Abstract

The phase equilibria in the Mg-rich corner of Mg–Zn–Gd ternary system at 673 K were investigated by means of X-ray diffraction (XRD), scanning electron microscopy (SEM) equipped with energy dispersive X-ray spectroscopy (EDS), and electron probe microanalysis (EPMA). Three ternary phases, X-(Mg12ZnGd), W-(Mg3Zn3Gd2) and I-(Mg3Zn6Gd1), have been identified, which are in equilibrium with Mg solid solution. A thermodynamic modeling and optimization of Zn–Gd and Mg–Zn–Gd systems has been carried out for the first time using the CALPHAD method. The sublattice model was used to describe the thermodynamic functions of both solution phases and intermetallic phases presented in these systems. In particular, order/disorder transition between BCC_B2 and BCC_A2 has been taken into account, and their Gibbs energies were expressed with identical function. The thermodynamic database was applied to case studies of experimentally observed microstructures and demonstrated that it is a valuable basis for alloy design.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the past decades, magnesium alloys have attracted increasing attention because of their high strength-to-weight ratio in automotive and aerospace applications [1, 2]. However, the use of magnesium alloys is currently limited to some extent due to their low mechanical properties at elevated temperatures. Magnesium alloys containing rare-earth elements are found to exhibit higher strength and better creep resistance than other Mg alloys [3, 4]. Gadolinium is often used due to its high solubility in Mg matrix [5]. Addition of a certain amount of Zn can further improve strengthening response of Mg-RE alloys. Nie et al. [6] reported that addition of 1–2 wt% Zn in Mg–6Gd–0.6Zr (wt%) can cause significant enhancement of age-hardening response and the creep strength. Mg–Zn–RE (ZE or EZ series) alloys have been commercialized as heat-resistant alloys [7]. In Mg–Zn–Gd alloys, stable icosahedral quasicrystal phase (I phase) has been identified [8–11]. Quasicrystals have unique properties such as high strength, high hardness, high corrosion resistance, low coefficient of friction and low surface energy, etc. [12]. Yuan et al. [10, 11] reported Mg–Zn–Gd-based alloy strengthened by quasicrystal phase exhibits better creep properties compared to AE42 alloy and higher room temperature mechanical properties close to that of AZ91 alloy. For Mg–Zn–Gd alloys annealed at high temperatures [13–16], a coherent 14H long period stacking ordered structure precipitate formed from the matrix. The alloys, with LPSO structure, performed remarkable high tensile yield strength and high ductility.

Although a number of experimental investigations of microstructure evolution in Mg–Zn–Gd alloys have been reported, phase diagram of Mg–Zn–Gd system has not been established yet. Detailed information about phase equilibria is critical in material design and manufacture. Computational thermodynamics offers an important tool for material design to reduce the experimental effort and costs during new materials development [17]. This work is dedicated to present a thermodynamic description of Mg–Zn–Gd system. In this paper, (1) experimental investigation into isothermal section at 673 K in Mg-rich corner will be presented and (2) a thermodynamic optimization of Zn–Gd and Mg–Zn–Gd systems will be performed using CALPHAD method based on available experimental data.

Literature data

Mg–Zn and Mg–Gd binary systems

Thermodynamic assessment of Mg–Zn system has been performed by Agarwal et al. [18], which is in good agreement with most experimental data on thermodynamic properties and phase boundaries. The optimization of this binary system was improved by Liang et al. [19] using new experimental data in the assessment of Al–Mg–Zn ternary system. Recently, new experimental values of the enthalpies of formation of all the intermediate phases in Mg–Zn system were determined by Berche et al. [20]. The experimental results are in good agreement with the assessed ones [19]. Thus, we can assume that the values assessed by Liang et al. [19] for the Mg–Zn system are reliable. Then they were employed in the present work for higher-order assessment.

Cacciamani et al. [21, 22] and Guo et al. [23] have optimized the Mg–Gd binary system. The thermodynamic parameters of Guo et al. [23] were adopted in the present work because the order–disorder transformation between BCC_B2 and BCC_A2 phase was taken into account.

