Abstract

Glass delamination, or the generation of glass flakes, continues to be an unwanted occurrence in the manufacture of parenteral (injectable) solutions and suspensions. In this root cause analysis study, advanced analytical tools including atomic force microscopy, environmental scanning electron microscopy, quantitative image analysis, and dynamic secondary ion mass spectroscopy (D-SIMS) showed significant differences in glass characteristics and performance. By observing the size and spatial arrangement of defects found on the interior surface of vials used as primary packaging for these products, in conjunction with the chemical changes that can occur to the glass because of product contact, a considerable amount of insight can be obtained into this phenomenon. Elemental depth profiling obtained by D-SIMS revealed that the interior vial surface was significantly altered by the presence of the parenteral solution, while another vial (manufactured by another vendor) was not. Although significant chemical changes can occur to the glass, the surface defect structure appears to be the dominant factor controlling the generation of glass flakes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Glass delamination is a phenomenon encountered in the pharmaceutical industry when a injectable (parenteral) solution or suspension is incompatible with the glass vial, resulting in the generation of glass flakes. The term “delamination” only appears in pharmaceutical contexts, and has been described in several previously published studies [1–3]. The focus of these historical investigations has been to assess the impact of glass chemistry on the drug product, evaluating factors such as pH shifts, extractable content, and the generation of glass flakes. The latter is particularly troublesome in parenteral products, where the appearance of visible foreign particulates is unacceptable.

From a materials science perspective, one must understand the physiochemical interaction of the solution with the glass to minimize, or even prevent, the occurrence of glass delamination in pharmaceutical products. The purpose of this study was to examine the chemical changes that occur at the glass–liquid interface in vials that exhibit visual signs of glass delamination, as well as to describe the factors that contribute to the phenomenon.

Glass corrosion and degradation

The materials science literature, although having no mention of delamination, contains a considerable body of work on the degradation of glass, particularly as it relates to the interaction of aqueous solutions with the glass structure. White [4] has identified five phenomenological mechanisms to describe the corrosion of glass: congruent dissolution by simple dissociation; congruent dissolution by chemical reaction, incongruent dissolution with the formation of crystalline reaction products; incongruent dissolution with the formation of non-crystalline layers; and ion exchange.

The fundamental reactions for the degradation of silicate glasses hinge on the disruption of the silicate network by water. For glasses containing alkali oxides, water displaces elements such as sodium according to the following reaction:

This reaction is representative of leaching. Doremus has shown the diffusion of water into the silicate structure as molecular water, rather than as a hydrolyzed species [5].

When dissolution is the dominant mechanism, the governing reaction is:

Above pH 8, the silicic acid is ionized:

This ionization increases the solubility of silicic acid in solution, thereby driving the silica dissolution reaction forward. If unbuffered, the solution will decrease in pH due to the generation of silicic acid. This phenomenon is frequently encountered when vials containing water for injection are autoclaved at 121 °C for 15 min (a standard sterilization cycle).

The degradation mechanism can shift with changes in temperature and pH. For example, with silicate glasses, lower temperatures and pH values tend to favor the incongruent corrosion mechanisms (incongruent dissolution with the formation of crystalline reaction products; incongruent dissolution with the formation of non-crystalline layers; and ion exchange), while elevated temperatures and highly basic solutions favor the congruent mechanisms (congruent dissolution by simple dissociation and chemical reaction) [6, 7]. Anions and cations can also exacerbate the degradation process. Citrate, gluconate, tartrate, and ethylene diamine tetraacetate form soluble complexes with silica in neutral solutions [8]. By removing the most stable oxide in borosilicate glasses, these anions will dissolve silica at the solid–liquid interface.

The chemical resistance of glass to the above mechanisms is influenced by the following factors [7]: the chemical composition of the glass; temperature; duration of contact between glass and the aggressive environment; and processing history of the glass (production method, annealing, surface treatment).

Delamination, however, is a far more aggressive attack than described by the diffusion and reaction of water with the silicate glass network.

Manufacturing conditions affecting corrosion resistance

In addition to the chemistry of the bulk glass and its surrounding environment, other factors have a strong influence on the corrosion resistance of glass, particularly as it relates to glass vials. Two different industrial processes can form glass cane, which is the precursor to the formation of the vial: the Danner and Vello processes.

