Abstract

A continued increase in the use of plastics has led to an increasing amount of plastics ending up in the waste stream; and the increasing cost of landfill disposal and public interest in support of recycling has meant that plastics recycling must increase. In this work, the effect of multiple extrusion and injection of poly(lactic acid)/polystyrene polymer blend (PLA/PS) on its rheological and mechanical properties is presented. Rheological properties were studied using a capillary rheometer, apparent shear rate (γ a), apparent shear stress (τ a), apparent viscosity (η a), and flow activation energy were determined. The mechanical properties of the blend were investigated on dog bone-shaped samples obtained by injection molding, tensile tests were performed, stress at break, strain at break, and Young’s modulus were determined. The results showed that the apparent viscosity of PLA/PS blend decreases monotonously with increasing the processing number. Also it was found that stress and strain at break of the blend decrease sharply after two processing cycles, whereas the processing number has a little effect on Young’s modulus.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, much more concern has increased on the deterioration of our environment due to plastics waste pollution. One way to solve that problem is replacing commodity synthetic plastics with biodegradable plastics. Among them, aliphatic polyester is one of the most promising biodegradable materials because they are readily susceptible to biological attack [1]. Poly(lactic acid) (PLA), a biodegradable aliphatic polyesters, produced from renewable resources has received much attention in the research of biodegradable polymers. Lactide and lactic acid monomers are obtained from the fermentation of crop like corn starch and sugar feed stocks. The most common way to obtain high molecular weight of PLA (greater than 100,000 Da), which has broadened its uses, is a through two-step ring-opening polymerization of lactide [2].

PLA has become an alternative to traditional commodity plastics for everyday applications as an environmentally friendly polymer due to its some unique properties such as high strength, high stiffness, and resistance to fats and oil [3]. However, brittleness and other properties such as low viscosity, low thermal stability, high moisture sensitivity, medium gas barrier properties, high cost (comparing with PE, PP, PS…) and low solvents resistance (e.g., against water) of the pure polymer are often insufficient for a lot of applications [4]. Also one of the drawbacks of processing PLA in the molten state is its tendency to undergo thermal degradation, which is related both to the process temperature and the residence time in the extruder and hot runner [5]. This drawback affects on the recyclability of PLA. Pillin et al. [6] studied the effect of the injection cycles on the properties of PLA and they found that the viscosity of PLA decreases strongly (from 3960 to 713 Pa s) after only one injection cycle. This behavior was attributed to the strong decrease in the molecular weight of PLA during the first injection cycle and after four cycles PLA’s viscosity becomes nearly 150 Pa s. They also found that the mechanical properties of the recycled PLA had become too weak for an industrial application of the polymer.

Polymer blending is a straightforward, versatile, and inexpensive method for obtaining new materials with improved properties. PLA properties were modified through polymer blending techniques [7–17]. PLA was blended with polystyrene (PS) [15–17] in effort to balance the cost effective issue of PLA and enhance the degradability of PS. In general, the results of these studies showed the properties of the PLA/PS blends to be between the values of pure polymers. As a result, PLA/PS polymer blend may become critical ingredients in the development of a variety of products including medical devices and packaging products [18].

Since PLA/PS blend is semi-biodegradable, which would significantly reduce environmental pollution associated with PLA/PS waste, the knowledge about the material recycling and changes in the properties of PLA/PS blend upon its multiple processing is a very important subject. This issue is also important because of possibility to re-use the post-production PLA/PS waste. So, the purpose of this work is to study the influence of multiple processing (extrusion and injection) of PLA/PS polymer blend on its rheological and mechanical properties.

Experimental

Materials and procedure

PLA (ESUN™ A-1001) [density = 1.25 g/cm3 (21.5 °C), MFI = 12.5 g/10 min (190 °C/2.18 kg)] was supplied by Bright China Industrial Company Ltd. (Shenzhen, China), the selected grade is an extrusion material; it was dried at 70 °C for 6 h before using. PS (SABIC®125PS) [density = 1.05 g/cm3, MFI = 7 g/10 min (200 °C/5 kg)] was supplied by Sabic (KSA).

