Abstract

Carbazole solid crystals have been mechanically attached to platinum or gold electrodes by two different methods and investigated by cyclic electrochemical quartz crystal microbalance measurements in the presence of aqueous acidic media. It was demonstrated that oxidative dimerization and polymerization can also be accomplished under such conditions. During electropolymerization, anions and water molecules enter the surface layer; however, these species leave the film after the reduction of the polymer formed. The mass changes observed in the course of the redox transformations of polycarbazole film can be explained by potential- and time-dependent sorption/desorption of H+ and ClO4 − ions. The electroactivity of the polymer diminishes in more dilute acid media; however, it is recovered again in concentrated HClO4 solutions. In more dilute acid solution the extent of the water sorption (film swelling) increases.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The preparation, characterization and application of electrochemically active, conducting polymers are still in the forefront of research activity in electrochemistry [1]. An important group of these polymers has been prepared by the electropolymerization of simple heterocyclic compounds such as pyrrole, thiophene and their derivatives; however, it has been discovered that the electropolymerization of compounds of more complicated structures, e.g. phenazines and phenothiazines, is also possible and results in polymers showing bioelectrocatalytic activity [2, 3, 4, 5, 6, 7, 8, 9, 10]. The anodic polymerization of carbazole (dibenzopyrrole) [11, 12, 13] and especially N-vinylcarbazole [14, 15, 16, 17, 18, 19] has received attention in the quest for novel polymer film electrodes. The intense interest in polycarbazoles is also stimulated because of their photoconductivity [20] and possible applications in electrochromic display devices [21] and batteries [22].

The mechanism of the electropolymerization reaction depends on the experimental conditions, especially on the solution composition and the potential applied. Beside the product distribution, the morphology, adherence and electrochemical behaviour of the films formed are affected by the method used for the electropolymerization. Carbazole is practically insoluble in water or acidic solutions; consequently, carbazole oxidation can be studied only in nonaqueous or mixed electrolytes. In most cases, two different solutions have been applied, either acetonitrile containing tetrabutylammonium or Li+ salts [14, 15, 16, 17, 18, 19] or a mixed system consisting of methanol, water and concentrated perchloric acid [12, 13].

About a decade ago, a new technique was introduced by Scholz [23, 24, 25], which was based on the perception that microparticles can be stably attached to an electrode surface and in this way very small amounts of substances can be studied by electrochemical methods. The immobilization of microparticles has become one of the most popular methods, owing to the ease of electrode preparation and the surprisingly good reproducibility of the measurements [25, 26]. Although even the early studies attested that solid state voltammetry is a powerful tool to study water-insoluble organic compounds, this technique is still less used in this area [27, 28, 29, 30, 31, 32, 33, 34, 35, 36, 37, 38, 39, 40], especially in comparison with the number of similar investigations of inorganic or organometallic compounds [25, 26]. It has been shown that not only solid particles but microdroplets can be attached to metal or graphite surfaces [36, 37, 38], which further widened the opportunities.

Combined methods have been also used [25, 26] to gain a deeper understanding of the processes occurring on the surface. In this respect, the application of piezoelectric microgravimetry at an electrochemical quartz crystal microbalance (EQCM) has proven to be very useful, as in the case of other modified electrodes [26, 34, 35, 39]. Carbazole microcrystals can be immobilized on an electrode surface and studied in the presence of aqueous solutions, since no dissolution is expected in water and acidic media. It is certainly an interesting possibility, since no organic solvent is needed that might affect the electrochemical oxidation reaction as well as the behaviour of the polymer film formed. As we have shown in a previous paper [39], another important feature is that by using piezoelectric microgravimetry the mass change referring to the ionic and solvent transport processes can be monitored during the electropolymerization process by itself, since no other processes causing mass increase take place. It differs from the usual electrodeposition of polymer films when the surface mass increases due to the gradual formation of the surface layers and during potential cycling when ionic and solvent sorption-desorption also occur.

