Abstract

The results of investigation of microwave electromagnetic properties in wide frequency range (1–67 GHz) of the hybrid polymer composites based on combined introduction of ferrite and MWCNTs nanoparticles are presented. The surge in 3–5 orders of the conductivity value has been founded in MWCNTs/Fe3O4 (BaFe12O19)/epoxy composites with 2 and 5 wt. % of MWCNTs as compared with MWCNTs/epoxy composites, and these changes are more considerable for lower content of MWCNTs in the epoxy matrix. The addition of 30 wt. % of Fe3O4 (BaFe12O19) nanoparticles to MWCNTs/epoxy composites leads to the significant increase of the complex permittivity values and to the frequency shift of relaxation maximums. The natural ferromagnetic resonance was revealed as the main mechanism of magnetic loss in MWCNTs/Fe3O4/epoxy composites at frequencies up to 10–12 GHz while the eddy current induced mechanism becomes the dominant in magnetic loss at the further frequency increase. The natural ferromagnetic resonance determines the character of magnetic loss in BaFe12O19-filled composites in the whole investigated frequency range.

The integration of nanotubes and ferrite admixture of Fe3O4 or BaFe12O19 in MWCNT/30 wt. % Fe3O4 (or 30 wt. % BaFe12O19) ternary composites provides synergetic effects and complementary behavior (e.g., various polarization relaxations as additional loss mechanisms), which greatly contribute to the microwave absorption properties for both studied ternary composites. The absorption bandwidth reaches 13–17 GHz for thin (0.6–0.8 mm) composite samples with 2 wt. % of nanotubes content. The increase of MWCNTs content and the use of two component fillers lead to decrease of the effective reflection loss in the frequency range above 20 GHz. The maximum reflection loss reaches 49 dB for Fe3O4- and 39 dB for BaFe12O19-filled composites of 1.1–1.2 mm thickness while the absorption bandwidth does not exceed 5 GHz.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

6.1 Introduction

Currently there is ongoing tremendous development in the radio frequency (RF) and microwave (MW) electronics: mobile communications, high-speed electronic switching components and circuits, radars, navigation, etc. [1]. To safeguard the device operation, the nearby electronic equipment operating in the RF and MW frequency bands should be properly shielded. In particular, this can be achieved by coating the case of the device with some shielding material. Many of high frequency electronic devices are being operated in X-band (8–12 GHz) of electromagnetic spectrum The development of prospective communication standards requires high-speed data transmission and, correspondingly, new effective materials operating in the frequency range of 20–100 GHz. Furthermore, the development of soft and flexible electronic devices, such as foldable phones, electronic paper displays and wearable devices requires thin and flexible electromagnetic radiation (EMR) shielding films. All indications are that EMR shielding materials for the next-generation electronics will need seamlessly networked hetero-nanostructures the composition of which is the subject of many modern researches. Structured organic–inorganic composites have been extensively studied because they combine the advantages of inorganic materials (electric and magnetic properties, mechanical strength, thermal stability) and organic polymers (dielectric properties, processability, flexibility, and ductility). These composites combine characteristics of the individual constituent that can enhance electromagnetic absorption efficiency. Electromagnetic (EM) absorbing materials are mostly expected to have a broad bandwidth, high reflection loss (RL), and small thickness or light weight. Bandwidth is one of the most important parameters characterizing an EMR absorbing material in terms of real applications.

Nanocarbon materials and polymer nanocomposites (NC) have many advantages for potential applications as wideband EMR shielding materials: high shielding efficiency (SE), light weight, flexibility, high conductivity, and low contact resistance values. However, they have a number of shortcomings as microwave absorbers. First, a large volume of filler is needed to provide strong MW absorption, i.e. high values (often more than 40 dB) of EMR SE required for electronic devices. High content of carbon fillers would deteriorate the dispersion of the filler and thus would greatly affect the mechanical properties of the composite. Moreover, a conductive network produced by increased filler content will keep the microwave EM field outside the main composite volume and lead to limited microwave absorption. What is worse, the increased permittivity resulted from the increased filler content is accompanied by unwanted restriction of the effective bandwidth (EB). Meanwhile, it is rather difficult to obtain higher values of EMR SE for polymer/conductive filler composites, especially when the sole type of conductive filler is used. The addition of another inorganic filler is one of effective ways to enhance EMR absorption. The use of a mixture of closely packed nanocarbon and WS2, MoS2, or BaTiO3 nanoparticles [2,3,4,5] supplies improved dielectric properties of the composite.

The mix of nanocarbon fillers with magnetic particles can achieve the enhancement of carbon-filled composites absorptive properties. Such magnetic admixtures can be ferrite or metal (alloy) particles. As compared with metallic (alloy) particles, ferrite particles offer important advantages of high ferromagnetic resonance frequency, high electric resistivity, low density, and good chemical stability. The addition of magnetic particles such as Fe2O3 or Fe3O4 [6, 7], MnFe2O4 [8], ZnO hollow spheres or nanoparticles [9], Co3O4 [10], MnZn-ferrite [11] could enhance the EMR SE and decrease the cost of NC. For instance, Li et al. [12] coated Fe3O4 on CNTs, and the specific RL min of 28.7 dB and effective bandwidth of 8.3 GHz was achieved. The excellent absorbing properties were obtained in [13] for microstructured filler of interconnected network of graphene and carbon nanotubes with magnetic Fe3O4 particles. Authors demonstrate the superb potential for application of such structure as EMR absorbing material. The maximum RL of CNT film-Fe3O4-rGO-polydimethylsiloxane (PDMS) composite with 4 layers is 50.5 dB and absorption bandwidth at 10 dB is 5.7 GHz (the thickness of that material is 1.42 mm).