A simple blend of (50/50) PLA/PS (PLA50) was prepared using a single screw extruder (SSE), the blend was extruded through a multi holes die (3 mm), and the extrudates were then fed into a granulator, which converted them into granules. The granules of PLA50 were injected into dog bone-shaped samples. The obtained samples were then cut into small pieces with a Brabender plastic grinder and extruded again; this process (extrusion, injection, and grinding) was repeated four times (Fig. 1).

Extrusion conditions

Extrusion process was performed using a laboratory scale SSE (D = 20 mm, L/D = 25) [SHAM EXTRUDER 25D Performance: Kreem Industrial Establishment, Damascus, Syria], it could be operated at different speeds, varied from 0 to 100 rpm. The screw has a fluted type mixing section located before the metering zone [19], in this type of mixers the material is forced to pass at a high shear stress. This brings in some level of dispersing action besides reorienting the interfacial area, and increasing the imposed total strain. The flight depth of screw in the metering zone was 1.5 mm, and the helix angle 17.7°. PT124G-124 melt pressure transducer (Shanghai Zhaohui Pressure Apparatus Co., Ltd, China) was located in the die head for measuring the melt pressure. The screw speed was set at 40 rpm, and the temperatures of the zones used for compounding the blend and recycling it are summarized in Fig. 2. As shown in Fig. 2 that the temperature decreased with the processing cycle.

Injection conditions

Injection molding process was performed at 190 °C using NEGRI BOSSI (NB 25) injection machine (Lessona Corporation, Italy). The tensile samples were prepared according to the following injection conditions, cooling time in the mold was 30 s, the mold temperature was room temperature with water-cooling (25 °C) and injection pressure was 9 MPa. The molded samples were dog bone-shaped samples with a thickness and width of 4 and 10 mm, respectively. The gauge length of the sample was 80 mm (Fig. 3). The obtained testing samples were immediately packed in plastics bags and stored in a dark cool surrounding.

Rheology

Rheological properties of PLA50 were studied using a capillary rheometer (Davenport 3/80), with a capillary diameter of 2 mm (L/R = 15). The rheological experiments were carried out at 165, 170, 175, 180 °C, no end corrections were applied. The apparent shear rate (γ a) is given by:

where R is the capillary radius and Q is the volumetric flow rate. The apparent shear stress (τ a) is given by:

where ΔP is the pressure at the capillary entrance, L is the capillary length, the apparent viscosity (η a) is given by:

The values of flow activation energy at a constant shear stress (E τ ) were determined by using Arrhenius form equation:

where A is the consistency related to structure and formulation, R is the gas constant (8.314 J/mol K).

Solution viscosity

The samples were dissolved in chloroform at 25 °C, and the solution viscosity measurements were performed by an Ubbelohde type viscometer. Relative viscosity was calculated by:

where t is the flow time of the PLA50 blend solution, t 0 is the flow time of the pure solvent. Intrinsic viscosity [η] was calculated by:

where C (g/mL) is the concentration of PAL50 blend in the solution.

Mechanical properties

Tensile testing to study stress at break (N/mm2), strain at break (%), and Young’s modulus (N/mm2) were performed using Testometric M350-10KN (The Testometric Company Ltd, Rochdale, UK) at room temperature (ASTM D638), all samples were strained at 50 mm/min. Samples were conditioned at room temperature for a period of 48 h prior to testing. Results from eight specimens were averaged. The relative property (RP) was given by:

where P i is the property after the ith processing cycle (i = 1, 2, 3, 4) and P 1 is the property after the first processing cycle.

Results and discussion

Solution viscosity

Although solution viscosity of the polymers in solvent does not provide direct relevance to the processing of the molten polymers, this property is frequently evaluated to determine the molecular weight of polymers; as expected, a polymer molecule with a greater dimension has a larger intrinsic viscosity. Figure 4 shows the effect of processing number on the intrinsic viscosity of the samples. It could be noted from Fig. 4 that the intrinsic viscosity of the blend decreases with increasing processing number and the relationship between intrinsic viscosity and processing number is linear (R 2 = 0.986; Fig. 4). Since the intrinsic viscosity is directly related to the molecular weight, so it can be said that the molecular weights in the blend decrease after the processing cycles.