The Danner process operates by depositing molten glass onto a hollow rotating mandrel. Simultaneously, air is blown through the mandrel as the glass is drawn. The Vello process produces cane by inserting a hollow mandrel into a refractory bowl containing molten glass. The bowl is rotated as air is blown through the mandrel, forming the cane interior. Greater detail can be found in Ref. [9]. Vials are produced during a secondary forming process, where the cane is cut, and the bottom and neck are formed.

Elevating the temperature of the glass melt can increase production rates; however, this can have a measured impact on product quality. Throughout the initial cane and vial formation processes, the thermal profile of the glass must be closely controlled. Excessive heat will cause sodium to migrate to the inside surface of the vial (where the vial contacts the liquid), thereby increasing surface alkalinity and reducing chemical durability. This physical change continues for the entire life of the vial. Vendor B produces the cane via the Danner process, while Vendor A utilizes the Vello process. Additionally, Vendor A uses higher temperatures in the vial manufacturing process as compared to Vendor B. Sterilization and depyrogenation, additional sources of heat the vials are exposed, can also promote the migration of sodium to the vial surface.

Experimental procedure

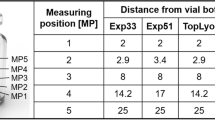

Three different Type IFootnote 1 glass vials were used in this study (Table 1): two experienced product contact; the third was used as an experimental control to quantify the interior surface of the glass. Although the composition of the formulation cannot be disclosed, the initial pH of the unbuffered liquid was approximately 8.2. The glass vials containing the solution were stored under two different temperature conditions: 40 °C and 30 °C. (These temperatures are required by the US Food and Drug Administration to demonstrate product stability.) After approximately 30 days at 40 °C, visible particulates were observed in the solution in both vials seeing product contact. After approximately 8 weeks, particles were observed in both sources of vials stored at 30 °C. The contents of ten vials per storage condition were passed through a 1.2-μm filter. After particle counting per USP 2004 <788> (data not shown), the filters were submitted for identification.

Using an FEI XL-30 field-emission environmental scanning electron microscope equipped with X-ray analysis capabilities (light element window in detector), the particles retained on the filter were identified as glass. To confirm the source of the glass particles was indeed the vial interior, the glass vials were sectioned using a diamond saw, and examined with the scanning electron microscope.

To further characterize the vial interior, glass samples were examined using atomic force microscopy (AFM, Digital Instruments Multimode Scanning Probe Microscope with IIIA controller).

Dynamic secondary ion mass spectrometry (D-SIMS) was performed to determine if any changes in glass chemistry during accelerated storage conditions could be ascribed to the delamination process. This technique has advantages over other surface analyses in that it provides elemental composition as a function of depth with a very high spatial resolution. For background information on the technique, consult Refs. [10–13]. Figure 1 shows a schematic of the D-SIMS technique. The spectra for this study were obtained using a PHI 660 DSIMS with a primary Cs+ ion beam operated at an energy of 3.0 keV. The secondary ion polarity was positive and the angle of incidence was 60°. A secondary ion gun was used for charge neutralization, thereby eliminating surface charging effects.

Results and discussion

Confirmation of glass flakes

Figure 2 shows a scanning electron micrograph and the accompanying X-ray spectrum that identify the flakes as glass.

To confirm that the source of the glass flakes was the interior of the glass vial, affected vials were sectioned using a diamond saw and examined using scanning electron microscopy. Figure 3 shows the vial interior, revealing the source of the flakes found in the solution

Characterization of surface features on the vial interior

After verification that the source of the glass flakes was the interior surface of the vial, an intense investigation was undertaken to determine if any physical attributes of the glass vial itself could be attributed to the root cause of the glass delamination. This involved examination of the interior of as-received glass vials (no exposure to drug product) using scanning electron and atomic force microscopy.

Figures 4a and b are scanning electron micrographs of the interior surface imperfections for Vendors A (ammonium sulfate treated) and B (with no ammonium sulfate treatment) vials, respectively. Note that in Fig. 4b the vials have not been ammonium sulfate treated and the surface features are less pronounced. It is hypothesized that these defects can be generated by two possible scenarios. The large crater like features shown in Fig. 4a are created by the nucleation of gas bubbles during the cooling of the glass cane (i.e. the glass tubing used to form the vials). These features are also evident in Fig. 4b. This process, known as reboil, can be controlled by decreasing the temperatures used in the cane and vial manufacture. The smaller features, however, are hypothesized to be the remnants of sodium-rich regions that have been removed by exposure to ammonium sulfate. Figures 4c and d shows the interior surface of vials produced by Vendor B that have been treated with ammonium sulfate. Pits, not visible previously, are now evident in these micrographs. Image analysis was used to quantify the size and proximity of these features. These data will be presented in a following section.

