Abstract

We describe a chemical method based on the use of cyclodextrins (CDs) and citric acid (CTR) as finishing chemicals for the modification of polyester fibers (PET). It was observed that the reaction between these reactants yielded a cross-linked polymer, by formation of ester functions between the polyol (CD) and the polycarboxylic acid (CTR). This polymer (called polyCTR-CD) permanently coated the PET fibers. The chemical structure of polyCTR-CD consisted of CD moieties and unreacted carboxylate groups. Theses groups resulted from the partial reaction of CTR and yielded ion exchange property to the fibers. The purpose of this paper was to set up the finishing parameters in order to obtain the best possible ion exchange capacity (IEC) of the fabrics. Firstly, we observed that the IEC did not perfectly evolve with the grafting rate (expressed in %-wt) of the fibers; As a matter of fact, we observed that a maximal IEC of 0.4–0.5 mmol/g of fabric was obtained for a compromise between the amount of polyCTR-CD fixed onto the fibers, and its cross-linking rate. In fact, the lesser the cross-linking rate, the more unreacted carboxylic groups remained on the fibers. Second, it was observed that CDs could not be replaced by starch in this process, because the later resulted to inferior IEC values than textiles grafted with CDs and CTR. Finally, the ion exchange finished fabrics were applied in the decontamination of water solutions containing Pb2+, Ni2+ and Cd2+. It was observed that 0.3 mmol of each cation were adsorbed per gram of fabrics.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The use of cyclodextrins (CDs) in the textile domain is a challenge that appeared in the early 80’s [1]. The complex forming properties of CDs towards a multitude of organic substances represent new functionalities for the textile supports. It is in order to develop such textiles that the CDs grafting reaction by using polycarboxylic acids has been developed. At the origin, this reaction was developed in order to graft CDs onto cotton and wool fabrics [2] and then, onto synthetic fibers such as polyester [3]. Thus, CD finished textiles present the capability to capture organic molecules like fragrance [4], aromatic pollutants [5] or drugs [6], through their inclusion into the grafted CDs cavities.

The mechanism has been studied in a preliminary study [3]. As CD presents many hydroxyl groups and thus may react with other polycarboxylic acid moieties, a polymerization can develop and a cross-linked polymer (polyCTR-CD) is formed in situ, in the fibrous network (Sch. 1). On one hand, the obtained modified fabrics presented the intrinsic properties of CDs (complexation properties towards organic molecules). On an other hand, as the esterification reaction was not complete, many free carboxylic groups were present on the surface of the coating polymer and yielded an ion exchange property to the fabrics. The aim of the present study was to measure the ion exchange capacity (IEC) of the textiles finished by this method. In order to obtain fabrics with the best IEC, we studied the reaction parameters (time and temperature of curing, nature and concentration of CDs). Then these fabrics were used in depollution tests, in the presence of water containing heavy metallic cations (Pb2+, Cd2+, Ni2+) to estimate their real aptitude in ion exchange.

Materials and methods

Materials

Poly(ethyleneterephtalate) (PET) nonwoven fabrics (surface weight = 65 g m−²) were supplied by NORDLYS PGI (Bailleul, France). Citric acid hydrate (CTR), sodium, hypophosphite (NaH2PO2), calcium acetate, sodium hydrogenocarbonate and metals used for the depollution tests (nitrate salts of lead, nickel and cadmium) were Aldrich chemicals (Milwaukee, Wi, USA). α-CD and γ-CD were supplied by Wacker Fine Chemicals GmbH (Burghausen, Germany), and β-CD and starch were gifts from Roquette (Lestrem, France). The textile finishing equipment consisted of two roll pad and curing oven equipped with a mechanical circulation of air (Roaches, Stafforshire, UK).

Methods

The textile finishing method was previously reported [3]. In standard conditions, the impregnation bath was an aqueous solution containing CTR (10% w/w), the catalyst (NaH2PO2) (1% w/w) and the polyol (CDs or starch) (10% w/w). Fabrics were impregnated with this solution and padded (wet pick up was 100% ± 3%). Then, the fabrics were oven dried at 90 °C for 6 min, and cured at a desired temperature and time. Samples were washed with water by soxhlet (solvent:water) in order to remove unreacted products. The grafting rate was reported as the weight gain (%-wt) of the samples.

where mf and mi were the weight of sample after and before treatment, respectively. The Ion Exchange Capacity (IEC) of the samples was determined by pH-metric titration according to the method of calcium acetate [7–8] described in the US Pharmacopoeia (USP 1995). A calcium acetate solution 2% (w/w) was prepared by solubilizing calcium acetate in distilled water. A sample of fabric, previously weighted, was finely cut and placed into the calcium acetate solution for 4 h. The solution was filtered, and the amount of acetic acid formed was measured by pH-metric titration with a sodium hydroxide solution (0.05 M) (Sch. 2). The results are reported in mmol of COOH groups per gram of fabric.