The calculated phase diagrams of Mg–Gd and Mg–Zn systems were shown in Fig. 1.

Zn–Gd binary system

Massalski et al. [24] showed a schematic Zn–Gd phase diagram based on experimental information summarized in [25]. Liquidus boundaries were mostly unknown, and all known GdZn and GdZn2 compounds melt congruently. Saccone et al. [26] investigated the whole Zn–Gd phase diagram by means of differential thermal analysis, optical microscopy, scanning electron microscopy, electron probe microanalysis and X-ray diffraction. Eight intermetallic phases were found: GdZn, cubic, cP2-CsCl type, congruent melting at 1020 °C; GdZn2, orthorhombic, oI12-CeCu2 type, congruent melting at 1010 °C; GdZn3, orthorhombic, oP16-YZn3 type, peritectic decomposition at 905 °C; Gd3Zn11, orthorhombic, oI28-La3Al11 type, peritectic decomposition at 880 °C; Gd13Zn58, hexagonal, hP142-Gd13Zn58 type, melting at 920 °C; Gd3Zn22, tetragonal, tI100-Pu3Zn22 type, peritectic decomposition at 910 °C; Gd2Zn17, high-temperature form, rhombohedral, hR57-Th2Zn17 type and low-temperature form, hexagonal, hP38-Th2Ni17 type, congruent melting at 935 °C; and GdZn12, tetragonal, tI26-ThMn12 type, peritectic decomposition at 660 °C. Five eutectic reactions occur at 780 °C and 27 at.% Zn ((αGd) + GdZn) at 945 °C and 59 at.% Zn (GdZn + GdZn2), at 875 °C and 77 at.% Zn (GdZn3 + Gd3Zn11), at 885 °C and 84 at.% Zn (Gd13Zn58 + Gd3Zn22) and finally at 400 °C and 99.5 at.% Zn (GdZn12 + (Zn)). A catalectic equilibrium was found in the Gd-rich end.

No thermodynamic data of the Zn–Gd alloys have been reported; however, the enthalpy of the formation of the intermediate phases of other Zn–RE systems are measured [27, 28]. Because of the similar chemical and physical properties of the rare earths, we can make a comparison with the known thermodynamic properties of Zn with other rare earths. In general, the minima of formation enthalpy generally correspond to the REZn2 compounds.

Ternary system

The experimental phase diagram of Mg–Zn–Gd ternary system has not previously been reported, although several ternary compounds have been discovered [8–11, 13–16].

(1) I-(Mg3Zn6Gd1): Liu et al. [10, 11] indicated that the I phase in Mg–Zn–Gd alloys is a face-centered icosahedral quasicrystal with approximately composition of 41.8 at.% Mg, 49.6 at.% Zn and 8.58 at.% Gd.

(2) X-(Mg12ZnGd): Yamasaki et al. [13] found that heat treatment at 773 K produces the coherent 14H LPSO structure precipitates from α-Mg supersaturated solid solution. Wu et al. [14, 15] investigated the formation and characterization of the lamellar 14H LPSO structure. The lattice constants of 14H LPSO structure are estimated to be a = 0.325 nm, c = 3.722 nm, and its composition are established to be Mg-8.10 ± 1.0 at.% Zn-11.05 ± 1.0 at.% Gd.

The microstructure of Mg–10Gd–3Y–1.8Zn–0.5Zr (wt%) alloys with different cooling rates were investigated by Zhang et al. [16]. Two kinds of LPSO structure were observed, including 14H LPSO structure in the grain interior and X phase at the grain boundaries. Lamellar 14H LPSO structure in Mg matrix propagated in the matrix with the decease of solidification rate. 14H LPSO-structured X phase transformed from eutectic phase when solidification rates are low.