Experimental

Carbazole (Sigma) and HClO4 (Merck, analytical grade) were used as received. Doubly distilled water was used. A 10 MHz AT-cut crystal coated with gold or platinum was used in the EQCM measurements. The detailed description of the apparatus and its calibration have been published in our previous papers [39, 41]. The geometrical and piezoelectrically active area of the working electrode was 0.4 cm2. A Pt wire was used as a counter electrode. The reference electrode was a saturated sodium calomel electrode (SCE). All potentials are referred to the SCE.

In separate experiments, a platinum working electrode with area of 0.018 cm2 was also used. This electrode was used also in electropolymerization experiments as well as to check the purity of the solution before and during electrolysis, i.e. we wanted to make certain that the current response observed is entirely due to the electrochemical reaction of the microcrystals attached to the metal surface and not to any species dissolved in the solution.

The electrodes were prepared in two different ways. The microcrystals were attached to the platinum or gold surface by wiping the electrode with a cotton swab or filter paper containing the material [40]. Alternatively, the electrodes were covered by carbazole by using an evaporation technique, i.e. carbazole crystals were dissolved in tetrahydrofuran (THF) and some drops of the solution were placed on the electrode surface (the layer formed in this way may be at least partially amorphous; however, no difference has been observed between the crystalline carbazole and the layer formed by the evaporation technique in respect of their electrochemical behaviour). The electrodes were used after evaporation of the solvent and rinsing with the supporting electrolyte. The evaporation technique was used in EQCM experiments in order to obtain a more uniform layer. However, the "dry" method (according to a visual inspection) also results in a rather uniform coating. Therefore, the Sauerbrey equation was used for the calculation of the surface mass changes, with an integral sensitivity [C f=(2.13±0.2)×108 Hz cm2 g−1] that was determined in separate experiments [40, 41].

The amount of carbazole immobilized on the surface was estimated by measuring the crystal frequency before and after deposition in the dry state. The surface mass determined was in direct proportion to the amount of carbazole content of the drops applied in the case of the evaporation technique. Usually a single drop was placed on the middle of the active crystal surface. The gold or platinum surfaces wetted well, i.e. the drops spread; however, care was taken to cover the piezoelectrically active area only. An immersion of the crystal into 9 mol dm−3 HClO4 solution caused a frequency decrease of ca. 4500 Hz, which is in good agreement with the expected value, taking into account the density and viscosity of the contacting solution. This frequency decrease was observed both for uncoated and coated electrodes, attesting that there is no dissolution of the material attached to the electrode surface as well as that there is no swelling of the virgin organic layer.

All solutions were purged with oxygen-free nitrogen and an inert gas blanket was maintained throughout the experiments. It should be mentioned that the presence of oxygen does not affect the electrochemical reaction studied.

An Elektroflex 453 potentiostat and an Universal Frequency Counter TR-5288 connected with an IBM personal computer were used for the control of the measurements and for acquisition of the data.

Results and discussion

Electropolymerization of carbazole

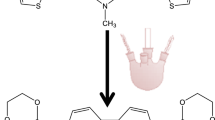

A typical series of cyclic voltammograms obtained for carbazole microcrystals attached to a platinum electrode and using a 9 mol dm−3 HClO4 aqueous electrolyte solution is shown in Fig. 1. The cyclic voltammograms and their changes during repetitive cycling are quite similar to those for carbazole oxidation in acetonitrile [11] or in mixed media [12], although no tendency towards passivation [12, 16] was observed. A high, irreversible oxidation peak appears at ca. E=0.9 V vs. SCE, which is in connection with the formation of carbazole cation radicals, the C-C dimerization of these cation radicals resulting in 3,3'-dicarbazyl and/or polymer of similar structure and the further oxidation of the dimer (polymer) [11, 12, 16, 17]. The progressively developing waves (E1 pa=0.4 V, E1 pc=0.23 V and E2 pa=0.82 V, E2 pc=0.66 V) belong to the reversible redox processes of the dimer or of the polymer (polycarbazole). The formation of polymer can be assumed because of the permanent growth of these waves. The redox processes were accompanied by a colour change from a pale yellow/colourless (reduced) to a dark green (oxidized) form. The irreversible wave at ca. 0.9 V gradually decreases, attesting that the carbazole attached to the platinum surface is transformed into dimer (polymer), and eventually the total amount will be consumed. In accordance with the scheme that has been suggested in the literature [11, 16, 17], the principal species and the possible reaction scheme shown in Figs. 2 and 3, respectively, can be considered.