The most suitable candidates for EM absorbing materials in this frequency range are composites based on barium hexaferrite BaFe12O19, since it is characterized by excellent magnetic properties such as significantly high magnetocrystalline anisotropy and high ferrimagnetic–paramagnetic transition temperature [14, 15]. Hexagonal ferrites demonstrate large anisotropy, besides as permanent magnetic materials and perpendicular recording materials.

However, the practical application of the above-mentioned materials is severely limited due to some impeding factors. The analysis of publications [16,17,18,19] shows that microwave absorption materials performance depends on many factors: the type of nanocarbon and inorganic fillers, their morphology and structure, the processing method, the choice of the polymer matrix, the filler distribution inside the matrix, the interfacial interaction between fillers and matrix, etc. Ferrites demonstrate considerable magnetic loss and absorbing capability but are limited to applications due to their high density and processing difficulties. The applications of nanocarbons as fillers for EMR absorbers are hindered by missing magnetic loss and narrow absorption bandwidth. To overcome these complications, hybrid materials are developed that combine several materials to offset respective limitation of the materials retaining enhanced shielding properties. Certain success has been reached in enhanced absorbing properties of polymer composites with combined filler [16,17,18,19]. However, the overpowering majority of research reports refer to frequency range under 20 GHz where hybrid nanocarbon filler chemically modified by magnetic particles was used. So, the problems include finding the correlation between structure, morphology and phase composition of constituents and the properties of microwave absorption materials (MAM) in microwave frequency range. That will permit to determine the optimal composition of constituents and to synthesize materials and structures with required tunable EMR absorbing properties.

In present work the experimental results on EM properties in wide frequency range (1–67 GHz) with microwave absorption capability of the hybrid polymer composites based on combined application of ferrites and MWCNTs nanoparticles as fillers are shown.

6.2 Materials and Methods

6.2.1 Experimental Details

Structural and morphological peculiarities of NCs were studied by the optical microscopy (“Mikmed-1” with ETREK DCM-510 attachment) and the electron microscopy (JEOL JSM-6490LV; Mira3 Tescan).

The study of the electric resistance of the nanocarbon-polymer NC at the room temperature was performed by a four- or two-probe methods.

A coaxial method was used to determine the electromagnetic parameters of the investigated composites by using an Agilent N5244A vector network analyzer (Keysight, USA) in the frequency range of 1–67 GHz. Samples for the investigations were prepared in the toroid shape. The toroids tightly fit into the coaxial measurement cell. The cell (Fig. 6.1) has inner diameter of 0.8 mm and outer diameter of 1.85 mm. Full two-port calibration was initially performed on the test setup in order to remove errors due to the directivity, source match, load match, isolation and frequency response in both the forward and reverse measurements. The complex permittivity (ε r) was determined from the scattering parameters using the Nicolson-Ross models.

The complex permittivity (ε r = ε′-jε ″) and permeability (μ r = μ′-jμ ″) were measured from S-parameters by using the simulation program of the Reflection/Transmission Nicolson-Ross model.

6.2.2 Production of Polymer Composites with Hybrid Filler

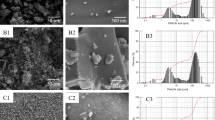

Three types of nanoparticles were used as fillers in the prepared composites: multiwall carbon nanotubes (MWCNTs), barium hexaferrite (BaFe12O19) and magnetite (Fe3O4). Figure 6.2a, b, and c presents the electron microscopy of MWCNTs, BaFe12O19, Fe3O4 fillers respectively.

MWCNTs were chosen as conductive filler due to their low specific density, high thermal and corrosion resistances and excellent electrical conductivity. The form of these particles is similar to highly elongated cylinders. The used MWCNTs were purchased in CheapTubesIns, USA. Their dimensions are the following: diameter d is of 10–30 nm, length l is of 10 μm. As it is seen in Fig. 6.2a, initially MWCNTs are tangled. That’s why at MWCNTs-based NC preparation dispersion of the composite mixture should be performed very careful. Table 6.1 summarizes the data on the size and morphology of the filler particles.

The powders of barium hexaferrite and spherical magnetite particles were used as secondary fillers in nanotubes/epoxy NC. The morphology of the mentioned magnetic fillers is essentially different in shape and size. As it is seen in Fig. 6.1b, barium hexaferrite powder consists of well-shaped plate-like hexagonal particles of 20–50 nm thicknesses and 150–450 nm diameters. Particles size distribution is quite wide but hexagonal shape persists. Compact self-organization of barium hexaferrite particles takes place, and individual BaFe12O19 particles are gathered in globules where they stick at each other with random orientation of facets.

Figure 6.2c shows Fe3O4 powder of spherical particles of 10–20 nm diameters with minor dispersion in size.

Figure 6.3 shows X-ray diffraction (XRD) analysis results for the used secondary fillers. XRD patterns for ferrite powders confirm the presence of barium hexaferrite phase which possesses hexagonal lattice P63/mmc with a = 5.9046 Å, b = 5.9046 Å, c = 23.229 Å (indicated with symbols ◆ on Fig. 6.3a). XRD pattern of Fe3O4 is presented in Fig. 6.3b where the sharp diffraction peak at 2Θ = 41.36° can be attributed to the (311) reflection of Fe3O4 nanoparticles. The main characteristic XRD peaks of magnetite are located at 2Θ = 35.04°, 50.47°, 67.38°, 74.30° and they correspond to the (220), (400), (511), (440) reflections of Fe3O4, respectively.

