Abstract

Polymer composites (PCs) with a polyurethane (PU) matrix filled with magnetic filler (MnZn ferrite) and hybrid polymer composites (HPCs) consisting of this magnetic filler and various types of conductive fillers (carbon black, carbon fibers, aluminum powder, polypyrrole) are prepared. The matrix structure of a HPC is formed (i) by a polymer filled with conductive filler, which forms the skeleton of an infinite cluster, and (ii) by ferrite particles that are larger than conductive particles. Thus, an HPC represents an ensemble of ferrite particles each of which is surrounded by a conductive medium and can be considered as a “core–shell” structure. The development of a core–shell structure is evidenced by the lower electric percolation threshold in an HPC compared with that in PU filled with conductive filler. Magnetic and dielectric spectra of PCs and HPCs are studied in the frequency range from 1 MHz to 10 GHz. Hybrid systems exhibit a considerable enhancement of magnetic losses compared with PCs. The enhancement of magnetic losses in HPCs is due to the conduction currents that are induced in the conductive shell by a microwave magnetic field.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

At present, the development of new electromagnetic wave absorbers (EWAs) is being encouraged as these materials provide an efficient means for reducing radiation pollution generated by electromagnetic devices (TV and radio broadcasting, radar systems, microwave ovens, mobile phones, etc.). Ferrite polymeric materials with a hybridized system have been the subject of considerable interest in this research area. The reason is that these systems allow one to alter the electromagnetic properties of materials and thereby to meet requirements such as the matching condition ε* ≈ μ* (where ε* is the complex permittivity and μ* is the complex permeability) and high absorption and thus reduce the reflection coefficient of EWAs and broaden their operating frequency band (f min − f max).

Ferrite powders are often used as filling components for preparing EWAs as the complex permeability (μ* = μ′ − jμ″) of such magnetic materials exhibits strong frequency dependence [1–7]. Moreover, it has been found that embedding ferrites into a polymer matrix together with the modification of the shape, size, concentration, and the size distribution of ferrite particles may strongly change the frequency dependence of μ* [8–11]. This change is mainly associated with additional disorder in the filler–matrix interface. This disorder is responsible for the magnetic discontinuity in the composites, which leads to the broadening of the resonance bandwidth and a shift of the resonance frequency to higher frequencies. However, at the same time, composite materials exhibit a considerable decrease in μ* compared with bulk ferrite materials. That is why one always seeks a compromise between the value of permeability and the critical frequencies.

One way of improving the electromagnetic properties of ferrite composites in microwave region is the development of hybrid polymer composites (HPCs) on the basis of multicomponent fillers, for example, permalloy–Ni-Zn ferrites [12], barium ferrite–carbon black [13], etc. In the permalloy–NiZn hybrid material, enhancement of complex permeability was observed compared with that of polymer composites (PCs) filled with permalloy or NiZn ferrite. We suggest that the observed permeability enhancement can be attributed to the interaction between embedded ferromagnetic metal particles (permalloy) and NiZn ferrite particles. The incorporation of both barium ferrite and carbon black powder into a rubber matrix changes the electromagnetic properties of the material and shows a broadband absorption in the microwave frequency range. Another example of a multicomponent system was reported by Josyulu and Sobhanadri [14]; they introduced a mixture of ferrites (with different chemical structures and characteristic resonance frequencies f r) into a polymer matrix. Such a hybrid component system exhibits, on one hand, a decrease in the μ*; however, on the other hand, it is characterized by a broadened peak of magnetic losses due to the frequency superposition phenomenon.

