Abstract

In the field of biomaterials applied in bony restoration, systems based on amorphous silicate network present the ability to link to bone matrix. Amorphous geopolymers of the potassium-poly(sialate)-nanopolymer type with a mole ratio Si:Al = 31 were studied for their use as potential biomaterials. This implied a heat treatment at 500 °C in order to reduce the alkalinity of the geopolymer matrix from pH 11.5 to pH 7.1 and to provide high porosity for biological compatibility. 27Al and 29Si MAS NMR spectroscopy has been used to characterise the foamed geopolymers obtained after different thermal treatments at 250 and 500 °C, and with three different mole ratios K2O/SiO2 for the potassium silicate: 0.54; 0.67 and 0.84. Best results in terms of biological compatibility were obtained with a geopolymer matrix resulting from a mole ratio K2O/SiO2. of 0.54, heat-treated at 500 °C.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the field of biomaterials applied in bony restoration, systems based on amorphous silicate network present the ability to link to bone matrix [1]. From the variety of geopolymers developed so far [2], our choice was to use a poly(sialate)-nanopolymer geopolymeric resin with high Si:Al ratio that had been evaluated for fireproof aircraft cabin interior panels, marine structural composites, and infrastructure applications. The use of aluminosilicatespecies in the field of biomaterials is limited by an important factor, namely the amount of “free” aluminium that could provide a certain toxicity. It is therefore mandatory to reduce the amount of aluminium involved in the geopolymerisation. The geopolymer resin used in this study is a potassium aluminosilicate with the empirical formula: Si31O99H24K7Al, i.e.a Si:Al ratio of 31. According to the structure deduced from the elemental composition, X-Ray diffraction, and magic angle spinning nuclear magnetic resonance spectroscopy (29Si and 27Al MAS-NMR) of the cured and dried geopolymer, it may be classified as poly(sialate-siloxo), or poly(metasilicate) with tetracoordinated sialate (–Si–O–Al–O–) crosslinks, according to J. Davidovits’ terminology [3].

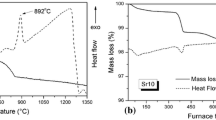

This particular resin hardens to an amorphous or glassy material at moderate temperatures with a density of 2.14 g/cm3 and is one of a family of geopolymeric poly(sialate)-nanopolymer with the ratio Si:Al ranging from 10 to 35. Thermogravimetric analyses had been conducted to determine the weight loss history of the cured geopolymer resin at elevated temperatures. They provide interesting results and properties that have been the base for the present work [4]. It was observed that the poly(sialate)-nanopolymer is thermally stable up to about 250 °C, at which temperature a 7% weight loss occurs over the range 250–625 °C. The mass loss at temperatures >250 °C is assumed to occur through a dehydration reaction which yields gaseous H2O according to:

The dehydration reaction produces steam at many times its liquid volume and pressure resulting in an unconstrained volume expansion of the resin of 488 ± 48% at 850 °C. The resulting morphology is a microcellular amorphous material at room temperature with open porosity and a low pH in the range of 7.5, to be compared with the pH = 11.5 of the starting geopolymer.

It is this foamed material that had been selected as the best candidate for biomaterial study. In our previous works, we elaborated a statistical experimental design to determine an optimal compromise between porosity and compressive strength. Both physical properties present advantages for a potential use as biomaterials in the biomedical field for bony restoration, as soon as the pH of the geopolymer is reduced to values near physiological ones (around 7.2) [5].

The aim of this work is to study the influence of synthesis parameters, in particular the mole K2O/SiO2 ratio and the effect of the thermal treatment temperature on the geopolymer structures, their morphologies and their alkalinity. The 29Si and 27Al MAS-NMR spectroscopy studies focused on the modifications of the geopolymeric structures as well as on the Si and Al environment. The 1H MAS-NMR study will help to understand the pH variations and the morphology modifications of the geopolymer matrix.

