Abstract

Recent developments in intelligent manufacturing have validated the use of probabilistic Boolean networks (PBN) to model failures in manufacturing processes and as part of a methodology for Design Failure Mode and Effects Analysis (DFMEA). This paper expands the application of PBNs in manufacturing processes by proposing the use of interventions in PBNs to model an ultrasound welding process in a preventive maintenance (PM) schedule, guiding the process to avoid failure and extend its useful work life. This bio-inspired, stochastic methodology uses PBNs with interventions to model manufacturing processes under a PM schedule and guides the evolution of the network, providing a new mechanism for the study and prediction of the future behavior of the system at the design phase, assessing future performance, and identifying areas to improve design reliability and system resilience. A process engineer designing manufacturing processes may use this methodology to create new or improve existing manufacturing processes, assessing risk associated with them, and providing insight into the possible states, operating modes, and failure modes that can occur. The engineer can also guide the process and avoid states that can result in failure, and design an appropriate PM schedule. The proposed method is applied to an ultrasound welding process. A PBN with interventions model was simulated and verified using model checking in PRISM, generating data required to conduct inferential statistical tests to compare the effects of probability of failures between the PBN and PBN with Interventions models. The obtained results demonstrate the validity of the proposed methodology.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Industrial manufacturing environments have a dynamic complexity due to constant changes in product demand, customer expectations, varied product types, features and suppliers, and the unplanned disturbances inherent to the manufacture and assembly of products. Industrial machines used in product manufacturing are also complex; multiple components operate at different speeds, often with dissimilar technologies, and at different levels of reliability. Mathematical models that permit the analysis of the manufacturing process operation under a set of specific constraints and operating modes are desirable, taking into account the complexity inherent of these systems. In this manner, requirement compliance, alternative design proposals, and the study and control of operating environmental conditions is facilitated. Modeling, paired with simulation, allows the assessment of behaviors and dynamics, among other factors, in a controlled virtual environment. It is imperative in manufacturing to aid the discovery of new techniques and systems, to assess future behaviors of a system, identify areas of improvement, and also develop mechanisms to assess change in systems that are in operation (Carlson and Yao 2008; Smith 2003; Hu and An 2011; Law and McComas 1997; Kumar 2013).

Probabilistic Boolean networks (PBN) had been proposed as a simplified representation of a manufacturing process’ dynamics to model and predict process behavior through the use of simulation and analysis (Rivera Torres et al. 2015a, b). PBNs are mathematical constructs used to model gene regulatory networks (GRN). GRNs are collections of DNA segments within a cell that interact indirectly with other segments and substances in a cell in order to govern the expression levels of genes (Shmulevich et al. 2002b; Shmulevich and Dougherty 2010). They can be used to better understand the general rules that govern gene regulation in genomic DNA. In GRNs, the mechanisms of perturbation and intervention are used to aid these networks to avoid undesirable states, like those associated with a disease, such as cancer.

Since the genome is an open system, it receives outside inputs, and the stimulus received can activate or inhibit genes, and modify their expression. The inclusion of a perturbation vector can provide the mechanism to reproduce this behavior. Interventions are those deliberate perturbations meant to guide the PBN. By introducing a perturbation vector for a given set of genes, the network can be guided to achieve a certain state, or move away from an undesired one, through perturbation of genes that have a greater impact on the network’s global behavior. Perturbing fewer genes, or reaching a desired state as quickly as possible can also achieve this. The first efforts in PBN intervention were ad hoc, like resetting the PBN as needed to a more favorable initial state, permitting the network to evolve from such state (Shmulevich et al. 2002a), and modifying the long-run behavior of the PBN through minimal alteration of the network’s rule structure (Shmulevich et al. 2002b). Given that PBNs can be treated as Markov chains, Markov decision processes (MDP) can be used to find optimal control intervention strategies (Datta et al. 2003).