Another type of HPCs is a core–shell structure containing two different phases, one of which is ferromagnetic and the other represents a thin conductive layer. This structure automatically leads to a change in the electron transport through the interface and thus can strongly influence the electromagnetic properties of composites. An example of such a system is given by a composite filled with coated ferromagnetic particles [15–19]. In our previous study, we established that the formation of a p-semiconductive nanolayer on the surface of multidomain MnZn ferrite particles changes the character of the frequency dispersion of permeability; this fact manifests itself in the shift of the resonance frequency from the MHz band close to the GHz band, which is accompanied by a change in the frequency dispersion of μ* [18, 19]. The interfacial effect between MnZn ferrite and polyaniline (PANI) nanofilm is responsible for the shift of the resonance frequency. This effect strongly depends on the specific area of the ferrite–PANI interface and, moreover, on its electromagnetic properties. This fact is very important for electromagnetic shielding applications because it enables one to control the characteristic resonance frequency of the composite (by an appropriate choice of the size of the ferrite particles and the PANI film structure) and the properties of the composite.

The concept of a core–shell structure is widely used in the investigation of filled polymers as well; for example, in [20], the concept of a core–shell structure was applied to the microstructure of a composite obtained by the compression molding of a high-density polyethylene powder mixed with carbon black. Owing to the structure of the composite in which carbon-black particles form a dense layer (shell) around polyethylene particles, the authors of [20] achieved a low electric percolation threshold (C Pσ ∼ 1 vol.%).

In the present work, we investigate the properties of composites based on mixed fillers (ferrite and conductive particles) that are introduced into a polymer matrix. We assume that such a composite forms a core–shell-like microstructure. Here, the ferrite particles are surrounded by a polymer shell filled with conductive particles, which form a percolating network. This three-component system is referred to as a HPC. We discuss a correlation between the electromagnetic properties and the microstructure of HPCs.

Experimental

Materials

Polyurethane (PU) produced by AXSON (UR 3420, France) was used as a polymer matrix. This type of matrix was chosen because of its convenient mechanical properties (final hardness = 50 Shore, tensile strength = 3.5 MPa, elongation at break is more than 1000%) and especially high elasticity.

Sintered MnZn spinel-like ferrite used in this study was produced by Ferropribor (Russian Federation) and is characterized by the initial permeability μ i ∼2700–3000, the maximum permeability μ max ∼ 3700–5200, the saturation magnetization M s = 3.5 kGs, the Curie temperature T N = 473 K, the conductivity σ f = 2 S cm−1, and the density ρ f = 4.8 g cm−3. The composition of this ferrite is 53.75 mol.% Fe2O3, 26.10 mol.% MnO and 20.15 mol.% ZnO. Ferrite particles with an average particle size of 40–60 μm were prepared by mechanical grinding of sintered ferrite cores.

We used different types of electrically conductive fillers: carbon black (CB), carbon fibers (CF), aluminum powder (Al), and polypyrrole (PPy). PPy belongs to electrically conductive polymers. A detailed description of conductive fillers is given in Table 1.

Preparation of composites and their SEM images

PC materials with different ferrite concentrations (10–57 vol.%) were prepared by mixing ferrite particles in PU prepolymer, molding, and curing at 80 °C for 4 h.

Ferrite-rich composites (with more than 60 vol.% of ferrite) were prepared by compressing (1500 MPa) ferrite with polyvinyl alcohol in toroidal compression forms.

HPCs combining 40 vol.% of ferrite with conductive fillers were prepared on the basis of PU prepolymer using the same technology as in the case of PCs. The densities of these HPCs are represented in Table 1.

The morphology of the samples was investigated by a JEOL JEM-200CX scanning electron microscope (SEM).

Preparation of samples for measuring dc conductivity, complex permeability, and complex permittivity

Toroidal samples with an outer diameter of 8 mm, inner diameter of 3 mm, and thickness of 2–2.5 mm were cut out of polymer-filled ferrite plates. These samples were used for investigating the complex permeability of ferrite materials in the range from 1 MHz to 3 GHz by an Agilent E4991A Impedance/Material Analyser (USA).

Samples for measuring the permittivity (1 MHz to 3 GHz) and the dc conductivity were prepared in the form of a slab with the base size of 15 × 15 mm2 and thickness of 1 mm. The permittivity spectra (1 MHz to 3 GHz) were measured by the Impedance/Material Analyser Agilent E4991A. The dc conductivity of the samples was calculated from their current–voltage characteristics measured by a Keithley 6517A electrometer (USA).