The series of NCs have been prepared with the above-mentioned fillers. Namely, MWCNTs/epoxy and MWCNTs/Fe3O4/(BaFe12O19)/epoxy NCs with 2 wt. % and 5 wt. % of MWCNTs were fabricated by mixing in solution with additional sonication. The fabrication routine is as follows. At first, appropriate amount of L285 epoxy resin (Lange & Ritter GmbH, Germany) was pre-dissolved in acetone. Further, MWCNTs were introduced into solution and sonication in BAKU ultrasonic bath was applied for 15 min with 40 kHz frequency and 50 W power. Fe3O4 (BaFe12O19) was added at the next stage for the NC with binary filler. That secondary filler amounts to 30% of weight in all composites. Mechanical mixing and sonication for 15 min was applied again. Finally, curing agent H285 was added (40% by weight of L285).

At curing process, the prepared NCs were subjected to continuous ultrasonic (800 kHz) effect to provide uniform random distribution of fillers without agglomeration. To complete the polymerization, 1 day after the NCs were prepared, they were exposed to the heating at temperature that gradually increased from 40 to 80 °C for 5 h.

The results of optical microscopic studies of BaFe12O19/epoxy, Fe3O4/epoxy NC surface are presented in Fig. 6.4.

As it is seen in Fig. 6.4 a, hexaferrite-filled NC is characterized by granular structure of BaFe12O19 globules distribution in epoxy matrix with 10–20 μm diameters of globules but there are many globules with a typical diameter of about 50 μm. These globules mostly have regular spherical form. Spatial orientation of BaFe12O19 globules is not observed. It should be noted that for composite samples with binary fillers the uniform distribution of the BaFe12O19 globules in the sample volume is slightly disturbed. Both BaFe12O19 phase and carbon phase form separate interpenetrating spatial networks. The nature of such formation in NCs with binary fillers can be linked to the influence of MWCNTs agglomerates on BaFe12O19 network formation. Specifically, van der Waals interaction forces between the carbon nanotubes prevent the BaFe12O19 phase distribution and contribute to its association.

A typical optical micrograph of Fe3O4/L285 NC is shown in Fig. 6.4b where Fe3O4 particles and their agglomerates are randomly oriented in the epoxy resin. Their distribution is rather uniform while agglomerates are present in large quantities.

Carbon nanoparticles are known as conductive structures while barium hexaferrite as well as ferric oxide are nonconducting. However, the addition of Fe3O4 or BaFe12O19 into the MWCNTs/epoxy NC leads to increase of electrical conductivity by 2 orders of magnitude for 2 wt. % MWCNTs/Fe3O4(BaFe12O19)/L285 and by 3 orders of magnitude for 5 wt. % MWCNTs/Fe3O4(BaFe12O19)/L285 NCs. These results are presented in Fig. 6.5.

However, as it was noted in [20], magnetite particles possess high interfacial resistivity and should not make a direct contribution to the increase of the composite electrical conductivity. Instead, they contribute to the formation of “excluded volume” in the composite, which results in the increase of local carbon filler concentration and promotes better dispersion of carbon filler at the manufacturing process. First of all, the composite electrical conductivity increase occurs due to the change in the distance between the conductive particles in the material when the second filler is introduced, i.e. due to the change of polymer layer thickness between the filler particles [21]. Authors have analyzed in [22, 23] in terms of the effective resistivity model the influence of a dielectric component addition on the percolation threshold and the electrical conductivity of NCs with carbon fillers of different types. It was shown that changes in those values depend on the shape and type of carbon particles used as conductive fillers. In the case of CNTs, the increase in electrical conductivity is mainly determined by the increase of the conductive chains number and the decrease of the contact resistance between the filler particles in the conductive chains.

6.3 Results and Discussion

6.3.1 Microwave Properties of Epoxy Composites with Carbon Nanotubes and Hybrid Fillers

The electromagnetic wave absorption are mainly determined by relative permittivity and permeability of the material in which the real parts of permittivity (ε′) and permeability (μ′) are associated with the electric and magnetic energy storage capabilities while the imaginary parts of permittivity (ε ″) and permeability (μ ″) stand for the electric and magnetic losses, respectively. In order to evaluate the influence of magnetodielectric particles types and content of MWCNTs on electrodynamic characteristics of hybrid polymer composites, complex permittivity and permeability were examined over a broad frequency range (1–67 GHz).

6.3.1.1 Permittivity

The real and imaginary parts of permittivity in the range of 1–67 GHz for composites with individual fillers and for ternary composites are presented in Fig. 6.6.

Frequency dependences of real (ε′) and imaginary (ε ″) parts of complex permittivity for NCs: (a) MWCNT/L285; curves 1, 2 – ε′ and ε ″ , curves 3, 4– ε′ and ε ″ for NCs with 2 wt. % MWCNTs/L285 and 5 wt. % MWCNTs/L285, respectively; (b) 30 wt. % BaFe12O19(Fe3O4)/L285; curves 1, 2 –ε′ andε ″ , curves 3, 4– ε′ and ε ″ for 30 wt. % Fe3O4/L285 and 30 wt. % BaFe12O19/L285 CMs, respectively

As one can see in Fig. 6.6a, the significant rise of ε′ is observed for MWCNTs/L285 NCs at the increase of MWCNTs content in the epoxy matrix. The composite with 5 wt. % MWCNTs shows higher ε′ values as compared to the composite with 2 wt. % MWCNTs. With the higher nanotubes content the major peak of ε ″ as well as the peak of dielectric loss factor are shifted towards lower frequencies. For instance, the major peaks of ε ″ are observed at 54 GHz and 30.3 GHz for NCs with 2 wt. % and 5 wt. % of MWCNTs, respectively, suggesting a higher electrical conductivity for the samples with higher MWCNTs content.

