Abstract

Calcium alginate film containing ellagic acid as a functional material was formed on polyethylene nonwoven sheet by the reaction of sodium alginate with calcium chloride in the presence of ellagic acid. The film had the intelligent function of release of ellagic acid triggered by sodium ion. This response resulted from conversion of the water-insoluble calcium alginate to water-soluble sodium alginate. The optimal conditions for the intelligent calcium alginate film prepared on the polyethylene surface were 0.5% CaCl2 solution and 0.05 or 0.1% sodium alginate solution.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent times, intelligent materials that exhibit functionality in response to external stimuli such as temperature [1–4], pH [3–6], and chemicals [7–9] have been actively studied. Drug delivery systems [3, 4], self-repairing materials [10, 11], and intelligent windows [12] are examples of applications of intelligent materials.

We have previously applied this concept of intelligent material to a functional paper [13–15]. In the present work, a polyethylene nonwoven sheet was functionalized with an alginate film that was able to release ellagic acid [16, 17] in response to sodium ion (Na+). Ellagic acid [16, 17] (Fig. 1) is a polyphenolic compound found in different fruits like strawberry and has various effects like antibacterial, anti-inflammatory, and a moisturizer for skin. The objective was to produce a sheet that is able to release the moisturizer in response to Na+ in sweat or urine, and thus to maintain the level of moisture in the skin.

The alginate polymer film with this intelligent function was prepared using sodium alginate (Na-Alg) (Fig. 2a) used in the food, pharmaceutical and biotechnology industries, ellagic acid, and calcium chloride (CaCl2). Na-Alg, which is soluble in water, is known to form calcium alginate (Ca-Alg) gel in the presence of calcium ion (Ca2+) [18–22]. The Ca-Alg gel has a three dimensional network (‘egg box’) structure, and has been widely used in the encapsulation of drugs, enzymes, and other applications [20–22].

Ca-Alg gel, incorporating ellagic acid, was formed directly on the polyethylene sheet surface, and conversion of the gel to film was accomplished by drying the coated sheet at 105 °C. Functional paper usually has been prepared by coating the functional materials with a binder. However, functional paper prepared by such a coating procedure would not be sufficiently functional for the present purpose, because the surface of the functional materials (e.g. alginate film with the intelligent function) would be covered with binder. Consequently, a technique that fixes the Ca-Alg film on the sheet surface, without using a binder, is important for the intelligent function. The water-insoluble Ca-Alg film is converted to water-soluble Na-Alg by an ion-exchange reaction that substitutes Na+ for Ca2+ as shown in Fig. 2b. By utilizing this property of the Ca-Alg film, an intelligent function is imparted to the film, in the form of the release of ellagic acid in response to Na+.

The characteristics of the Ca-Alg film formed on the polyethylene nonwoven sheet are presented in this report. Suitable conditions for the intelligent function of the Ca-Alg film were found, and the effects of the CaCl2 and Na-Alg concentrations on the release amounts of ellagic acid from the Ca-Alg coating were elucidated.

Experimental section

Materials

Sodium alginate (with solution viscosity 80–120 mPa s), anhydrous ellagic acid, sodium chloride (NaCl), and anhydrous calcium chloride (CaCl2) used as a source of divalent cations, were purchased from Wako Pure Chemical Industries Ltd. Nonwoven polyethylene used as the substrate was supplied by Unicharm Corporation.

Preparation of calcium alginate film containing ellagic acid on polyethylene surface

A 30 × 25 mm2 sheet of nonwoven polyethylene impregnated with an aqueous solution of 0.25–1.0% (w/w) CaCl2 was immersed in 0.05–0.5% (w/w) Na-Alg solution (50 mL) containing ellagic acid (0.25 g) for 5 min, and then dried at 105 °C for 30 min.

Evaluation of the amount of ellagic acid fixed on the sheet

A 10 × 10 mm2 prepared sheet was immersed in 0.01 M sodium hydroxide (5 mL) for 30 min at room temperature. After filtration of the solution using a membrane filter, a 1 μL aliquot was subjected to high-performance liquid chromatography (HPLC) analysis without further purification.

Evaluation of the amount of ellagic acid released from the sheet in response to sodium ion

A 10 × 10 mm2 prepared sheet was immersed in 0.65% NaCl (3 mL) or distilled water (3 mL) for 30 min at room temperature in a laboratory dish. The dish was then dried at 105 °C, and the ellagic acid residue was dissolved with 0.01 M NaOH (3 mL). After filtration of the solution with a membrane filter, a 1 μL aliquot was subjected to HPLC analysis without further purification.

The amounts of ellagic acid released from the sheet (RA) were evaluated by calculating according to:

where W Na is amount of ellagic acid released from the sheet immersed in NaCl solution for 30 min, W W is the corresponding quantity for sheet immersed in distilled water for 30 min, and W 0 is the amount of ellagic acid fixed on the sheet.