Experimental procedures

Geopolymers synthesis and thermal treatments

The preparation of poly(sialate)-nanopolymer with the empirical formula Si31O99H24K7Al, ie. a mole Si:Al ratio of 31:1, involved following steps:

At first, KOH flakes were added to a potassium silicate solution (K2O, 3 SiO2, 21 H2O) to get the appropriate mole ratio K2O/SiO2. Solutions were depolymerised by addition of KOH versus the K2O/SiO2 ratio between 0.54 and 0.8. Three different K2O/SiO2 ratios were used: 0.54; 0.67 and 0.84. The resulting geopolymers were named G54, G67 and G84 accordingly. To 100 g of the resulting solution was added 135 g of SiO2. Al2O3 microsilica powder having a mole ratio Si:Al = 31:1. Table 1 present the synthesis process used for the elaboration of our compunds. This microsilica was provided by the company CORDI-GÉOPOLYMÈRE Sarl, 02100 Saint-Quentin, France. The choice of high ratio Si/Al was conducted by the to have a low concentration of Al because of it’s probably toxic character in the organism. The geopolymer resins were cast into Teflon moulds, covered with Teflon tops and treated at 60 °C during 150 min.

After demolding, the obtained poly(sialate)-nanopolymers were heat treated at 250 or 500 °C during 180 min and labeled : G54_250, G54_500, G67_250, G67_500, G84_250, G84_500. They are listed in Table 2.

Morphology and “in vitro” behaviour of geopolymers

The morphology of different compounds was investigated by JEOL 6301F Scanning Electron Microscope (SEM). SEM allowed a comparison among the geopolymers as a function of the K2O/SiO2 ratios and thermal treatment temperatures.

“In vitro” and “in vivo” studies were carried out with geopolymers G_54. For the “in vitro” studies, the geopolymers were put in physiological fluids—the SBF (Simulated body fluid) with ionic composition near to that of the human blood. The pH of the SBF solution was of 7 units. The effect studied as a function of contact time, from 2 h to 60 days was carried out. Samples extracted from SBF solution were dissolved and analysed by ICP-OES (Inductively Coupled Plasma). This method present some advantages like its multielementary character, its high sensitivity (around 1 ppb) and its accuracy.

For the preliminary “in vivo” experiments, compounds were implanted in the rabbit thighbone. Samplings were made at one, three and six months after implantation.

pH measurements

To obtain pH values of samples, geopolymers were ground and dispersed in distilled water (15 mg of grounded material into 150 ml of water). The solution was stirred and pH values were recorded on pHmeter Orion730. The pHmeter calibration was obtained using two reference solutions at pH 7 and 10.

Sample preparation and NMR measurements

After synthesis and thermal treatments, samples were ground and disposed into zirconia Bruker rotors (4-mm diameter). High-resolution solid state NMR experiments were acquired at room temperature and pressure using a Bruker MAS spectrometer ASX300 (7T). The important parameters for each nucleus are listed on Table 2. The shifts (ppm) have been calculated from various references: aqueous solution of Al(NO3)3 (1 M), tetramethylsilane (CH3)4Si (TMS) and water for aluminium, silicium and proton nucleus respectively.

29Si, 27Al and 1H MAS-NMR spectra have been fitted with dm2002, a MAS-NMR software developed by Massiot [6].

Results

pH values and morphology of geopolymers

The pH values of geopolymers are dislayed in Fig. 1. The variation of the K2O/SiO2 ratio does not influence the alkalinity of the untreated geopolymers (labeled <without>). The increase of the thermal treatment temperature influences the pH values of the aluminosilicates. The higher the temperature is, the lower are the pH values of the geopolymers. The effect of the decrease in the K2O/SiO2 ratio is most important for heat-treated materials than for untreated ones.

