Abstract

In vitro studies are reported of the behaviour of potassium aluminosilicate inorganic polymers containing 10 wt% Ca(OH)2, nanostructured calcium silicate and Ca3(PO4)2 exposed to simulated body fluid (SBF). Heating to 600 °C lowers the alkalinity of Ca3(PO4)2-containing samples, but their X-ray powder diffraction characteristics, 27Al, 29Si and 43Ca MAS NMR spectra are unchanged by heating. Exposure of the heated compounds to SBF usually results in the formation of the crystalline biomineral phases hydroxylapatite and hydroxycarbonate apatite in the samples containing Ca(OH)2 and Ca3(PO4)2, but scanning electron microscopy/energy dispersive spectroscopy suggests that all the samples in the present study form calcium phosphates on exposure to SBF. This conclusion is also consistent with the removal of P from the SBF by all the samples. The concentrations of Al leached from the samples containing nanostructured calcium silicate and Ca3(PO4)2 (0.05 and 0.47 ppm, respectively) are acceptable for biomaterials use, but apart from the Ca3(PO4)2-containing sample, which takes up Ca from the SBF, the levels of Ca released into the SBF by the other samples are well in excess of the published optimum amount for stimulation of new bone growth by gene transcription in osteoblasts. Only the calcium silicate-containing samples release Si into the SBF, but in a concentration that falls short of the optimum amount. The strength of all the present compounds after heating is probably adequate for applications as biomaterials, but the Ca3(PO4)2-containing compound shows slightly greater strength. Thus, on balance, the Ca3(PO4)2-containing compound appears to be the most promising as a bioactive material.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Conventional inorganic polymers, sometimes known as geopolymers, are aluminosilicate materials based on a clay mineral such as kaolinite in which the structure has been perturbed by thermal removal of structural water at up to 800 °C, or by high-energy grinding [1]. When the solid aluminosilicate is reacted at near-ambient temperature with an alkali silicate solution at high pH, it forms a strong, durable material [2]. In addition to applications such as low-energy substitutes for Portland cement, fireproof panels and encapsulation of hazardous waste [3], inorganic polymers have been proposed [4–6] as bioactive materials capable of forming bone-like minerals by interaction with blood plasma. Several potential problems arise when an aluminosilicate geopolymer is brought into contact with living cells; the highly alkaline nature of the material can induce cell death, and there is a possibility of leaching of aluminium from the implant. The effect of aluminium in living organisms is controversial; Yap et al. [7], Geyer et al. [8] and Hanston et al. [9] report that aluminium concentrations <2 ppm lead to brain disease, although lower concentrations of aluminium may be beneficial and stimulate the proliferation of osteoblasts and new bone formation [7]. Studies of gene-expression stimulation by the ionic products of a commercial bioactive glass (Bioglass® 45S5) indicate that the mechanism of new bone formation involves the stimulation of gene transcription in osteoblasts by Ca and Si ions leached from the glass [10]; the critical concentrations of these ionic species lie in the range 15–20 ppm of Si and 6–8 ppm of Ca.

In one approach to the development of bioactive inorganic polymers, a standard potassium geopolymer composition was heat treated at 250–625 °C to immobilise the leachable alkali and render the material sufficiently porous to allow the permeation of bone-forming fluids [5]. Heat treatment at 500 °C proved to be successful in fixing both the leachable alkali and aluminium in the geopolymer structure, giving a material that was stable both in vitro and in vivo [5]; however, there was no evidence that these compounds formed hydroxycarbonate apatite (HCA) or any other bioactive phase, suggesting they lacked inherent bioactivity.

In an attempt to introduce bioactive functionality into geopolymers, the known bioactive compounds hydroxyapatite (HA), tricalcium phosphate (TCP) and mixtures of both were added to potassium geopolymers which were then heat treated at 500 °C to introduce porosity [4]. In vivo studies in rabbits showed these materials were non-toxic up to 1 month and bonding to the bone was inferred from observations of bone penetration into the implants. Longer term in vivo experiments [6] using the same material showed that samples of about 64% porosity and compressive strengths of about 5 MPa represented the best compromise and that the implants were stable up to 6 months, with negligible leaching of Al into the blood up to 750 h. The decrease in pH from 10 to 7 upon heating was inferred from 1H MAS NMR to be due to a reduction in the number of protons in the structure, although bound water is always present even up to 500 °C, either trapped in closed pores and/or associated with (SiO)3–Al–OH groups [6].