Quantification of ellagic acid

Ellagic acid concentration was determined using HPLC (LC-10A series, Shimadzu) equipped with a C18 column (Gemini C18, Phenomenex, 150 × 4.6 mm) and a UV detector (254 nm). The mobile phase was an 18:82 parts by volume acetonitrile: 20 mM phosphorous acid solution, with constant flow rate 1.0 mL min−1. The column temperature was 40 °C.

Characterization of calcium alginate gel containing ellagic acid on the polyethylene surface

Fourier transform infrared (FT-IR) attenuated total reflection (ATR) spectra were obtained using an FT-IR-480 (JASCO, Inc.) spectrometer at a resolution of 4 cm−1. 100 scans were accumulated in the spectral range 4000–700 cm−1. The sheet surface was analyzed, after platinum coating, using scanning electron microscopy (SEM, JSM-5510LV, JEOL Inc.) with accelerating voltage 15 kV.

Results and discussion

Characteristics of calcium alginate film containing ellagic acid formed on the sheet surface

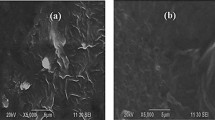

Figures 3 and 4 show FT-IR spectra and SEM images of the sheet treated with Na-Alg and CaCl2 solution. In Fig. 3b, the characteristic bands of Ca-Alg without ellagic acid are the C=O stretching vibration at 1600 cm−1, a –CH2– in-plane bending vibration at about 1420 cm−1 and a C–O–C stretching vibration at approximately 1035 cm−1. In the case of Ca-Alg with ellagic acid, mostly bands attributable to ellagic acid were observed except for the peaks due to the Ca-Alg at about 1600, 1420, and 1035 cm−1 (Fig. 3c). Thus, the Ca-Alg film containing ellagic acid was formed on the sheet surface by reaction between Na-Alg and CaCl2. The formation of Ca-Alg film containing ellagic acid on the polyethylene surface was also confirmed by SEM (Fig. 4).

SEM images of a blank sheet and b sheet with Ca-Alg film incorporating ellagic acid. Experimental conditions as per Fig. 3

The Ca-Alg film on the sheet surface was formed by crosslinking reaction between Ca2+, from the CaCl2 adsorbed on the sheet and the carboxyl group of the Na-Alg.

Ellagic acid release from the sheet in response to sodium ion

When Ca-Alg film on the sheet was prepared without CaCl2, the magnitude of W 0 was in the range 0.06–0.14 g m−2 as shown in the Table 1. These values were smaller than for the Ca-Alg film prepared using CaCl2, which could fix the ellagic acid from about 2.0 to 8.0 g m−2. Consequently, fixation of ellagic acid on the sheet was caused by the formation of Ca-Alg film crosslinked between Na-Alg and Ca2+, and the ellagic acid was encapsulated in the three dimensional network formed by the Ca-Alg film.

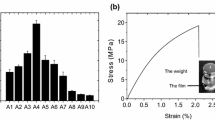

As shown in the Table 1 and Fig. 5, RANa was much larger than RAW when the concentrations of the CaCl2 and Na-Alg solutions were 0.25 and 0.5%, and 0.05 and 0.1%, respectively. Figure 6 shows FT-IR spectra of the sheet after impregnation with NaCl solution or distilled water. The bands attributed to Ca-Alg film and ellagic acid in Fig. 3c are not present in Fig. 6b. In the case of distilled water, bands due to Ca-Alg and ellagic acid on the sheet are shown in Fig. 6a. In the SEM images of Fig. 7a or b, the presence or absence of the Ca-Alg film on the sheet was confirmed, respectively. These results demonstrated that Ca-Alg film was soluble only in NaCl solution. In other words, the Ca-Alg film on the sheet was able to release ellagic acid in response to Na+, and that functionality was selective to Na+. This intelligent function with selective response to Na+ is believed to result from the ion-exchange reaction between Ca-Alg and NaCl shown in Fig. 2b. It is well known that Na-Alg is soluble in water, while Ca-Alg is insoluble. Ellagic acid is released from the Ca-Alg film by conversion of the insoluble Ca-Alg film to soluble Na-Alg, following impregnation of the Ca-Alg film by NaCl solution and ion exchange.

FT-IR spectra of sheet impregnated with (a) distilled water and (b) 0.65% NaCl solution. Experimental conditions as per Fig. 3

SEM images of sheet impregnated with a distilled water and b 0.65% NaCl solution. Experimental conditions as per Fig. 3

In the case of Ca-Alg film prepared using 0.2% and 0.5% Na-Alg solution, RANa was slightly greater than or smaller than RAW, as shown in the Table 1 and Fig. 5. In addition, as shown in Fig. 5, the Ca-Alg films formed using 0.2 and 0.5% Na-Alg solution did not release ellagic acid, and the films prepared with 1.0% CaCl2, and 0.05% or 0.1% Na-Alg solutions behaved similarly. The Ca-Alg films formed using increased concentrations of Na-Alg and CaCl2 solutions should have been more highly crosslinked, due to the larger number of crosslinking sites (carboxyl groups) and crosslink-forming cations at higher Na-Alg and Ca2+ concentrations. Consequently, it was difficult for the subsequent ion-exchange reaction between Ca2+ and Na+ to occur, and the RANa values for Ca-Alg films prepared using high concentrations of Na-Alg and CaCl2 were correspondingly very low.