For the comparison, the complex permittivities of NCs filled with solely BaFe12O19 or Fe3O4 particles are also presented in Fig. 6.6b.

It is notable that the real part of the complex permittivity of composites with an individual magnetodielectric filler is almost invariant for NCs with BaFe12O19 filler (up to 45 GHz) and for NCs with Fe3O4 filler at frequencies above 5 GHz, while the values of ε ″ are near 1 and fluctuate as the frequency increases revealing several resonance peaks. ε′ is the representation of the material dipolar polarizability at microwave frequencies, and ε ″ curve resonance peaks demonstrate multi-relaxations also originated from the dipole polarization.

Figure 6.7 shows frequency dependences of complex permittivity for MWCNTs/BaFe12O19/epoxy NC and for MWCNTs/Fe3O4/epoxy NC with different MWCNTs content.

Frequency dependences of real (ε′) and imaginary (ε″) parts of complex permittivity of ternary composites MWCNTs/BaFeO(Fe3O4)/L285 with different MWCNTs content: (a) 2 wt. % MWCNTs/30 wt. % BaFe12O19(Fe3O4)/L285; curves 1, 3, 5 – ε′ and curves 2, 4, 6 – ε″ for composites 2 wt. % MWCNTs/L285, 2 wt. % MWCNTs/30 wt. % Fe3O4/L285, 2 wt. % -MWCNTs/BaFe12O19/L285, respectively; (b) 5 wt. % MWCNTs/30 wt. % BaFe12O19−(Fe3O4)/L285; curves 1, 3, 5 – ε′ and curves 2, 4, 6 – ε″ for composites 5 wt. % MWCNTs/L285, 5 wt. % MWCNTs/30 wt. % Fe3O4/L285, 5 wt. % MWCNTs/BaFe12O19/L285, respectively

The influence of additional magnetic filler on permittivity of MWCNTs/epoxy NC is analyzed in Table 6.2.

Substantial increase of both permittivity parts has been observed in ternary composites in comparison with binary composites (see Table 6.2). The distinct maximum have been observed for ternary composites with Fe3O4 at 2,6 GHz. Broad relaxation peak is appeared in the range of 40–45 GHz for 2 wt. % MWCNTs/BaFe12O19/epoxy composites which became more pronounced with the increase of MWCNTs content in the composite. The relative changes of ε′ for composites with 2 wt. % of MWCNTs almost does not depend on the type of additional magnetic filler and frequency in whole investigated range. The relative changes of ε′ for composites with 2 wt. % of MWCNTs are weakly dependent on the type of additional magnetic filler and frequency. The values of relative changes of real permittivity are approximately 1.2–1.4 while ε ″ demonstrates higher changes which reflects substantial conductivity increase after addition of magnetic nanoparticles. On the contrary, significant frequency dependences of both permittivity parts have been observed for composites with higher MWCNTs content as well as the increase of ε′ and ε ″ in ternary composites in comparison with binary composites.

The frequency-dependent dielectric loss tangents (tg α = ε ″ /ε′) of the investigated NC are shown in Fig. 6.8. One can see that tg α in binary composites is about 0.2 almost in the whole frequency range and raises up to 0.7–0.9 in the relaxation peaks band.

For ternary composite with BaFe12O19 and Fe3O4 an essential enhancement of tg α was found the value of which increases with frequency.

Several relaxation peaks of dielectric loss tangent are manifested in Fig. 6.8 for both ternary and binary NCs. As it is known, dielectric properties of mixtures can be described in terms of the Maxwell–Wagner theory of interfacial polarization (interfacial polarization developed at conductor-insulator interface) where the accumulated electric charges increase with the introduction of conducting fillers.

The interfacial polarization and the associated relaxation always appear in a heterogeneous system, and the accumulation and uneven distribution of space charges at the interfaces will produce a macroscopic electric moment that can effectively absorb the incident EM energy. The relaxation process can be described by the Cole−Cole semicircle, which can be deduced based on the Debye dipolar relaxation. The relationship between ε′ and ε′′ is described as follows [24, 25]:

where ε s is the static permittivity, and ε ∞ is the relative dielectric permittivity at the high-frequency limit. If there is a polarization relaxation process, the plot of ε ″ versus ε′ will be a single semicircle, which is also defined as the Cole-Cole semicircle.

Figure 6.9 shows typical ε′′(ε′) curves for MWCNTs/L285 NCs (Fig. 6.9a), MWCNTs/Fe3O4/L285 NCs (Fig. 6.9b), and MWCNTs/BaFe12O19/L285 NCs (Fig. 6.9c).

As it was observed, three semicircles for MWCNTs/L285 composites can be attributed to the Debye relaxation processes of L285 and nanotubes as well as to the interfacial polarization between nanotubes and epoxy. Obviously, five semicircles for MWCNTs/Fe3O4/L285 and MWCNTs/BaFe12O19/L285 composites can be attributed to the Debye relaxation processes of epoxy, nanotubes, and Fe3O4 or BaFe12O19 as well as to the interfacial polarization between epoxy, nanotubes, and magnetic filler. As one can see in Fig. 6.9a, the major peak of MWCNTs/L285 ε′ is associated with interfacial polarization between nanotubes and epoxy as well as with the higher nanotubes content. This major peaks of ε ″ and the dielectric loss tangent are shifted towards lower frequencies.