Preventive maintenance (PM) is maintenance that is regularly performed on a piece of equipment to reduce the likelihood of unexpected breakdowns or failures, thus maximizing the time it is working and available. PM is planned and scheduled based on time or usage thresholds. Its main goal is to improve equipment efficiency while reducing failures. PM is appropriate on equipment that has a critical operational function, when the system or component’s failure modes can be prevented with regular maintenance, and when the likelihood of failures increases with time or usage.

This paper expands the application of PBNs in industrial systems by proposing the use of interventions in PBNs to model a PM schedule. The idea behind this research is that intervention in the context of an industrial process modeled as a PBN can be used to guide the network’s evolution. This strategy will avoid or delay unhealthy states of the system that correspond to failure and therefore extend the useful work life of the system or process.

Then, the main contribution of this paper is the introduction of the mechanism of Intervention in Probabilistic Boolean Network modeling PM in manufacturing systems. This bio-inspired, stochastic methodology provides a new mechanism for the study and prediction of the future behavior of the system at the design phase, assessing future performance, and identifying areas to improve design reliability and system resilience.

In order to illustrate how the PM can be modeled with this method, a representation of an industrial assembly process using the aforementioned methodology is proposed. The system chosen is frequently used in manufacturing processes, where different machines are integrated, to load and unload parts in assembly lines. The system has three machines with known reliability; however, it is relevant to assess the reliability and interaction of the machines functioning as an integrated system.

Using a perturbation vector as a control input in a schedule defined by the mean time between failures (MTBF) of the systems’ components, intervention guides the network, and as a result, delays the failure of the system.

The present article is organized as follows. Section “Related work and theoretical background” presents the theoretic fundaments of the proposal. In Sect. “PBN with interventions models of manufacturing processes” the proposal methodology is applied to an industrial assembly process. Section “Experimental results ” shows and discusses the experimental results. Finally, a section covering conclusions and suggestions for future work is presented.

Related work and theoretical background

Biologically-inspired modeling methods in manufacturing

The use of BNs to model biological systems, particularly GRNs, has been extensively documented in scientific literature (Arnosti and Ay 2012; Bane et al. 2012; Chaouiya et al. 2013; Cheng et al. 2013; Didier and Remy 2012; Ghanbarnejad 2012; Vahedi 2009). PBNs have also been used extensively to model GRNs (Chen and Sun 2014; Chen et al. 2012; Ching et al. 2009; Gao et al. 2013; Kobayashi and Hiraishi 2010; Trairatphisan et al. 2013).

BNs were introduced by Kauffman (1969), and are a finite set of Boolean variables for which their state (represented as 0 or 1) can be determined by the state of other variables in the network. Several input genes called regulatory genes/nodes, through the use of a determined Boolean function, regulate the value of a target gene/node. If the nodes and the corresponding functions are given, then the BN is defined. Boolean Networks and Probabilistic Boolean Networks are discussed in detail in Shmulevich and Dougherty (2010).

Though it is not uncommon to find several applications of BNs and PBNs in Computational Biology to model GRNs, applications or uses outside this realm remain vastly unexplored. One of the few studies venturing on the application of PBNs outside GRNs proposed to model credit defaults (Gu et al. 2013). A PBN-based model was applied to study the link between correlated defaults of different industrial sectors and business cycles, and the impact of these cycles on modeling and predicting defaults. With PBNs, a transition probability matrix that describes the correlated defaults of the business sectors studied was determined and decomposed into several BN matrices that house information about business cycles. Actual default data was used in building the PBN to explain the default structure, and achieve predictions of joint defaults in different business sectors. In this same area of application, Liang et al. (2014) concentrates on the construction of PBNs from credit default data and presents a heuristic construction algorithm. These recent studies provided a baseline from which to expand further the utility of PBNs.