The RANa values of the sheets formed by 0.25% CaCl2 solution were smaller than those of the sheets formed by 0.5% CaCl2, when the concentrations of Na-Alg solutions were 0.05 and 0.1%. These results can be attributed to the smaller crosslink density of the Ca-Alg films formed with 0.25% CaCl2 solution. The Ca-Alg films with lower crosslink density would have retained less Na+ ion during the period of ion-exchange reaction between Ca2+ in the Ca-Alg films and Na+ in the NaCl solution. The extent of ion exchange would have been reduced, with a consequentially smaller release amount of ellagic acid.

The optimal conditions for the intelligent functionality of ellagic acid release in response to Na+ ion were 0.5% CaCl2 solution and 0.05 or 0.1% Na-Alg solution. It is suggested that Ca-Alg film prepared under those conditions led to effective Na+ ion trapping by the Ca-Alg film, hence efficient conversion of the insoluble Ca-Alg film to soluble Na-Alg and concomitant release of ellagic acid.

Thus adsorption of Na+ and ion-exchange reaction between Ca2+ and Na+ was important for release of ellagic acid from the sheet in response to Na+, and mainly depended on the concentrations of the Na-Alg and CaCl2 solutions.

Conclusions

Ca-Alg film containing ellagic acid formed on the surface of polyethylene nonwoven sheet by the reaction between Na-Alg and CaCl2 has an intelligent functionality whereby ellagic acid is released from the film in response to Na+. The Ca-Alg film formed on the sheet is solubilized by conversion of Ca-Alg to Na-Alg via ion-exchange between Ca2+ and Na+, resulting in release of ellagic acid. The intelligent function of the Ca-Alg film is dependent on the concentrations of the Na-Alg and CaCl2 solutions; the optimum concentrations are 0.5% CaCl2 solution and 0.05 or 0.1% Na-Alg solution. This technique is expected to be useful in the preparation of sheets for release of a variety of functional materials in response to Na+.

References

Yoshida R, Uchida K, Kaneko Y, Sakai K, Kikuchi A, Sakurai Y, Okano T (1995) Nature 374:240

Beines PW, Klosterkamp I, Menges B, Jonas U, Knoll W (2007) Langmuir 23:2231

Zhang K, Wu XY (2004) Biomaterials 25:5281

Fundueanu G, Constantin M, Ascenzi P (2008) Biomaterials 29:2767

Annaka M, Tanaka T (1992) Nature 355:430

Dias CI, Mano JF, Alvesab NM (2008) J Mater Chem 18:2493

Hiroki A, Maekawa Y, Yoshida M, Kubota K, Katakai R (2001) Polymer 42:1863

Chu LY, Li Y, Zhu JH, Wang HD, Liang YJ (2004) J Control Release 97:43

Kataoka K, Miyazaki H, Bunya M, Okano T, Sakurai Y (1998) J Am Chem Soc 120:12694

Yamaguchi M, Ono S, Terano M (2007) Mater Lett 61:1396

White SR, Sottos NR, Geubelle PH, Moore JS, Kessler MR, Sriram SR, Brown EN, Viswanathan S (2001) Nature 409:794

Watanabe H (1998) Sol Energy Mater Sol Cells 54:203

Ichiura H, Morikawa M, Fujiwara K (2005) J Mater Sci 40:1987. doi:https://doi.org/10.1007/s10853-005-1221-7

Ichiura H, Morikawa M, Ninomiya J (2006) J Mater Sci 41:7019. doi:https://doi.org/10.1007/s10853-006-0789-x

Ichiura H, Ohi T, Oyama H, Yokota H, Kunitake T, Ohashi S, Morikawa M (2008) J Mater Sci 43:1486. doi:https://doi.org/10.1007/s10853-007-2341-z

Gutiérrez RMP, Mitchell S, Solis RV (2008) J Ethnopharmacol 117:1

Sudheer AR, Muthukumaran S, Devipriya N, Menon VP (2007) Toxicology 230:11

Bajpai SK, Sharma S (2004) React Funct Polym 59:129

Aslani P, Kennedy RA (1996) J Control Release 42:75

Sugiura S, Oda T, Izumida Y, Aoyagi Y, Satake M, Ochiai A, Ohkohchi N, Nakajima M (2005) Biomaterials 26:3327

Srivastava R, McShane MJ (2005) J Microencapsul 22:397

Iskakov RM, Kikuchi A, Okano T (2002) J Control Release 80:57

Acknowledgement

This work was supported in part by a Grant-in-Aid for Cooperation of Innovative Technology and Advanced Research in Evolutional Area (CITY AREA) from the Ministry of Education, Science and Culture, Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ichiura, H., Konishi, T. & Morikawa, M. Alginate film prepared on polyethylene nonwoven sheet and its function for ellagic acid release in response to sodium ions. J Mater Sci 44, 992–997 (2009). https://doi.org/10.1007/s10853-008-3220-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-3220-y