The aim of the present work was to synthesise inorganic polymers with inherent bioactivity based on the previous successful synthesis of potassium compounds containing a range of calcium compounds including Ca(OH)2, amorphous nanostructured calcium silicate and Ca3(PO4)2 [11]. The effect of heating on the transfer of alkalinity from these materials into simulated body fluid (SBF) was investigated in vitro, and the mechanical strength and leaching of ionic species in SBF were determined. The effect of exposure to SBF on the structure of the inorganic polymers was determined by 27Al, 29Si and natural abundance 43Ca MAS NMR, and the formation of new crystalline bone-forming phases was determined by X-ray powder diffraction (XRD).

Experimental

The potassium aluminosilicate inorganic polymers were prepared from New Zealand halloysite clay (Imerys Premium grade) dehydroxylated at 600 °C for 12 h. This was thoroughly mixed with potassium silicate solution (K66, Ineos Silicas, UK) and KOH (BDH reagent grade) dissolved in distilled water such that the molar composition was SiO2/Al2O3 = 3.24, K2O/SiO2 = 0.19 and H2O/K2O = 24.4. This base composition was used to prepare samples containing 10 wt% Ca(OH)2 (BDH reagent grade), amorphous nanostructured calcium silicate of composition CaSi1.67O3.75·3H2O (kindly supplied by Prof. J.H. Johnston and Dr. T. Borrmann), or Ca3(PO4)2 (BDH reagent grade). XRD showed the Ca(OH)2 to be highly crystalline, conforming to portlandite, PDF no. 44-1841, and the nanostructured calcium silicate to be an amorphous phase with additional major peaks of poorly crystalline calcium silicate hydrate (PDF no. 33-0306) and calcite, CaCO3 (PDF no. 47-1743). The calcium phosphate was highly crystalline, but consisted of a mixture of calcium phosphate (PDF no. 17-0499) and basic calcium hydrogen phosphate (PDF no. 46-0905). After thorough mixing, the samples were placed in lubricated cylindrical polycarbonate moulds 30-mm diameter and 25-mm high, any trapped air was removed and the samples were compacted using a vibrating table, sealed in plastic bags and cured at 40 °C overnight. After demoulding and drying at 40 °C, the samples were stored in sealed plastic bags for further testing.

Prior to in vitro testing by exposure to SBF, the samples were heated to 600 °C at a heating rate of 3.5°/min before cooling at the natural furnace rate. These slow heating and cooling rates were used to minimise the risk of cracking the samples.

The SBF was of the improved Kokubo type, prepared according to the method of Oyane et al. [12] and stored in polythene bottles in a refrigerator until required. The inorganic polymer samples were immersed in 50 ml of SBF in closed plastic jars and placed in a water bath at 37.5 ± 0.5 °C for varying periods up to 7 weeks. To counteract depletion of the ionic species in the SBF due to the formation of biominerals by the inorganic polymer samples, the SBF was replaced every 2 weeks.

The unheated, heated and SBF-treated samples were investigated by a number of techniques, as follows.

Both powder and monolithic surfaces were examined by XRD (Philips PW 1700 with computer-controlled goniometer and graphite monochromator, using CoKα radiation). 29Si, 27Al and natural abundance 43Ca solid-state MAS NMR was carried out under the following conditions.

The 29Si spectra were acquired at 11.7 T (99.926 MHz) using a Bruker Avance spectrometer and a 5-mm Doty MAS probe spun at 5–6 kHz with a 6 μs (π/10) pulse and a 30-s delay, the spectra being referenced to tetramethylsilane.

The 11.7 T 27Al spectra were acquired at 130.224 MHz using a 4-mm Doty MAS probe spun at 10–12 kHz, with 1 s (π/10 pulse for solution), the spectra referenced to Al(H2O) 3+6 .

The 14.1 T natural abundance 43Ca MAS NMR spectra were acquired at 40.388 MHz using a Chemagnetics spectrometer and a 9.5-mm Varian probe spun at 3.5 kHz. A 3.5–4 μs (π/9 pulse for solution) RAPT enhanced single-pulse sequence was used [13, 14], with a delay of 0.5 s found to give the best signal-to-noise ratio. Between 59,227 and 117,824, scans were acquired per spectrum and the spectra were referenced to 1 M CaCl2 solution [15].

