Y2O2S:Eu3+ nanobelts

Y2O2S:Eu3+ nanobelts were prepared by an Ar gas-aided sulfur treatment through calcining Y2O3:Eu3+ nanobelts precursor using sulfur powder as a sulfurization agent. Some sulfur powders were put into a small crucible, the sulfur powders were covered by some carbon rods, and the Y2O3:Eu3+ nanobelts were placed on the carbon rods. Next, this small crucible was put into a big crucible, some sulfur powders were loaded into the space between the two crucibles, and the big crucible was covered with the lid. We call this process as a double-crucible method. The crucibles were annealed at 800 °C for 4 h under Ar gas atmosphere at the heating rate of 5 °C/min. Then, the calcination temperature was decreased to 200 °C at a rate of 5 °C/min followed by decreasing it down to room temperature naturally. Thus, Y2O2S:Eu3+ nanobelts were successfully acquired.

Synthesis of Y2O2S:Eu3+ particles

For comparison, we prepared Y2O2S:Eu3+ bulk particles through a conventional solid-state reaction method according to the Ref. [24]. The mean size of particles is ca. 6 μm.

Characterization methods

X-ray diffraction (XRD) measurements were carried out using a Rigaku D/max-RA XRD diffractometer with Cu Kα radiation of 0.15418 nm. The size and morphology of the products were observed by a field emission scanning electron microscope (FESEM, XL-30, FEI Company). The purity of the products was examined using OXFORD ISIS-300 energy dispersive spectrometer (EDS). Transmission electron microscope (TEM) analysis was performed using a JEM-2010 transmission electron microscope under a working voltage of 200 kV. The excitation and emission spectra of samples were recorded using a HITACHI F-7000 Fluorescence Spectrophotometer using a Xe lamp as the excitation source.

Results and discussion

XRD analysis

Figure 1 shows the XRD patterns of the as-prepared Y2O3:3 %Eu3+ nanobelts and Y2O2S:3 %Eu3+ nanobelts with different doping concentration of Eu3+ ions. All the diffraction peaks of the Y2O3:3 %Eu3+ (Fig. 1a) can be readily indexed to those of the pure cubic phase with primitive structure of Y2O3 (PDF#43-0661), space group is Fm \( \bar{3} \) m. No other phases are identified. The reflection peaks of the Y2O2S:Eu3+ (Fig. 1b–e) can be perfectly indexed as the pure hexagonal phase of Y2O2S (PDF#24-1424), space group is Pm \( \bar{3} \)1. No diffraction peaks of any other phases or impurities are also detected. These results indicate that the pure-phase Y2O3:Eu3+ could be obtained after the PVP/[Y(NO3)3 + Eu(NO3)3] composite were calcined at 700 °C for 8 h and the hexagonal Y2O2S:Eu3+ were acquired via the sulfurization of the cubic Y2O3:Eu3+ at 800 °C for 4 h. The doping of Eu3+ did not change the Y2O2S host lattice structure.

SEM, TEM, and EDS analysis

Figure 2a shows the typical SEM image of PVP/[Y(NO3)3 + Eu(NO3)3] composite before calcinations. One can see that the composite is composed of nanobelts with smooth surface and uniform width, indicating the formation of nanobelt. After annealing at 700 °C, these nanobelts experience about 70 % reduction in width due to loss of the PVP and associated organic components [22], as shown in Fig. 2b. The obtained Y2O3:3 %Eu3+ nanobelts still have smooth surface. Figure 2c shows the SEM image of the Y2O2S:3 %Eu3+ nanobelts. It reveals that morphology and the widths of Y2O2S:3 %Eu3+ nanobelts are nearly similar to those of Y2O3:3 %Eu3+ nanobelts. Preliminarily, we can conclude that the sulfur atmosphere plays an important role in keeping the morphology of the nanobelts. The thickness of Y2O2S:3 %Eu3+ nanobelts becomes thinner due to the decomposition of the organic species and the formation of inorganic phase. The thickness of PVP/[Y(NO3)3 + Eu(NO3)3] composite nanobelts, Y2O3:3 %Eu3+ nanobelts, and Y2O2S:3 %Eu3+ nanobelts are 494, 172, and 125 nm, respectively. Under the 95 % confidence level, the widths of those nanobelts analyzed by Shapiro–Wilk method are normally distributed. Histograms of widths of these belts are shown in Fig. 3. The widths of PVP/[Y(NO3)3 + Eu(NO3)3] composite nanobelts, Y2O3:3 %Eu3+ nanobelts, and Y2O2S:3 %Eu3+ nanobelts are 7.2 ± 0.6, 6.6 ± 0.5, and 6.7 ± 0.6 μm, respectively.