Scheme of the oxidation and dimerization of carbazole as well as the redox transformations of the dimer/polymer. \( E_{{\rm{C}}^{\rm{ + }} {\rm{/C}}}^{\rm{o}} \approx 0.9\;{\rm{V}},\;E_{{\rm{D}}^{{\rm{2 + }}} {\rm{/D}}}^{\rm{o}} \approx E_{{\rm{P}}^{\rm{ + }} {\rm{/P}}}^{\rm{o}} \approx 0.33\;{\rm{V}},\;E_{{\rm{P}}^{{\rm{2 + }}} {\rm{/P}}^{\rm{ + }} }^{\rm{o}} \approx 0.8\;{\rm{V}}\;{\rm{vs}}{\rm{.}}\;{\rm{SCE}} \)

The oxidation of carbazole can be described by an ECE mechanism where each electrochemical step involves one electron per parent molecule and the coupling reaction is very rapid. Consequently, the primary oxidation wave is a mixture of ECE and EC processes [11]. It has also been found that the ratio between the overall charge associated with the first redox transformation of polycarbazole (PCz) and the net synthesis charge is about 1:4, i.e. its product is an emeraldine-like, half-oxidized polymer [12]. According to a previous EQCM study [19], the formation and redox reaction of poly(N-vinylcarbazole) (PVCz) can be described by the scheme given above; however, the interpretation of the results is complicated due to several processes accompanying the charge transfer steps. A deviation was observed from the molar mass calculated for a perfectly efficient deposition process. It was interpreted by the saturation with polymer of the solution in the vicinity of the electrode surface as well as by the preadsorption of the monomer [19].

In our case, no such effects can arise since there is no deposition from the solution phase. The total amount of carbazole is on the surface from the very beginning of the electrolysis; therefore the mass increase that can be observed is entirely due to the incorporation of counterions and solvent molecules into the organic layer on the electrode surface. In [19] the electropolymerization was carried out potentiostatically by applying a potential step from 0 V to either 0.69 V or 0.72 V. Herein we present results of simultaneous cyclic voltammetric oxidation and the accompanying surface mass changes obtained by piezoelectric microgravimetry at an EQCM. Another difference is that carbazole and not N-vinylcarbazole was studied, which makes the situation somewhat simpler, as well as water and not acetonitrile as solvent being used.

Figure 4 shows the first cycle and the simultaneously obtained frequency changes for a rather thin, virgin carbazole film on gold deposited by the evaporation technique (for the sake of comparison, the background responses are also presented).

The amount of the carbazole on the surface and thickness of this film were estimated from the frequency measured before and after the deposition of the material. The measured value, −1341 Hz, corresponds to ca. 2.5 μg, i.e. to a surface coverage of 3.75×10−8 mol cm−2 [this value agrees well with that estimated from the amount (ca. 2 μL) and concentration (ca. 0.005 M) of the carbazole solution applied]. By using a film density of 1.36 g cm−3 [19, 42], a film thickness of 38 nm can be calculated. Taking into account the possible swelling, the actual film thickness may be somewhat higher, especially after completion of the electropolymerization. Measurements have been carried out with films of different thicknesses; however, the results shown in Fig. 4, which were obtained for a thin film, are very instructive because in this case the total amount of carbazole sample on the surface was oxidized during a single cycle.

As seen in Fig. 5, where the next two cycles are displayed, the high oxidation peak did not appear, and only the reversible redox response of the polymer can be observed. From these data we can calculate the mass changes accompanying the dimerization (polymerization) process and the redox transformations, respectively. In the course of the first irreversible oxidation of the carbazole sample, a −670 Hz frequency decrease can be detected and the total charge consumed for the oxidation was 1.778 mC. By using the Sauerbrey equation [43], the surface mass change can be calculated: Δm=1.26 μg.