Rheological properties

Flow curves

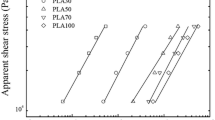

Figure 5 represents the flow curves for all sample melts at 165 °C. It could be noted from Fig. 5 that the linearity of these lines is excellent and they obey the power law in a certain range of shear rate:

The non-Newtonian index (n) was calculated from the slope of the fitted lines in Fig. 5. All the values of n were less than 1, implying that all sample melts were pseudo plastic.

Viscosity curves

The relationship between apparent viscosity and apparent shear rate, for all sample melts at 165 °C, is shown in Fig. 6. It could be noted from Fig. 6 that all sample melts show a typical shear-thinning behavior over the range of the studied shear rates, this behavior was attributed to the alignment or arrangement of chain segments of polymers in the direction of applied shear stress.

Figure 7 shows the apparent viscosity (at shear rate = 10 s−1) and non-Newtonian index as a function of the processing number at 165 °C. It could be noted that the apparent viscosity decreases steadily with increasing the processing number. The compounded blend (PLA50) has an apparent viscosity of 3100 Pa s, and after each processing cycle, the apparent viscosity of the blend decreased nearly by a factor of 0.15–0.3. These observations can be attributed to the reduction of the molecular weights with the processing cycles. Also, it could be noted from Fig. 7 that the relationship between apparent viscosity and processing number is well approximated by a second-order polynomial (R 2 = 0.992; Fig. 7). By comparing these results with those obtained by Pillin et al. [6], it could be concluded that PLA50 has higher thermal stability comparing with pure PLA, where after one injection cycle, the zero viscosity of pure PLA decreased by a factor of 0.82, and this difference might be attributed to the good thermal stability of PS [20].

Also it could be noted from Fig. 7 that the non-Newtonian index of PLA50 decreases at first with increasing the processing number and after two processing cycles, n becomes constant. The value of n describes the deviation from the Newtonian fluids about flow behavior, so it is also called the flow behavior index. A higher value of n reveals less influence of shear rate on flow behavior. In other words, the changes in viscosity upon shear rate are not obvious, so it could be said that the flow behavior of PLA50 becomes more sensitive to shear rate after the recycling process.

Flow activation energy

Figure 8 shows the dependency of the apparent viscosity for the sample melts on the temperature at a constant shear stress, it could be seen that the apparent viscosity of the blend increases with the reciprocal of the absolute temperature (1/T), this means that the dependence of the apparent viscosity is consistent with the Arrehnius equation (Eq. 4). With a rise of temperature the motion ability of polymer chains enhances, and the resistance between the melt layers decreases relevantly, leading to reduction of the melt viscosity. The flow activation energy at a constant share stress (E τ ) of the blend was determined from the slopes of the lines in Fig. 8. It is well known that the value of flow activation energy reflects the temperature-sensitivity of viscosity, so the more E τ was the more sensitive the behavior of blend was to the temperature.

Figure 9 shows the effect of processing number on the flow activation energy of the sample melts at shear stress = 12.9 kPa, it could be noted from Fig. 9 that the flow activation energy increases with processing number, this behavior is attributed to the reduction of the molecular weight with the processing number. The relationship between the flow activation energy and molecular weight was reported by Collins and Metzger [21], where they found that as the molecular weight of the polymer increases the influence of the temperature on the viscosity (flow activation energy) decreases.

Mechanical properties

For all samples, no yield phenomenon is existed. The relative stress at break of PLA50 versus processing number is shown in Fig. 10. It could be noted from Fig. 10 that stress at break of PLA50 decreases sharply after two processing cycles (reduction by a factor of 0.68) and after four processing cycles the stress at break of PLA50 decreases by a factor of 0.79. These results can be attributed to a reduction of the molecular weights after the processing cycles which causes a lower cohesion in the blend. The effect of processing number on the strain at break of PLA50 is shown in Fig. 11, it is clearly seen from Fig. 11 that strain at break of the blend decreases by a factor of 0.61 after two processing cycles and by a factor of 0.73 after four processing cycles. This phenomenon may be a consequence of both the decrease of the chain length and the increase of the degree of crystallinity which both favor the crack propagation above the elastic domain.