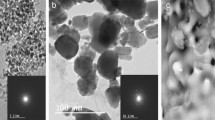

Figure 2 shows the pictures obtained for G54 (untreated and heat treated at 250 or 500 °C). The geopolymer morphology is not influenced by the variation of the K2O/SiO2 ratio. The untreated materials are not porous and the low porosity is just at the surface. After thermal treatment at 250 °C, the increase in porosity of the samples is due to the presence of macro porosities (bigger than 100 μm). After thermal treatment at 500 °C the samples get a micro porosity that occurs in the walls of the macro cavities.

29Si MAS-NMR studies

The broad 29Si MAS-NMR of the unheated geopolymers (G54, G67 and G80) shows four resonances (Fig. 3). Si atoms are in tetrahedral environments, the different contributions correspond to the number of non-bridging oxygens : Q2, Q3 and Q4 correspond to SiO4 tetrahedra with 2, 3 and 4 bridging oxygens, respectively [7–9]. Before thermal treatment, the major resonances are located at −98 and −109 ppm and correspond to Si atoms with 3 (noted Q3) and 4 (noted Q4) bridging oxygens, respectively (Fig. 3; Table 4). Furthermore in all geopolymers, we have two broadly different types of Si Q4 species. The first one, located at about −115 ppm, would be a Q4 Si atom with all Si Q4 next-nearest neighbours. The second specie is located at −109 ppm and would correspond to Si Q4 linked to mixed Q3 and Q4 next-nearest neighbours. These two species of Si atoms are noted henceforth Q4–4 and Q4–3, respectively [10].

The diminution of the quantity of KOH added during the synthesis of geopolymers (decrease of K2O/SiO2 ratio) increases the proportion of Si Q4. This phenomenon is also observed for geopolymers after thermal treatment at 250 °C. For geopolymers heat treated at 500 °C, the ratio (Q3 + Q2)/Q4 remains low (and is mostly due to a strong decrease of Q3 units) (Table 3).

For all poly(sialate)-nanopolymers, a higher thermal treatment temperature improves the polymerisation of the geopolymer matrix. After thermal treatment at 500 °C, the order of abundance changed: Q4 > Q2 > Q3 and the ratio Q4–4/Q4–3 increases compared to untreated geopolymers (Fig. 4; Table 4).

27Al MAS-NMR studies

For all geopolymers, the experimental 27Al MAS-NMR spectra can be split into three asymmetric lines with typical line shapes of Al in amorphous environment (Figs. 5, 6; Table 3). The chemical shift of the major resonance is located at 56 ppm and corresponds to Al in tetrahedral environment (noted AlIV) [11]. The two other contributions are associated to Al in pentahedral and Al in hexagonal environment [12], their chemical shifts are located at 34 and 15 ppm, respectively (Table 5).

The diminution of the ratio K2O/SiO2 does not modify the order of abundance of these three bands. However, the decrease of this ratio favours the proportion of AlVI to the detriment of AlIV. This phenomenon is still observed for geopolymer after thermal treatment at 250 °C (Table 5). The treatment at 500 °C significantly rises the percentage of AlIV : the ratio AlIV/AlVI compared to unheated geopolymers. After the thermal treatment at 500 °C, a higher ratio K2O/SiO2 decreases the percentage of AlIV involved in the sialate (–Si–O–Al–O–) tetrahedral crosslink.

The percentage of AlV does not vary with the variation of the ratio K2O/SiO2 or the thermal treatment temperature. The variations of AlIV and AlVI depend on the thermal treatment temperature and on the mole ratio K2O/SiO2. The aluminium is always found in the sites described above and the isotropic chemical shifts stay constant. The shape of the 27Al MAS-NMR spectra is strongly modified with the thermal treatment temperature. The spectra of all heat-treated geopolymers (G80, G67 and G54) are much broader than the spectra of untreated heat materials (Fig. 6). This is a typical effect for the increase in distribution of the second order quadrupolar interaction in 27Al solid state. The NMR spectroscopy shows that the degree of polymerisation increases with the heat-treatment temperature, for all geopolymers (Table 6).