Upon discovery of the surface defects created by reboil, it was hypothesized that these defects could be playing an active role in the delamination of the glass vials. Vials manufactured by both vendors produced glass flakes in the pharmaceutical solution; however, the flakes produced in vials made by Vendor B were smaller and appeared in a shorter time period. Figure 5 shows representative images that were obtained using AFM. The AFM, operated in phase contrast mode, was able to enhance the contrast for the surface defects. These images were then analyzed using Image Pro Plus®, a commercially available image analysis software package.

Using Image Pro Plus®, the minimum distance between adjacent pores (i.e. the nearest neighbor distance) and the circular equivalent diameter were measured for the two ammonium sulfate-treated vials. These distributions are shown in Figures 6 and 7, respectively. Approximately 800 measurements were taken for each vial. These histograms show that the surface defects in the A vials are larger and farther apart form compared to the surface features in the B vials. Figure 7 shows a plot of normalized frequency versus size for the surface features. Vendor A shows a much broader size distribution for the defects, as compared to Vendor B.

Chemical analysis using D-SIMS

Dynamic SIMS was employed to determine if differences were present in the surface chemistry between vials produced by Vendors A and B. This surface analytical technique is particularly well suited for analyzing the surface chemistry of glass because of its ability to provide elemental composition as a function of depth, without requiring a secondary ion sputtering source. Figure 8 contains elemental depth profiles of Vendor A vial (treated with ammonium sulfate to reduce surface alkalinity) that has been exposed to drug product at 40 °C for approximately three months, compared with the profiles obtained from a vial that had no exposure to the parenteral solution. Boron is depleted at the surface, which is to be expected as boron is typically leached from glass. Notice how the near surface layer, however, is enriched with barium, potassium, and magnesium, atypical of leaching. Figure 9 shows the same data as in Fig. 8, with an overlay of data taken from a vial stored at 25 °C for the same length of time. The leaching of boron is more pronounced in the vial stored at 40 °C, as is the surface enrichment with barium and magnesium.

Figure 10 shows the depth profile obtained from a Vendor B vial (no ammonium sulfate treatment), stored at 40 °C for approximately three months overlaid with the elemental depth profiles obtained from an unexposed vial. There is no difference between the depth profiles of the exposed and unexposed glass.

Glass degradation by water diffusion

Water diffusion into glass-forming networks is the dominant phenomenon for the degradation of glass and has been widely studied. Doremus [14] has published the definitive work on the subject and concludes that the diffusion of molecular water and its interaction with the silicon–oxygen network describes the process. Tomozawa [15] has published diffusion coefficients for the diffusion of water in borosilicate glass (Pyrex®) as follows:

Using the above equation, diffusion profiles were plotted for 40 °C and 30 °C, as shown in Fig. 11. Also shown is the distance water would diffuse during a routine vial sterilization cycle (15 min, 121 °C, blue line on graph).

As measured by AFM, the delaminated glass flakes were approximately 200 nm thick (see Fig. 12). This thickness corresponded with the pore depth of the larger pores for the Vendor A vials. Under conditions of 40 °C, it took approximately 30 days for visible flakes to be observed, denoted by the vertical line in Fig. 11. If the diffusion of water into the oxygen–silicon network was the rate-limiting step in the process, and the critical diffusion depth was 200 nm, delamination would have occurred much more quickly. For 40 °C, delamination should have occurred in 2.1 days, while at 30 °C, the required time for water to diffuse 200 nm is 3.9 days. These calculations do not include the water diffusion encountered during the sterilization of the glass. If this were considered in the calculation, then delamination would have occurred nearly at the onset of introducing the drug solution into the vial. Thus, one can infer that either (1) the pharmaceutical molecule itself is participating in the delamination process, or (2) there is a second failure mechanism such as the actual spallation of the flakes, caused by the loss of mechanical integrity with the interior surface of the vial.

Additionally, although exhibiting much greater chemical stability in the presence of the pharmaceutical compound, delamination was first observed with vials produced by Vendor B. However, AFM showed that the surface defects on B vials were closer together.