Solid samples for electron microscopy were coated with 16 nm of carbon (for backscattered electron imaging and energy dispersive spectroscopy (EDS) analysis) or with 18 nm of gold/platinum for high-resolution imaging. The scanning electron microscope was a JEOL JSM-6500F, operated at 15 kV for the EDS analyses.

In order to determine whether the mechanical strength of these inorganic polymers is compromised by heating to reduce the alkalinity, the tensile strengths of the samples were determined by the Brazil method, in which cylindrical samples are broken by applying stress across their diameter [16]. The tensile strength σ is then given by,

where P is the applied load and D and t are the diameter and thickness of the specimen, respectively. The tensile strength tests were carried out on 6–10 replicates using an Instron Universal testing machine with a 250-kN load cell and a crosshead speed of 1 mm/min.

The tensile strengths of samples after immersion in SBF were not determined because the small number of samples available would have given statistically unsatisfactory results. After immersion of the inorganic polymer samples in SBF, the Al, Si, P, K and Ca concentrations of the SBF were determined by inductively coupled plasma-atomic emission spectrometry (ICP-AES), and changes in its pH were monitored as a function of immersion time using an RS V5969 portable pH meter.

Results and discussion

Reduction of alkalinity by heating

Changes in the pH of the SBF are shown in Fig. 1 as a function of soaking time for the calcium inorganic polymers and the reference compound without calcium. All the samples produce a brief initial decrease in the pH of the SBF, but after equilibration the pH gradually increases with time. This increase in the pH of the SBF produced by both the reference material (Fig. 1a) and the compound containing Ca3(PO4)2 (Fig. 1b) is significantly lower in samples heated to 600 °C, whereas the reverse is the case with the compounds containing Ca(OH)2 (Fig. 1c) and nanostructured calcium silicate (Fig. 1d). These pH values recorded as the samples approaching equilibrium are higher than those reported by Oudadesse et al. [5, 6], but their experiments were conducted in distilled water and are, therefore, not directly comparable, as some of the present bulk samples showed evidence of reaction with the SBF (formation of microcracks with gas evolution). The results for the phosphate-containing compounds may be understood in terms of the solubility of calcium phosphate in aqueous alkaline conditions, under which the stable phase at pH >4.2 is hydroxylapatite (HA) [17]. Unhydrated high-tempertature calcium phosphate phases, such as TCP, interact with water or body fluids at 37 °C to form hydroxyl apatite. Thus, the solubility of TCP at the surface of the sample approaches the solubility of HA and decreases the solution pH [17]. On the other hand, the higher overall alkalinity of the samples containing nanostructured calcium silicate may reflect the higher content of KOH required to synthesise these samples. In terms of pH and material stability in SBF, the heated reference inorganic polymer and the heated calcium phosphate compound are the most promising.

X-ray powder diffraction

Representative XRD traces of the potassium inorganic polymers containing 10 wt% of the calcium compounds are shown in Fig. 2. The as-prepared sample containing Ca(OH)2 (Fig. 2a) is a typical inorganic polymer showing an amorphous baseline feature centred at about 32°2θ with superimposed sharp reflections of quartz and cristobalite impurities from the halloysite reactant. This sample also contains the major reflection of calcite (CaCO3) resulting from atmospheric carbonation of some of the Ca(OH)2 (although crystalline Ca(OH)2 is undetectable by XRD in these samples, its presence in an X-ray amorphous form is indicated by the scanning electron microscopy (SEM)/EDS results (below)). Apart from the loss of the calcite reflection, the XRD trace is unchanged after heating to 550–600 °C to reduce the alkalinity (Fig. 2b). After 4 weeks immersion in SBF, these samples previously heated at 600 °C show XRD evidence of the formation of both the bone-forming minerals HA (PDF no. 09-432) and hydroxylcarbonate apatite (PDF no. 19-272) (Fig. 2c). Samples pre-heated at 500 °C also show the presence of these new phases after SBF soaking, but in a less crystalline form. From the point of view of HA and HCA formation, these samples containing Ca(OH)2 appear to be good candidates as bioactive materials.