Rivera Torres et al. 2015a; b demonstrated the use of PBNs in manufacturing systems, a realm outside systems biology and of interest to the engineering scientific community. Rivera Torres et al. (2015a) demonstrated that PBN modeling of industrial machines is appropriate because of the similarities in characteristics between both, and because this stochastic modeling methodology could aid the development and validation of bio-inspired models for manufacturing machines from which statistically valid predictions about its behavior were obtained. In Rivera Torres et al. (2015b), the same methodology was used to model a manufacturing system and to generate quantitative data for occurrence assessment in design failure mode and effects analysis (DFMEA).

In GRN modeling, the objective is to find adequate targets for therapeutic intervention (Shmulevich and Dougherty 2007). Intervention in GRNs is a mechanism used to avoid undesirable states (Choudhary 2006), like those that can be associated with a particular disease (Pal et al. 2005). Research includes models for cell regulation that are combined with therapeutic interventions for personalized cancer therapy (Vahedi 2009). Appropriate alteration of the expression of a gene, as it may be of therapeutic use, and therefore an optimal intervention strategy can be found (Bittner et al. (2000); Datta et al. (2007)). Therapeutic interventions can be designed, and these are intended to reduce gene expression profiles that can cause the wrong cellular function, by manipulating a control gene (Datta and Dougherty 2006; Shmulevich and Dougherty 2007). Most efforts have concentrated in external control variable manipulation (Datta et al. 2003). This paper proposes that the therapeutic intervention used in GRN modeling has a parallel with preventive maintenance schedules, and focuses on demonstrating that a PM schedule modeled with PBNs with interventions will delay the overall failure of the system, increasing its reliability.

Preventive maintenance modeled as an intervention in PBN

PM scheduling and its adequacy under several disparate conditions has been covered in earlier studies (Banerjee and Burton 1990; Burton et al. 1989; Mosley et al. 1998). These tested the adequacy of rather simple PM practices and policies that use discrete-event simulation instead of optimizing those with production scheduling decisions. Other studies have addressed integrated preventive maintenance and job scheduling for single manufacturing machines (Batun and Azizoglu 2009; Cassady and Kutanoglu 2003; Pan et al. 2010; Sortrakul et al. 2005). The objective function considered in these is the minimum total weighted expected completion time. In Verma and Ramesh (2007), systems and subsystems of a large manufacturing plant were integrated into modular assemblies with an applied multi-objective PM scheduling approach. A multi-criteria approach for finding optimal PM intervals of workstations in production lines in a paper manufacturing facility is discussed in (Chareonsuk et al. (1997)), which includes the total expected cost and reliability as objective functions.

Genetic algorithms (GAs) have been used in PM literature extensively. Yulan et al. (2008) showcases a genetic algorithm with different objectives that is used to solve a mathematical model that considers five objective functions that have to be minimized. Cavory et al. (2001) deals with optimization of scheduling of maintenance tasks of the machines in a single production line, in the context of a single machine and one operator, with the goal to increase overall throughput of this line. Through simulation of the production line and an optimizer that uses a genetic algorithm, they set the parameters of the GA in order to optimize the throughput.

Guided self-organization (Prokopenko 2009) steers the self-organizing dynamics of a system to a favored configuration, balancing design and self-organization. PBNs exhibit self-organizing characteristics (Kauffman 1993). BN and PBN dynamics self-organize towards attractors (Hopfensitz et al. 2012), be it attractor cycles or point attractors. They reduce system complexity; as an example, there are over 30,000 genes (nodes) in the human genome, and only around 300 cell types (attractors, cells that self-organize towards a limited sub-set of possible states) (Kauffman 1993). When a system has a group of preferred states, or attractors, the system will self-organize toward them. When two levels of representation are present, and there is a relationship or interaction between these, the system can be self-organizing and the interactions of the lower level change the properties of the higher level (bee-swarm, ant-colony, gene-cell, etc.). This self-organization can be useful for designers and engineers; in PBNs, the mechanism of intervention can be used as a guided self-organizing technique that steers the evolution of the system towards a desired operational or chosen state. The criticality (balance between ordered and chaotic behavior) of a system or network depends on many factors, and these can be advantageous to engineers and designers to guide the evolution of the system. The evolution of a manufacturing process can be guided towards a preferred state (normal operation), and the process’ evolution in time will oscillate (criticality) between ordered dynamics (the operating state of the machine) and chaos (states leading to machine failure). Every time a machine fails and steers the system into chaotic behavior, the system can eventually organize and correct its behavior to reach a preferred state.

