Abstract

Poly(N-methylaniline) (PNMA) films were electrosynthesized on carbon paste electrode by oxidation of N-methylaniline (NMA) in acidic aqueous solution and in the presence of anionic surfactant. The films were characterized by cyclic voltammetry and scanning electron microscopy (SEM) and were contrasted with PNMA prepared under identical conditions in the absence of surfactant. The cyclic voltammograms of the film indicate a good redox behavior. Also, SEM studies show that the presence of the anionic surfactant strongly influences the morphology of the polymer product. This polymeric modified electrode has a very good activity toward the nitrite electroreduction via a EC′ mechanism. The electrocatalytic reduction peak current is linearly dependent on the concentration of nitrite. The good linearity between the electroreduction peak current and the concentration of nitrite makes it possible to determine nitrite concentration accurately in the range of 1 × 10−4 to 1.8 × 10−2 M.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

During the last years, conjugated polymers and oligomers, obtained by electrooxidation of the corresponding monomers, have been the subject of a number of studies devoted to the optimization of the electropolymerization conditions and characterization of the resulting polymers [1–14]. The applications of conducting electroactive polymers are manifold in various fields such as metallization of dielectrics, batteries, antistatic coatings [15–17], shielding of electromagnetic interferences, sensors, biosensors [18] and sensor arrays such as electronic nose [19], and in nano fields.

It has been shown recently the interest of using aqueous anionic micellar media, based mainly on sodium dodecylsulfate (SDS), for electrosynthesizing conducting polymers, such as polypyrroles [20–22] and polythiophenes [23–31]. The presence of anionic micelles leads to an increase of the monomer solubility in aqueous solution and a lowering of its oxidation potential thus making possible the electrodeposition of adherent films in aqueous media. The polymeric components can provide, for instance, mechanical strength and thermal stability, while the surfactants retain their tendency to assemble in layered structures. This may be particularly useful for fabrication of multifunctional materials for technological application, e.g., electronic devices, microsensors, separation membrane, and biomembranes, etc. [32–36].

On the other hand, in the field of sensors, nitrite ions have gained renewed attention in view of its relevance to pollution control due to extensive use in fertilizers, detergents, industrial processes, and food technologies [37–39]. Therefore, the detection of nitrite in liquid waste, foods, and electrochemical reduction of nitrite ions to its corresponding reduced form have received continued attention over the past 10 years. Direct electroreduction of nitrite ions requires high overpotential at most bare electrode surfaces. It is well known that modifying the traditional electrode surface opportunely is an effective way of enhancing its electrocatalytic activity. Thus, some chemically modified electrodes with various active mediators immobilized at the electrode surface have been used for the catalysis of electroreduction of nitrite [40–45].

In our previous work, we have demonstrated the ability of ferrocyanide [46], copper hexacyanoferrate [47], and poly(ortho-toluidine) [48] as catalysts for electrocatalytic reduction of nitrite on the surface of carbon paste electrode (CPE).

Herein, we report for the first time on a comparative study of the catalytic properties of poly(N-methylaniline) (PNMA) preparing in the presence and absence of SDS for the electrocatalytic reduction of nitrite. The results show that the PNMA/SDS films have a very good catalytic activity toward the nitrite reduction.

Experimental

Reagents and apparatus

Sulfuric acid, N-methyl aniline, SDS, sodium nitrite, and total chemical reagents were of analytical grade (Fluka). High viscosity paraffin (density = 0.88 g cm−3) from Fluka was used as the pasting liquid for the CPE. Graphite powder (particle diameter = 0.1 mm) from Merck was used as the working electrode (WE).

The electrochemical experiments were carried out using a Metrohm potentiostat/galvanostat model 764 VA trace analyzer instrument. Voltammetry was conducted using a three-electrode cell in which a CPE modified with PNMA/SDS, platinum electrode and Ag|AgCl|KCl (3 M) were used as working electrode, counter electrode, and reference electrode, respectively. Scanning electron microscopy (SEM) was performed on a VG2080573IR instrument.

Preparation of working electrode

Graphite powder and paraffin were blended by hand mixing with a mortar and pestle for preparation of CPE. The resulting paste was then inserted in the bottom of a glass tube (internal radius = 1.7 mm). The electrical connection was implemented by a copper wire lead fitted into the glass tube.