(3) W-(Mg3Zn3Gd2): W phase has a face-centered cubic structure with composition of 31.2 at.% Mg, 43.1 at.% Zn and 25.7 at.% Gd, and the lattice parameter is estimated to be a = 0.768 nm by Liu et al. [10, 11]. Padezhnova et al. [29] determined the structure of the W-Mg3Zn3Y2 phase by X-ray diffraction. It has a similar structure as AlMnCu2-type face-centered cubic (fcc) structure, and its space group is Fm \( \bar{3} \) m. As shown from the structural model of the W phase, four Y atoms occupy the 4(a) positions of the AlMnCu2-type structure, four Mg atoms the 4(b) positions and eight (Mg + Zn) atoms, with the ratio of 1:3, occupy the 8(c) positions.

In Table 1, crystallographic data of reported ternary Mg–Zn–Gd phases and binary subsystems are summarized.

Experimental procedure

Mg blocks (99.96 wt% purity), Zn blocks (99.9 wt% purity) and Mg–39.92 wt% Gd master alloy were used as starting materials. Their surfaces were pre-grinded using SiC paper and then were cleaned with 99% ethanol for some minutes in the ultrasonic bath. Thirteen ternary alloys, each with a total weight of approximately 20 g, were prepared in this work. In order to avoid evaporation and oxidation, the samples were sealed in tantalum crucibles by electric arc welding under argon atmosphere. No reactions between the crucibles and the samples were observed. Then, the welded tantalum crucible containing the sample was encapsulated in a quartz tube filled with pure argon to avoid the reaction of tantalum crucible in air environment. After melted at 1173 K for 2 h, the samples were quenched in water. During melting, the capsules were turned up and down every 30 min for the alloy composition homogenization. All the quenched alloys were annealed at 673 K for 720 h and then water-quenched.

Phase identification was carried out by X-ray diffraction (XRD) (Dmax-2500VBX) with Cu Kα diffraction, at 40 kV and 250 mA. The microstructure of each alloy was examined using scanning electron microscopy (SEM) (FEI Quanta 200) equipped with energy dispersive X-ray spectroscopy (EDS) (EDS GENESIS 60S). At least three valid EDS point analyzes were made for each phase in order to guarantee a good analysis of their compositions. The samples were ground and polished under alcohol to avoid reaction with water. To acquire more accurate data, the composition of each phase was studied by electron probe microanalysis (EPMA) (JXA-8800R, JEOL, Japan) using a 20 kV voltage and 20 nA current. The high-pure Mg, Zn and Gd were served as standards to revise the characteristic radiations.

Thermodynamic models

There are solution phases, stoichiometric intermetallic compounds and intermetallic compounds with noticeable solubility ranges in Mg–Zn–Gd system. In order to maintain consistency with other thermodynamic assessment, the Gibbs energies of the pure elements, referred to the enthalpy of each element in its so-called standard element reference (SER) state (the stable state at 105 Pa and 298.15 K), were taken from the Science Group Thermodata Europe (SGTE) Pure Elements Database [30].

Solution phases

The Gibbs energies of solution phases, liquid, BCC_A2, FCC_A1, HCP_A3 and HCP_Zn are described with the substitutional solution model based on random mixing of the metal atoms as follows:

where \( {}^{0}G_{i}^{\Upphi } \) is the molar Gibbs energy of pure element i (i = Gd, Mg, Zn) with structure Φ; R is gas constant; T is the temperature in K; x i is mole fractions of component i and \( {}^{\text{E}}G_{\text{m}}^{\Upphi } \) is the excess Gibbs energy formulated with the Redlich–Kister polynomial [31] as

where \( {}^{i}L_{\text{Gd,Mg}}^{\Upphi } \), \( {}^{i}L_{\text{Mg,Zn}}^{\Upphi } \) and \( {}^{i}L_{\text{Gd,Zn}}^{\Upphi } \) are the interaction parameters between elements Gd and Mg, Mg and Zn, and Gd and Zn, respectively; \( {}^{i}L_{\text{Gd,Mg,Zn}}^{\Upphi } \) is the ternary interaction parameter; \( {}^{i}L_{\text{Gd,Zn}}^{\Upphi } \) and \( {}^{i}L_{\text{Gd,Mg,Zn}}^{\Upphi } \) are to be evaluated in the present work. The general form of the interaction parameters is

In most cases, only the first one or two terms are used according to the temperature dependence on the experimental data.\( {}^{\text{mg}}G_{\text{m}}^{\Upphi } \) is the magnetic contribution to the Gibbs energy. Due to a lack of experimental data about magnetism, the interaction parameters \( {}^{\text{mg}}G_{\text{m}}^{\Upphi } \) were not optimized in the present work.