Typical X-ray powder diffractograms of various Ca-containing aluminosilicate inorganic polymers. a As-synthesised sample containing Ca(OH)2, b sample containing Ca(OH)2, 600 °C, (also sample containing nanostructured calcium silicate, unheated and heated at 600 °C), c sample containing Ca(OH)2, 600 °C, soaked in SBF, d sample containing nanostructured calcium silicate, 600 °C, soaked in SBF, e sample containing Ca3(PO4)2, unheated, heated at 600 °C and soaked in SBF. C cristobalite (PDF no. 39-1425), Q quartz (PDF no. 33-1161), cal calcite (PDF no. 5-586), HA hydroxylapatite (PDF no. 9-432), HCA hydroxycarbonate apatite (PDF no. 19-272), CaP calcium hydrogen phosphate hydroxide (PDF no. 46-0905)

The as-prepared samples containing 10 wt% nanostructured calcium silicate show a typical inorganic polymer XRD pattern with no additional reflections (Fig. 2b); this XRD trace is unchanged by heating at 600 °C, but on soaking for 4 weeks in SBF, broad new reflections of poorly crystalline HA and HCA appear (Fig. 2d).

The XRD pattern of as-prepared inorganic polymer containing 10 wt% Ca3(PO4)2 (Fig. 2e) is that of a typical inorganic polymer with superimposed sharp reflections of calcium hydrogen phosphate hydroxide (PDF no. 46-0905), which are unchanged either by heating to 600 °C or by soaking in SBF. As the reflections of the calcium phosphate phase in the as-prepared inorganic polymer coincide with those of the products of biomineralization, these results cannot unambiguously prove the occurrence of such in vitro reactions, although SEM observations (below) show a change in morphology after soaking in SBF, which may be associated with the formation of new X-ray amorphous phases.

There is no XRD evidence of bioactivity in the control polymers not containing calcium compounds.

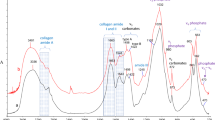

Multinuclear solid-state MAS NMR

Typical 27Al and 29Si MAS NMR spectra are shown in Fig. 3. The 27Al spectra (Fig. 3a–c) are all very similar, showing the typical dominant tetrahedral resonance of an inorganic polymer containing these calcium compounds [11]. The asymmetry in the resonance from the AlO4 site with a tail to negative shift is consistent with some degree of structural disorder producing a spread of quadrupole interaction parameters [18]. Apart from a slight broadening, the spectra of the as-prepared samples are essentially unchanged by heating or soaking in SBF, suggesting that the polymer structural unit is unaffected by these treatments. The 29Si spectra (Fig. 3d–g) are likewise typical of samples containing these calcium compounds [11], and are essentially unchanged by heating or soaking in SBF.

a–c Typical 11.7 T 27Al MAS NMR spectra, d–g typical 11.7 T 29Si MAS NMR spectra. a and d Sample containing Ca(OH)2, unheated, heated at 600 °C and soaked in SBF, b sample containing nanostructured calcium silicate, unheated, heated at 600 °C and soaked in SBF, c and g sample containing Ca3(PO4)2, unheated, heated at 600 °C and soaked in SBF, e sample containing nanostructured calcium silicate, unheated, heated at 600 °C, f sample containing nanostructured calcium silicate soaked in SBF

A selection of 43Ca MAS NMR spectra of the samples containing 10 wt% Ca3(PO4)2 is shown in Fig. 4. The spectra of the Ca3(PO4)2 reagent (Fig. 4a) and the as-prepared phosphate-containing polymer (Fig. 4b) are as previously published [11] (but with a difference in reported chemical shifts resulting from the adoption of a recently recommended calibration procedure [15]). Heating of this sample and its subsequent soaking in SBF produces little difference in the centre-of-gravity (COG) position of the 43Ca NMR resonance, which broadens on heating and narrows again on soaking, attaining a final COG and width similar to that of synthetic hydroxyapatite (Fig. 4d) [19, 20]. Thus, the environment of the calcium is essentially unchanged from its original state in the starting phosphate reagent by its incorporation in the inorganic polymer or by its subsequent heating and exposure to SBF.