Figure 4a illustrates TEM images of the Y2O2S:3 %Eu3+ nanobelts. It indicates that the nanobelts composed of nanoparticles with size of 10–30 nm. The corresponding selected area electron diffraction (SAED) patterns in Fig. 4b exhibit typical polycrystal diffraction patterns and are in good agreement with those of pure Y2O2S phase. These results further confirm the formation of the Y2O2S:Eu3+ nanobelts.

EDS spectrum of the Y2O2S:3 %Eu3+ nanobelts (Fig. 5) reveals the presence of Y, O, S, and Eu elements, and no other impurity elements including carbon, indicating that the pure Y2O2S:3 %Eu3+ nanobelts are obtained. Au peak is from the conductive film of Au plated on the sample for SEM observation.

Photoluminescence properties

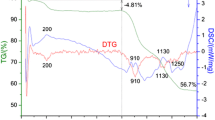

Figure 6 illustrates the excitation (monitored by 628 nm) and emission (excited by 325 nm) spectra of the different Y2O2S:Eu3+ nanobelts. It is found from Fig. 6a that there is a wide band with two peaks at 260 and 325 nm, which are attributed to Eu3+–O2− CTB (charge transfer band) and Eu3+–S2− CTB, respectively. In the longer wavelength region (400–500 nm), the f–f transition peaks of the Eu3+ ions can be observed with very weak intensity compared with those of the CTB. The strongest intensity of the excitation spectrum (CTB) is obtained when the doping concentration of Eu3+ ion is 3 %. The matrix absorption band at 247 nm is also observed.

Figure 6b demonstrates the emission spectrum of the Y2O2S nanobelts doped with various concentration of Eu3+. When the Eu3+ content is greater than 3 %, the concentration quenching effect occurs, as shown in the Fig. 7. At this time, the bond length between Eu3+ and O2− becomes shorter and the mixture of wave function of Eu3+ and O2− is enhanced [25], therefore, shows the strongest luminescence at 3 %. It is remarkably seen that the main emission peaks between 550 and 650 nm are observed from Fig. 6b, which is in agreement with the results reported by Kader and Elkholy [26]. The emission spectrum is associated with the transitions from the excited level of the 5DJ (J = 0, 1) to the level of 7FJ (J = 1, 2) of the Eu3+ ions. The strongest red emission split into two peaks at 628 nm and 618 nm are ascribed to the 5D0 → 7F2 transition of the Eu3+ ions, indicating that non-Y2O3 phase exists and the oxysulfide host has been formed [26]. Among several luminescence transitions of Eu3+ ion, the 5D0 → 7F1 (~ 592 nm) is mainly a magnetic-dipole transition, while the 5D0 → 7F2 (~628 nm) is an electric-dipole transition which is closely related to the coordination environment around Eu3+. The stronger 5D0 → 7F2 transition suggests that the Eu3+ ions occupy the sites at low symmetries without inversion center since this transition is hypersensitive to crystal structure and chemical surroundings [11, 27, 28]. The other emission peaks at 558 and 566 nm are attributed to the electron transition from the 5D1 to 7F2 level of the Eu3+ ions. It is clearly indicated from these emissions that the Eu3+ ions have been effectively distributed into the Y2O2S matrix.