Results and discussion

Electrooxidation of N-methylaniline in the presence of SDS

Before studying the properties of PNMA electrodeposited in the micellar media, we investigated the effect of SDS on the N-methylaniline (NMA) oxidation potential (E ox) values. It was assumed that the E ox was equal to the electropolymerization starting potential; it was determined by applying successively different potentials and noting the potential at which the film formation begins.

It is worthwhile to note that the E ox value changes in the micellar media, according to the order: with SDS < without SDS. In the presence of SDS, E ox was 0.9 V. This result must be compared to the oxidation potential E ox obtained with H2SO4 (without SDS): 0.94 V. These results underline the significant effect of surfactants on the lowering of monomer oxidation potentials. This behavior may be due to specific interactions [49] occurring between the dodecylsulfate or anions and the radical-cations formed during the first step of the electropolymerization mechanism [2].

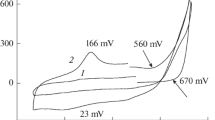

The electropolymerization of NMA was carried out by cyclic voltammetry between 0 and 1.1 V on the surface of CPE. The solutions used contained 0.01 M NMA and 0.01 M of electrolyte (i.e., SDS + H2SO4 or H2SO4). Upon scanning repetitively the potential, we observed the electrodeposition and growth of a dark-brown PNMA film on the CPE surface. As example, electrodeposition voltammograms are presented for the presence and absence of SDS (Fig. 1a and b). The anodic peaks occurring between 400 and 750 mV are assigned to the film oxidation, corresponding to intercalation of SO4 2− and/or DS− anions, whereas the cathodic peaks appearing at 350–650 mV are due to reduction or undoping (release of anions) of the oligomer already formed.

Figure 2 shows that the peak currents in the presence of SDS are larger than in the absence of SDS; in the latter case, the current density reaches a maximum value for about five cycles, and then decreases, indicating a passivation of the electrode. In order to evaluate more precisely the role of surfactant in the electrodeposition rate, we plotted the anodic and cathodic peak current against the number of cycles (Fig. 2). The slope is steeper for the anionic micellar media than in the absence of it, reflecting an enhancing the local concentration of monomer at the electrode/electrolyte interface in the former media.

Effect of SDS concentration on electrochemical polymerization

In order to study the effect of varying concentrations of SDS on PNMA growth, NMA was electropolymerized from monomer solution (0.01 M NMA in 1 M H2SO4) on the surface of a CPE in the presence of varying amounts of SDS (0.01–32 mM). The peak current after preparation of film in 1 M H2SO4 solution has been taken as the index for the rate of polymerization. A plot of peak currents versus SDS concentration is shown in Fig. 3. It is clear from the figure that the rate of polymerization is constant as the concentration of SDS increases and reaches around 0.05 mM SDS. The rate of polymerization then increases rapidly on further increase of the SDS concentration and saturates at around 10 mM. The rate of polymerization does not change significantly when the concentration of SDS is further increased from 10 up to 32 mM. Therefore, we used a concentration of 10 mM SDS to prepare the modified electrode.

Effect of pH

The voltammetric behavior of PNMA/SDS film on the surface of CPE was characterized at various solution pHs. The results showed that the redox behavior of the film was strongly dependent on the pH of the electrolyte solution. The response obtained in less acidic solution showed a gradually loss of electrode activity in the potential range from 0 to 0.9 V (Fig. 4). However, the film was not degraded under these experimental conditions and its response was recovered when the electrode was immersed in a supporting electrolyte solution at pH = 0.7. Therefore, the utility of the modified electrode is limited to strongly acidic solutions.

Effect of scan rate

The formed PNMA film was cycled between 0 and 0.9 V in monomer free electrolyte (1 M H2SO4). The characteristic waves for the films electrosynthesized using SDS were observed. It is worthwhile to note that the anodic and cathodic peak currents vary linearly either with the scan rate (v = 0.01–0.60 V s−1) (Fig. 5A). The influence of scan rate on the redox peak currents of film are shown in Fig. 5B. The peak currents increase linearly with scan rates which are characteristic of electroactive species immobilized on the electrode surface [50, 51].