1H MAS-NMR studies

All the 1H MAS-NMR spectra are broad and it is to note that the variation of the K2O/SiO2 ratio influences only slightly the shape of 1H NMR spectra as well for unheated as for heated geopolymers.

Important modifications are observed in these spectra with the various structural evolutions that occur with the variation of the heat-treatment temperature (intensity scales are the same).

Figure 7 presents the 1H MAS-NMR spectra of untreated geopolymers. All the compositions exhibit a broad and important maximum at about 6 ppm that can be attributed to water molecules.

The major effect on 1H MAS-NMR spectra is observed with the increase of the thermal treatment temperature as seen in Fig. 7. For untreated samples, the major resonance is located at about 6 ppm corresponding to water protons. After thermal treatments, this band strongly decreases and a new important band located between 11 and 16 ppm appears at 250 °C, which can be attributed to OH groups [13]. Between 250 and 500 °C, the rise of the thermal treatment temperature strongly decreases the intensity of the 1H MAS-NMR spectra indicating a very important loss of water by these materials.

Behaviour of geopolymers in contact with SBF solution

After immersion in the SBF solution versus time, samples were extracted and dissolved in HNO3 solution. Compounds and synthetic physiological liquid were analysed by the ICP-OES method.

We focused particularly on the eventual releasing of the Al chemical element from geopolymer matrix to the SBF solution.

Obtained results show the total absence of Al in the SBF solution which was contain geopolymer compounds from 2 h to 60 days. Similar behaviour was observed concerning Ca, P and Mg.

This result shows the mineral chemical stability of the geopolymer network after immersion in physiological liquid until 60 days.

Discussion

We have studied the effect of the variation of the K2O/SiO2 mole ratio together with the thermal treatment temperature, on the geopolymer structures, their alkalinity and their morphology.

Untreated geopolymers (G54, G67 and G80) show similar morphologies characterised by a low porosity. Their high pH values result from the alkaline synthesis conditions. The 1H MAS-NMR study of these samples displays complex spectra characterised by high signal intensities. The structure of these untreated samples is made of a network of Si Q4 and AlIV. Aluminium is constitutive of the network (the sialate crosslink), only a low percentage is present in interstitial sites. The variation of the K2O/SiO2 ratio does not significantly change the structure of the obtained geopolymers.

Thermal treatments increase the geopolymers porosity and change their morphologies (Fig. 2) and also decrease the pH values (Fig. 1). The 1H MAS-NMR qualitative study shows that the morphology changes at 250 °C are linked to a significant decrease of the signal intensity and to a modification of the proportions of the different protons in the structure. The variation of the K2O/SiO2 ratio does not have a major influence on the structure of the poly(sialate)-nanopolymer. Samples treated at 500 °C present the same results as after thermal treatment at 250 °C, yet the signal intensity is much lower.

We have seen that the thermal treatment increases the amount of Si Q4 and AlIV, which stabilises the aluminium in the sialate (–Si–O–Al–O–) network. After the thermal treatment at 500 °C, the diminution of the ratio K2O/SiO2 contributes to the stabilisation of the structure. The geopolymer G54_500 presents the highest amount of AlIV and Si Q4 simultaneously.

It is this geopolymer G54_500 that has been used in our biomaterials applications study. It represents the optimal configuration between porosity, mechanical strength and pH. Biomaterials with these physico-chemical parameters are of great interest in the biomedical field of applications. After thermal treatment, geopolymers are porous and present pH values near physiological values. The increase of the porosity is linked to the departure of protons out of the structure (confirmed by the 1H MAS-NMR). The diminution of the quantity of protons induces the decrease of the pH values.

Aluminium is part of the geopolymer network and it is important to look at the toxicity problems that may be connected with its presence in geopolymers. It has been used in different biomaterials in the Al2O3 chemical form [14–16]. Its toxicity [17, 18] depends on the degradation process of the implanted materials and on the aluminium structure. It has been shown however that the simultaneous presence of silicium and aluminium decreases the aluminium toxicity [19, 20].