The continuation of the experiment shown in Fig. 4: the second and the third cycles

From the charge consumed according to the reaction scheme presented in Fig. 3 (Eqs. 1–3), the amount of the incorporated ClO4 − ions can be estimated. According to the reaction scheme, the number of electrons involved in the oxidation of a carbazole molecule and that of the dimer formed is n=3. However, for the electropolymerization, usually n=2.5 is considered, i.e. two electrons are associated with the polymerization and 0.5 electrons are associated with doping of one monomer unit in PCz [11, 12, 19]. This means that the primary oxidation wave is a mixture of ECE and EC processes and a single charge is distributed for every two monomer units in a reasonably long polycarbazole chain. By using n=2.5 the sorption/desorption of 7.4×10−9 mol ClO4 − ions can be calculated, which corresponds to a mass change of 0.74 μg. Considering also the slight mass loss due to the desorption of H+ ions during the dimerization process, a surplus of 0.52 μg (1.26−0.74) remains. This amount can be assigned to the sorption of solvent molecules, consequently ca. 2.9×10−8 mol H2O molecules, i.e. four H2O molecules per ClO4 − ion also enter the film during the oxidation process. A comparison with the mass of carbazole on the surface reveals that indeed only one half of the carbazole dimers are oxidized to a dication form, since the total amount of carbazole on the surface was 1.5×10−8 mol while the number of positively charged sites was found to be 7.4×10−9 mol.

Redox transformations of polycarbazole

Figure 5 shows the next two cycles, whose curves already exhibit typical responses of polycarbazole films [12, 19], i.e. a reversible wave at lower potentials and a second oxidation process at higher positive potentials. The difference between the first and the subsequent cycles relates to a break-in effect [19] (the first cycle in Fig. 5 was taken after 1 min delay time at −0.1 V). However, in this case, this effect is most likely due to the incomplete reduction during cycling and not to morphological changes. The redox transformations are accompanied by a mass increase during the oxidation and a mass decrease during the reduction. However, a closer inspection of the frequency responses reveals that in fact three sections can be distinguished. Similarly to the redox transformations of polyaniline [41], the current begins to increase, i.e. a certain amount of charge is injected, prior to the frequency decrease (mass increase). Therefore, it may be assumed that, in the first stage of oxidation, deprotonation occurs and the protons leave the film. Owing to the very low molar mass of hydrogen ions, only a very small mass decrease can be expected (provided that H+ ions and not H3O+ ions cross the film/solution interface). This phenomenon can be seen also in fig. 6 of [19]; however, it was not discussed therein.

The second section belongs to the first redox process, while the third relates to further oxidation. There is not a substantial difference in the slopes of the frequency vs. potential or frequency vs. charge plots with respect to these two oxidation steps, although the slopes of the second oxidation process are somewhat smaller. From the slope of the Δm vs. Q plots, an equivalent (apparent) molar mass (M) for the mobile species causing the mass changes can be calculated. If the formation of one positively charged site is expected as a result of a −1e− oxidation process, one ClO4 − ion has to enter the film in order to maintain the electroneutrality. In this case, M=99.5 g mol−1 can be calculated. However, the calculation by using the respective data derived from the experiments shown in Fig. 5 gives a value of M=61. This means (if the silent H+ ion transport is neglected) that the sorption of ClO4 − ions is accompanied by the desorption of water molecules since no other reversible processes can be assumed. Quantitatively, while one ClO4 − ion enters the film, more than two water molecules leave the surface layer.

Similar conclusions from piezoelectric microgravimetric measurements for PVCz films in acetonitrile media have been drawn, i.e. the oxidation of PVCz involves ingress of one anion per mole of redox sites, with simultaneous egress of approximately one solvent molecule at slow scan rates [19]. At higher scan rates it was found that the solvent transfer diminishes, ca. 0.25 solvent molecule per perchlorate ions transferred [19]. According to the elemental analysis data, polycarbazole contains ca. 1 mol H2O per carbazole unit both in reduced and oxidized forms [12]. For the evaluation of the mechanical resonance effects observed for PCz films, solvation of the film was also considered [13]. We have concluded that, in the course of the oxidative electropolymerization of carbazole, water molecules enter the film. On the other hand, the results obtained for the redox transformations indicate that H2O molecules leave the PCz film during oxidation. It may happen if the film is more swollen in its reduced state or it has a rigid structure, i.e. during the oxidation the exchange of ions and solvent molecules is a necessary process because there is no free volume available for the ions, the film volume being more or less constant.