Surface images

Figure 6 shows the surface morphology of PNMA, PNMA/SDS on the CPE. The polymer formed in the presence of SDS, exhibited amorphous like surface with polydisperse morphology (Fig. 6b). This SEM also revealed the difference between the structures of polymers with and without SDS. In the presence of SDS, the exchange of electron between the monomer and the electrode is facilitated and hence the polymer growth is increased compared with the growth of polymer in the absence of surfactant.

Real surface area of modified electrodes

We used chronoamperometric experiments in ferrocyanide solution and the Cottrell equation [52] to obtain an estimate of the PNMA/CPE and PNMA/SDS/CPE real surface area.

where A is the real surface area of the electrode, D the diffusion coefficient (0.65 × 10−5), and C* the bulk concentration of ferrocyanide. Figure 7 shows the plots of I versus t −1/2 for CPE modified with PNMA and PNMA/SDS. Since the other terms are the same in both experiments, the value of the slope can be considered to be an estimate of A. From the slopes of these plots, it can be concluded that the real surface area of PNMA/SDS/CPE is 5.6 times that of the PNMA/CPE electrode.

Electrochemical behavior of PNMA/SDS film in the presence of nitrite

In this work, in order to investigate whether the PNMA/SDS film has excellent electrocatalytic property, control experiments were carried out by using bare CPE, CPE modified with PNMA, and CPE modified with PNMA/SDS. Voltammetric responses of these electrodes with addition of 4 mM nitrite are presented in Fig. 8.

As shown in Fig. 8, no obvious response can be observed at bare CPE (Fig. 8A), which shows that it is difficult for nitrite to be reduced at bare CPE. The current responses can be found at PNMA/SDS/CP and PNMA/CP electrodes (Fig. 8B and C), which indicate that both polymeric films have direct electrocatalytic properties to the reduction of nitrite. Due to the irreversible electroreduction of nitrite ions, addition of nitrite ions make the reduction peak current of polymer much larger than that of without nitrite while the oxidation peak current of film reduce. The reductive peak potential of NO2 − on PNMA/SDS film electrode is about 0.3 V. The significant decrease of overpotential (500 mV) during electroreduction of nitrite demonstrates that PNMA/SDS film has a good catalytic activity toward the nitrite reduction as follows (EC′ mechanism):

In comparison with PNMA/SDS, PNMA film has low sensitivity and its potential shifts to negative values by adding nitrite concentration (Fig. 8C). In the latter case, redox process is affected by the presence of nitrite in bulk solution, but much less extent. The current response of the PNMA/SDS film to nitrite was examined (Fig. 9A). The response of PNMA film was also investigated for comparison (not shown) and the corresponding calibration curves are shown in Fig. 9B. A linear range from 1 × 10−4 to 1.8 × 10−2 M (LOD (2δ) = 9 × 10−5) has been observed for the PNMA/SDS film (curve b), which is wider than that for PNMA film (1 × 10−3 to 8 × 10−3 M, curve a). In this figure, we showed the error bars to represent overall distribution of the data (mean ± standard error, n = 3). Also, in the linear range, the sensitivity of the PNMA/SDS film was estimated to be 45.4 mA M−1 cm−2, which is about 13 times of that obtained at PNMA film (3.5 mA M−1 cm−2). Compared with common PNMA modify layer, PNMA/SDS modify layer has higher effective surface area and lower diffusion resistance toward electrolyte, thus has higher response current density.

A Voltammetric responses of PNMA/SDS film in the presence of various nitrite concentrations (a) 0, (b) 0.1, (c) 0.5, (d) 0.8, (e) 2.1, (f) 3.1, (g) 4, (h) 7, (i) 10 mM. B Calibration curves for the determination of NO2 − at the surface of (a) CPE modified with PNMA and (b) CPE modified with PNMA/SDS

Also, the electrocatalytic reduction of nitrite in this work has been compared with other research works (Table 1). The results show that PNMA/SDS polymeric film is comparable with other pervious mediators.