Ordered solid solutions

The compounds MgGd and GdZn have the same BCC_B2 structure and probably form a cP2-CsCl-type solution in the Mg–Zn–Gd ternary system. In order to indicate their structural relationship between ordered BCC_B2 and disordered BCC_A2, the two phases are modeled using a single function based on the two-sublattices (Gd,Mg,Zn)0.5(Gd,Mg,Zn)0.5 with the following form [32]:

where x i represents the mole fraction of constituent i, and y I i and y II i are the site fractions, i.e., the mole fractions in the first and second sublattices, respectively. The first term, \( G_{\text{m}}^{\text{dis}} (x_{i} ) \), represents the Gibbs energy of the disordered phase BCC_A2, which is expressed by Eq. 1. The second term, \( G_{\text{m}}^{\text{ord}} \left( {y_{i}^{{\text{\rm I}}} ,y_{i}^{{{\text{{\rm I}{\rm I}}}}} } \right) \), is the Gibbs energy of the ordered phase BCC_B2 as described by the sublattice model and contains implicitly a contribution of the disordered state. It is expressed as follows:

The parameters \( {}^{v}L \) have the form shown in Eq. 3. Due to the crystallographical symmetry, the following relations are introduced in [33]:

The last term,\( G_{\text{m}}^{\text{ord}} \left( {x_{i} ,x_{i} } \right) \), represents the energy contribution of the disordered state to the ordered phase. The last two terms cancel each other when the site fractions are equal, thus corresponding to a disordered phase. Hence, the parameters of both ordered and disordered phases can be evaluated independently.

Binary intermetallic phases

Because of the negligible solid solubilities for the third element, all the binary intermetallic compounds in Zn–Gd system except GdZn are treated as stoichiometric phases Zn p Gd q . According to the Neumann–Kopp rule, the Gibbs energy of Zn p Gd q can be formulated as:

where A and B are the adjustable parameters to be optimized in this work.

The Mg5Gd with a homogeneity range was modeled as (Mg,Zn)5Gd in the Mg–Zn–Gd system. According to the general sublattice model [34], the Gibbs energy is expressed as:

where \( G_{\text{Mg:Gd}}^{{({\text{Mg,Zn}})_{5} {\text{Gd}}}} \) has the same value as \( G_{\text{Mg:Gd}}^{{{\text{Mg}}_{5} {\text{Gd}}}} \), and \( G_{\text{Zn:Gd}}^{{({\text{Mg,Zn}})_{5} {\text{Gd}}}} \) represents Gibbs energy of the hypothetical Zn5Gd, which is formalized as

where C and D are the parameters to be optimized in this work.

Ternary intermetallic compounds

In the Mg–Zn–Gd ternary system, stoichiometric intermetallic phase, X-Mg12ZnGd, is modeled as Mg x Zn y Gd z , and its Gibbs energy expression is written as:

where E and F are the parameters to be optimized.