The major relaxation peak is located at 3.7 GHz for Fe3O4/L285 NCs and can be associated with interfacial polarization between Fe3O4 and epoxy. That peaks’ position does not notably change after MWCNTs addition into a composite. The relaxation peaks are wide and feebly marked for BaFe12O19/L285 NCs that could be connected with the larger sizes of BaFe12O19 particles and their wider size distribution.

6.3.1.2 Permeability

The results of investigation of magnetic permeability of developed composites are presented in the Fig. 6.10.

Figure 6.10 shows the real part (μ′) and the imaginary part (μ ″) of the complex permeability of the developed composites. μ′ of Fe3O4/L285 and Fe3O4-filled ternary composites is sharply-decreasing in the frequency range from 1 to 9 GHz while μ ″ exhibits a peak located at ∼2.01 GHz for Fe3O4/L285 NC. The latter could be caused by the natural ferromagnetic resonance (NFMR). It is known that NFMR of conventional Fe3O4 bulk materials is equal to 1.3 GHz [26].

Higher resonance frequency for Fe3O4/L285 NC can be explained by the natural resonance equation for ferromagnetic materials [27]:

where γ is the gyromagnetic ratio, κ 1 is the anisotropy coefficient, μ 0 is permeability of free space, and M s is the saturation magnetization .

As our previous BaFe12O19/epoxy polymer composite magnetic properties research [28] has shown, the encapsulation of magnetic powder in polymer core leads to changes of chemical bonding at the particles surface. That leads to decrease of the saturation magnetization of the magnetic particles and affects on the contributions of the surface anisotropy, the shape anisotropy, and the interface anisotropy to the net anisotropy. So, polymer coating of fine Fe3O4 particles and subsequent changes of their magnetic characteristics (particularly, saturation magnetization decrease) in a polymer composite produces the shift of f r towards higher frequencies. MWCNTs addiction into the NC results in subsequent decreasing of M s and shift of f r towards higher frequencies which is reflected in initial increase of magnetic loss factor (tg δ = μ ″ /μ′). tg δ frequency dependencies for the developed NCs are presented in Fig. 6.11.

μ′ of BaFe12O19-based NCs is essentially higher than μ′ of Fe3O4-based NCs, and μ ″ demonstrates a peak with the maximum at 48.3 GHz. Such frequency is somewhat higher of the value that is known for the natural ferromagnetic resonance of bulk BaFe12O19 [29].

For magnetic EM absorption materials, the magnetic loss originate from the magnetic hysteresis, domain wall resonance, natural ferromagnetic resonance, exchange resonance, and eddy current effect [30]. The magnetic hysteresis loss is negligible in weak EM field. The domain wall resonance generally occurs in a lower frequency range in multi-domain materials. The eddy current loss is another important factor for microwave absorption. It is determined by the electric conductivity (σ) and thickness (d) of the samples and can be evaluated by the parameter [31]:

where μ 0 is the permeability in a vacuum, σ is the electric conductivity of the material. If C is a constant with the change of frequency, we can say that the magnetic loss results from the eddy current loss [31].

To analyze the effect of eddy-current on the magnetic loss, we plotted μ ″ (μ′) −2 f −1 via frequency for ternary composites with Fe3O4 and BaF12O19. In case of MWCNTs/epoxy NC with Fe3O4, C decreases with frequency increase up to 12 GHz, implying that the eddy current has no significant effect on the electromagnetic microwave absorption in the frequency range below 12 GHz. Therefore, the natural ferromagnetic resonance may be the main contributor to magnetic loss in that frequency range. C becomes almost constant with the frequency increase above 12 GHz, i.e. eddy-current-induced magnetic loss is prevalent at high frequencies. The increase of non-magnetic MWCNTs content enhances loss in high frequency range where eddy-current-induced mechanism of magnetic loss dominates. A conductive material subjected to an alternating EM field produces an induced current, which dissipates EM energy within the material.

As to the composite with BaFe12O19 filler, as it is seen from Fig. 6.12, C is not constant and has serious fluctuations in whole studied field, indicating that the eddy current effect has no significant effect on the microwave absorption observed and natural resonance loss determined the character of magnetic loss.

Interestingly, it is observed from Fig. 6.10 b that the BaFe12O19 NC show negative μ ″ in the frequency range 9.5–18.0 GHz and the minimum value of μ ″ is −0.17. In order to prove the reliability of the negative μ ″, we measured the EM parameters of the samples which were produced in different production cycles and with different thicknesses and we found that μ ″ was always negative in this frequency range, manifesting that μ ″ was intrinsically negative rather than an artifact. The similar behavior of μ ″ had been observed in [32] for nanocomposites containing 30 wt. % of iron nanorods. We have no reasonable explanation of observed results and more studies are necessary to understand the originality of the negative μ.

Thus, the investigated materials have shown feasible microwave properties for effective EM wave attenuation. The attenuation constant α is often used to take account of the integral dissipation [33]:

where f is the frequency of the EM wave and c is the velocity of light. Figure 6.13 shows frequency dependence of α of the investigated CMs.

