Abstract

Wire Arc Additive Manufacturing is a Direct Energy Deposition additive technology that uses the principle of wire welding to deposit layers of material to create a finished component. This technology is finding an increasing interest in the manufacturing industry, especially thanks the low cost and the possibility to build large-scale components. Nowadays, the boosting to transition into smart manufacturing systems and the increasingly computational resources allowed the development of intelligent applications for smart production systems for both in situ inspection and process parameter control. This paper aims to provide an review of applications developed using artificial intelligence techniques for Wire Arc Additive Manufacturing, with particular focus on defect detection software modules, feedback generation for control system and innovative control strategies as reinforcement learning to overcome problems related to model non-linearity and uncertainties.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

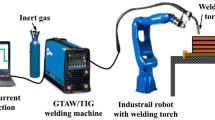

Wire Arc Additive Manufacturing (WAAM) is a largely promising welding-based additive manufacturing process due to its simplicity and high efficiency of metal transfer, near to 90% (Dupont & Marder, 1995), but especially for its low cost and possibility to build large size components (Williams, 2016) with a high deposition rate. A WAAM workstation Fig. 1 consists of a motion platform, a welding equipment and of a Weld Monitoring System (WMS). The WMS comprises a data acquisition unit, processing unit and other relevant associated sensors that can be used to acquire various welding process parameters like voltage, current, weld pool image etc, useful for various applications such as online quality inspection, closed-loop control and system identification of the process.

To identify the most discussed topic about this technology we conducted a brief bibliometric analysis. Using the query “ WAAM OR (Wire AND Arc AND Additive AND Manufacturing) ” to the Scopus website and limiting the research to document writing in the english language, 1920 documents on WAAM can be founded. As reported in Fig. 2, even more articles are published on this topic starting from 2010, with an annual growth rate of 60% and 5337 total citations. Moreover, in the last 4 years (2019–2022), 1417 articles were produced so 73 % of the total production.

Furthermore, as reported in the histograms in Figs. 3 and 4 in which the top 6 keywords are obtained for the period from 2010 to 2022 and from 2020 to 2022 as results of clustering activity, during the period between 2020 and 2022, the most discussed topic is changed from mechanical proprieties and post-processing, process parameters, defects, materials and welding process to artificial intelligence, welding process, process monitoring, defect monitoring and system control, so for this reason even more attention has to be made in the usage of artificial intelligence techniques.

Finally, using the following query (WAAM OR (wire AND arc AND additive AND manufacturing) OR (arc AND welding) OR GTAW OR GMAW) AND (control OR monitoring OR model) AND ((machine AND learning) OR (reinforcement AND learning) OR (artificial AND intelligence) OR (neural AND network)) and considering the articles produced from 2012 to 2022, 424 documents are obtained, and the tree of most used keywords, reported in Fig. 5, shown that the principal used technique is the deep learning and the most applications are related to bead geometry (30), defects monitoring and quality control (19–28) and process control and optimisation (28–19).

Additional information about the conducted bibliometric analysis is reported in the appendix of this work A. One of the most discussed topics is related to defect detection since it is particularly beneficial during an Additive Manufacturing process because the presence of a defect in the previous layers affects the integrity of the subsequent ones. The on-line in situ defect detection software modules associated with WMS have a crucial role in the new production paradigm of industry 4.0, since they overcome some of the challenges associated to the currently used Non-destructive testing (NDT), e.g. an ultrasonic test reported in Fig. 6, which requires experienced observers and is time-consuming.

Since WAAM is a technological process based on welding, it is characterized by the same defects, such as porosity, cracks, inclusions, sticking, and burn-through as reported in Fig. 7, which depend on the choice of process parameters and especially their variation during processing. Mathers (2002)

Typical defects in a Gas Metal Arc Welding process (Madhvacharyula et al., 2022)

Furthermore, WAAM is also subjected to typical additive process defects such as porosity, delamination, residual stresses, and deformation, which can be reduced by choosing and controlling the interpass temperature (Ma et al., 2015), which act as pre-heating of the next layer or other post-processing techniques, as reported in a review article of Wu (2018). For what concerns defect genesis, it is possible asses that the supplied heat has a crucial role. By observing the Eq. 1, which describes the amount of heat source supplied during the process, it is possible to identify the parameters that are connected to heat generation, so with the presence of defects in the components, such as the arc voltage drop, the arc current and the welding speed.

As described by Doodman Tipi and Pariz (2015), the arc current \((I_{arc})\) depends on the arc length \((l_a)\), which in turn depends on Contact To Workpiece Distance (CTWD) and stick-out (\(l_s\)), as highlighted by the geometrical representation in Fig. 8. The stick-out (\(l_s\)) depends on the Wire Feed Speed (WFS) and the wire material and diameter \((2r_d)\). Finally, the whole presented parameters are also connected to the arc drop voltage \((V_{arc})\). This means that the controllable variables of a WAAM process are:

-

the rotational speed of the feeder unit, which leads to Wire Feed Speed (WFS) through a gearbox

-

the voltage of the welding machine (V)

-

the height of the torch from components, namely Contact To Workpiece Distance (CTWD)

-

the welding speed (WS), which together with CTWD is a control parameter associated with the motion platform

It is important to notice that the controllable parameters are related to heat generation and so with the presence of defects, so the correct selection and control of process parameters is crucial from a quality point of view.

Moreover, considering the work of Pires et al. (2006), also the gas mix and flowrate have an impact also on the final surface, as reported in Fig. 9, so it is another important parameter to monitoring and control during the process.

Effects of gases on bead geometry. Argon (a); argon+oxygen (b); CO2 (c); argon+CO2 (d); helium (e); argon+helium (f) (Pires et al., 2006)

Finally, it is demonstrated that also the interpass temperature has a significant impact on the final quality of the components, in terms of residual stress or final distortion Wu et al. (2006) and layer geometry Kozamernik et al. (2020). For this reason, a WMS need to be able to monitor all of these process parameters, using different sensors, with the aim of speed-up the inspection phase and, simultaneously, creating a feedback loop for the control system. Even if a relationship between process parameters and defects exists, finding a reliable correlation between them is not a trivial task, so different advanced data-driven techniques can be used and merged together to reach the goal, such as deep neural networks. Furthermore, these advanced techniques can be used also with the aim to obtain data-driven models for Wire Arc Additive Manufacturing, with the twofold objective to create (I) a model useful for simulations and control design (II) and soft-sensor that help to estimate variables and create feedback loop bypassing the necessity of the presence of additional sensors and software modules to elaborate the information making systems cheaper and smarter. These are the main reasons why several researchers have become involved in bead geometry modelling, process optimisation and optimal control as reported by the bibliometric analysis. Following the idea proposed By Xu (2018), there are two types of parameters to monitor:

-

Process parameters, that depends directly by welding machine and motion platform, such as arc current, arc voltage, shielding gas flow rate, welding speed and wire feed speed

-

Part/environmental parameters, which are the parameters associated to the part condition such as heat accumulation, bead geometry, defects, which are essentially consequences of process parameters and path planned.

So a good WMS has to monitor both process and parts parameters to estimate the final quality and to allow the closed-loop control of all the important features of the process. From a control perspective, the Wire Arc Additive Manufacturing process, like welding, suffers from many difficult problems related to (i) its non-linear (Bingu & Cook, 1999) and (ii) stochastic behaviour, since not all physical relationships are known, e.g. the effect of gasses on layer geometry, and (iii) the necessity to have a controller able to manage constraints on manipulate and state variables and (iv) their multivariable interactions (Xiong et al., 2014). In practice, the WAAM system is a non-linear stochastic MIMO system subjected to constraints on control variables and on the state value, that are connected to defects, so even if traditional control design tools are still used, thanks to their stability and performance proofs, more advanced techniques had been additionally developed to reach higher performance. In particular, nowadays even more attention is given to data-driven control methods based on artificial intelligence and machine learning. In this work, after a brief introduction to deep learning techniques, a review of applications of artificial intelligence in monitor and control Wire Arc Additive Manufacturing is presented. Since WAAM is based on single pass arc welding, they have many similarities in monitoring and control methods, so some relevant wire welding applications will also be presented, as they can be easily extended to WAAM. The paper is outlined as follows: since the most used data-driven technique is deep learning, in Sect. Deep learning techniques a brief recap of these techniques is presented. In Sect. Applications in Wire Arc Additive Manufacturing monitoring the applications in process monitoring are presented for both defect monitoring and process parameters monitoring. Finally, in Sect. Applications in Wire Arc Additive Manufacturing control applications in process parameter control and optimisation are presented.