Rectangular samples of polymer–ferrite composites with a cross-section area of 1 × 1 mm2 and length of 15 cm were used for determining ε*(f) and μ*(f) by the resonant cavity method in the frequency range 2–10 GHz using the Scalar Network Analyser [21].

Results

SEM images of PC (40 vol.% of MnZn ferrite) and HPC (40 vol.% of MnZn ferrite and 5 vol.% of Al powder) samples are shown in Fig. 1. Both PC and HPC samples show a matrix structure in which the continuous phase is formed by a polymer and ferrite particles are arranged as separate inclusions. However, in the case of a hybrid composite, due to the fact that particles of aluminum (or other conductive filler) were preliminarily introduced into the polymer, each ferrite particle is surrounded by a conductive medium and can be considered as a core–shell structure. This structure is formed when

-

a polymer comprises a continuous phase;

-

the concentration of conductive particles is above the electrical percolation threshold;

-

the concentration of ferrite particles is above the magnetic percolation threshold;

-

ferrite particles are larger than conductive particles.

The permeability spectra (μ* = μ′ − jμ″) of PCs with different concentrations of MnZn ferrite in PU are shown in Fig. 2. As expected, the real part of permeability (μ′) and the magnetic losses (μ″) of composites decrease as the ferrite concentration decreases, whereas the resonance frequency (f r) increases.

Figure 3 shows the dependence of magnetic susceptibility \( \chi (\chi = {\mu }\ifmmode{'}\else$'$\fi - 1) \) on the volume concentration of ferrite at 10 MHz.

The concentration dependence of magnetic susceptibility (permeability) of PC with MnZn ferrite at 10 MHz: (a) the experimental data is fitted by Eq. 2; (b) the experimental data is fitted by Musal and Lichtenekker equations

In the low-concentration region, up to 15 vol.% of ferrite, χ (respectively, μ′) increases linearly with the ferrite concentration following the Wagner equation for permeability [8]

where μ m is the permeability of the matrix and C is the volume fraction of the filler. For high concentrations, χ shows a nonlinear behavior, which can be approximated by Eq. 2 reported by Floc’h et al. [22]:

where χ is the magnetic susceptibility of the effective medium (composite material), χ i is the intrinsic magnetic susceptibility of the magnetic material, N is the effective shape factor responsible for the demagnetizing effects, and C is the volume fraction of the magnetic material. For high concentrations, Eq. 2 shows an asymptotic behavior. The point at which the graph of χ versus the ferrite concentration starts to deviate from a linear law can be found as the intersection of the asymptote with the x-axis. This concentration point is referred to as a magnetic percolation threshold C Pμ.

The best agreement between the measured concentration dependence and Eq. 2 was obtained for a shape demagnetizing factor of N = 0.32 and initial magnetic susceptibility of χ i = 30. The value of the magnetic percolation threshold amounts to C Pμ = 0.32, which only slightly differs from the percolation threshold of the PC with NiZn ferrite (C Pμ = 0.35) reported in [23].

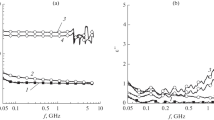

Additional introduction of various types of conductive fillers (2–10 vol.%) into a PC with 40 vol.% of ferrite leads to the enhancement of magnetic losses from μ″max ∼ 2.5 (for a PC) to μ″max ∼ 3.5 (for an HPC), as shown in Fig. 4. As for the hybrid composites, all types of HPCs have approximately the same value of the real part of the complex permeability (μ′ ∼ 6). In the case of HPCs with CF, PPy, and Al, the ferromagnetic resonance frequency f r shifts from 830 MHz (PC) to f r ∼ 1.1 GHz, whereas, the HPC filled with CB (7 vol.%) shows a slight decrease of f r down to 740 MHz.