It was derived that, during the electropolymerization, four water molecules per perchlorate ion or two water molecules per carbazole unit enter the surface layer; however, the frequency practically returns to its initial value after completion of the electropolymerization (Fig. 4). After 1 min delay at −0.1 V the cycle started approximately at the same frequency value as before electropolymerization. The permanent frequency decrease is 10–30 Hz, which corresponds to 1–3×10−9 mol H2O, i.e. only this amount of solvent molecules may remain in the film.

This finding is certainly inconsistent with results of the calculation for the redox transformations, since it was found that in the potential region from 0.38 V to 0.75 V, where Δm vs. Q plots give a straight line with a well defined slope, 8.35×10−9 mol ClO4 − ions enter the film while simultaneously 1.78×10−8 mol H2O molecules leave the film. This amount of water is much higher than remained in the film after the electropolymerization. Consequently, we have to assume that even in this potential interval the deprotonation reaction and the desorption of protons still proceed simultaneously with the sorption of counterions, and the solvent motion plays a minor role, if any. It apparently disagrees with previous findings; however, in [19], PVCz in acetonitrile media was studied. Regarding the conclusions drawn from the elemental analysis [12], there is no real contradiction inasmuch as only excess hydrogen and not water was found. Figure 6a and Fig. 6b show the sweep rate dependence of the cyclic voltammograms. The slope of the double logarithmic plot peak current vs. scan rate is ca. 0.8, which indicates an interplay between the surface and diffusional responses.

The cyclic voltammetric responses of the polycarbazole film described in Fig. 4 at different scan rates: a 10 (1), 50 (2) and 100 mV s−1 (3); b 100 (3), 500 (4), 1000 (5) and 2000 mV s−1 (6)

The apparent molar mass calculated from the slope of the Δm vs. Q plot at different sweep rates (v) increases with increasing v, e.g. M=41 and 62 at 10 mV s−1 and 100 mV s−1, respectively. A somewhat higher value for M at 10 mV s−1 can be calculated if the charge and frequency changes belonging to the second oxidation step (from ca. 0.82 V) are not taken into account. At slower scan rates (Fig. 7) this effect plays a more substantial role than that at high scan rates (Fig. 8).

A comparison of the cyclic voltammograms and the frequency changes reveals other interesting features. With decreasing v, both the anodic and cathodic peaks of the first wave shift in direction to the less positive potentials, and at 10 mV s−1 not only the current increase can be observed at high positive potentials as an indication of further oxidation, but the appearance of a second reduction wave at ca. 0.6 V is also evident. After many cycles a not too substantial permanent mass increase can also be detected and, unusually, the mass excursion is less reversible at slow sweep rates than at high sweep rates, as can be seen in Figs. 7 and 8. Furthermore, at 100 mV s−1, between −0.1 V and 0.28 V the change of the frequency was practically zero, while already substantial charge (ca. 0.1 mC) has been consumed. On the other hand, at 10 mV s−1, Δf is more or less proportional to Q from ca. 0.2 V, i.e. from the evaluation of the anodic current. These observations may be explained as follows. At high sweep rates at the beginning of the oxidation the fast moving H+ ions play a dominant role in assuring the electroneutrality; the anions enter the film only at a further phase of oxidation. At higher positive potentials, both the desorption of H+ ions and the incorporation of ClO4 − ions occur. With decreasing sweep rates, this kinetic effect becomes less and less important; however, the relatively slow, not field-driven solvent transport may also contribute to the mass change observed. This is in accordance with the idea expressed in [19].