Deep learning techniques

In computer science, the researcher defines AI as the study of intelligent agents, devices that perceive environments and can take actions to reach goals. Bini (2018) Machine learning is a subset of AI, and the typical workflow consists of collecting data, extracting features from this data and labelling data. Once the prior knowledge is ready, an optimization algorithm [(Nesterov, 1983; Hinton et al., 2012; Kingma & Ba, 2014)] might be used to allow machines to learn from this “experience” composed of correlation between features and labels. In this framework, the goodness of “ground-truth” and extracted features generated by computer scientists significantly impact the final results. Inspired by biology, computer scientists, mainly thanks to increasingly powerful computer chips and microprocessors, created statistical models called Artificial Neural Networks (ANNs) (Hopfield, 1988) that can process data inputs as the human brain does. These models can extract essential features directly from data in a self-way manner, allowing scientists to focus on the raw data quality and hyper-parameters tuning.

Artificial neural network

The core idea of a neural network (Fig. 10) is to find the parameters \(\theta \) of a function f that minimize a cost, once a non linear combination of the inputs are made \(y = f_\theta (x)\). The success of the method came from a universal approximation theorem due to Cybenko (1989) and Hornik et al. (1989) and from backpropagation (LeCun et al., 1988). The basic structure of a neural network is the artificial neuron, a function f of the inputs \(x=(x_1...x_n )\) weighted by a vector of connection weights \(w = (w_{j,1}... w_{j,n})\) and completed by a bias \(b = (b_1... b_j)\) and non linear function called activation function \(\Phi \):

The activation function \(\Phi \) and the initialization algorithm of the weights at the beginning of training are crucial ingredients for neural networks (Pedamonti, 2018) and several functions (Clevert et al., 2015) and initialization algorithms (Glorot & Bengio, 2010) might be used.

Recurrent Neural Network

Recurrent Neural Networks (Fig. 11) are used to infer sequential data such as text or time series, and for this purpose, a feedback loop is created into the networks’ inputs.

Elman (1990) and Jordan (1990) proposed this model for the first time in 90’s and the difference was the feedback, the hidden layer or the output. Respect to Eq. 2 another gate is added to compute the output at time t:

The matrix \(w^{r}\) is composed by weights at layer k for the memory of previous hidden/output layer. Even if RNN are very powerful dynamic models used to menage sequential data they falls to learn long time dependancies (Bengio et al., 1994) due to the vanishing gradient problem (Hochreiter et al., 2001), which has led to the development of other architectures as Long Short-Term Memory (LSTM) (Hochreiter & Schmidhuber, 1997) or Gated Rrecurrent Unit (GRU) (Cho et al., 2014) (Fig. 13).

Thanks to the presence of weighted input, output and forget gates an LSTM could prevent the gradient vanishing, allowing to store long term memory without losing training performance. The Gated Recurrent Unit (GRU) is similar to LSTM but simpler to compute and implement. Based on LSTM the GRU combines the forget gate and input gate into the update gate and merges the hidden state with cell state, simplifying the architecture by reducing the number of weights, which corresponds to faster training, without losing performance.

Convolutional Neural Network

For some data like images, in which spatial information is relevant, multilayer perceptrons are not helpful since they are defined for vectors as input data; The innovations introduced by LeCun with the Convolutional Neural Networks (CNN) (LeCun & Bengio, 1995) were helpful since the development of computer vision applications passed by the “manual” extraction of features that required a lot of image processing experience to a self-learning features capability of the agent. The CNN is composed of several layers, such as the Convolutional and Pooling layers, that stacked together (LeCun et al., 1998) allow the network to extract features during the learning process, and a fully connected layers, as reported in Fig. 14 that solves the defined task using the extracted features. Over the years, more complex and accurate architectures were proposed, and new hints to build a performance CNN were discovered. [(Krizhevsky et al., 2017; Zeiler & Fergus, 2014; Simonyan & Zisserman, 2014; Szegedy, 2015; He et al., 2016; Huang et al., 2017)]

A comprehensive benchmark of different architectures is shown in the ball chart in Fig. 15. Bianco et al. (2018) The presented ball chart reports the accuracy with respect to computational complexity on the ImageNet-1k validation set for different convolutional neural network architectures, each one described by a ball. The ball size corresponds to the model complexity, described by the number of parameters.

Deep reinforcement learning

Reinforcement learning (RL) is a subfield of machine learning used to solve sequential decision-making problems, such as optimal control problems, which nowadays is ever more used in different fields of sciences such as robotics (Polydoros & Nalpantidis, 2017) and finance (Mattera & Mattera, 2023). The main idea, in Fig. 16, is that an intelligent agent interacts with an environment and receives states and scores (or rewards) from it, depending on the goals. Subsequently, the agent acts on the environment to minimize/maximize a loss/reward.

The optimal control law, a function between environment states and control output, is called policy \(\pi \), and it is the output of RL. Unlike other optimal control frameworks such as LQR or MPC, RL approach does not care about the dynamics of the system. In order to to find an optimal policy RL uses the Bellman equation and the Dynamic Programming (DP) (Bellman, 1954) technique if the system under control has Markovian properties or the Monte Carlo methods when the transition function of the system is unknown (Sutton & Barto, 2018).

The value function V can be defined as a function able to provide an output in response to an state input. This output comprises a scalar that explains how good the state is. We can also define the Q function as the same of the value function but for the tuple action-state. We can assert that the aim of RL is to find the correlation between the current state and the action to take. In that sense, the optimal policy is obtained using a straightforward method, taking the action which is associated with the higher Q value.

In addition to algorithms like Q-learning (Watkins, 1992), temporal-difference error (TDE)-based algorithms such as SARSA (Rummery & Niranjan, 1994) have been proposed to update the V and Q values. These algorithms can be used only for discrete space systems, and the optimization problem becomes complicated and time-consuming to solve when the number of states or action increase. In order to overcome these limitations, neural networks are used to approximate the V and Q tables, in Fig. 17 thanks to their generalization capability. Algorithms like Deep Q Networks (Mnih, 2015) or Double Deep Q Networks (Van Hasselt et al., 2016) are used to estimate Q tables, using neural networks with a softmax output layer and argmax policy based on Q-learning ideas. Meanwhile gradient-based techniques such as REINFORCE (Williams, 1992) have been developed to estimate the optimal policy directly using optimization algorithms as stochastic gradient ascent. Tamari (2016) Nowadays even more complicated algorithms are developed with the aim to manage system with continuous space (Grondman et al., 2012) as REINFORCE with baseline (Fig. 18) (O’Donoghue et al., 2016), advantage actor-critic (A2C), Asynchronous Actor-Critic A3C (Mnih et al., 2016) or that have faster-convergency proprieties likes Trust Region Policy Optimization (TRPO) (Schulman et al., 2015), Deep Deterministic Policy Gradient (DDPG) (Hou et al., 2017), Proximal Policy Optimization (PPO) (Schulman et al., 2017) and Soft Actor-Critic (SAC) (Haarnoja et al., 2018). In conclusion, even if the direct interaction with the system led to the use of such methods to solve complex real-world problems, since they give a general-purpose method to explore a complex environment and learn the fundamental principles of the world through observation and action, (Arulkumaran et al., 2017) the major problem is guaranteeing the stability of the trained model and verifying the stability of the system under control (Recht, 2019).

Applications in Wire Arc Additive Manufacturing monitoring

Nowadays, driven by the increasing demands for improved quality, productivity and flexibility, advanced methods to online inspect components’ quality have become crucial targets for the development of modern production systems. For this purpose, different sensors are applied to observe and estimate process parameters with the aim to generate a feedback loop for the control system and monitoring the presence of defects. Generally, robotic systems are equipped with encoders that provide information about the joint’s pose and velocity, while power sources could provide information regarding wire feed speed, current and voltage. External sensors could be integrated into a WAAM system with appropriate processing modules to provide additional information about the process, such as geometry information, using optical sensors such as profilometers and camera, temperature information, using thermal camera or pyrometer, or information regarding metal transfer mode and presence of defects using acoustic sensors. In the following section, AI applications in the development of monitoring systems are presented for arc current and voltage signals (I), acoustic signals (II), optical signals (III) and thermal signals (IV). Furthermore, each section is divided into defect and process monitoring applications.