Images collected using scanning electron microscopy support the assertion that the active pharmaceutical compound is indeed participating in the glass degradation. Vials exposed to no liquid at all or ultra clean water show no degradation, while the glass that was exposed to the pharmaceutical liquid shows significant attack, as shown in Fig. 13

Scanning electron micrographs showing the effect of different processing/exposure conditions on glass degradation for vials produced by Vendor B (no ammonium sulfate): (a) exposed to ultra-clean water, no exposure to drug, (b) exposed to ultra-clean water and sterilized at 121 °C for 15 min, (c) same treatment as (b) but exposed to active drug compound for approximately 30 days

Explanation of D-SIMS data

At first glance, the present chemical data compared to the chemical composition data shown in Table 1 appear to contradict the visual observations observed with each vial. Chemical durability is directly proportional to the silica content in the glass [16]. Therefore, glass used by Vendor A should, theoretically, show a greater resistance to chemical attack because of the higher SiO2 content, yet the D-SIMS analysis showed a distinct segregation of specific elements in this vial as a result of exposure to this parenteral product.

Although no experimental data exists to explain this significant different in chemical resistance between the two different glass vials, a possible explanation can be extracted from the processing history of each material. Vendor A utilizes the Vello process to produce the cane and uses higher temperatures to manufacture the glass vials, thus to reduce surface alkalinity and to impart greater chemical resistance, the vials are treated with ammonium sulfate [7, 8, 17]Footnote 2 (Note: increasing temperature during the vial formation process allows the manufacturing line to run at a faster speed.)

Another way to reduce the vial interior surface alkalinity is to reduce the processing temperatures used in forming vials from the glass cane. Vendor B, using the Danner process to produce the cane, relies on this strategy to impart chemical resistance. In doing so, if sodium-rich phases form, they would be smaller and closer together. Overall, however, one would not observe gross differences in sodium distribution because there would be insufficient time and temperature for these phases to grow, thereby depleting the adjacent area of sodium. This is consistent with the observation that the defects in Vendor B vials were smaller and closer together. The ternary phase diagram does reveal that phase separation can occur in sodium borosilicate glasses of the composition in question. The results of Hair and Chapman indicate that the glassy phases that form consist of a phase that is nearly 100% silicon oxide (silica) and a boron-rich phase that forms on the surface of the glass [18].

Unfortunately, in this instance, the lower processing temperatures were insufficient to prevent delamination from occurring in the Vendor B vials. The surface defects were sufficiently close to each other that the flakes were generated even in the absence of the strong chemical bonding events demonstrated with the Vendor A vials.

Proposed delamination mechanism

The degradation of a material surface by the presence or creation of surface defects is well known in the metallurgical community. Pitting corrosion and stress corrosion cracking are localized degradation processes where the chemistry of the corrosive environment is significantly different from the ambient chemistry. These processes usually occur in alloy systems that do not exhibit generalized corrosion (e.g. “rust”). The corrosion process can create the pits due to a localized breakdown in a passive surface layer, or in this instance, they can be a pre-existing surface defect generated during manufacturing [19–21] (Fig. 14).

The nearest neighbor and size data shown in Figs. 6 and 7, combined with visual observation, show that although vials produced by Vendor B are more chemically intert, signed of delmation were exhibited signs of more quickly.

Below is the proposed mechanism for glass delamination based upon the data found in this investigation. Aqueous solution diffuses into the surface defects. Over time, the ionic concentration in the pits increases, creating a highly corrosive environment. This solution proceeds to attack the material on the interior of the pits, perhaps at a faster rate than the ambient liquid located at the glass–liquid interface. From the scanning electron micrograph shown in Fig. 1, combined with the D-SIMS data, it appears the corrosive liquid diffuses under the surface layer, causing it to spall and create glass flakes in the parenteral solution.

Figure 15 shows a flake that has spalled from the interior surface of an “A” vial, revealing the presence of pits on the surface.

Another factor that could explain the “slowness” of the delamination reaction when compared with the kinetics of water diffusion in glass, is the presence of another failure mechanism that is rate limiting: the actual separation or breakage of the flake away from the vial interior. Glass flakes may appear only when there is a sufficient shear force exerted by mechanical agitation to separate the flakes from the vial interior.

A similar phenomenon, known as crizzling, has been documented in the literature regarding the degradation of glass antiquities in the presence of ambient moisture [22–26]. According to Rogers et al. [26], ambient moisture diffuses into the glass. Hydronium ions replace the alkali ions in the glass network. Because these ions are smaller than their alkali counterpart, a residual tensile stress is developed, which eventually leads to microcracking of the glass surface. The increasing surface alkalinity will also dissolve the silicate structure, causing flakes to be generated.