W-Mg3Zn3Gd2 and I-Mg3Zn6Gd1 in the Mg–Zn–Gd system has a homogeneity range and are treated as the following formula by a three-sublattice model [35]:

- W::

-

(Mg)0.2(Gd)0.2(Mg,Zn)0.6

- I::

-

(Mg)0.3(Mg,Zn)0.6(Gd)0.1

The Gibbs energies for a general three-sublattice model (Mg,Zn) x (Mg,Zn) y (Gd) z are expressed as follows:

Results and discussion

Experimental results

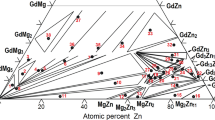

The constituent phases and their compositions in the selected alloys are listed in Table 2. Three ternary phases, X-(Mg12ZnGd,), W-(Mg3Zn3Gd2) and I-(Mg3Zn6Gd1), are in direct equilibrium with the Mg solid solution. The existence of a ternary solid solution of Mg5Gd was confirmed. The determined isothermal section of Mg–Zn–Gd ternary system at 673 K in the Mg-rich region was shown in Fig. 2. The triangles drawn in as dotted lines indicate three-phase equilibria, and the thick dotted lines are the measured tie-lines.

The partial isothermal section in the Mg-rich corner of the Mg–Zn–Gd system at 673 K. The symbol (+) represents the investigated sample compositions. The thick dotted lines are the measured tie-lines. The triangles drawn in as dotted lines indicate three-phase equilibria. The symbol ( ) denotes the phase compositions

) denotes the phase compositions

According to the EPMA results, the composition of X-Mg12ZnGd is about 88.1–89.8 at.% Mg, 3.9–4.6 at.% Zn and 5.5–6.1 at.% Gd. The measured composition is very close to the stoichiometric composition of Mg12ZnGd reported previously [13, 15].

The composition of W phase determined in this work is Mg: 45–50 at.%, Zn: 30–35 at.%, Gd: 20 at.%, which is in good agreement with the experimental results Mg3Zn3Gd2 (face-centered cubic structure) reported by Liu et al. [10, 11]. I-Mg3Zn6Gd1 phase was considered as a Frank–Kasper type with a composition of Mg42Zn50Gd8 (at.%) by Tsai et al. [8]. The consistent results have been obtained in this work, Mg: 38 ± 1 at.%, Zn: 54 ± 1 at.%, Gd: 8 ± 1 at.%.

Within the investigated composition ranges, three three-phase regions (αMg + X-Mg12ZnGd + Mg5Gd, αMg + X-Mg12ZnGd + W-Mg3Zn3Gd2, αMg + W-Mg3Zn3Gd2 + I-Mg3Zn6Gd1) and two two-phase regions (αMg + X-Mg12ZnGd, αMg + W-Mg3Zn3Gd2) are determined at 673 K in this work. The SEM micrographs and XRD diffraction profile of alloy 2 are shown in Fig. 3a, b. As is shown in Fig. 3b, the alloy 2 consists of three phases: (αMg), W-Mg3Zn3Gd2 and X-Mg12ZnGd. Based on the EPMA results, it can be concluded that the dark phase is (αMg), the gray phase is X-Mg12ZnGd and the bright phase is W-Mg3Zn3Gd2. The BSE image and X-ray diffraction profile of alloy 6, shown in Fig. 4a, b, consists of three phases (αMg), W-Mg3Zn3Gd2 and I-Mg3Zn6Gd1. Based on the EPMA data, the dark phase is (αMg), the white block phase is W-Mg3Zn3Gd2 and the eutectic structure is I-Mg3Zn6Gd1 phase. In the image of alloys 13, shown in Fig. 5a, liquid phase exists. Based on the EPMA data, the dark phase is (αMg), the lamellar eutectic phases are I phase surrounding the inner region of Mg7Zn3 phase. The alloy of interest is in the (L + I + (αMg)) equilibrium region, Mg7Zn3 phase forms by the binary peritectic reaction L + (αMg) → Mg7Zn3.

Thermodynamic modeling

On the basis of lattice stabilities taken from the PURE database [30], the optimization of the Zn–Gd and Mg–Zn–Gd systems is carried out using the PARROT module in the Thermo-Calc software package developed by Sundman et al. [36] based on the experimental data.

Pandat software [37] was used to check the database. All the parameters obtained in present work are listed in Table 3.