In order to evaluate the efficiency of ternary composites as absorbing materials, their attenuation constants have been calculated using the experimental values of μ ″ ,ε ″ , μ′, ε′. The increase of α in MWCNT/L285 NCs has been observed with the increase of MWCNTs content. Besides it, the frequency range of maximum attenuation shifts to the lower frequencies. Naturally, the addition of magnetic nanoparticles into the composite leads to enhancement of attenuation. However, as Fig. 6.13 demonstrates, EMR attenuation is more intensive and realized in wider and higher frequency range in MWCNTs/BaFe12O19/L285 in comparison with MWCNTs/Fe3O4/L285 NCs at the same mass content of BaFe12O19 and Fe3O4 particles in the corresponding composites. It may be primarily connected with NFMR-based mechanism of magnetic loss in BaFe12O19 and consequently in BaFe12O19-based composites. Which is realized for BaFe12O19 at frequency of 47 GHz [29].

6.3.1.3 Microwave-Absorbing Properties

It is known that the performance of microwave absorption properties reflects frequency, effective bandwidth, and RL min values, so it is meaningful to investigate materials with good microwave absorption properties (MAP) over a wide frequency range. To reveal the microwave absorption performance of developed composites, their RL values were calculated using the relative complex permeability and permittivity at a given layer thickness. In theory, the incident microwave power is divided into portions of the reflected and the absorbed ones at the interaction with metal-backed composite layer

where P in is the power of the incident wave, P R is the power of the reflected wave, P A is the power of the absorbed wave, RL and A are the reflection and the absorption losses, respectively, measured in decibels (dB). Here the microwave absorbing efficiency can be evaluated from RL. The larger the absolute value of RL is, the stronger will be the wave-absorbing ability.

In order to investigate the possibility to widen the range of strong absorption and increase the absorbing peak value for the composites with low concentration of nanocarbon filler, we simulated RL (dB) by applying the transmission line theory. RL of EMR under normal wave incidence at the surface of a single layer material backed by a perfect conductor can be defined as [34]:

where\( {Z}_0=\sqrt{\mu_0/{\varepsilon}_0} \) – is the characteristic impedance of free space,\( {Z}_{in}=\sqrt{\mu_0\mu /{\varepsilon}_0\varepsilon}\left(\tanh \left(i\cdot 2\pi f\sqrt{\mu_0{\mu \varepsilon}_0\varepsilon }d\right)\right) \) – is the input impedance at the interface of free space and material.

According to the foregoing Eqs. (6.5) and (6.6), the surface reflection loss of an absorber is a function of six characteristics parameters: ε′, ε ″, μ′, μ ″, f and d. Thus, the reflection loss of the material can be calculated from the measured values of ε′, ε ″, μ′ and μ ″ which characterize namely the property of material and proper value of f and d which could be related to, if it is possible to say, design and condition of functioning.

To examine microwave-absorbing properties of developed ternary hybrid/epoxy composites in the wide frequency range (1–67 GHz), we have calculated RL (dB) for different thicknesses and different types of composites. It is important to analyze the influence of MWCNTs content and types of additional fillers on the df and RL min values in order to obtain good MAP in wide effective frequency range, in particular, at higher frequencies with samples of minimum thickness.

The influence of MWCNTs content on MAP and above-mentioned absorber characteristics of MWCNTs/L285 composites is illustrated in Fig. 6.14. The results of RL (f, d) dependencies calculation are plotted for epoxy-nanotubes composites with 2 wt. % and 5 wt. % of MWCNTs.

The analysis of MA performance of composites with nanotubes have shown that increase of nanotubes content lead to worsening of MA characteristics. Namely, as one can see from the Figs. 6.14a, b, value of RL min decreases from 31 dB for 2 wt. % MWCNTs/L285 NC to 23 dB for 5 wt. % MWCNTs/L285 NC. In the investigated frequency range, the effective reflection loss (RL ≤ −10 dB) of 2 wt. % MWCNTs/L285 NC covers wider frequency range than that of 5 wt. % MWCNTs/L285 NC. The widest frequency range of effective reflection loss (RL ≤ −10 dB) for 2 wt. % MWCNTs/L285 NC reach 6 GHz at d = 0.8 mm. The widest frequency range of effective reflection loss for 2 wt. % MWCNTs/L285 NC reaches 6 GHz at d = 0.8 mm. Furthermore, considerable value of effective reflection loss appears at higher frequencies of 50–57 GHz, and it was observed for samples with thickness d < 1 mm. It comes from the complex permittivity excessive increase with the nanotubes content increase while the complex permeability remains practically unchanged. Such modification leads to stronger impedance mismatch at the air-composite interface. Figure 6.15 shows df and f min dependences on MWCNTs/L285 NCs thickness.

Besides the effect of nanotubes content, the additional magnetic filler content and type also have important effects on the MAP of hybrid composites. The character of MAP changes in composites depends on the additional magnetic filler: Fe3O4 or BaFe12O19. Figure 6.16 shows reflection loss versus frequency and thickness for the investigated ternary composites 2 wt. % MWCNTs/30 wt. % Fe3O4 (or 30 wt. % BaFe12O19).

As one can see, the integration of nanotubes and magnetic inorganic additives such as Fe3O4 or BaFe12O19 creates obvious synergetic effects and complementary behavior as well as more loss mechanisms (e.g. various polarization relaxations), which greatly contribute to the MAP for both types of ternary composites. df reaches rather high value of 13–17 GHz for thin samples (d = 0.6–0,8 mm) of composites with 2 wt. % of nanotubes (see Fig. 6.17).

Such wide band of effective reflection loss (RL > 10 dB) is observed at f > 20 GHz. The value of reflection loss is not very high and does not exceed 20 dB for both composite types. RL < 10 dB was observed in the whole examined frequency range for rather thick (> 1.2 mm) samples of composites with Fe3O4 while RL of 6–11 dB was observed at high (30–60 GHz) frequencies for BaFe12O19-filled composite samples of 1–2 mm thickness.