Typical 14.1 T natural abundance 43Ca MAS NMR spectra of inorganic polymers containing 10 wt% Ca3(PO4)2. a Pure Ca3(PO4)2 (from ref. 11), b sample containing Ca3(PO4)2, unheated, c sample containing Ca3(PO4)2, heated 600 °C, d sample containing Ca3(PO4)2, heated 550 °C, soaked in SBF, e pure synthetic hydroxyl apatite. Chemical shift values are the centre-of-gravity peak positions. Uncertainties are shown in parenthesis

Changes in the ionic composition of the SBF during the in vitro experiments

Table 1 presents the ICP analyses for P, Al, Ca and Si of the SBF in which the reference sample and the samples containing the Ca compounds had been soaked for the first 2-week period before replenishment of the SBF. All the inorganic polymers, including the reference sample, absorbed phosphorus from the SBF, its concentration dropping during the first 2 weeks from 57 to ~0 ppm in all but the inorganic polymer containing Ca3(PO4)2; in that case about 6 ppm of phosphorus remained. These results are consistent with the formation of new phosphate phases by reaction with the inorganic polymers, even though XRD did not confirm the formation of such new compounds in the reference polymer or the phosphate-containing material.

Although aluminium was not present at a detectable level in the SBF, all the inorganic polymers released some aluminium into the SBF, more particularly during the first 2-week period, but dropping after the change of the SBF at the end of the second week. During the first 2-week period, the greatest aluminium release (about 2.7 ppm) was from the sample containing Ca(OH)2, and the lowest release (0.05 ppm) was from the sample containing nanostructured calcium silicate. The reference sample and that containing Ca3(PO4)2 released 0.15 and 0.47 ppm of aluminium, respectively, during the first 2 weeks, but in common with all the other samples, this release dropped off significantly after the first change of SBF (0.05 and 0.1 ppm from the reference and Ca3(PO4)2-containing samples, respectively).

Although these aluminium concentrations are reasonably low, as noted above, the literature is contradictory with regard to safe (and possibly beneficial) levels. On this basis, the safest material is probably that containing nanostructured calcium silicate, but the Ca3(PO4)2-containing samples may be equally safe.

The leaching behaviour of calcium and silicon in the SBF is of particular interest, as these elements have been shown to be implicated in new bone formation by the stimulation of gene transcription in osteoblasts [10]. The inorganic polymers containing Ca(OH)2 were found to release Ca to the SBF, the concentration of this element rising to 210 ppm after 2 weeks, and increasing to 500–600 ppm after replenishment of the SBF. By contrast, the reference inorganic polymers and those containing calcium phosphate take up calcium from the SBF, the concentrations decreasing to 30 and 5 ppm, respectively, during the first 2 weeks of soaking. Upon replenishment of the SBF, a similar decrease in calcium concentration was found for these two materials, suggesting the removal of Ca by formation of an insoluble compound or X-ray amorphous gel on the sample surface.

The behaviour of the samples containing nanostructured calcium silicate is intermediate between these two extremes. During the first 2 weeks of soaking, these inorganic polymers remove almost all the calcium from the SBF, but after replenishment of the solution, the samples re-release the absorbed calcium back to the solution, resulting in an increase in Ca concentration to 200 ppm. The replenishment of the SBF increases the concentration of Ca2+ in solution, disturbing the equilibrium and causing some of the previously formed Ca compound on the surface to re-dissolve. Apart from the Ca3(PO4)2-containing samples, which take up Ca from the SBF, the Ca levels released from the other materials are well in excess of the optimum level of 6–8 ppm, even allowing for the fact that the initial Ca concentration in the SBF is 85 ppm.

Although the SBF formulation does not include silicon, the initial Si level is 4.4 ppm, which is introduced either as an impurity from the reagents or from the glassware. All the samples, other than those containing nanostructured calcium silicate, absorb this Si from the SBF. The amount of Si taken up from the SBF varies with the different samples, the greatest amount being taken up by the Ca(OH)2-containing samples, which absorb almost all of the Si. The samples containing nanostructured calcium silicate release 8.9-ppm Si into the SBF after 2 weeks, but on replenishment of the solution, the Si is reabsorbed and its concentration falls to 2.6 ppm after a further 2 weeks. Thus, only the calcium silicate-containing samples have the potential to release the Si necessary for gene transcription; however, the amount released falls somewhat short of the optimum 15–20 ppm.