Arc current and voltage signals

Defect monitoring

The arc current and voltage signals recorded during welding operation are reliable indicators of arc stability and help to identify defects in the weld bead or the deposited layers for WAAM. As mentioned above, typical WAAM defects are cracks, porosity and lack of penetration; these defects are associated with non-correct process parameters or specific heat. The specific heat during an arc process is 1:

Observing the formula 1, it is clear that arc current and voltage greatly impact defect presence. In general, if the specific heat is too low due to low current or high welding speed, a lack of penetration with the previous layer occurs, while high values of specific heat, associated with a low welding speed, may lead to the presence of cracks that lead to the mechanical properties of final components.

Several studies have used statistical tools to evaluate defects, principally porosity or lack of penetration, as proposed in [Wei et al. (2001), Johnson et al. (1991), Sumesh (2017), Wu et al. (2006)], once features were extracted from signals (Figs. 10, 11, 12, 13, 14, 16, 17, 18, 19).

For example (Adolfsson et al., 1999) used features such as arc and short-circuit times, short-circuit count, short-circuit peak current, average welding current and arc voltage waveforms in a short arc welding process and the Sequential Probability Ratio Test (SPRT) as defect detection alghortim. Few works have evaluated the possibility of using neural networks to solve the defect detection problem based on signals from the welding machine. Shin et al. (2020) used six features extracted each 0.1 s of a short circuit welding as input of a fully connected network once CTWD, WFS, welding speed and shielding gas mix were fixed. These features were voltage standard deviation (std), voltage std during arc period, average arc time, number of short-circuiting periods, std of short-circuit time and std of instantaneous short-circuit voltage. During experiments, arc voltage was measured with a sampling rate of 10kHz for 20 s. In this way, an accuracy of 89.5% was reached. Nele et al. (2022) (Fig. 19) used four features to train a deep neural network that were the errors of instantaneous values of current, voltage and welding speed from those defined in the Welding Procedure Specification (WPS) (max and min current, mean voltage and mean welding speed) with an accuracy of 94,7%.

Li (2022) proposed a Support Vector Machine incremental learning approach to identify defects during the WAAM process after statistical features extraction. This method can identify defects with an accuracy of 90% using a small amount of data initially; the system is also reinforced over time as more data enters the system and exhibits the ability to find new defects during the learning process (Figs. 24, 25, 31, 32, 33, 35, 36).

Process monitoring

Another significant usage of process parameter signals is associated with the possibility of estimating the bead geometry. Xiong et al. (2014) used a second-order regression model and a neural network, as reported in Fig. 20, to predict bead width and height based on process parameters signals such as WFS, welding speed, arc voltage and CTWD, since arc current depends on these factors with an RMSE% less than 2 % for ANN and 2,6% for second-order regression. They showed that neural networks gave better results thanks to their generalization capability. Sivasakthivel and Sudhakaran (2018) studied also the effect of shielding gas and torch angle on bead formation.

Kumar et al. (2016) used a neural network to predict bead convexity index and penetration with a mean error of 1.63 % for a CMT welding using the average current, voltage and welding speed. They found that the geometry of the layers depends principally on the wire feed speed and welding speed ratio. In particular, the layer width and height increased with an increase in wire feed speed, and the bead width decreased for higher welding speed. Chen et al. (2000) developed a neural network to estimate the backside geometry of the weld pool during a GTAW process using process parameters such as arc current and voltage, welding speed and CTWD at sample time t and the same parameters acquired with two times delay. Yin et al. (2019) used the current and previous CMT current to estimate the weld penetration, bead width and weld height or reinforcement for a single pass CMT welding through a simple neural network with an accuracy of 97%, and the used scheme is shown in Fig. 21.

Jin et al. (2020) converted the current signal in a scalogram by a Morlet wavelet transform and processed it in a CNN to estimate the back-bead model with an accuracy of 93,5%. According to the literature, this approach might also be used to estimate the welding penetration.

Acoustic signal

Defect monitoring

Monitoring the audible sound emitted by the welding process is often based on the experience of the welders since it gives good information regarding the transfer mode (Arata et al., 1979) or pool behaviour in general. The new computational capabilities allowed researchers to investigate the possibility of elaborating these signals with innovative deep learning techniques. As shown by Horvat et al. (2011) different sound sources appear during welding as a sound impulse, when a short arc occurs, or as a turbulent noise during spray arc mode. As demonstrated in Erdmann-Jesnitzer et al. (1967) the sound is related to the arc length and current. In particular, the sound pressure increases according to current and arc length, which enables the use of the acoustic signal to find defects during the process as current and voltage measurements. In particular, since the sound intensity can directly reflect the energy variation of the process, and since most defects are related to energy variation, acoustic signal analysis is widely used in features and defect recognition. Chen et al. (2010), Pal et al. (2010) showed that some features of the audio signal (e.g. kurtosis) could be used to detect burn-through during welding, as reported in Fig. 22. Other authors used audio signals to estimate defects during welding; Yusof et al. (2017) used an Hilbert Huang transform and the energy information to detect the presence of defects.

Process monitoring

Audio signals can be used also to predict the process behaviour, such as stability and level of penetration. Roca et al. (2009) developed an artificial neural network that predicts the stability of GMAW process based on statistical and temporal features extracted by the acoustic emission (AE) signal. The features used in this work were the average of the peaks amplitudes in the instant of short circuit, the standard deviations of these peaks, the short circuit frequency, the time between peaks and its std, the sound pressure level in dB and RMS value of the acquired signal. Similarly, Pernambuco et al. (2019) used an artificial neural network with three hidden layers to classify transfer mode with 84% accuracy, which is related to process stability. Lv et al. (2017) demonstrated that the acoustic signal is also related to the penetration state, as reported in Fig. 23, so they extracted 39 features from the audio signal and train a neural network to classify the state of penetration in 3 different states. Subsequently, they developed a controller for the penetration level. In particular, they increase the heat input to achieve more penetration, otherwise, they reduced it, increasing or decreasing the arc current of a pre-defined value, but no intelligent control system is used in this work.

Network architecture and software module proposed in Nele et al. (2022)

Rohe et al. (2021) (Fig. 24) used a CNN to evaluate the deviation of the shielding gas from the ones defined in the Welding Procedure Specification using arc sound. Since audio is distance-dependent, they mounted the microphone parallel to the welding torch with a distance of 380 mm from the arc. Starting from a gas flow rate of 15 L/min they decreased by steps of 1.5 L/min until no shielding gas was used. Once the signal was filtered with a passband filter 500-20kHz, they used an STFT. The spectrogram, after a normalization, passed in a CNN, reaching an accuracy of 94%. They showed that a flow rate below 70% of reference also produces unacceptable pores in the weld, which makes this method suitable as a defect detection module.

Soft sensor to measure bead geometry used in Xiong et al. (2014)

Using of current signal to predict bead geometry in Yin et al. (2019)

Welding defect monitoring with sound kurtosis (Pal et al., 2010)

Sound signal of different penetration states reported by Lv et al. (2017)

CNN trained by Rohe et al. (2021) to predict from sound spectrogram the deviation of shielding gas from once defined in the WPS

Optical signal

Process monitoring

As presented above, it is possible to estimate geometrical parameters of the weld pool with secondary sensors, such as current sensors or encoders, and artificial intelligence tools that create soft-sensors. However, their use increases measurement uncertainty, making developing truly robust control systems challenging. Furthermore, as mentioned above, a trusty acquisition of the pool geometry is mandatory to develop supervised learning algorithms. For these reasons, optical sensors are used to create direct feedback to the control system or to create labels for AI algorithms that allow the creation of soft sensors. Due to the intense light noise induced by the arc, high-speed laser sensors or cameras with appropriate 660 or 850 nm band-filters have to be used. Pinto-Lopera et al. (2016) used cameras to compute the pool geometry in real-time through computer vision algorithms. In other examples, Xia (2020) extracted geometrical information from the welding camera by using computer vision techniques as Canny algorithm, as reported in Fig. 25.