Effect of pH

The effect of pH value of the detection solution on the voltammetric response of the PNMA/SDS film to nitrite at fixed concentration of 4 mM was also investigated and the corresponding result is shown in Fig. 10. Apparently, current response of the sensor was greatly influenced by pH value. With the increase of pH, the response current decreased significantly and only small response could be observed when pH was higher than 3.6. The decrease in current response with pH is probably due to the decrease in the electrochemical activity of PNMA. Also, HNO2 deprotonation (pK a = 3.3) was effective for the signal decrease. The PNMA film possesses higher electronic conductivity in acidic solution and the conductivity decreases with the increase of pH value.

Interference study

Possible interference for the detection of nitrite on the surface of modified electrode with PNMA/SDS film was investigated by addition of various ions to 1 M H2SO4 aqueous solution in the presence of 4 mM sodium nitrite. The common ions such as K+, Na+, Mg2+, Cl−, NO3 −, H2PO4 −, HPO4 2−, and SO4 2− in a 50-fold concentration did not show interference to nitrite detection, while Fe3+, I−, and ClO3 − have been found to exhibit serious interference. As for the common interferences in biological samples for the determination of nitrite, acetaminophen in the same concentration of nitrite had no effect on the detection, but the addition of ascorbic acid showed minor interference (<5%) on the sensor response in the same concentration of nitrite.

Stability and reproducibility of the modified electrode

Stability of the modified electrodes with PNMA/SDS film stored in 1 M H2SO4 aqueous solution was investigated by measuring the current responses after 5 days. Nitrite ion was reduced at the same potential and the current response was found to be about same as that obtained by the freshly polymerized electrode, so the electrode showed a stable response. In terms of reproducibility, it has been found that the relative standard deviation of the response current of nitrite for five repetitive measurements was about 4.8% (n = 5). The excellent long-term stability and reproducibility of these electrodes make them attractive for the fabrication of chemical sensors.

Conclusions

A simple method was introduced to modified CPE with PNMA/SDS. SEM showed that the presence of the anionic surfactant affected the morphology of PNMA. Cyclic voltammetry and chronoamperometric studies show this polymeric modified electrode has an electrocatalytic effect toward the nitrite reduction (reduced over voltage value of nitrite in the presence of modified electrode = 500 mV) and well long-term stability. The good linearity between the electroreduction current and the concentration of nitrite makes it practically usable in determining nitrite accurately in the range of 1 × 10−4 to 1.8 × 10−2 (LOD (2δ) = 9 × 10−5).

References

Tourillon G (1986) In: Skotheim TA (ed) Handbook of conducting polymers. Marcel Dekker, New York

Roncali J (1992) Chem Rev 92:711

Tourillon G, Garnier F (1983) J Phys Chem 87:2289

Blankespoor RL, Miller LL (1985) J Chem Soc Chem Commun 90

Sato M, Tanaka S, Kaeriyama K (1986) J Chem Soc Chem Commun 873

Inzelt G (2003) J Solid State Electrochem 7:503

Chen SM, Chuang GH (2005) J Electroanal Chem 575:125

Yang C, Yi J, Tang X, Zhou G, Zeng Y (2006) Reactive Funct Polym 66:1336

Reyna-Gonzalez JM, Aguilar-Martinez M, Bautista-Martinez JA, Rivera E, Gonzalez I, Roquero P (2006) Polymer 47:6664

Badawy W, Ismail K, Medan S (2006) Electrochim Acta 51:6353

Yagan A, Pekmez NQ, Yildiz A (2006) Electrochim Acta 51:2949

Blomquist M, Lindfors T, Vahasalo L, Pivrikas A, Ivaska A (2006) Synth Met 156:549

Yu B, Khoo SB (2005) Electrochim Acta 50:1917

Ruiz V, Colina A, Heras A, Lopez-Palacios J (2004) Electrochim Acta 50:59

Kraft A, Grimsdale A, Colmes A (1998) Angew Chem 110:416

Manisankar P, Vedhi C, Selvanathan G, Somasundaram RM (2005) Chem Mater 17:1722

Manisankar P, Vedhi C, Selvanathan G (2005) J Poly Sci Part A Poly Chem 43:1702

Kros A, Nolte RJM, Sommerdijk NAJM (2002) J Poly Sci Part A Poly Chem 40:738

Malinauskas A (2001) Polymer 42:3957

Naoi K, Oura Y, Maeda M, Nakamura S (1995) J Electrochem Soc 142:417

Barr GE, Sayre CN, Conner DM, Collard DM (1996) Langmuir 12:1395

Moussa I, Hedayatullah M, Aaron JJ (1998) J Chim Phys 95:1551

Bazzaoui EA, Aeiyach S, Lacaze PC (1996) Synth Met 83:159

Sakmeche N, Aaron JJ, Fall M, Aeiyach S, Jouini M, Lacroix JC, Lacaze PC (1996) J Chem Soc Chem Commun 2723