The dependence of μ″max on the volume loading of the conductive components exhibits nonlinear behavior. This can be easily seen in the case of a hybrid composite with carbon black (Figs. 5, 6). The maximal value of the magnetic losses is attained when the concentration of CB is 6 vol.%, which is higher than the electrical percolation threshold in carbon-black-filled PU (C Pσ ∼ 4 vol.%; Fig. 7). An HPC with CF shows similar dependence of μ″max on the concentration of conductive filler (percolation threshold of C Pσ ∼ 0.5 vol.%).

In the case of HPCs with Al powder and PPy, the enhancement of magnetic losses is attained for the conductive filler concentrations of 5 and 10 vol.%, respectively (Fig. 4). In contrast to PU filled with CB and CF, the conductivity for the PU with Al powder and PPy increases with increasing the filler content, without any percolation transition (Fig. 7). This result confirms that Al particles are coated with an Al2O3 layer and thus cannot be in direct contact as expected in the percolation behavior, whereas PPy is characterized by irregular granular structure of particles with alternating metallic and dielectric phases; thus, in both cases, electric conduction occurs through tunneling [24, 25].

Figures 8 and 9 represent the dielectric spectra (ε* = ε′ − jε″) of PCs with different concentrations of MnZn ferrite and of HPCs filled with 40 vol.% of ferrite for different concentrations of CB. As the ferrite concentration in PU increases, ε′ and ε″ increase nonlinearly (Fig. 8); in HPCs, ε′ and ε″ increase by several orders of magnitude as the concentration of CB increases from 1 to 10 vol.% (Fig. 9).

Figure 10 shows the dielectric spectra of HPCs with different conductive fillers whose concentrations correspond to the maximal value of magnetic losses at resonance. One can see that different types of HPCs and PCs have quite different absolute values of the real and imaginary parts of ε* over the entire frequency range. The maximal difference is observed in the low-frequency region of the RF band. For example, for HPCs with CB and HPCs with PPy, the values of ε′ and ε″ are greater than those of PCs by orders of magnitude, whereas, for HPCs with CF, this difference amounts to tens. For an HPC filled with Al powder, the values of ε′ and ε″ are less than those for PCs.

Discussion

Background

Before discussing the electromagnetic properties of MnZn-ferrite-based magnetic PCs, we will dwell on the characteristic features of the frequency dispersion of the permeability of magnetic composites proper.

The first and the principal feature of the magnetic spectra of composite magnetic materials is the shift of the dispersion region of permeability (μ*) to higher frequencies compared with that in bulk homogeneous magnetic materials. The shift of the dispersion region of μ* in composites is associated with several physical processes, first of all, with the magnetic polarization of magnetic particles isolated by a nonmagnetic polymer layer [12]. The interphase polarization and the formation of effective magnetic charges/dipoles are responsible for the nonuniform distribution of magnetization over the bulk of the material. As a result, the effective field (H i) acting on a magnetic particle decreases by the value of the demagnetizing field (H d), which is proportional to the demagnetization factor:

where H e is the strength of the applied field; H i is the strength of the internal field; \( \hat{N}_{{\text{M}}} \) is the tensor of demagnetization factors (a second-rank material tensor that determines the relationship between the magnetization vector and the vector of the demagnetization field); and M is magnetization.

Demagnetizing fields in a composite material are associated with the morphology and the microstructural inhomogeneity of magnetic particles, as well as with the structural inhomogeneity of the composite material. While the microstructural inhomogeneity of magnetic particles (distortion of chemical composition, inhomogeneous elastic stresses, pores, cracks, surface roughness, etc.) is ultimately responsible for the enhancement of magnetic losses and broadening the ferromagnetic resonance bandwidth in bulk ferromagnetic materials [23, 26, 27], the structural inhomogeneity of composite magnetic materials is responsible for the significant decrease of both components of μ* compared with those in bulk homogeneous magnetic materials due to the violation of the “magnetic coupling” of magnetic inclusions [11, 12, 18, 19, 22, 28–30]. The gaps/interphase boundaries (for example, polymer layers) break the magnetic flux and give rise to local demagnetizing fields on the particle scale in the case of a low-concentration magnetic component (distributed magnetic charges on the surface of particles) and to the external demagnetizing field on the sample scale when the concentration of the magnetic component is higher than the magnetic percolation-threshold concentration (C Pμ) [11, 22, 28–30]. For most composites, the value of C Pμ is close to 0.45, in which case the interaction between any two particles gives rise to a cluster and forms a closed magnetic system. Moreover, the effective permeability and the ferromagnetic resonance frequency of composites depend not merely on the ratio of volume concentrations of magnetic and nonmagnetic phases but also on the configuration and the electromagnetic properties of the interface, which are associated with the variation of the boundary conditions for a microwave field on this interface [18, 19].