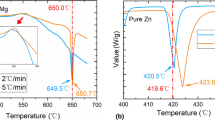

Of the three constituent binary systems, the Mg–Gd [23] and Mg–Zn [19] systems have been thermodynamically optimized previously and the parameters are adopted in the present work. Due to the lack of thermodynamic data, no attempt has been made to thermodynamically model the Zn–Gd binary system previously. In this work, all the intermetallic phases in the Zn–Gd system are treated as stoichiometric ones except the ZnGd (BCC_B2) phase. The calculated phase diagram of the Zn–Gd system compared with the experimental data [26] is shown in Fig. 6. The calculated invariant reactions, shown in Table 4, agree very well with the experimental data. The calculated minima of formation enthalpy correspond to the GdZn2 phase, which is consistent with the experimental results [27, 28]. The optimized thermodynamic data for Zn–Gd system is satisfactory and can be used for modeling the higher-order system.

Calculated Zn–Gd phase diagram using the present thermodynamic description compared with the experimental data [23]

All ternary phases in the Mg–Zn–Gd system, the X, W and I phases, are treated with the three-sublattice model on the basis of available crystallographic information. The X phase is treated as stoichiometric one; for W and I phases, mixing between sublattices of Mg and Zn are considered. Based on the experimental results of phase compositions and available crystallographic data, W and I phases are treated as (Mg)0.2(Gd)0.2(Mg,Zn)0.6 and (Mg)0.3(Gd)0.1(Mg,Zn)0.6. The calculated isothermal section at 673 K of Mg–Zn–Gd system is shown in Fig. 7a, b. Compared with the experimental isothermal section (Fig. 2), the calculated phase relationships in Mg-rich corner are consistent with the experimental data. Figure 8a, b are the calculated projection of the liquidus surface of the Mg–Zn–Gd system according to the present thermodynamic description. The calculated temperatures of invariant reactions presented in Table 5.

As a validation for the obtained database, Scheil model was used to simulate the process of non-equilibrium solidification of the Mg–5 at.% Zn–0.5 at.% Gd alloy. The point on the liquidus surface refers to the composition of Mg–5 at% Zn–0.5 at% Gd, and the line presents the solidification path of this alloy simulated by Scheil model. The calculated solidification curve about temperature versus fraction of solid, shown in Fig. 9, is in accordance with the experimental results of Liu [38], in which W phase was observed within the lamellar I phase. Being in agreement with the thermodynamic prediction, W phase firstly appears during solidification, then I phase appears via L + W → I + (αMg).

Overall, the results of the current database are considered fairly satisfactory. The resultant thermodynamic database can be applied to study various phase equilibrium-related materials problems.

Conclusion

The partial isothermal section of Mg–Zn–Gd ternary system in Mg-rich corner at 673 K was investigated. Three ternary phases, X-(Mg12ZnGd), W-(Mg3Zn3Gd2) and I-(Mg3Zn6Gd1), are identified and they are directly in equilibrium with the Mg solid solution. The Zn–Gd and Mg–Zn–Gd systems are thermodynamically modeled for the first time using the CALPHAD method. In particular, the order/disorder transition between BCC_B2 and BCC_A2 in these system has been taken into account. The calculated phase diagrams are in reasonable agreement with available experimental data. The resultant thermodynamic database is applied to case studies, showing that the present thermodynamic description of the Mg–Zn–Gd system is reliable for computer-assisted design of magnesium-based materials.

References

Mordike BL, Ebert T (2001) Mater Sci Eng A 302:37

Schumann S, Friedrich H (2003) Mater Sci Forum 51:419

Luo AA (2004) Int Mater Rev 49:13

Nie JF, Muddle BC (2000) Acta Mater 48:1691

Nayeb-Hashemi AA, Clark JB (1998) Phase diagrams of binary magnesium alloys. ASM International, Metals Park

Nie JF, Gao X, Zhu SM (2003) Scr Mater 53:1049

Avedesian MM, Baker H (1999) Magnesium and magnesium alloys. ASM International, Materials Park