Computer vision algorithm toe xtract bead width during WAAM proposed in Xia (2020)

Xiong and Zhang (2013) used classical computer vision techniques such as Gaussian filter, Sobel operator and Hough transformation to extract the characteristic points of the bead geometry to compute bead width. Since the bead height is not always equal to the programmed distance during the process, an error of layer height accumulates rapidly and defects occur due to changes in stick out (or CTWD) and consequently to the arc current. For this reason, another camera is used to estimate the CTWD, which helps better estimate the bead width. The information coming from this processing module might be used for a closed-loop controller. Chen et al. (2000) used a vision system to extract geometrical information of a weld pool from images to train a neural network that estimates the geometrical parameters of the pool based on time-delayed process parameters, avoiding inserting a camera and a heavier processing algorithm in the software module. The same authors in Chen et al. (2003) designed a neuron self-learning Proportional-Summational-Differential (PSD) controller that adaptively changes PSD gains by interacting with the system, using this soft-sensor-like feedback signal. Optical signals might also be used to detect defects during the process. Chen et al. (2021), used an Active appearance model to extract information about the geometrical aspect of the weld pool and a random forest algorithm to estimate the penetration level using the extracted visual features. Not only CCD cameras are used with artificial intelligence techniques to measure or estimate the the geometrical aspect of the deposited bead. Xia (2022) used a profilometer to measure the surface roughness of the deposited layers, as reported in Fig. 26, varying the overlap ratio and the ratio between the welding speed and the wire feed. They compared the performance of different machine-learning algorithms, such as Extreme learning machine (ELM), Support vector regression (SVR) and Adaptive neuro-fuzzy inference system (ANFIS) in which parameters are optimised using Genetic algorithm (GA) or Particle swarm optimisation (PSO). They demonstrated that, among developed models, GA–ANFIS achieved the highest prediction performance with an RMSE of 0.069.

Schematic diagram to quantify average surface roughness proposed by Xia (2022)

Wang (2020) discovered that the image of the molten pool in the next frame would be affected by the previous one due to heat accumulation, which suggests that a correlation between frames exists. With this assumption, they used a Lotter et al. (2016) to predict the molten pool geometry after 140 ms in the long term; this allowed to improve the control margin since quick solidification dynamics introduced some uncertainties in the pool geometry control.

Defect monitoring

In addition to defects internal to the material, such as porosity or sticking of the different layers, important defects are also those observable externally such as the humping defect, so also optical sensors can be used to monitor the presence of defects. Cho et al. (2022) used CNN for anomaly detection tasks with respect to a regular bead. In particular, they compared the results of Net169, ResNet50V2, InceptionResNetV2, and MobileNetV2 and discovered that MobileNetV2 gives the best results in computational time (33 ms) and similar results in accuracy (95%). Also, Lee et al. (2021) used transfer learning with a VGG16 CNN architecture to develop a defect detection system with high accuracy once HDR images of abnormal humping and regular beads were collected. Zhang et al. (2019) used 11 layers-CNN to estimate the lack of penetration defects during GTAW once images from different angles are acquired, and data augmentation with rotation and additional noise was made with an accuracy of 99%. Pan et al. (2020) used a transfer learning algorithm that modified the structure of the existing MobileNet to monitor welding defects in a small dataset. Xia et al. compared the results in accuracy for defects classification for WAAM process (Xia et al., 2022) of different CNN architectures and discovered that ResNet gave the best results with an accuracy of 97.62% in classification of humping, spatter and regular process. Similar results are reached in Xia et al. (2020), where some images that composed the dataset are reported in Fig. 27. Nomura et al. (2021) used a CNN to solve a classification problem to predict a burn-through defect and a CNN with a final regression layer to estimate the penetration depth from images acquired every 0.1 s with a band-pass filter of 980 nm.

Dataset used in Xia et al. (2020) to train a CNN for quality inspection purpose

Methodology in Penttilä et al. (2019) for intelligent process parameters variation

ANN proposed by Yu et al. (2021) for penetration state monitoring from features extracted by thermal camera

Illustration of single bead geometry and schematic diagram of the multilayer neural network proposed by Wang (2020). The input of the neural networks are the measured interpass temperature, the wire feed speed and welding speed (TS) used during deposition

Evolution of the shape of the weld pool from the elliptic (flawless) to the drop type (start of the formation of humping) reported by Alfaro et al. (2015)

Architecture of ANN for optimal reference generation and Fuzzy controller developed in Cruz et al. (2015)

ARX model response of system in Xia (2020)

Illustration of the ML framework for Adaptive Welding Speed Adjustment, developed in Kershaw et al. (2021)

Results of MPC controller proposed by Xia (2020) at changing in references (1-2) and disturbances (3)

Closed loop performance of actor-critic controller proposed by Jin et al. (2019)

Li (2022) explored the possibility of using YOLOv3 (Redmon & Farhadi, 2018) architecture with modified anchors to develop a software module for item location detection and defect detection. Although the results regarding component location are excellent (100%), the same is not valid for defect detection accuracy (53%). However, the usage of optical vision systems is not limited to system identification and defect detection. Penttilä et al. (2019) designed a vision system with an intelligent decision-making software module, reported in Fig. 28, composed of a neural network to develop an adaptive artificial intelligence (AI)-based gas metal arc welding (GMAW) parameter control system. The machine vision system uses a laser sensor to scan the upcoming seam, so welding parameters are optimized according to the trained neural network.

Thermal signal

Process monitoring

Wire Arc Additive Manufacturing is a very complex thermal process with different and quick thermal exchanges. In analogy to welding processes, the thermal history is a crucial parameter that influences the mechanical properties due to its strong correlation with microstructures. Wu et al. (2019) Since the temperature is a significant parameter to monitor, infrared thermography is widely used since it provides fast responses, broad detection ranges and non-contact in welding and WAAM applications. As such, thermal cameras or pyrometers (Almeida & Williams, 2010) are currently used in WMS. It has been recently demonstrated that there is a relationship between temperature and weld penetration (Chen & Chin, 1990). Furthermore, thermography is also used to estimate this parameter and the pool geometry (Menaka et al., 2005) thanks to the acquisition of images, and given the complexity of the problem, artificial intelligence techniques might be used. Chokkalingham et al. (2012) used a thermal camera to extract eight features from the pool geometry such as peak temperature, the mean and standard deviation of the Gaussian temperature profile, thermal area, length and width of the weld pool, full-width half maximum of the Gaussian temperature curve and Bead width computed from the first derivative curve of the Gaussian temperature curve and an ANN to estimate the depth of penetration in a GTAW process. Vishnuvaradhan et al. (2013) used two different ANFIS models to predict bead width and depth of penetration with better results than two MLP networks, using a Cellular Automata algorithm to manipulate the thermal image and extracting from processed images the best features. Ghanty (2008) showed that a Radius Based Function Network (RBF) performs better in estimating the bead width and the depth of penetration compared to a Multi-Layer Perceptron network using features extracted from a thermal camera during a GTAW process. Yu et al. (2021) extracted features such as the first moment, second moment and Hu invariant moments from thermal images ROI for a CMT welding process. These features were used in an ANN to classify the state of penetration such as full-penetration, no-penetration and excessive penetration, as reported in Fig. 29, with an accuracy of 99% for each class.

Furthermore, Wang (2020) used also the temperature information, in particular the interpass temperature value, to predict the bead geometry, together with wire feed speed and welding speed, as reported in Fig. 30.

In another example, Caio (2021) used neural networks to predict microstructure properties, using as label thermographic parameters obtained from a thermal camera and as input the process parameters as arc current and voltage, WFS and welding speed. The Fusion Zone and four parameters that explain Heat Affected Zone (namely CGHAZ, FGHAZ, IHAZ, and SHAZ) were predicted with an error of 12%. Nguyen (2022) proposed an approach based on the usage of feedforward neural networks to simulate the thermal cycle of a wall-structure component made by a single WAAM deposition, once synthetic data is obtained by a finite element (FE)-based model.

Defect monitoring

Alfaro et al. (2015) (Fig. 31) found that seamless welds have a temperature distribution that varies smoothly in the weld pool, while welds with defects, such as humping, present abrupt changes in the distribution of temperatures; this means that temperature could be used to estimate the presence of defects.

Sreedhar et al. (2012) extracted statistical features from a stacked thermal image of a shell and dome structure and correlated these to the presence of defects. Chen et al. (2010) proposed a residual neural network to classify defects with an accuracy of 96% using thermal images collected by a MAG32 at 50 Hz with an inference time of 1.35 ms. Mozaffar (2018) showed that Gated Recurrent Units could predict thermal behaviour during a Direct Energy Deposition process using temperature signals. Fernández et al. (2020) used a CNN-LSTM network to identify defects by acquiring images from a thermal camera for a CMT welding process with 97% accuracy. According to the authors, this network architecture can exploit the complex temporal dynamics of the process, improving the classification accuracy with respect to a standard CNN (95% on the same dataset) that uses only spatial information and no temporal ones.