Magnetic percolating behavior of PCs with MnZn ferrite

Embedding MnZn ferrite into PU radically decreases the permeability of the composite compared with that of sintered ferrite, but, as an advantage, it shifts the frequency dispersion of the complex permeability from the MHz to the GHz band (Fig. 2).

Obviously, the increase of the ferrite content increases the permeability of the composite; for a dilute magnetic system of non-interacting particles this increase is linear and can be described by the Wagner equation (1). In PCs, such linear dependence of magnetic susceptibility (respectively, μ′) is observed up to MnZn concentrations of about C = 20 vol.% (Fig. 3). A further increase in the volume of the magnetic phase leads to the deviation of the concentration dependence of μ′ from a linear law. The fit of data with Eq. 2 leads to a shape demagnetizing factor of N = 0.32 and initial magnetic susceptibility of χ i = 30. The value of the magnetic percolation threshold amounts to C Pμ = 0.32, which only slightly differs from the percolation threshold of the PC with NiZn ferrite (C Pμ = 0.35) [23]. According to the physical model developed by Floc’h and colleagues [11, 22, 28, 29], the percolation character of the dependence of μ eff on the concentration of the magnetic phase and the C Pμare related both to the shape demagnetizing factor of a magnetic particle (inner demagnetizing factor, N i) and the geometry of a sample (external demagnetizing factor, N е). When C < C Pμ, the magnetic filler is diluted and the magnetic flux is not continuous throughout a sample but is alternated with nonmagnetic gaps. This increases the magnetic anisotropy and, consequently, the inner demagnetizing factor. This is also responsible for the shift of the resonance frequency to higher values. On the other hand, above the magnetic percolation threshold C Pμ, the topology of the composite is quite different. The continuous (percolative) cluster formed throughout the sample enables the magnetic flux to go from one end of the sample to the other. The inner demagnetizing effects are suppressed, while the outer demagnetizing effect switches from zero to its maximal value. Hence, the effective demagnetizing effects are mainly determined by the sample geometry [29]. However, the inner demagnetizing effects do not depend on the particle shape only, but also on their affinity for aggregation (magnetostatic coupling): the stronger the coupling, the weaker the demagnetizing effects, and, hence, the lower their total magnetic anisotropy energy. Therefore, the N in Eq. 2 represents the so-called effective shape factor for the global representation of the microscopic demagnetizing effects. That is why N depends on the distribution of particles (e.g., on the properties of the surrounding medium) in the mixture.

Apart from the model described by Eq. 2, there are other models that are based on the effective medium theory and take into account the nonlinear character of μ′ = f(C). Among these models are the equation proposed by Lichtenekker [30] and model proposed by Musal et al. [31]. Although both equations give quite satisfactory results to fit with experimental data (see Fig. 3b), only Musal model considers a transition of the composite microstructure from a discontinuous to a continuous magnetic medium.

It should be mentioned that the role of the magnetic percolation is more pronounced in materials with high permeability, as in the case of MnZn ferrite with μ i = 3000. Such filler is good for preparing HPCs because one can achieve low C Pμ, and therefore the total loading of a composite (the content of magnetic and conductive filler) is relatively low and does not degrade the mechanical properties of the composite.