Before the depollution tests, a post treatment with a solution of sodium hydrogenocarbonate was applied to obtain the carboxylate form (COONa) of the ion exchange groups. Indeed, the carboxylate groups are more efficient to realize ion exchange than the carboxylic groups.

Depollution tests were carried out in static batch system. Metal solutions were prepared by solubilization of nitrate salts of the metallic species in distilled water. The textile samples were placed into the metallic solution and stirred for 2 h. The supernantant were then filtered and the amounts of metal were determined by flame atomic absorption (Spectrometer Perkin-Elmer 2380).

Results and discussion

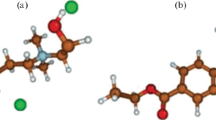

Picture 1(a) and (b) shows respectively SEM views of PET fibers before and after treatment. One can observe the regular and smooth aspect of untreated fibers on Picture 1(a) and empty spaces between the fibers. Picture 1.(b) shows the modification of the polyester fibers surface due to the coating by polyCTR-CD. The surface of the fibers is less regular and smooth, and the empty spaces between untreated fibers are partially, filled by the polymer.

Influence of the curing parameters

The evolution of the grafting rate versus temperature and time of curing for samples treated with CTR are represented on Fig. 1a and b. We observed an increase of grafting rate with the temperature of curing, and then the curves reached a plateau at different temperatures, depending on curing time. The upper limit of temperature was fixed to 200°C because of the thermal degradation of fabrics, CDs and polymer over this value. In parallel, we observed that the grafting rate increased with time of curing and then stabilized at a maximal value also depending on the temperature of curing. The data obtained from Fig. 1a and b was combined to generate a two-dimension graph presented in Fig. 1c. Thanks to this graph it is possible to determine the best adapted curing parameters to obtain a desired grafting rate. The maximal values of %-wt (16–18%) were obtained with temperatures between 180°C and 200°C, and a reaction time comprised between 30 and 60 min.

Figure 2a and b represent the evolution of IEC respectively versus curing temperature and curing time. We observed that the curves of IEC versus time and temperature of curing, firstly, increase, reach an optimal value, and then present a tendency to decrease (especially for increasing temperature (Fig. 2a)). In fact, for low values of time and temperature of curing, IEC evolved in a parallel way with %-wt, then the maximum value of IEC was reached, and then it decreased with increasing curing parameters. This phenomenon is easy to observe on Fig. 2c, representing the IEC of fabrics versus time and temperature of curing, where we observed that the maximum IEC (0.4–0.5 mmol/g) is obtained for temperatures between 160°C and 170°C and a reaction time comprised between 20 and 45 min.

The explanation of these phenomenon is that first, a threshold time or temperature of curing is necessary to develop the formation of cross-linked polymer between CTR and CD. The parallel increase of IEC and %-wt is due to the growth of the polymer around the fibers. Then, the decrease of the IEC (despite the constant %-wt) at highest time and temperature of curing is due to a post-cross-linking phenomenon that overcame the growth of polymer. This post-cross-linking reaction consumes the free carboxylic groups that are esterified with the surrounding OH groups of CDs. Therefore, the maximum of IEC corresponds to the best compromise between the growth of polyCTR-CD onto the fibers and its cross-linking rate.

Influence of the nature and concentration of polysaccharides

We compared the three native cyclodextrins and starch as polyols in the impregnating bath. CDs differ only by the number of glucopyranosic units in the macrocycle, and starch consists of the same repetition units that build high molecular weight branched macromolecules.

Figure 3a and b represent the variation of %-wt and IEC versus the concentration of the different polyols. Figure 3a shows that the nature of polyols did not involve any difference in the grafting rates of samples as an overlapping of the four curves is observed. The same results obtained with the three CDs shows that the ion exchange capacity is not in relation with the cavity size, and that CDs are not directly involved ion exchange mechanism. On the other hand, the IEC measurements showed a different behavior between CDs and starch. Indeed, the evolution of IEC was equivalent for the three kinds of CDs treated samples and it was superior to the IEC of the starch treated samples. This is probably due to the different reactivity between CD and starch in the polyesterification reaction with CTR. PolyCTR-CD contains more free COOH groups than poly CTR-STARCH. To conclude, the IEC measurements show that CDs are appropriate to our goal and cannot be replaced by starch in the present textile finishing process.