Compared with the Y2O2S:Eu3+ bulk particles, the excitation bands (Eu3+–O2−/S2−CTB) in the Y2O2S:Eu3+ nanobelts show apparent blue-shift, as shown in Fig. 8a. This result can be possibly explained by size-dependent changes associated with quantum confinement effect in this wide-gap semiconductor materials [18]. Figure 8b shows emission spectra of the Y2O2S:Eu3+ bulk particles and the Y2O2S:Eu3+ nanobelts; it is clearly seen that the emission intensity of bulk particles is obviously stronger than that of nanobelts due to more surface defects of the Y2O2S:Eu3+ nanobelts. All results are in good agreement with that of the Ref. [29, 30].

Formation mechanism for the Y2O2S:Eu3+nanobelts

Formation mechanism of Y2O2S:Eu3+ nanobelt is shown in Fig. 9. PVP, Y(NO3)3, and Eu(NO3)3 were mixed with DMF to form precursor solution. Y3+, Eu3+, and NO3 − were mixed or absorbed onto PVP to form sol with certain viscosity. Then, PVP/[Y(NO3)3 + Eu(NO3)3] composite nanobelts were fabricated via electrospinning. PVP acted as template during the formation of Y2O3:Eu3+ nanobelts. In the process of calcination, PVP was oxidized to break the chain and then to volatilize. Nitrates were decomposed and oxidized to produce NO2, and Y3+/Eu3+ was oxidized to form Y2O3:Eu3+ crystallites; many crystallites were combined into nanobelt. In the sulfurization process, Y2O3:Eu3+ nanobelt was sulfurized using S as a sulfurization agent and S was gasified at about 350 °C. With the increase of calcination temperature, gasified sulfur reacts with Y2O3:Eu3+ nanobelts to produce Y2O2S:Eu3+ nanobelt. During the reaction process, sulfur powders and Y2O3:Eu3+ nanobelts were separated by carbon rods which prevented Y2O3:Eu3+ nanobelts from the morphology damage and also played a key role in reduction through reacting with oxygen species of Y2O3:Eu3+ in the heating process. The double-crucible method we proposed here is actually a solid–gas reaction, which has been proved to be an important method, not only can retain the morphology of the Y2O3:Eu3+ nanobelts but also can fabricate the Y2O2S:Eu3+ nanobelts with pure phase at relatively low temperature. Reaction schemes for the formation of the Y2O2S:Eu3+ nanobelts proceed as follows:

Conclusions

In summary, pure hexagonal phase Y2O2S:Eu3+ nanobelts with space group P \( \bar{3} \) m1 were fabricated via the sulfurization of the cubic Y2O3:Eu3+ nanobelts. The morphology of the Y2O3:Eu3+ nanobelts precursor can be inherited to Y2O2S:Eu3+ nanobelts using sulfur powders as sulfurization reagent via a double-crucible method. The width and thickness of the Y2O2S:Eu3+ nanobelts are 6.7 ± 0.6 μm and 125 nm, respectively. PL measurements demonstrate the strongest emission peak is at 628 nm, originating from the 5D0 → 7F2 transition of the Eu3+ ions, indicating that the Eu3+ ions occupy a site without inversion center in the Y2O2S:Eu3+ nanobelts. The strongest luminescence is obtained when doping concentration of Eu3+ is 3 %. Compared with Y2O2S:Eu3+ bulk particles, the Y2O2S:Eu3+ nanobelts show a significant blue-shift in Eu3+–O2−/S2− CTB. The double-crucible method proposed here is of great importance. This technique can be employed to fabricate rare earth oxysulfide nanomaterials with various morphologies.