Figure 12 shows the effect of processing number on Young’s modulus of PLA50. It is clearly seen from Fig. 12 that Young’s modulus of PLA50 decreases by a factor of 0.2 after two processing cycles and by a factor of 0.26 after four processing cycles. The decrease of stress and strain at break of PLA50 with processing number was more pronounced comparing with the decrease of Young’s modulus; the same behavior was noted in the recycling of pure PLA [6], where it was found that the processing number has no influence on tensile modulus although the reduction of the molecular weight, and this behavior was attributed to the increase of crystallinity in PLA after processing cycles.

Conclusion

The aim of this work is to study the effect of recycling on the rheological and mechanical properties of PLA/PS polymer blend. The blend was prepared using a SSE. The rheological results show that the apparent viscosity of the blend decreases with increasing the processing number, which was attributed to the reduction of the molecular weights with the processing cycles. Also it was found that the flow behavior of the blend becomes more sensitive to shear rate and temperature after the recycling process. Also it was found that the mechanical properties of the blend get worse with increasing the processing number. The least change was for Young’s modulus (reduction by a factor of 0.26 after four processing cycles), there was a larger change for the strain at break (0.73 after four processing cycles) and the largest change was for the stress at break (0.79 after four processing cycles). The presented results indicate that PLA/PS waste is suitable to be re-used as an additive during compounding the PLA/PS blends or to the raw polymers (PLA, PS).

References

Rudnik E (2008) Compostable polymer materials. Elsevier, Netherlands

Lunt J (1998) Polym Degrad Stab 59:145

Auras R, Singh S, Singh J (2005) Package Technol Sci 18:207

Anderson KS, Hillmyer MA (2004) Polymer 45:8809

Taubner V, Shishoo R (2001) J Appl Polym Sci 79:2128

Pillin I, Montrelay N, Bourmaud A, Grohens Y (2008) Polym Degrad Stab 93:321

Ishida S, Nagasaki R, Chino K, Dong T, Inoue Y (2009) J Appl Polym Sci 113:558

Sarazin P, Li G, Orts W, Favis B (2008) Polymer 49:599

Bhatia A, Gupta R, Bhattacharya S, Choi H (2007) Korea-Australia Rheo J 19:125

Lee S, Lee JW (2005) Korea-Australia Rheo J 17:71

Ren J, Fu H, Ren T, Yuan W (2009) Carbohydr Polym 77:576

Li Y, Shimizu H (2009) Eur Polym J 45:738

Bourmaud A, Pimbert S (2008) Compos A 39:1444

Reddy N, Nama D, Yang Y (2008) Polym Degrad Stab 39:233

Hamad K, Kaseem M, Deri F (2010) Polym Bull 65:509

Biresaw G, Carriere CJ (2004) Compos A 35:313

Biresaw G, Carriere CJ (2002) J Polym Sci B 40:2248

Mishra S, Tripathy SS, Misra M, Mohanty AK, Nayak SK (2002) J Reinf Plast Compos 21:55

Tadmor Z, Gogos CG (2006) Principles of polymer processing. Wiley, New Jersey

Pielichowski K, Njuguna J (2005) Thermal degradation of polymeric materials. Rapra Technology Limited, UK

Collins EA, Metzger AP (1970) Polym Eng Sci 10:57

Acknowledgement

The authors are grateful to Miss. Ida Lau (Bright China Industrial Company. Ltd) for her aid in supplying PLA.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hamad, K., Kaseem, M. & Deri, F. Effect of recycling on rheological and mechanical properties of poly(lactic acid)/polystyrene polymer blend. J Mater Sci 46, 3013–3019 (2011). https://doi.org/10.1007/s10853-010-5179-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-5179-8