The reflection loss versus frequency and thickness for the investigated ternary composites 5 wt. % MWCNTs/30 wt. % Fe3O4 (or 30 wt. % BaFe12O19) NCs is presented at Fig. 6.18. Figure 6.19 illustrates the influence of MWCNTs content and additional filler type on composites microwave properties.

Increase of MWCNTs content in MWCNTs/L285 NCs as well as in the case of ternary compounds with additional Fe3O4 or BaFe12O19 leads to decrease of the effective reflection loss in the frequency range more than 20 GHz unless under increasing d up to 1,2–1,1 mm RL min reach rather high value −49 dB and −39 dB for Fe3O4 and BaFe12O19 composite, consequently, but in this case df don’t exceed 5 dB and f min is founded in the region 20 GHz.

6.4 Conclusions

The sharp increase of conductivity of 3–5 orders of magnitude was revealed in MWCNTs/Fe3O4/(BaFe12O19)/epoxy ternary NCs with 2 wt. % and 5 wt. % of MWCNTs in comparison with binary MWCNTs/epoxy NCs. That effect is more considerable for lower content of MWCNTs in the epoxy matrix.

The addition of 30 wt. % of Fe3O4 (BaFe12O19) nanoparticles as well as MWCNTs content increase in NCs have significant influence on the complex permittivity of materials. The ε r values increase and the f min position shifts.

It was shown that NFMR may be the main magnetic loss mechanism in MWCNTs/Fe3O4/epoxy composites at frequencies below 10–12 GHz while eddy current-induced magnetic loss prevails with the increase of microwave frequency. The natural ferromagnetic resonance determines the character of magnetic loss in BaFe12O19–filled NCs in the whole examined frequency range.

The analysis of microwave absorbing properties of the developed hybrid NCs has demonstrated good prospective of the NCs application as effective absorbing materials in the frequency range beyond 20 GHz.

High values of effective reflection loss (up to 17 dB) at frequencies above 20 GHz can be reached by the manipulating of MWCNTs content and types of additional magnetic fillers in hybrid NCs with d of 0.6–0.8 mm.

References

Golio M, Golio J (2007) RF and microwave passive and active technologies. CRC Press, London, p 736

Thomassin JM, Jerome C, Pardoen T, Bailly C, Huynen I, Detrembleur C (2013) Polymer/carbon based composites as electromagnetic interference (EMI) shielding materials. Mater Sci Eng R 74(7):211–232

Park DH, Lee YK, Park SS, Lee CS, Kim SH, Kim WN (2013) Effects of hybrid fillers on the electrical conductivity and EMI shielding efficiency of polypropylene/conductive filler composites. Macromol Res 21(8):905–910

Yoo TW, Lee YK, Lim SJ, Yoon HG, Kim WN (2014) Effects of hybrid fillers on the electromagnetic interference shielding effectiveness of polyamide 6/conductive filler composites. J Mater Sci 49(4):1701–1708

Chhowalla M, Shin HS, Eda G, Li L, Loh KP, Zhang H (2013) The chemistry of two-dimensional layered transition metal dichalcogenide nanosheets. Nat Chem 5(4):263–275

Hu C, Mou Z, Lu G, Chen N, Dong Z, Hu M, Qu L (2013) 3D graphene–Fe3O4 nanocomposites with high-performance microwave absorption. Phys Chem Chem Phys 15(31):13038–13043

Zhang H, Xie A, Wang C, Wang H, Shen Y, Tian X (2013) Novel rGO/α-Fe2O3 composite hydrogel: synthesis, characterization and high performance of electromagnetic wave absorption. J Mater Chem A 1(30):8547–8552

Zhang X, Wang G, Cao W, Wei Y, Liang J, Guo L, Cao M (2014) Enhanced microwave absorption property of reduced graphene oxide (RGO)-MnFe2O4 nanocomposites and polyvinylidene fluoride. ACS Appl Mater Interfaces 6(10):7471–7478

Wu F, Xia Y, Wang Y, Wang M (2014) Two-step reduction of self-assembed three-dimensional (3D) reduced graphene oxide (RGO)/zinc oxide (ZnO) nanocomposites for electromagnetic absorption. J Mater Chem A 2(47):20307–20315

Liu PB, Huang Y, Wang L (2013) Synthesis and excellent electromagnetic absorption properties of polypyrrole-reduced graphene oxide–Co3O4 nanocomposites. J Alloys Compd 573:151–156

Phan CH, Mariatti M, Koh YH (2016) Electromagnetic interference shielding performance of epoxy composites filled with multiwalled carbon nanotubes/manganese zinc ferrite hybrid fillers. J Magn Magn Mater 401:472–478

Li N, Huang GW, Li YQ, Xiao HM, Feng QP, Hu N, Fu SY (2017) Enhanced microwave absorption performance of coated carbon nanotubes by optimizing the Fe3O4 nanocoating structure. ACS Appl Mater Interfaces 9(3):2973–2983

Li J, Xie Y, Lu W, Chou T-W (2018) Flexible electromagnetic wave absorbing composite based on 3D rGO-CNT-Fe3O4 ternary films. Carbon 129:76–84

Kong B, Li ZW, Liu L, Huang R, Abshinova M, Yang ZH, Tang CB, Tan PK, Deng CR (2013) Recent progress in some materials and structures for specific electromagnetic applications. Int Mater Rev 58(4):203–259

Zahari MH, Guan BH, Meng CE, Mansor MFC, Chuan LK (2016) EMI shielding effectiveness of composites based on barium ferrite, PANI, and MWCNT. PIER M 52:79–87