References

Mikami M, Oshiyama A (1998) Phys. Rev. B 57:8939–8944

Jüstel T, Nikol H, Ronda C (1998) Angew Chem Int Ed 37:3084–3103

Lian JB, Sun XD, Li JG, Li XD (2011) Opt Mater 33:596–600

Cavouras D, Kandarakis I, Nomicos CD, Bakas A, Panayiotakis GS (2000) Radiat Meas 32:5–13

Jiang Y, Wu Y, Xie Y, Qian YT (2000) J Am Ceram Soc 83:2628–2630

Lo CL, Duh JG, Chiou BS, Peng CC, Ozawa L (2001) Mater Chem Phys 71:179–189

Chou TM, Mylswamy S, Liu RS, Chuang SZ (2005) Solid State Commun 136:205–209

Luo XX, Cao WH, Xing MM (2006) J Rare Earths 24:20–24

Dai QL, Song HW, Wang MY, Bai X, Dong B, Qin RF, Qu XS, Zhang H (2008) J Phys Chem C 112:19399–19404

Li YY, DC D, Cai SH (1996) J Rare Earths 14:16–20

Kim H, Hang DW, Lee JS (2004) J Am Chem Soc 126:8912–8913

Song YH, You HP, Huang YJ, Yang M, Zheng YH, Zhang LH, Guo N (2010) Inorg Chem 49:11499–11504

Li WY, Liu YL, Ai PF, Chen XB (2009) J Rare Earths 27:895–899

Thirumalai J, Chandramohan R, Vijayan TA, Somasundaram RM (2011) Mater Res Bull 46:285–291

Wang F, Yang B, Zhang JC, Dai YN, Ma WH (2010) J Lumin 130:473–477

Pires AM, Serra OA, Davolos (2004) J Alloy Compd 374:181–184

Ai PF, Li WY, Xiao LY, Li YD, Wang HJ, Liu YL (2010) Ceram Int 36:2169–2174

Fu Y, Cao WH, Peng Y, Luo XX, Xing MM (2010) J Mater Sci 45:6556–6561. doi:10.1007/s10853-010-4744-5

Wang HY, Yang Y, Wang Y, Zhao YY, Li X, Wang C (2009) J Nanosci Nanotechnol 9:1522–1525

Wang JX, Che HR, Dong XT, Liu L, Liu GX (2010) Acta Optica Sinica 30:473–479

Liu Y, Wang JX, Dong XT, Liu GX (2010) Chem J Chin Univ 31:1291–1296

Dong XT, Liu L, Wang JX, Liu GX (2010) Chem J Chin Univ 31:20–25

Cui QZ, Dong XT, Wang JX, Li M (2008) J Rare Earths 26:664–669

Lei BF, Liu YL, Zhang JW, Meng JX, Man SQ, Tan SZ (2010) J Alloy Compd 495:247–253

Xu L, Song HW, Dong B, Wang Y, Bai X, Wang GL, Liu Q (2009) J Phys Chem C 113:9609–9615

Kader AA, Elkholy MM (1990) Chem Mater Sci 1:95–99

Chou TW, Mylswamy S, Liu RS, Chuang SZ (2005) Solid State Commun 136:205–209

Thirumalai J, Chandramohan R, Divakar R, Mohandas E, Sekar M, Parameswaran P (2008) Nanotechnology 19:455–458

Blasse G (1976) Chem Mater Sci 26:43–79

Nakkiran A, Thirumalai JM, Jagannathan R (2007) Chem Phys Lett 436:155–161

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (NSFC 50972020, 51072026), Ph.D. Programs Foundation of the Ministry of Education of China (20102216110002,20112216120003), the Science and Technology Development Planning Project of Jilin Province (Grant Nos. 20070402, 20060504), and Key Research Project of Science and Technology of Ministry of Education of China (Grant No. 207026).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, L., Wang, J., Dong, X. et al. Synthesis of Y2O2S:Eu3+ luminescent nanobelts via electrospinning combined with sulfurization technique. J Mater Sci 48, 644–650 (2013). https://doi.org/10.1007/s10853-012-6768-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6768-5