Fall M, Aaron JJ, Sakmeche N, Dieng MM, Jouini M, Aeiyach S, Lacroix JC, Lacaze PC (1998) Synth Met 93:175

Fall M, Aaron JJ, Dieng MM, Jouini M, Aeiyach S, Lacroix JC, Lacaze PC (1998) J Chim Phys 95:1559

Gningue-Sall D, Fall M, Dieng MM, Aaron JJ, Lacaze PC (1999) Phys Chem Chem Phys 1:1731

Sakmeche N, Aeiyach S, Jouini M, Lacroix JC, Aaron JJ, Lacaze PC (1999) Langmuir 15:2566

Fall M, Dieng MM, Aaron JJ, Aeiyach S, Lacaze PC (2001) Synth Met 118:149

Aranzazu-Heras M, Lupu S, Pigani L, Pirvu C, Seeber R, Teriz F (2005) Electrochim Acta 50:1685

Schweiss R, Lubben-Jorn F, Johannsmann D, Knoll W (2005) Electrochim Acta 50:2849

Okahata Y, Enna G, Taguchi K, Seki T (1985) J Am Chem Soc 107:5300

Sun H, Ma H, Hu N (1999) Bioelectrochem Bioenerg 49:1

Liu H, Wang L, Hu N (2002) Electrochim Acta 47:2515

Ogawa K, Wang B, Kokufuta E (2001) Langmuir 17:4704

Kanungo M, Kumar A, Contractor AQ (2002) J Electroanal Chem 528:46

Alonso A, Extraniz B, Martinez MD (1992) Food Add Contam 9:111

Pham EK, Chang SG (1994) Nature 369:139

Li H, Robertson DH, Chamber JQ, Hobbs DT (1988) J Electrochem Soc 135:1154

Ruhlmann L, Genet G (2004) J Electroanal Chem 568:315

Keita B, Mbomekalle IM, Nadjo L, Contant R (2001) Electrochem Commun 3:267

Chad I, Mekki B, Emek B, John G, Patrick F (2004) J Am Chem Soc 126:4934

Nakayama M, Komatsu H, Ozuka S, Ogura K (2005) Electrochim Acta 51:274

Sljukic B, Banks CE, Crossley A, Compton RG (2007) Anal Chim Acta 587:240

Sljukic B, Banks CE, Crossley A, Compton RG (2007) Electroanalysis 19:79

Ojani R, Raoof JB, Zarei E (2006) Electrochim Acta 52:753

Ojani R, Raoof JB, Norouzi B (2008) Electroanalysis 20:1996

Ojani R, Raoof JB, Zarei E (2008) Electroanalysis 20:379

Wroblewski AE, Verkade JG (1979) J Am Chem Soc 101:7720

Krishnamoorthy K, Kanungo M, Contractor AQ, Kumar A (2001) Synth Met 24:471

Manisankar P, Vedhi C, Selvanathan G (2005) J Poly Sci A Poly Chem 43:1702

Bard AJ, Faulkner LR (2001) Electrochemical methods. Wiley, New York

Casella IG, Contursi M (2005) Electrochim Acta 50:4146

Tian Y, Wang J, Wang Z, Wang S (2004) Synth Met 143:309

Guo M, Chen J, Li J, Tao B, Yao S (2005) Anal Chim Acta 532:71

Milczarek G (2008) Electroanalysis 20:211

Chen SM, Fa YH (2003) J Electroanal Chem 553:63

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ojani, R., Raoof, JB. & Norouzi, B. Electropolymerization of N-methylaniline in the presence of sodium dodecylsulfate and its application for electrocatalytic reduction of nitrite. J Mater Sci 44, 4095–4103 (2009). https://doi.org/10.1007/s10853-009-3591-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3591-8