Applications in Wire Arc Additive Manufacturing control

As discussed above, process parameters are strongly related to the presence of defects in WAAM components, and WMS with AI software modules might be developed to identify the defects in real-time. The possibility of identifying defects during the process is an essential characteristic of innovative production systems; these systems should also be able to regulate in real time all the process parameters to avoid defect occurrence. For these reasons, the same sensors used for quality monitoring have to be used to create feedback loops for control systems; however in the optics of intelligent systems, also the information processed by these software modules might be used in this scope. Since the welding process behind WAAM is a non-linear, high-coupled dynamic system, classical control systems such as PIDs, developed on the assumption of linear dynamics of the system under control, cannot be used optimally. For this reason, the research community developed innovative control techniques, such as those based on deep learning. Cruz et al. (2015) (Fig. 32) used an ANN to estimate the welding speed, WFS and voltage to obtain the desired bead width and a Fuzzy logic controller for the welding speed adjustment based on measurements from the vision sensor.

Lü et al. (2010) developed a model-free gradient-based controller (MFC) for the backside width. This controller had peak current welding and WFS as control variables and errors in the input. The error was computed by subtracting the reference width from the estimated backside width. The estimated backside width was given from a soft sensor composed of a neural network in which the inputs were the output of the vision algorithm that measured the topside width and the control variables. Xia et al. developed two works related to intelligent control of WAAM. In Xia (2020) (Fig. 33) the authors developed an ARX model to describe the relationship between layer width and WFS, using computer vision algorithms such as Canny and Wiener filters and least square estimation. Based on this data-driven model, they developed a Model Predictive Control and tested the performance in simulation, comparing the results reached with a PID controller (Fig. 34). The same authors in Xia (2020) developed a data-driven model for the WAAM process, an Adaptive Neuro Fuzzy Inference System (ANFIS), and they showed lower error compared with ARX model. They developed a Model-Free Adaptive Iterative Learning Controller (MFAILC) and tested it on a real system once learning was done in a simulated environment with an ANFIS model to simulate the WAAM dynamics.

Mu et al. (2022) used a similar approach, based on an ARX model and MPC, to build multilayer components and compared the results with a PID controller. Kershaw et al. (2021) developed a machine learning framework to adjust the welding speed for the bead width control. In particular, as reported in Fig. 34, a CNN is used to estimate the bead width, while a feedforward network is used to adjust the welding speed with the aim to reduce the error.

Wang (2021) proved that controlling only the bead width or bead height brought no useful results because even if the error for one state is minimized, e.g. the error for the bead width, the error associated with the other state tends to be large. Therefore they developed an active disturbance rejection control (ADRC) to adjust the welding current to obtain the desired bead height and width for a multi-layer WAAM process for wall structures, once a model by step-response identification was obtained, and non-linearities were treated as external disturbances. As discussed above, the bead geometry is not depended only by current, so without controlling other parameters as welding speed, a greater height at the beginning of the layer and a lower height at the end were discovered due the heat accumulation. Furthermore, all the proposed controllers are tested for multi-layer single bead deposition, so other considerations have to be considered, such as the influence of the overlapping distance (Ding et al., 2015).

For these reasons, other controllers have to be explored. Reinforcement learning is a control technique increasingly used in the automation field because fascinating results are reached in literature to solve complex problems, such as playing Go (Silver, 2016). In this framework, a policy selects the optimal control action to take based on input from the environment. This action subsequently influences the environment, and a reward quantifies the effect of this influence on the problem of interest. Dharmawan et al. (2020) proposed a model-based RL algorithm using a Gaussian Process Regression model for the WAAM and a greedy policy that maximizes rewards. The results showed that better surface finish and more near-net-shape could be obtained with a learning approach; this reduced the materials waste or buy to fly ratio. In the context of Selective Laser Melting Additive Manufacturing Ogoke and Farimani (2021) used the Proximal Policy Optimization algorithm for optimal control of the laser velocity and power to obtain a more stable melt pool and reduce overheating during the path, according with reward. Jin et al. (2019) (Fig. 36) applied an Actor-Critic agent with RBF neural networks to obtain the optimal welding current that minimizes the error of pool width during a GMAW process. They trained the agent in simulation with a simple regression model obtained from the experiments once the other parameters were fixed. They also tested the robustness of the AC controller concerning disturbances, and they discovered the ability of the agent to react to disturbances in an optimal way, which is not possible for an open-loop controller in which the current is chosen through the inversion of plant dynamics.

Other exciting approaches are proposed in the literature. Li et al. (2019) used an Actor-Critic agent to estimate the optimal gains of an adaptive PID controller, meanwhile Mezaache et al. (2022) used a Particle Swarm Optimization (PSO) algorithm to choose the optimal parameters of welding speed, welding voltage, WFS and CTWD in order to minimize the width of the Heat Affected Zone (HAZ) during a GMAW process.

A digital twin interacts with the real process in a bidirectional way. It evolves dynamically impulsed by the real system, and act on it once a simulation of its future behaviour is done. In this way, e.g., an optimal control system, that is a part of DT, can change process parameters to avoid defect formation or an excessive roughness value. Furthermore additional information can be send to a SCADA system

Future research opportunity and conclusion

Defect monitoring

Different types of defects can be found in WAAM components and it is known that they are related to the process parameter selection. For example, porosity and lack of penetration defects can be monitored with arc current, arc voltage, wire feed speed, welding speed and using acoustic or thermal information. As shown in the literature, with suitable sensors and simple neural network architectures, it is possible to develop online defect detection software with reasonable accuracy, generally better than standard software based on signal processing techniques. Although the estimates obtained from neural networks are accurate, they are trustworthy when input parameters stay in the observation range with which the network was trained; this means that what happens outside the ranges is uncertain. So, even if from the above literature review it is possible to state that the potential of using AI techniques for defect monitoring is well known, future research should be investigating the performance of such methodologies outside the training ranges, since most of the greater results are related to overfitting. For this purpose, more robust defect monitoring systems based on multi-sensor platforms and sensor fusion algorithms should be developed and innovative techniques to deal with the network overfitting needed to be developed.

Process monitoring

As reported in the presented literature review, process parameters are also related to layer geometry (bead width, height and penetration); also in this case, neural networks can be used to approximate data-driven relationships with great results due to their generalization capabilities. Optical sensors can also be used to measure the bead geometry, but even if they give more realistic results, the required high frame rate and the hardware and software complexity increase the equipment cost. For this reason, soft-sensors can introduce a redundant acquisition system and can reduce equipment costs, so the possibility of developing data-driven models is very important for the industry. Moreover, these methodologies make it possible to find unknown relationships between variables, such as the influence of shielding gases or the influence of the interpass temperature on the final geometry of the deposited layer. Furthermore, some parameters that can only be observed after characterisation, such as the extent of heat-altered zones and penetration depth, can be estimated using approximation methods such as neural networks, providing the only way to create a feedback loop for a control system. From a control point of view, the possibility of developing data-driven models that relate bead geometry, and other process information, to process parameters plays a key role in the development of simulation environments. By coupling these models with existing physical models (Doodman Tipi & Pariz, 2015), highly detailed and computationally low-cost simulation models can be developed, which can enable the design of control systems in simulation. Furthermore, such modelling techniques can be used in the future for the realisation of Digital Twin, which is of fundamental importance in view of I4.0 and I5.0 production systems. In particular, by defining digital twins as computational units that dynamically evolve by exchanging data with the real system and that act at the same time on the system (Tao et al., 2018), the presented modelling and monitoring methodologies can be used to develop optimal control applications, estimate some not observable parameters and send them to a SCADA system and make it possible to overcome the main limitations related to the enormous computational power required for the simulation of a DT, which is schematic reported in Fig. 37.

Also if the developed works opened to these new applications, no works can be founded in the literature regarding this application for digital twin development.

Process control

In addition to online monitoring applications, the importance of control systems was highlighted. In fact, the control system allows for varying the process parameters to achieve the desired requirements. A review of the literature showed that most authors explored solutions to control only one geometrical feature of the deposition process, e.g. only the bead width or the bead width. Even if the results were significant, many limitations affect the applicability in an industrial environment, since the same process parameters affect in a different manner the geometry parameters, so multi-variable control system needed to be developed. Deep learning provides practical tools that might overcome the challenges associated to control of non-linear multi-input multi-output stochastic systems subjected to states and control variables constraints and easily allow for full integration and development in simulation, also considering the potential of these techniques in system modelling. Furthermore, the possibility accompanying techniques such as Reinforcement Learning are numerous, as well as the possibility of training controllers in the absence of models simply by interacting with the process. Finally, an interesting point for future research might be integrating all presented techniques’ outcomes. In particular, the output of a defect monitoring module might be used together with an output of a process monitoring module and a physical model to obtain a simulation model for the process, while an actor-critic agent can be used to learn an optimal control policy in simulation, once the reward function is written. Finally, deploying the agent policy on an industrial controller is possible using the new high-performance hardware. A representative image of what is presented and that is under development by the authors, is reported in Fig. 38.