The effects of the “core–shell” structure on the complex permeability of HPCs

PU-based HPCs were prepared with MnZn ferrite in combination with different types of conductive particles in order to improve the magnetic properties of PCs in the microwave band. The presence of conductive particles in HPCs has remarkable influence on the magnetic losses of HPCs compared with those of PCs, although both types of composites have the same amount of ferrite (40 vol.%; Fig. 4). At the same time, there is only small difference in the permeability (spectra μ*(f)) for various conductive fillers, although they greatly differ in dc conductivity (Fig. 7) and complex permittivity ε*(f) (Fig. 9). The increased values of magnetic losses and the changes in σ(C) and ε*(f) are due to the formation of a core–shell-like structure (Figs. 1b, 6, 11) in an HPC.

The presence of ferrite particles in a composite reduces the free volume space and increases the volume fraction of the conductive component in the polymer matrix, thus substantially reducing the percolation threshold for dc conductivity (Fig. 6). Consequently, ferrite particles are separated from each other by a conductive interlayer. Most probably, conductive particles in PCs are not in direct contact but conduction occurs through tunneling [32]. The values of conductivity and the frequency dispersion of ε* in HPCs depend on the type of conductive filler (Figs. 7, 10) and on the structure of the conducting network. The observed difference in ε′ and ε″ between different types of HPCs is primarily attributed to the features of charge transport and the contact conditions. Nevertheless, from the viewpoint of the formation of a HPC structure and its influence on the magnetic properties, the most important fact is the formation of an infinite conductive network interconnecting ferrite particles.

To explain the observed enhancement of magnetic losses in an HPC, we analyzed the effect of the conductive overlayer on the uniform ferromagnetic resonance in a spherical ferrite particle and on the effective magnetic susceptibility of an ensemble of such particles embedded into a nonmagnetic matrix. Theoretical analysis has shown that the conductive overlayer partially shields a microwave field induced by the ac magnetization of a ferrite particle. This leads to an increase in the energy of the dipole field and, hence, in the ferromagnetic resonance frequency of a uniformly magnetized particle. The shift of the resonance frequency increases with the conductivity and the thickness of the conductive coating; however, in this case, the coupling between the oscillations of magnetization and the external electromagnetic field decreases. When the thickness of the coating is on the order of the skin depth, the shift of the ferromagnetic resonance frequency amounts to about 4π|g|M S (g < 0 is the gyromagnetic ratio and M S is the saturation magnetization of the ferrite). On the other hand, when the thickness of the coating and the size of a ferrite particle are much smaller than the skin depth of the conductive overlayer, the effect of this overlayer is mainly reduced to the increase of the absorption loses due to ohmic loses; at the same time, the effective magnetic susceptibility of the system increases.

In HPCs, the thickness of the conductive polymer interlayer (“shell”) and the size of a ferrite particle (“core”) are much smaller than the skin depth of the conductive interlayer (Fig. 12); the skin depth of conductive particles is larger than the average particle size (Table 1). Thus, in the HPC structure, the presence of a conducting shell does not decrease the coupling between the oscillations of magnetization of ferrite particles and the external electromagnetic field. At the same time, in the core–shell structure of HPCs (which can be represented as an inductor with a magnetic core), the inductive current is generated under the influence of a microwave magnetic field. As a result, one can observe enhancement of magnetic losses in HPCs compared with those in PCs.

An important property of HPCs for their application in electromagnetic shielding problems is that these composites allow one to simultaneously increase the permeability and to control the frequency dependence of the complex permittivity, thus making it possible to find a frequency interval in which ε* and μ* have close values.

Conclusions

The complex permeability spectra of MnZn ferrite and their composites (PCs and HPCs) have been studied, and the influence of the ferrite concentration on the frequency dispersion in PCs has been investigated. The dependence of the permeability on the ferrite volume concentration shows a nonlinear character and the presence of a critical concentration like a magnetic percolation threshold.

Considerable enhancement of magnetic losses in HPCs compared with those in PCs has been observed, which is attributed to the presence of conductive filler in HPCs irrespective of the type and the conductivity of this filler. On the other hand, the concentration of the conductive filler is important because the enhancement effect is observed only for a certain concentration of the filler, which is close to the electrical percolation threshold of the filler component in a matrix. It is assumed that the observed effect is associated with the development of a core–shell structure in an HPC, where the “conductive shell” is formed by electrically contacting particles that surround each ferrite particle (“core”). The microwave magnetic field induces a current in the conductive shell and thus increases the magnetic losses in HPCs compared with those in PCs.