The SBF liquid used for the in vitro experiments, the samples and blood extracted from the in vivo experiments, were analysed with the ICP technique. This method offers a high sensitivity with a good accuracy. The results obtained show the total absence of Al release from geopolymers to SBF liquid or to blood.

The results obtained with “in vitro” studies, highlight the chemical stability of geopolymers and confirm the network stability determined by the MAS-NMR investigations.

Initial mineral composition of geopolymers compounds was keep inalterable after immersion in synthetic physiological liquid during 60 days.

Conclusion

In the field of biomaterials for osseous substitution, key parameters are pH values and porosity. As for aluminosilicate species, another factor is of importance, namely the amount of “free” aluminium that could provide a certain toxicity. This study was therefore aimed at characterising the geopolymeric structure in the poly(sialate)-nanopolymer in order to confirm the Al and Si co-ordination in the network. The geopolymer G54_500 (mole ratio K2O/SiO2 = 0.54 and a thermal treatment temperature of 500 °C) shows the highest proportion of AlIV constitutive of the network, a porous morphology and the lowest pH value. The structure of this sample is stable and more than 90% of the aluminium present in the geopolymer are involved in the tetrahedral sialate (–Si–O–Al–O–) crosslink. The stability of G54_500 has been established by 27Al and 29Si MAS-NMR spectroscopy and the biological compatibility confirmed by the ICP analyses for in vitro and in vivo experiments.

References

Hench LL, Wilson J (1986) Ciba Found Symp 121:231

Davidovits J (1991) J Thermal Anal 37:1633

Davidovits J (1999) Proc Second Int Conf Geopolymere 99:9

Lyon RE, Foden AJ, Balaguru P, Davidovits J, Davidovics M (1997) Fire Mater 21:67

Derrien A-C, Oudadesse H, Sangleboeuf J-C, Briard P, Lucasgirot A (2004) J Thermal Anal 75:937

Massiot D, Fayon F, Capron M, King I, Le calve S, Alonso B, Durand J-O, Bujoli B, Gan Z, Hoatson G (2002) Mag Res Chem 40:70

Dupree R, Holland D, Mortuza MG, Collins JA, Lockyer MWG (1989) J Non-Crys Solids 112:111

Engelhardt G (1989) Trac Trends Anal Chem 8:343

Magi M, Lippmaa E, Samoson A, Engelhardt G, Grimmer A-R (1988) J Chem Phys 88:1518

Sen S, Youngman RE (2003) J Non-Crys Solids 331:100

Yasui I, Hagihara H, Arai Y (1988) Mater Sci Forum 32:173

Barbosa VFF, Mac Kenzie KJD, Thaumaturgo C (2000) Int J Inorg Minerals 2:309

Robert E, Whittington A, Fayon F, Pichavant M, Massiot D (2001) Chem Geol 174:291

Shinzato S, Kobayashi M, Choju K, Kokubo T, Nakamura T (1999) J Biomed Mater Res 46:287

Kobayashi M, Nakamura T, Kikutani T, Okada Y, Ikeda N, Shinzato S, Kokubo T (1997) Bioceramics 10:313

Kobayashi M, Kikutani T, Kokubo T, Nakamura T (1997) J Biomed Mat Res 37:554

Faugere MC, Malluche HH (1986) Kidney Int 30:717

D’Haese PC (1988) PhD Thesis, Antwerp

van Landeghem GF, de Broe ME, D’haese PC (1998) Clin Biochem 31:385

Exley C (1998) J Inorg Biochem 69:139

Acknowledgements

The authors would like to acknowledge J.C. Lelannic from the CMEBA, Institut de Chimie, Université de Rennes1, France, for the fruitful collaboration.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Oudadesse, H., Derrien, A.C., Lefloch, M. et al. MAS-NMR studies of geopolymers heat-treated for applications in biomaterials field. J Mater Sci 42, 3092–3098 (2007). https://doi.org/10.1007/s10853-006-0524-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0524-7