References

Adolfsson, S., Bahrami, A., Bolmsjö, G., & Claesson, I. (1999). On-line quality monitoring in short-circuit gas metal ARC welding. Welding Journal-New York, 78, 59s.

Alfaro, S. C. A., Vargas, J. A. R., de Carvalho, G. C., & de Souza, G. G. (2015). Characterization of “humping’’ in the GTA welding process using infrared images. Journal of materials processing technology, 223, 216–224.

Almeida, P., & Williams, S. (2010). Innovative process model of ti-6al-4v additive layer manufacturing using cold metal transfer (cmt). University of Texas at Austin.

Arata, Y., Inoue, K., Futamata, M., & Toh, T. (1979). Investigation on welding arc sound (report I): Effect of welding method and welding condition of welding arc sound (welding physics, processes & instruments). Transactions of JWRI, 8(1), 25–31.

Aria, M., & Cuccurullo, C. (2017). bibliometrix: An r-tool for comprehensive science mapping analysis. Journal of Informetrics, 11(4), 959–975.

Arulkumaran, K., Deisenroth, M. P., Brundage, M., & Bharath, A. A. (2017). A brief survey of deep reinforcement learning. arXiv preprint arXiv:1708.05866.

Bellman, R. (1954). The theory of dynamic programming. Bulletin of the American Mathematical Society, 60(6), 503–515.

Bengio, Y., Simard, P., & Frasconi, P. (1994). Learning long-term dependencies with gradient descent is difficult. IEEE Transactions on Neural Networks, 5(2), 157–166.

Bianco, S., Cadene, R., Celona, L., & Napoletano, P. (2018). Benchmark analysis of representative deep neural network architectures. IEEE Access, 6, 64270–64277.

Bingul, Z., & Cook, G. E. (1999). Dynamic modeling of gmaw process, (Vol. 4, pp. 3059–3064, IEEE) .

Bini, S. A. (2018). Artificial intelligence, machine learning, deep learning, and cognitive computing: What do these terms mean and how will they impact health care? The Journal of Arthroplasty, 33(8), 2358–2361.

Caio, L. B. A., et al. (2021). Mild steel gma welds microstructural analysis and estimation using sensor fusion and neural network modeling. Sensors, 21(16), 5459.

Chen, B., Wang, J., & Chen, S. (2010). A study on application of multi-sensor information fusion in pulsed gtaw. Industrial Robot: An International Journal.

Chen, W., Chin, B., et al. (1990). Monitoring joint penetration using infrared sensing techniques. Welding Journal, 69(4), 181s–185s.

Chen, C., Lv, N., & Chen, S. (2021). Welding penetration monitoring for pulsed GTAW using visual sensor based on AAM and random forests. Journal of Manufacturing Processes, 63, 152–162.

Chen, S.-B., Zhang, Y., Qiu, T., & Lin, T. (2003). Robotic welding systems with vision-sensing and self-learning neuron control of arc welding dynamic process. Journal of Intelligent and Robotic Systems, 36(2), 191–208.

Chen, S., Zhao, D., Wu, L., & Lou, Y. (2000). Intelligent methodology for sensing, modeling and control of pulsed GTAW: Part 2–butt joint welding. Welding Journal (USA), 79(6), 164.

Cho, K., Van Merriënboer, B., Bahdanau, D., & Bengio, Y. (2014). On the properties of neural machine translation: Encoder-decoder approaches. arXiv preprint arXiv:1409.1259.

Chokkalingham, S., Vasudevan, M., Sudarsan, S., & Chandrasekhar, N. (2012). Predicting weld bead width and depth of penetration from infrared thermal image of weld pool using artificial neural network. Insight-Non-Destructive Testing and Condition Monitoring, 54(5), 272–277.

Cho, H.-W., Shin, S.-J., Seo, G.-J., Kim, D. B., & Lee, D.-H. (2022). Real-time anomaly detection using convolutional neural network in wire arc additive manufacturing: Molybdenum material. Journal of Materials Processing Technology, 302, 117495.

Clevert, D.-A., Unterthiner, T., & Hochreiter, S. (2015). Fast and accurate deep network learning by exponential linear units (ELUS). arXiv preprint arXiv:1511.07289.

Cruz, J. G., Torres, E. M., & Absi Alfaro, S. C. (2015). A methodology for modeling and control of weld bead width in the GMSW process. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 37(5), 1529–1541.

Cybenko, G. (1989). Approximation by superpositions of a sigmoidal function. Mathematics of Control, Signals and Systems, 2(4), 303–314.

Dharmawan, A. G., Xiong, Y., Foong, S., & Soh, G. S. (2020). A model-based reinforcement learning and correction framework for process control of robotic wire arc additive manufacturing, pp. 4030–4036 (IEEE).

Ding, D., Pan, Z., Cuiuri, D., & Li, H. (2015). A multi-bead overlapping model for robotic wire and arc additive manufacturing (waam). Robotics and Computer-Integrated Manufacturing, 31, 101–110.

Doodman Tipi, A. R., Pariz, N., et al. (2015). Improving the dynamic metal transfer model of gas metal arc welding (GMAW) process. The International Journal of Advanced Manufacturing Technology, 76(1), 657–668.

Dupont, J. N., Marder, A. R., et al. (1995). Thermal efficiency of arc welding processes. Welding Journal-Including Welding Research Supplement, 74(12), 406s.

Elman, J. L. (1990). Finding structure in time. Cognitive Science, 14(2), 179–211.

Erdmann-Jesnitzer, F., Feustel, E., & Rehfeldt, D. (1967). Akustische untersuchungen am schweislichtbogen. Schw. und Schn, 19(3), 95–100.

Fernández, A., Souto, Á., González, C., & Méndez-Rial, R. (2020). Embedded vision system for monitoring arc welding with thermal imaging and deep learning, pp 1–6 (IEEE).

Ghanty, P., et al. (2008). Artificial neural network approach for estimating weld bead width and depth of penetration from infrared thermal image of weld pool. Science and Technology of Welding and Joining, 13(4), 395–401.

Glorot, X., & Bengio, Y. (2010). Understanding the difficulty of training deep feedforward neural networks, pp. 249–256 (JMLR Workshop and Conference Proceedings).

Grondman, I., Busoniu, L., Lopes, G. A., & Babuska, R. (2012). A survey of actor-critic reinforcement learning: Standard and natural policy gradients. IEEE Transactions on Systems, Man, and Cybernetics, Part C, 42(6), 1291–1307.

Haarnoja, T., Zhou, A., Abbeel, P., & Levine, S. (2018). Soft actor-critic: Off-policy maximum entropy deep reinforcement learning with a stochastic actor, pp. 1861–1870 (PMLR).

He, K., Zhang, X., Ren, S., & Sun, J. (2016). Deep residual learning for image recognition, pp. 770–778.

Hinton, G. E., Srivastava, N., Krizhevsky, A., Sutskever, I., & Salakhutdinov, R. R. (2012). Improving neural networks by preventing co-adaptation of feature detectors. arXiv preprint arXiv:1207.0580.

Hochreiter, S., Bengio, Y., Frasconi, P., & Schmidhuber, J. et al. (2001). Gradient flow in recurrent nets: the difficulty of learning long-term dependencies.

Hochreiter, S., & Schmidhuber, J. (1997). Long short-term memory. Neural Computation, 9(8), 1735–1780.

Hopfield, J. J. (1988). Artificial neural networks. IEEE Circuits and Devices Magazine, 4(5), 3–10.

Hornik, K., Stinchcombe, M., & White, H. (1989). Multilayer feedforward networks are universal approximators. Neural Networks, 2(5), 359–366.

Horvat, J., Prezelj, J., Polajnar, I., & Čudina, M. (2011). Monitoring gas metal arc welding process by using audible sound signal. Strojniški vestnik-Journal of Mechanical Engineering, 57(3), 267–278.