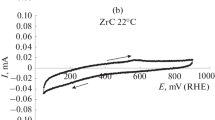

The electroactivity of the film diminishes as the acid concentration decreases. Figure 9 shows the responses obtained in 1 mol dm−3 HClO4 solution. The voltammogram becomes more drawn-out, which indicates that beside the protonation equilibria the film conductivity and the ionic permeability also play a role, as has been shown previously [12]. The total mass change is much smaller and less reversible since the frequency change is smaller by an order of magnitude and there is a permanent mass increase at the end of the cycle. The apparent molar mass that can be calculated from the Δf and Q values measured is about one-half of that determined in the case of high acid concentration. This finding may relate to the increased solvent transport and a polyelectrolyte effect, i.e. the film is more swollen in less concentrated ionic media. Of course, we may also assume that the desorption of protons increases at the expense of the anionic sorption. The film electroactivity is recovered in 9 mol dm−3 HClO4. Figure 10 shows the voltammetric and the EQCM responses after replacing 1 mol dm−3 HClO4 by 9 mol dm−3 HClO4 again.

The voltammetric and the frequency responses of the PCz studied in Fig. 9 after replacing the electrode in 9 mol dm−3 HClO4 again. Scan rate: 50 mV s−1

Although the combined electrochemical and piezoelectric measurements certainly help to elucidate the rather complex events occurring during the electropolymerization of carbazole and the redox transformations of the PCz formed, it is most likely that the "ideal" reaction scheme is only an approximation of the real situation concerning the possible reaction mechanism. It is not unique, since new and more detailed reaction schemes have been appearing even for such widely studied polymers as polyaniline and polypyrrole [1]. For instance, the formation of σ-bonds via intermolecular coupling of two π-radical centers [44] and dimerization and disproportion of the polaronic segments [45] may occur in the case of polycarbazole as well. More data are needed, e.g. more detailed UV-Vis and ESR results, if we wish to understand perfectly the electrochemical behaviour of polycarbazole.

Conclusions

It has been demonstrated that carbazole microcrystals can be attached to platinum or gold surfaces and can be investigated in aqueous acidic solutions by electrochemical techniques without the dissolution of the immobilized samples. The results of the cyclic voltammetric QCM experiments attest the formation of polycarbazole during the first oxidation cycle (or cycles for thicker deposit) and that the process is accompanied by simultaneous sorption of counterions and water molecules. In the course of the cathodic cycle, practically all species sorbed leave the film, i.e. there is no permanent swelling in 9 mol dm−3 HClO4 solution. A comparison of the mass change and the amount of charge consumed during the reversible redox transformations of the PCz polymer suggests that the oxidation of the polymer involves a mixed cationic and anionic charge transport, i.e. the desorption of H+ ions and the sorption of ClO4 − ions. Water sorption is negligible in very concentrated acid solutions, while in more dilute acid the sorption of solvent molecules may also be considered. The expulsion of protons at the beginning of the oxidation and the incorporation of anions at the later stage of oxidation is determined by thermodynamics, as in the case of polyaniline, but also influenced by the kinetics of the sorption/desorption of ions and solvent molecules. The electroactivity of the films prepared in 9 mol dm−3 HClO4 diminishes with decreasing acid concentration; however, they can be activated again in concentrated acid solutions.

The rather complex behaviour of polycarbazole films may be also connected with the formation of side products and intermolecular coupling of two π-radical centers forming a σ-bond, similar to that assumed for polyaniline.

References

Inzelt G, Pineri M, Schultze JW, Vorotyntsev MA (2000) Electrochim Acta 45:2403

Schlereth DD, Karyakin AA (1995) J Electroanal Chem 395:221

Karyakin AA, Karyakina EE, Schmidt HL (1999) Electroanalysis 11:149

Kontrec J, Svetlicic V (1998) Electrochim Acta 43:589

Kertész V, Bácskai J, Inzelt G (1996) Electrochim Acta 41:2877

Brett CM, Inzelt G, Kertész V (1999) Anal Chim Acta 385:119

Inzelt G, Csahok E (1999) Electroanalysis 11:744

Cai CX, Xue KH (1997) J Electroanal Chem 427:147

Benito D, Garcia-Jareno JJ, Navarro-Laboulais J, Vicente F (1998) J Electroanal Chem 446:47