Chemical analysis of environmentally degraded glass, however, reveals a different scenario. Rather than surface enrichment with elements such as Mg, K, Ba, etc., there is enrichment in Si, indicating that other elements have been leached [23, 26]. This difference could be created by the interaction of the drug molecule with the glass-forming elements.

Conclusions

Based upon the experimental data and theoretical interpretations, the following statements can be asserted: the overall chemical resistance of glass used in pharmaceutical vials is not sufficient to prevent delamination from occurring for all compounds. Delamination has been observed with other molecules and functional groups (data not presented here); the manufacturing processes used to produce the cane and vial can have a significant impact on the chemical resistance of the glass; the size and distance between surface defects are the dominant factors in glass delamination; in this study, the active drug molecule participated in the degradation of vials produced by Vendor A; and the generation of glass flakes has been documented with the environmental degradation of glass antiquities; however, with this phenomenon, the glass surface exposed to ambient moisture is deplete of group IA and IIA elements.

Notes

Pharmaceutical nomenclature for borosilicate glass.

Upon heating, the ammonium sulfate decomposes. The gaseous sulfate reacts with the sodium in the glass, forming sodium sulfate, which is then removed when the vials are washed.

References

Ennis RD et al (2001) Pharm Dev Technol 6(3):393

Roseman TJ, Brown JA, Scothorn WW (1976) J Pharm Sci 65(1):22

Borchert SJ, Ryan MM (1989) J Parent Sci Technol 43(2):67–79

White WB (1992) In: Clark DE, Zoitos BK (eds) Corrosion of glass, ceramics and ceramic superconductors: principles, testing, characterization, and applications. Noyes Publications, Park Ridge, NJ, pp 2–28

Doremus RH (1967) In: Mitchell JW, DeVries RC (eds) Reactivity of solids. Wiley, New York, p 667

McIntyre NS, Strathdee GG, Phillips BF (1980) Surf Sci 100:71

Dimbley B (1953) J Pharm Pharmacol 5:969

Bacon FR, Raggon FC (1959) J Am Ceram Soc 42(4):199

Stevens HJ (1991) In: Schneider SJ (ed) Ceramics and glasses. ASM International, Materials Park, pp 394–401

Leadley SR et al (1998) Macromolecules 31(25):8957

Rossi A et al (2000) Surf Interface Anal 29(7):460

Swift AJ (1995) Mikrochim Acta 120(1–4):149

Vickerman JC, Briggs D (eds) (2001) ToF-SIMS: surface analysis by mass spectrometry. IMS Publications and Surface Spectra Limited, Chichester

Doremus RH (1995) J Mater Res 10(9):2379

Tomozawa H, Tomozawa M (1989) J Non-Crystal Solids 109:311

Doremus RH (1994) Glass science, 2nd edn. John Wiley & Sons Inc, New York, p 339

Adams PB (1977) Bull Parent Drug Assoc 31(5):213

Hair ML, Chapman ID (1966) J Am Ceram Soc 49(12):651

Davison RM, DeBold R, Johnson MJ (1987) In: Korb LJ, Olson BA (eds) ASM handbook. ASM International, Materials Park, OH, pp 547–566

Uhlig HH, Revie RW (1985) Corrosion and corrosion control, 3rd edn. John Wiley & Sons, New York, p 441

Fontana MG (1986) Corrosion engineering, 3rd edn. McGraw-Hill, New York, p 556

Fern S, McPhail DS, Oakley V (2004) Appl Surf Sci 231–232:510

Branda F et al (1999) Glass Technol 40(3):89

Gillies KJS, Cox A (1988) Glastech Ber 61(4):101

Schreiner M (1988) Glastech Ber 61(7):197

Rogers P, McPhail D, Ryan J (1993) Glass Technol 34(2):67

Acknowledgments

The authors would like to acknowledge the many participants in this study including: Dr. Dinesh Mishra, Dr. Heather Weimer, Mr. Eric Olsen, Ms. Sheryl Peoples, and Mr. David Crozier.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Iacocca, R.G., Allgeier, M. Corrosive attack of glass by a pharmaceutical compound. J Mater Sci 42, 801–811 (2007). https://doi.org/10.1007/s10853-006-0156-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0156-y