Hou, Y., Liu, L., Wei, Q., Xu, X., & Chen, C. (2017). A novel DDPG method with prioritized experience replay, pp. 316–321 (IEEE).

Huang, G., Liu, Z., Maaten, L. V. D., & Weinberger, K. Q. (2017). Densely connected convolutional networks, 2261–2269. IEEE Computer Society.

Jin, Z., Li, H., & Gao, H. (2019). An intelligent weld control strategy based on reinforcement learning approach. The International Journal of Advanced Manufacturing Technology, 100(9), 2163–2175.

Jin, C., Shin, S., Yu, J., & Rhee, S. (2020). Prediction model for back-bead monitoring during gas metal arc welding using supervised deep learning. IEEE Access, 8, 224044–224058.

Johnson, J., Carlson, N., Smartt, H., & Clark, D. (1991). Process control of GMAW: Sensing of metal transfer mode. Welding Journal, 70(4), 91.

Kershaw, J., Yu, R., Zhang, Y., & Wang, P. (2021). Hybrid machine learning-enabled adaptive welding speed control. Journal of Manufacturing Processes, 71, 374–383.

Kingma, D. P., & Ba, J. (2014). Adam: A method for stochastic optimization. arXiv preprint arXiv:1412.6980.

Kozamernik, N., Bračun, D., & Klobčar, D. (2020). Waam system with interpass temperature control and forced cooling for near-net-shape printing of small metal components. The International Journal of Advanced Manufacturing Technology, 110(7), 1955–1968.

Krizhevsky, A., Sutskever, I., & Hinton, G. E. (2017). Imagenet classification with deep convolutional neural networks. Communications of the ACM, 60(6), 84–90.

Kumar, N. P., Vendan, S. A., & Shanmugam, N. S. (2016). Investigations on the parametric effects of cold metal transfer process on the microstructural aspects in aa6061. Journal of Alloys and Compounds, 658, 255–264.

Lecun, Y., & Bengio, Y. (1995). Convolutional networks for images, speech, and time series. The Handbook of Brain Theory and Neural Networks, 3361(10), 1995.

LeCun, Y., Bottou, L., Bengio, Y., & Haffner, P. (1998). Gradient-based learning applied to document recognition. Proceedings of the IEEE, 86(11), 2278–2324.

LeCun, Y., Touresky, D., Hinton, G., & Sejnowski, T. (1988). A theoretical framework for back-propagation,1, 21–28.

Lee, C., Seo, G., Kim, D. B., Kim, M., & Shin, J.-H. (2021). Development of defect detection ai model for wire+ arc additive manufacturing using high dynamic range images. Applied Sciences, 11(16), 7541.

Li, Q., Li, G., Wang, X., & Wei, M. (2019). Diffusion welding furnace temperature controller based on actor-critic, pp. 2484–2487 (IEEE).

Li, Y., et al. (2022). A defect detection system for wire arc additive manufacturing using incremental learning. Journal of Industrial Information Integration, 27, 100291.

Li, Y., et al. (2022). Towards intelligent monitoring system in wire arc additive manufacturing: A surface anomaly detector on a small dataset. The International Journal of Advanced Manufacturing Technology, 120(7), 5225–5242.

Lotter, W., Kreiman, G., & Cox, D. (2016). Deep predictive coding networks for video prediction and unsupervised learning. arXiv preprint arXiv:1605.08104.

Lü, F., Chen, H., Fan, C., & Chen, S. (2010). A novel control algorithm for weld pool control. Industrial Robot: An International Journal.

Lv, N., Xu, Y., Li, S., Yu, X., & Chen, S. (2017). Automated control of welding penetration based on audio sensing technology. Journal of Materials Processing Technology, 250, 81–98.

Ma, Y., Cuiuri, D., Shen, C., Li, H., & Pan, Z. (2015). Effect of interpass temperature on in-situ alloying and additive manufacturing of titanium aluminides using gas tungsten arc welding. Additive Manufacturing, 8, 71–77.

Madhvacharyula, A. S., et al. (2022). In situ detection of welding defects: A review. Welding in the World, 18, 1–18.

Mathers, G. (2002). Weld defects and quality control. Welding of Aluminium and Its Alloys, 15, 199–215.

Mattera, G., & Mattera, R. (2023). Shrinkage estimation with reinforcement learning of large variance matrices for portfolio selection. Intelligent Systems with Applications. Forthcoming.

Menaka, M., Vasudevan, M., Venkatraman, B., & Raj, B. (2005). Estimating bead width and depth of penetration during welding by infrared thermal imaging. Insight-Non-Destructive Testing and Condition Monitoring, 47(9), 564–568.

Mezaache, M., Babes, B., & Chaouch, S. (2022). Optimization of welding input parameters using PSO technique for minimizing HAZ width in GMAW. Periodica Polytechnica Mechanical Engineering, 66(2), 99–108.

Mnih, V. et al. (2016). Asynchronous methods for deep reinforcement learning, pp. 1928–1937 (PMLR).

Mnih, V., et al. (2015). Human-level control through deep reinforcement learning. Nature, 518(7540), 529–533.

Mozaffar, M., et al. (2018). Data-driven prediction of the high-dimensional thermal history in directed energy deposition processes via recurrent neural networks. Manufacturing Letters, 18, 35–39.

Mu, H., et al. (2022). Layer-by-layer model-based adaptive control for wire arc additive manufacturing of thin-wall structures. Journal of Intelligent Manufacturing, 33(4), 1165–1180.

Nele, L., Mattera, G., & Vozza, M. (2022). Deep neural networks for defects detection in gas metal arc welding. Applied Sciences, 12(7), 3615.

Nesterov, Y. E. (1983). A method for solving the convex programming problem with convergence rate. 269, 543–547

Nguyen, H. D., et al. (2022). Rapid and accurate prediction of temperature evolution in wire plus arc additive manufacturing using feedforward neural network. Manufacturing Letters, 32, 28–31.

Nomura, K., Fukushima, K., Matsumura, T., & Asai, S. (2021). Burn-through prediction and weld depth estimation by deep learning model monitoring the molten pool in gas metal arc welding with gap fluctuation. Journal of Manufacturing Processes, 61, 590–600.

O’Donoghue, B., Munos, R., Kavukcuoglu, K., & Mnih, V. (2016). Combining policy gradient and q-learning. arXiv preprint arXiv:1611.01626.

Ogoke, F., & Farimani, A. B. (2021). Thermal control of laser powder bed fusion using deep reinforcement learning. Additive Manufacturing, 46, 102033.

Pal, K., Bhattacharya, S., & Pal, S. K. (2010). Investigation on arc sound and metal transfer modes for on-line monitoring in pulsed gas metal arc welding. Journal of Materials Processing Technology, 210(10), 1397–1410.

Pan, H., Pang, Z., Wang, Y., Wang, Y., & Chen, L. (2020). A new image recognition and classification method combining transfer learning algorithm and mobilenet model for welding defects. IEEE Access, 8, 119951–119960.

Pedamonti, D. (2018). Comparison of non-linear activation functions for deep neural networks on MNIST classification task. arXiv preprint arXiv:1804.02763.

Penttilä, S., Kah, P., Ratava, J., & Eskelinen, H. (2019). Artificial neural network controlled GMAW system: Penetration and quality assurance in a multi-pass butt weld application. The International Journal of Advanced Manufacturing Technology, 105(7), 3369–3385.

Pernambuco, B. S. G. et al. (2019). Online sound based arc-welding defect detection using artificial neural networks, (pp. 263–268, IEEE).

Pinto-Lopera, J. E., ST Motta, J. M., & Absi Alfaro, S. C. (2016). Real-time measurement of width and height of weld beads in GMAW processes. Sensors, 16(9), 1500.

Pires, J. N., Loureiro, A., & Bölmsjo, G. (2006). Welding Robots: Technology, System Issues and Application. Springer.

Polydoros, A. S., & Nalpantidis, L. (2017). Survey of model-based reinforcement learning: Applications on robotics. Journal of Intelligent & Robotic Systems, 86(2), 153–173.

Recht, B. (2019). A tour of reinforcement learning: The view from continuous control. Annual Review of Control, Robotics, and Autonomous Systems, 2, 253–279.

Redmon, J. & Farhadi, A. (2018). Yolov3: An incremental improvement. arXiv preprint arXiv:1804.02767.