Qing Y, Zhou W, Huang S, Huang Z, Luo F, Zhu D (2014) Evolution of double magnetic resonance behavior and electromagnetic properties of flake carbonyl iron and multi-walled carbon nanotubes filled epoxy-silicone. J Alloys Compd 583:471–475

Liu PB, Huang Y, Yan J, Yang YW, Zhao Y (2016) Construction of CuS nanoflakes vertically aligned on magnetically decorated graphene and their enhanced microwave absorption properties. ACS Appl Mater Interfaces 8:5536–5546

Biswas S, Kar GP, Bose S (2015) Tailor-made distribution of nanoparticles in blend structure toward outstanding electromagnetic interference shielding. ACS Appl Mater Interfaces 7(45):25448–25463

Gao Y, Gao X, Li J, Guo S (2017) Improved microwave absorbing property provided by the filler’s alternating lamellar distribution of carbon nanotube/carbonyl iron/ poly(vinyl chloride) composites. Compos Sci Technol 158:175–185

Korskanov V, Dolgoshey V, Shantaliy T, Karpova I, Dragan K, Rukhaylo M (2017) Influence of an external magnetic field on the structure formation and transport properties of polymeric composites based on epoxy and Fe3O4. Ceram: Sci Life 3(36):28–33

Lazarenko A, Vovchenko L, Prylutskyy Y, Matzuy L, Ritter U, Scharff P (2009) Mechanism of thermal and electrical conductivity in polymer-nanocarbon composites. Mat-wissu Werkstofftech 40:268–272

Perets Y, Matzuy L, Vovchenko L, Prylutskyy Y, Scharff P, Ritter U (2014) The effect of boron nitride on electrical conductivity of nanocarbon-polymer composites. J Mater Sci 49(5):2098–2105

Matzui L, Vovchenko L, Perets Y, Lazarenko O (2013) Electrical conductivity of epoxy resin filled with graphite nanoplatelets and boron nitride. Mat-wissuWerkstofftech 44(2–3):254–258

Chen YH, Huang ZH, Lu MM, Cao WQ, Yuan J, Zhang DQ, Cao MS (2015) 3D Fe3O4 nanocrystals decorating carbon nanotubes to tune electromagnetic properties and EnhanceMicrowave absorption capacity. J Mater Chem A 3(24):12621–12625

Zhao B, Zhao WY, Shao G, Fan BB, Zhang R (2015) Morphology-control synthesis of a core-shell structured NiCu alloy with tunable electromagnetic-wave absorption capabilities. ACS Appl Mater Interfaces 7:12951–12960

Song NN, Yang HT, Liu HL, Ren X, Ding HF, Zhang XQ, Cheng ZH (2013) Exceeding natural resonance frequency limit of monodisperse Fe3O4 nanoparticles via superparamagnetic relaxation. Sci Rep 3:3161

Kittel C (1948) On the theory of ferromagnetic resonance absorption. Phys Rev 73:155–161

Yakovenko OS, Matzui LY, Vovchenko LL, Trukhanov AV, Kazakevich IS, Trukhanov SV, Prylutskyy YI, Ritter U (2017) Magnetic anisotropy of the graphite nanoplatelet–epoxy and MWCNT–epoxy composites with aligned barium ferrite filler. J Mater Sci 52(9):5345–5358

Walz F, Rivas J, Martínez D, Kronmüller H (1994) Influence of Ba content on the magnetic after-effect spectra in barium ferrites. Phys Status Solidi A 143:137–148

Wang GZ, Gao Z, Tang SW, Chen CQ, Duan FF, Zhao SC, Lin SW, Feng YH, Zhou L, Qin Y (2012) Microwave absorption properties of carbon nanocoils coated with highly controlled magnetic materials by atomic layer deposition. ACS Nano 6:11009–11017

Zhang H, Rao Y, Guo J, Qin G (2016) Multiple-phase carbon-coated FeSn2/Sn nanocomposites for high-frequency microwave absorption. Carbon 96:972–979

Fan X, Guan J, Wang W, Tong G (2009) Morphology evolution, magnetic and microwave absorption properties of nano/submicrometre iron particles obtained at different reduced temperatures. J Phys D Appl Phys 42(7):075006

Liu XG, Jiang JJ, Geng DY, Han Z, Liu W, Zhang ZD (2009) Dual nonlinear dielectric resonance and strong natural resonance in Ni/ZnO nanocapsules. Appl Phys Lett 94(5):053119

Al-Ghamdi AA, Al-Hartomy OA, Al-Solamy FR, Dishovsky N, Mihaylov M, Malinova P, Atanasov N (2016) Natural rubber based composites comprising different types of carbon-silica hybrid fillers. Comparative study on their electric, dielectric and microwave properties, and possible applications. Mater Sci Appl 7(6):295–306

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature B.V.

About this paper

Cite this paper

Matzui, L.Y., Yakovenko, O.S., Vovchenko, L.L., Lozitsky, O.V., Oliynyk, V.V., Zagorodnii, V.V. (2019). Polymer Nanocomposites with Hybrid Fillers as Materials with Controllable Electrodynamic Characteristics for Microwave Devices. In: Maffucci, A., Maksimenko, S. (eds) Fundamental and Applied Nano-Electromagnetics II. NATO Science for Peace and Security Series B: Physics and Biophysics. Springer, Dordrecht. https://doi.org/10.1007/978-94-024-1687-9_6

Download citation

DOI: https://doi.org/10.1007/978-94-024-1687-9_6

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-024-1686-2

Online ISBN: 978-94-024-1687-9

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)