Benito D, Gabrielli C, Garcia-Jareno JJ, Keddam M, Perrot H, Vicente F (2002) Electrochem Commun 4:613

Ambrose JF, Nelson RF (1968) J Electrochem Soc 115:1159

Mengoli G, Musiani MM, Schreck B, Zecchin S (1988) J Electroanal Chem 246:73

Sarawathi R, Hillman AR, Martin SJ (1999) J Electroanal Chem 460:267

Dubois JE, Desbene-Morvernay A, Lacaze PC (1982) J Electroanal Chem 132:177

Desbene-Morvernay A, Lacaze PC, Dubois JE (1983) J Electroanal Chem 152:87

Desbene-Morvernay A, Dubois JE, Lacaze PC (1985) J Electroanal Chem 189:51

Compton RG, Davis FJ, Grant SC (1986) J Appl Electrochem 16:239

Skompska M, Peter LM (1995) J Electroanal Chem 383:43

Skompska M, Hillman AR (1997) J Electroanal Chem 433:127

Block H (1979) Adv Polym Sci 33:93

Monk PMS, Mortimer RJ, Rosseinsky DR (1995) Electrochromism. VCH, Weinheim

Kakuta T, Shirota Y, Makawa H (1985) J Chem Soc Chem Commun 553

Scholz F, Nitschke L, Henrion G (1989) Naturwissenschaften 76:71

Scholz F, Nitschke L, Henrion G, Damaschun F (1989) Naturwissenschaften 76:167

Scholz F, Meyer B (1998) Voltammetry of solid microparticles immobilized on electrode surfaces. In: Bard AJ, Rubinstein I (eds) Electroanalytical chemistry, vol 20. Dekker, New York, pp 1–86

Fiedler DA, Scholz F (2002) Electrochemical studies of solid compounds and materials In: Scholz F (ed) Electroanalytical methods. Springer, Berlin Heidelberg New York, pp 201–222

Evans CD, Chambers JQ (1994) Chem Mater 6:454

Bond AM, Fletcher S, Marken F, Shaw SJ (1996) J Chem Soc Faraday Trans 92:3925

Bond AM, Marken F (1994) J Electroanal Chem 372:125

Bond AM, Marken F, Hill E, Compton RG, Hugel H (1997) J Chem Soc Perkin Trans 2 1735

Komorsky-Lovric S (1997) J Solid State Electrochem 1:94

Zhuang QK, Scholz F, Pragst F (1999) Electrochem Commun 1:406

Keyes TE, Foster RJ, Bond AM, Miao W (2001) J Am Chem Soc 123:2877

Shaw SJ, Marken F, Bond AM (1996) J Electroanal Chem 404:227

Scaboo KM, Grover WH, Chambers JQ (1999) Anal Chim Acta 380:47

Marken F, Compton RG, Goeting CH, Foord JS, Bull SD, Davies SG (1998) Electroanalysis 10:821

Komorsky-Lovric S, Lovric M, Scholz F (2001) J Electroanal Chem 508:129

Gergely A, Inzelt G (2001) Electrochem Commun 3:753

Fehér K, Inzelt G (2002) Electrochim Acta 47:3551

Inzelt G (2002) J Solid State Electrochem 6:265

Inzelt G (2000) Electrochim Acta 45:3865

Bargon J, Mohmand S, Waltman RJ (1983) IBM J Res Dev 27:330

Sauerbrey G (1959) Z Phys 155:206

Heinze J, Tschuncky P, Smie A (1998) J Solid State Electrochem 2:102

Neudeck A, Petr A, Dunsch L (1998) J Phys Chem B 103:912

Acknowledgements

Financial support by the National Scientific Research Fund (OTKA T031762) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Inzelt, G. Formation and redox behaviour of polycarbazole prepared by electropolymerization of solid carbazole crystals immobilized on an electrode surface. J Solid State Electrochem 7, 503–510 (2003). https://doi.org/10.1007/s10008-003-0357-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-003-0357-0