Depollution tests

Depollution tests were realized in batch experiments. They consisted to put the IEC textile samples in the presence of solutions containing the different metallic cations (Pb2+, Ni2+ and Cd2+). Figure 4 shows the adsorption kinetics of the heavy metals by the textile samples. We observed that the sorption phenomenon occurred within the first 30 min of the experiment for the three cationic species. A time of contact of 120 min was applied for the isotherms of adsorption presented on Fig. 5 to ensure that the sorption equilibrium was reached. Besides, the isotherms presented on Fig. 5 shows that the fabric was saturated with 50, 20 and 18 mg/g (0.25, 0.17 and 0.30 mmol/g) for lead, cadmium and nickel, respectively. The amounts (in mmol/g) of sorbed metal mentioned above are approximately twice inferior to the IEC of fabrics measured by titration with calcium acetate (Table 1). This indicates that probably more than one COOH group is involved in the chelating of these divalent cations.

Conclusion

In this paper we studied the reaction which allowed to functionalize polyester nonwoven fabrics by a cyclodextrin polymer. The ion exchange capacity of the modified fabrics was not due to CDs, but to the existence of unreacted carboxylic groups in the structure of the CD polymer which coated the fibers. It was also observed that the replacement of CDs by starch in the process resulted to a lesser ion exchange capacity. This remark highlighted the opportunism of the use of CD as carbohydrate compound for our purpose. Furthermore, other possible chemical paths reported in the literature did not reach IEC in the same range as the one described here.

We showed that optimal IEC values were obtained for intermediate curing parameters, in order to obtain an optimal quantity of grafted polyCTR-CD with the lesser possible cross-linking rate. Depollution tests carried out in static conditions towards lead, nickel and cadmium cations proved that the modified fabrics presented a real efficiency in ion exchange. In addition, the measured sorption capacity was comparable to other existing systems like resins or commercial ion exchange textiles. Other polycarboxylic acids with different structures are in experiment in order to reach superior IEC values.

Finally, such a finishing process presents the advantage to give versatile fabrics that may interact not only by ion exchange mechanism, as studied in this paper, but also by inclusion of organic compounds in the CDs cavity (see reports of the same authors in the literature). Such a finishing process that may involve interactions with substrates by two complementary mechanisms should offer a large panel of applications, especially in the field of technical textiles and biomaterials.

References

Szejtli, J., Zsadam, B., Fenyvesi, E., Horvarth, O., Tudos, F., US Patent 4.357.468 (1982)

Martel, B., Weltrowski, M., Ruffin, D., Morcellet, M.: Polycarboxylic acids as crosslinking agents for grafting cyclodextrins onto cotton and wool fabrics : study of the process parameters. J. Appl. Polym. Sci. 83, 1449–1456 (2002)

Martel, B., Morcellet, M., Ruffin, D., Ducoroy, L., Weltrowski, M.: Finishing of polyester fabrics with cyclodextrins and polycarboxylic acids as crosslinking agents. J. Inclusion Phenom. Mol. Recognit. Chem. 44(1–4), 443–446 (2002)

Martel, B., Morcellet, M., Ruffin, D., Vinet, F., Weltrowski, M.: Capture and controlled release of fragrances by cyclodextrins finished textiles. J. Inclusion Phenom. Mol. Recognit. Chem. 44(1–4), 439–442 (2002)

Martel, B., Le Thuaut, P., Bertini, S., Crini, G., Bacquet, M., Torri, G., Morcellet, M.: Grafting of cyclodextrins onto polypropylene non woven fabrics for the manufacture of reactive filters. III: study of the sorption properties. J. Appl. Polym. Sci. 85(8), 1771–1778 (2002)

Martel, B., Blanchemain, N., Morcellet, M., Hildebrand, H.F., Haulon, S., Boschin, F., Delcourt, F., Debruyne, E.: FR Patent 04.12.086 (2004)

Xun, H., Xiang, Z.: Determination of carboxyl group on fabric by acid-base titration. J. China Textile Univ. (Eng. Ed.), 15(4), 10–12, (1998)

USP (United States Pharmacopeia 23/National formulary 18) (1995)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ducoroy, L., Martel, B., Bacquet, B. et al. Ion exchange textiles from the finishing of PET fabrics with cyclodextrins and citric acid for the sorption of metallic cations in water. J Incl Phenom Macrocycl Chem 57, 271–277 (2007). https://doi.org/10.1007/s10847-006-9172-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10847-006-9172-4