Abe E, Sato TJ, Tsai AP (2000) Mater Sci Eng A 294–296:29

Uhrig E, Brühne S, Assmus W, Grüner D, Kreiner G (2005) J Cryst Growth 275:e1987

Liu Y, Yuan GY, Lu C, Ding WJ (2006) Scr Mater 55:919

Liu Y, Yuan GY, Lu C, Ding WJ, Jiang JZ (2008) J Mater Sci 43:5527. doi:10.1007/s10853-008-2839-z

Janot C (1994) Quasicrystals. Clarendon Press, Oxford

Yamasaki M, Sasaki M, Nishijima M et al (2007) Acta Mater 55:6798

Wu YJ, Lin DL, Zeng XQ, Peng LM, Ding WJ (2009) J Mater Sci 44:1607. doi:10.1007/s10853-008-3213-x

Wu YJ, Peng LM, Zeng XQ, Lin DL, Ding WJ (2010) Mater Sci Forum 654–656:623

Zhang S, Yuan GY, Lu C, Ding WJ (2011) J Alloys Compd 509:3515

Kaufman L, Bernstein H (1970) Computer calculation of phase diagrams. Academic Press, New York

Agarwal R, Fries SG, Lukas HL, Petzow G, Sommer F, Chart TG, Effenberg G (1992) Z Metallkd 83:216

Liang P, Tarfa T, Robinson JA, Wagner S, Ochin P, Harmelin MG et al (1998) Thermochim Acta 314:87

Berche A, Drescher C, Rogez J, Record MC, Brühne S, Assmus W (2010) J Alloys Compd 503:44

Cacciamani G, Saccone A, Borzone G, Delfino S, Ferro R (1992) Thermochim Acta 199:17

Cacciamani G, De Negri S, Saccone A, Ferro R (2003) Intermetallics 11:1135

Guo C, Du Z, Li C (2007) Calphad 31:75

Massalski TB, Okamoto H, Subramanian PR, Kacprzak L (1990) Binary alloy phase diagrams, 2nd edn. ASM International, Materials Park

Bruzzone G, Fornasini ML, Merlo F (1970) J Less Common Met 22:253

Sccone A, Cardinale AM, Delfino S, Ferro R (2001) Z Metallkd 92:959

Chiotti P, Mason JT (1973) Metall Trans 4:1527

Borzone G, Cacciamani G, Ferro R, Charles J, Hertz J (1987) J Less Common Met 128:297

Padezhnova EM, Mel’nik EV, Miliyevskiy RA, Dobatkina TV, Kinzhibalo VV (1982) Russ Metall 4:185

SGTE (2008) SGTE Pure Elements (Unary) Database (version v 4.6), developed by SGTE (Scientific Group Thermodata Europe), 1991-2008, and provided by TCSAB. SGTE website, http://www.sgte.org

Redlich O, Kister AT (1948) Ind Eng Chem 40:345

Ansara I, Dupin N, Lukas HL, Sundman B (1997) J Alloys Compd 247:20

Dupin N, Ansara I (1999) Z Metallkd 90:76

Sundman B, Agren J (1981) J Phys Chem Solids 42:297

Toffolon C, Servant C, Gachon JC, Sundman B (2002) J Phase Equilib 23:134

Anderson JO, Helander T, Hoglund L, Shi P, Sundman B (2002) CALPHAD 26:273

PANDAT Software, CompuTherm, LLC, Madison, WI, USA. http://www.computherm.com

Liu Y (2007) Ph.D. thesis, Shanghai Jiao Tong University

Acknowledgements

This work was financially supported by the National Science Foundation of China (Grant no. 50731002), Center of Phase Diagram & Materials Design and Manufacture Foundation (Grant no. 1773-206001146) and Excellent PhD Thesis Support Foundation of Central South University (Grant no. 2008yb013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qi, H.Y., Huang, G.X., Bo, H. et al. Experimental investigation and thermodynamic assessment of the Mg–Zn–Gd system focused on Mg-rich corner. J Mater Sci 47, 1319–1330 (2012). https://doi.org/10.1007/s10853-011-5905-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5905-x