Scanning electron microscopy

Figure 5 shows a selection of scanning electron micrographs of the heated and SBF-soaked inorganic polymers. The sample containing Ca(OH)2 heated to 600 °C shows a homogeneously distributed mixture of lath-shaped and agglomerate morphologies (Fig. 5a). EDS shows the lath-shaped crystals to contain exclusively Ca, whereas the agglomerates are the aluminosilicate polymer, indicating a lack of reaction between the calcium compound and the aluminosilicate. After exposure to SBF for 7 weeks, EDS shows that the Ca-rich regions have become associated with phosphorus from the SBF, confirming the formation of calcium phosphate phases, whereas the composition of the aluminosilicate-rich agglomerates remains unchanged.

SEM images of Ca-containing inorganic polymers. a Sample containing Ca(OH)2 heated 600 °C, b sample containing nanostructured calcium silicate heated at 600 °C, c sample containing nanostructured calcium silicate heated at 600 °C soaked in SBF, d sample containing Ca3(PO4)2, heated 600 °C, soaked in SBF

The morphology of the heated polymer containing calcium silicate (Fig. 5b) contains agglomerates of large particles and other areas of very fine nanoporous texture. EDS shows that the distribution of Ca is not homogeneous, containing Ca-rich features (one of which is circled in Fig. 5b) that are not associated with Si. This suggests that the Si from the original calcium silicate has entered the geopolymer structure, leaving the Ca in isolated microregions of oxide or carbonate. On exposure of this sample to SBF, cubic crystals are formed (Fig. 5c), shown by EDS to contain Na and Cl. This sodium chloride has crystallised from the SBF by nucleating and growing on the underlying crystal aggregates. EDS also shows that the Ca-rich regions of Fig. 5b become associated with P from the SBF, forming the HA identified by XRD.

The microstructure of the heated inorganic polymer containing Ca3(PO4)2 contains very fine 30–140 nm particles forming 200–500 nm agglomerates. EDS shows that the Ca and P are associated with each other, but occur in regions not homogeneously distributed throughout the sample; the Ca3(PO4)2 is, therefore, behaving as a filler in the polymer matrix. After exposure to SBF, the morphology changes slightly, with the appearance of 500 nm to 1.4 μm acicular crystals, together with pores ranging in size from <30 to 200 nm (Fig. 5d). EDS indicates that SBF treatment causes all the elements to be distributed more homogeneously throughout the sample, possibly due to the exchange of Ca, Si and P from the SBF to the polymer and the exchange of Al from the sample to the SBF, as indicated by the ICP analyses of the SBF. Any new phases formed in these exchange reactions must be X-ray amorphous, as XRD does not indicate the formation of new crystalline phases.

Strength measurements

The average tensile strengths of the inorganic polymers both before and after heating at 600 °C are shown in Table 2, and a selection of literature values for tensile strengths of bone and bioactive materials in Table 3. Direct comparison of the present strengths with literature values for other bioactive materials is problematic, as the values depend on the test method, of which there are a number and in most cases have not been not specified. For example, the two tensile strength values for Bioglass® shown in Table 2 are very different, the lower value having been determined by a method similar to that used in this work, and therefore, more directly comparable with the present values. It is known that diametral tensile strengths are much lower than compressive strengths; reported measurements of the compressive strength σc and tensile strength σt for a porcelain ceramic [23] indicate that for this material, the two strengths are related by:

This suggests that compressive strengths could be up to 11 times greater than tensile strengths; if this reasoning holds for the present materials, then their strengths could be comparable with the bone and Bioglass®/polymer composites. This may be particularly true of the Ca3(PO4)2 inorganic polymer which is the strongest of the materials heated to 600 °C, although slightly weaker than Bioglass® tested by the same method.

Conclusions

Potassium aluminosilicate inorganic polymers containing 10 wt% Ca(OH)2, nanostructured calcium silicate and Ca3(PO4)2 have been investigated in vitro as possible bioactive ceramics. The as-synthesised samples were typical X-ray amorphous aluminosilicate inorganic polymers displaying normal 27Al and 29Si MAS NMR spectra. Heating the samples to 600 °C lowered the amount of alkali leached from the control samples and those containing Ca3(PO4)2 into the SBF, whereas samples containing Ca(OH)2 and calcium silicate leached more alkali after heating, possibly reflecting the higher alkali content used in their synthesis. The XRD inorganic polymer characteristics and MAS NMR spectra are unchanged by heating, but after soaking in SBF, XRD indicates that the samples containing Ca(OH)2 and Ca3(PO4)2 contain crystalline biomineral phases (HA and hydroxylcarbonate apatite). The formation of HA in the Ca3(PO4)2-containing materials was confirmed by 43Ca MAS NMR. However, SEM/EDS suggests the formation of calcium phosphate compounds in all the samples exposed to SBF, including those containing nanostructured calcium silicate; the phosphate formed in these materials is, therefore, X-ray amorphous. The formation of phosphate phases in all the inorganic polymers is consistent with their uptake of P from the SBF. All the samples release small amounts of Al into the SBF, the lowest concentrations being from the samples containing calcium silicate, followed by Ca3(PO4)2. All the polymers take up Si from the SBF, except the calcium silicate samples which release Si into the SBF. The strength of all the present materials is probably adequate for biomedical purposes, but the Ca3(PO4)2-containing materials are the strongest after heating. All these measurements suggest that any of the present compounds may be suitable candidates as a bioactive material, but the combined properties of the Ca3(PO4)2-containing compounds make them the most attractive of the present materials.