Roca, A. S., Fals, H., Fernández, J., Macías, E., & De La Parte, M. (2009). Artificial neural networks and acoustic emission applied to stability analysis in gas metal arc welding. Science and Technology of Welding and Joining, 14(2), 117–124.

Rohe, M., Stoll, B. N., Hildebrand, J., Reimann, J., & Bergmann, J. P. (2021). Detecting process anomalies in the GMAW process by acoustic sensing with a convolutional neural network (CNN) for classification. Journal of Manufacturing and Materials Processing, 5(4), 135.

Rummery, G. A., & Niranjan, M. (1994). On-line Q-learning using connectionist systems (Vol. 37). Cambridge: Department of Engineering, University of Cambridge.

Schmidhuber, J.(1990). Artificial neural network. IEEE 112–127.

Schulman, J., Levine, S., Abbeel, P., Jordan, M., & Moritz, P. (2015). Trust region policy optimization, pp. 1889–1897 (PMLR).

Schulman, J., Wolski, F., Dhariwal, P., Radford, A., & Klimov, O. (2017). Proximal policy optimization algorithms. arXiv preprint arXiv:1707.06347.

Shin, S., Jin, C., Yu, J., & Rhee, S. (2020). Real-time detection of weld defects for automated welding process base on deep neural network. Metals, 10(3), 389.

Silver, D., et al. (2016). Mastering the game of go with deep neural networks and tree search. Nature, 529(7587), 484–489.

Simonyan, K., & Zisserman, A. (2014). Very deep convolutional networks for large-scale image recognition. arXiv preprint arXiv:1409.1556.

Sivasakthivel, P., & Sudhakaran, R. (2018). Modelling and optimisation of welding parameters for multiple objectives in pre-heated gas metal arc welding process using nature instigated algorithms. Australian Journal of Mechanical Engineering.

Sreedhar, U., Krishnamurthy, C., Balasubramaniam, K., Raghupathy, V., & Ravisankar, S. (2012). Automatic defect identification using thermal image analysis for online weld quality monitoring. Journal of Materials Processing Technology, 212(7), 1557–1566.

Sumesh, A., et al. (2017). Establishing correlation between current and voltage signatures of the arc and weld defects in GMAW process. Arabian Journal for Science and Engineering, 42(11), 4649–4665.

Sutton, R. S., & Barto, A. G. (2018). Reinforcement learning: An introduction (2nd ed.). The MIT Press.

Szegedy, C. et al. (2015). Going deeper with convolutions, pp. 1–9.

Tamari, R. (2016). Reinforce framework for stochastic policy optimization and its use in deep learning.

Tao, F., Zhang, H., Liu, A., & Nee, A. Y. (2018). Digital twin in industry: State-of-the-art. IEEE Transactions on industrial informatics, 15(4), 2405–2415.

Van Hasselt, H., Guez, A., & Silver, D. (2016). Deep reinforcement learning with double q-learning, (Vol. 30).

Vishnuvaradhan, S., Chandrasekhar, N., Vasudevan, M., & Jayakumar, T. (2013). Intelligent modeling using adaptive neuro fuzzy inference system (anfis) for predicting weld bead shape parameters during a-tig welding of reduced activation ferritic-martensitic (rafm) steel. Transactions of the Indian Institute of Metals, 66(1), 57–63.

Wang, Y., et al. (2020). Weld reinforcement analysis based on long-term prediction of molten pool image in additive manufacturing. IEEE Access, 8, 69908–69918.

Wang, Y., et al. (2021). Coordinated monitoring and control method of deposited layer width and reinforcement in waam process. Journal of Manufacturing Processes, 71, 306–316.

Watkins, C. D. P. (1992). Q-learning. Machine Learning, 8(3), 279–292.

Wei, E., Farson, D., Richardson, R., & Ludewig, H. (2001). Detection of weld surface porosity by statistical analysis of arc current in gas metal arc welding. journal of Manufacturing Processes, 3, 50–59.

Williams, R. J. (1992). Simple statistical gradient-following algorithms for connectionist reinforcement learning. Machine Learning, 8(3), 229–256.

Williams, S. W., et al. (2016). Wire+ arc additive manufacturing. Materials Science and Technology, 32(7), 641–647.

Wu, B., Pan, Z., van Duin, S., & Li, H. (2019). in Thermal behavior in wire arc additive manufacturing: characteristics, effects and control pp. 3–18 (Springer).

Wu, B., et al. (2018). A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. Journal of Manufacturing Processes, 35, 127–139.

Wu, C., Gao, J., & Hu, J. (2006). Real-time sensing and monitoring in robotic gas metal arc welding. Measurement Science and Technology, 18(1), 303.

Xia, C., et al. (2020). Model-free adaptive iterative learning control of melt pool width in wire arc additive manufacturing. The International Journal of Advanced Manufacturing Technology, 110(7), 2131–2142.

Xia, C., et al. (2020). Model predictive control of layer width in wire arc additive manufacturing. Journal of Manufacturing Processes, 58, 179–186.

Xia, C., et al. (2022). Modelling and prediction of surface roughness in wire arc additive manufacturing using machine learning. Journal of Intelligent Manufacturing, 33(5), 1467–1482.

Xia, C., Pan, Z., Fei, Z., Zhang, S., & Li, H. (2020). Vision based defects detection for keyhole tig welding using deep learning with visual explanation. Journal of Manufacturing Processes, 56, 845–855.

Xia, C., Pan, Z., Li, Y., Chen, J., & Li, H. (2022). Vision-based melt pool monitoring for wire-arc additive manufacturing using deep learning method. The International Journal of Advanced Manufacturing Technology, 120(1), 551–562.

Xiong, J., & Zhang, G. (2013). Online measurement of bead geometry in GMAW-based additive manufacturing using passive vision. Measurement Science and Technology, 24(11), 115103.

Xiong, J., Zhang, G., Hu, J., & Wu, L. (2014). Bead geometry prediction for robotic GMAW-based rapid manufacturing through a neural network and a second-order regression analysis. Journal of Intelligent Manufacturing, 25(1), 157–163.

Xu, F., et al. (2018). Realisation of a multi-sensor framework for process monitoring of the wire arc additive manufacturing in producing ti-6al-4v parts. International Journal of Computer Integrated Manufacturing, 31(8), 785–798.

Yin, L., Wang, J., Hu, H., Han, S., & Zhang, Y. (2019). Prediction of weld formation in 5083 aluminum alloy by twin-wire CMT welding based on deep learning. Welding in the World, 63(4), 947–955.

Yu, R., Han, J., Bai, L., & Zhao, Z. (2021). Identification of butt welded joint penetration based on infrared thermal imaging. Journal of Materials Research and Technology, 12, 1486–1495.

Yusof, M., Kamaruzaman, M., Ishak, M., & Ghazali, M. (2017). Porosity detection by analyzing arc sound signal acquired during the welding process of gas pipeline steel. The International Journal of Advanced Manufacturing Technology, 89(9), 3661–3670.

Zeiler, M. D., & Fergus, R. (2014). Visualizing and understanding convolutional networks (pp. 818–833). Springer.

Zhang, Z., Wen, G., & Chen, S. (2019). Weld image deep learning-based on-line defects detection using convolutional neural networks for al alloy in robotic arc welding. Journal of Manufacturing Processes, 45, 208–216.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

Formal analysis, GM and LN; Investigation, GM and DP; Methodology, GM and LN; Supervision, LN All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A: A brief bliometric analysis

Appendix A: A brief bliometric analysis

In the introduction of this work some main bibliometric results are presented, which come from a brief bibliometric analysis conducted with the open-source R package bibliometric (Aria & Cuccurullo, 2017) using two different queries from Scopus website:

-

1: WAAM OR (Wire AND Arc AND Additive AND Manufacturing)

-

2: WAAM OR (wire AND arc AND additive AND manufacturing) OR (arc AND welding) OR GTAW OR GMAW) AND (control OR monitoring OR model) AND ((machine AND learning) OR (reinforcement AND learning) OR (artificial AND intelligence) OR (neural AND network))

Using the first query some main results are presented, such as the annual growth rate and the number of total citations. Furthermore, the top 6 keywords are presented, once a clustering activity is made limiting to the first 200 most frequent keywords. Additional information is presented in this appendix about authors and journals.

Starting from the journals the top-15 productive journals are reported in Fig. 39, and as reported in Fig. 40, The first article, written by Wang and Williams from Cranfield university UK, was published in International Journal of Advanced Manufacturing Technology, which has been the most important journal about this topic until 2018, when it was passed by Additive Manufacturing.