References

Schloemann E (2000) J Magn Magn Mater 209:15

Pardavi-Horvath M (2000) J Magn Magn Mater 215–216:171

Lebourgeois R, Ganne J-P, Peyresoubes G, Rebernak W, Adenot A-L, Acher O (2003) J Magn Magn Mater 254–255:608

Nakamura T, Miyamoto T, Yamada Y (2003) J Magn Magn Mater 256:340

Yusoff AN, Abdullah MH (2004) J Magn Magn Mater 269:271

Nakamura T, Tsutaoka T, Hatakeyama K (1994) J Magn Magn Mater 138:319

Tsutaoka T (2003) J Appl Phys 93:2789

Fiske TJ, Gokturk HS, Kalyon DM (1997) J Mater Sci 32:5551

Labbé S, Bertin P-Y (1999) J Magn Magn Mater 206:93

Kazantseva NE, Ponomarenko AT, Shevchenko VG, Klason C (2000) Electromagnetics 20:387

Mattei J-L, Le Floc’h M (2003) J Magn Magn Mater 257:335

Kasagi T, Tsutaoka T, Hatakeyama K (2004) J Magn Magn Mater 272–276:2224

Annadurai P, Mallick AK, Tripathy DK (2002) J Appl Polym Sci 83:145

Josyulu OS, Sobhanadri J (1985) J Mater Sci 20:2750

Mchenry ME, Brunsman EM, Majetich SA (1995) IEEE Trans Magn 31:3787

Crisan O, Angelakeris M, Flevaris NK, Filoti G (2003) J Optoel Adv Mater 5:959

Yavuz O, Ram MK, Aldissi M, Poddar P, Hariharan S (2005) Synth Met 151:211

Kazantseva NE, Vilčáková J, Křesálek V, Sáha P, Sapurina I, Stejskal J (2004) J Magn Magn Mater 269:30

Kazantseva NE, Bespyatykh YuI, Sapurina I, Stejskal J, Vilčáková J, Sáha P (2006) J Magn Magn Mater 301:155

Strümpler R, Glatz-Reichenbach J (1999) J Electroceramics 3(4):329

Kazantsev Yu (1998) In: Proceedings of the XIV international conference on gyromagnetic electronics and electrodynamics (microwave ferrites), Moscow, vol 2, p 205

Le Floc’h M, Mattei JL, Laurent P, Minot O, Konn AM (1995) J Magn Magn Mater 140–144:2191

Gurevich AG, Melkov GA (1996) Magnetization oscillation and waves. CRC Press, Inc

Baziard Y, Breton S, Toutain S, Gourdenne A (1988) Eur Polym J 24:521

Prigodin VN, Epstein AJ (2002) Synth Met 125:43

Smit J, Wijn HPJ (1959) Ferrites. Philips Technical Library, Eindhoven

Vonsovskii SV (1971) Magnetism. Nauka, Moscow

Chevalier A, Mattei JL, Le Floc’h M (2000) J Magn Magn Mater 215–216:66

Mattei JL, Le Floc’h M (2003) J Magn Magn Mater 264:86

Lichtenekker K (1926) Phys Z S 27:118

Musal HM, Hahn HT, Bush GG (1988) J Appl Phys 63:3768

Balberg I (2002) Carbon 40:139

Acknowledgements

The authors acknowledge the financial support of the Ministry of Education, Youth and Sports of the Czech Republic (ME 883 KONTAKT), and the Russian Foundation for Basic Research (project no. 06-08-00145).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moučka, R., Lopatin, A.V., Kazantseva, N.E. et al. Enhancement of magnetic losses in hybrid polymer composites with MnZn-ferrite and conductive fillers. J Mater Sci 42, 9480–9490 (2007). https://doi.org/10.1007/s10853-007-2081-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-2081-0