References

MacKenzie KJD (2009) In: Provis JL, Van Deventer JSJ (eds) Geopolymers: structures, processing, properties and industrial applications, chap 14. Taylor & Francis, London

Davidovits J (1991) J Thermal Anal 37:1633

Davidovits J (2008) Geopolymer chemistry and applications. Geopolymere Institut, St Quentin

Martin S, Derrien AC, Oudadesse H, Chauvel-Lebret D, Cathelineau G (2005) Eur Cells Mater 9:71

Oudadesse H, Derrien AC, Lefloch M, Davidovits J (2007) J Mater Sci 42:3092. doi:https://doi.org/10.1007/s10853-006-0524-7

Oudadesse H, Derrien AC, Mami M, Martin S, Cathlineau G, Yahia L (2007) Biomed Mater 2:59

Yap AUG, Pek YS, Kumar RA, Cheang P, Khor KA (2002) Biomaterials 23:955

Geyer G, Baier G, Helms J (1998) J Laryngol Otol 112:344

Hanston P, Mathieu P, Gersdorff M, Sindic CJM, Lauwerys R (1994) Lancet 344:1647

Xynos ID, Edgar AJ, Buttery LDK, Hench LL, Polak JM (2001) J Biomed Mater Res 55:151

MacKenzie KJD, Smith ME, Wong A (2007) J Mater Chem 17:5090

Oyane A, Kim H-M, Furuya T, Kokubo T, Miyazaki T, Nakamura T (2003) J Biomed Mater Res 65A:188

Kwak KT, Prasad S, Yao Z, Grandinetti PJ, Sachleben JR, Emsley L (2001) J Magn Reson 150:71

Madhu PK, Pike KJ, Dupree R, Levitt MH, Smith ME (2003) Chem Phys Lett 367:150

Gervais C, Laurencin D, Wong A, Pourpoint F, Labram J, Woodward B, Howes AP, Pike KJ, Dupree R, Mauri F, Bonhomme C, Smith ME (2008) Chem Phys Lett 464:42

Kerber MK, Wereszczak AA, Jenkins MG (1998) Fracture strength, chap 4. Marcel Dekker Inc, New York

MacKenzie KJD, Smith ME (2002) Multinuclear solid state NMR of inorganic materials. Pergamon Press, Oxford

Laurencin D, Wong A, Hanna JV, Dupree R, Smith ME (2008) J Am Chem Soc 130:2412

Laurencin D, Wong A, Dupree R, Smith ME (2008) Magn Reson Chem 46:347

Heimann RB (2002) CMU J 1:23

Thompson ID, Hench LL (1998) Proc Inst Mech Eng 212H:127

Bresciani E, Barata T, Fagundes TC, Adachi A, Terrin MM, Navarro MF (2004) J Appl Oral Sci 4:344

Karpilovskii LP, Letskaya NV (1978) Steklo Keram 9:29

Acknowledgements

We are indebted to James Johnston and Thomas Borrmann for kindly supplying the nanostructured calcium silicate and to David Flynn for assistance with the electron microscopy. MES thanks the University of Warwick, EPSRC, AWM and the ERDF for partial funding of NMR infrastructure at Warwick. AW thanks NSERC for a postdoctoral research fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

MacKenzie, K.J.D., Rahner, N., Smith, M.E. et al. Calcium-containing inorganic polymers as potential bioactive materials. J Mater Sci 45, 999–1007 (2010). https://doi.org/10.1007/s10853-009-4031-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-4031-5