In the literature, PM modeling with different optimization objectives has been extensively studied, but from that perspective, characterizing a system using PBNs and intervention is an area of study that presents an interesting opportunity of development. The proposed approach of applying PBN modeling to manufacturing systems was originally introduced in Rivera Torres et al. (2015b). A modification to this methodology is presented in Fig. 1, which incorporates periodic interventions necessary to model a PM cycle.

According to Zhang and Van Luttervelt (2011), the resiliency of a system does not imply that the system will recover in order to perform the same functions, i.e., return to its original stable state. The system, as a PBN, can have several stable states and when there is a failure, it can reconfigure itself and develop other functions, meaning it can be in another stable state. The objective of this research is not particularly reconfiguration, but to extend the useful life of a system to achieve a well defined objective, and that is why this methodology models PM to improve reliability. If instead of modeling PM with an intervention to extend the useful life of the system and achieve its goal, the reconfiguration of the system is modeled when a failure is detected to continue the systems work in another stable state, the PBN with intervention can be used to model failure recovery. This is another advantage of PBN with intervention modeling.

Intervention in PBN models of manufacturing processes

This section discusses the use of intervention in PBNs that model manufacturing systems. In systems biology, a PBN is used to model GRNs and study their evolution in time. In a PBN, a BN is stochastically selected from a set, and each BN has an associated transition diagram and a set of Boolean Functions. Given an initial state, each BN will transition into a fixed state or set of states within a finite number of steps, known as attractor. These attractors characterize the network’s long-run behavior. There are certain states or sets of states in a BN that equate to unhealthy states, i.e., a certain form of cancer, etc. Through the use of intervention, the network’s state can be altered in order to avoid or reduce the chance of reaching a certain state, or favor the selection of healthy states.

In the previous sections and in other papers, the authors have discussed how PBNs can be used to model industrial machines and systems. In a manufacturing system, an industrial machine will start operation in an initial state, and from it evolves through time to normal operation, or failures in the system, due to component reliability and/or manufacturing conditions. In this context, PM is used with the intention of delaying failure occurrence, or incrementing the system’s normal operating time and efficiency. Given that a manufacturing system can be modeled as a PBN, a PM maintenance schedule in an industrial machine can be modeled analogous to an intervention in a PBN. PM alters the normal evolution of a manufacturing system, as the replacement or maintenance of a component in a machine delays the machine’s failure occurrence and increases its MTBF, altering the otherwise undisturbed succession of states. If left undisturbed, the probability of failure of a machine increases through time, reaching 1. The thesis of this research is that, similar to GRN modeling, where PBNs with interventions can be used to guide the network’s evolution to favor or avoid states (as in a therapeutic intervention), in manufacturing systems modeled using PBNs, and that intervention can be used to guide the design of a system for reliability and improve maintainability, avoiding states that can lead to system failure, thus improving OEE.

Different to perturbation, intervention deliberately changes the state of some components in order to guide the network to skip undesirable states that may lead to system failure. Stimulus from outside the system can be applied to the network, and in order for an intervention to be effective, control policies are set for different types of interventions. Since different components can affect the next state of a target component, a single component that has the most influence on the network’s state is identified as the control component. The state transition matrix is changed thus by an external intervention. In a network with n components, a vector \({\varvec{x}}=\left( {x_1 ,x_2 ,\ldots ,\,x_n } \right) \) with \(x_i \in \left\{ {0,1} \right\} ,\,\forall \,i\in \left\{ {1,2,\ldots ,n} \right\} \) defined as the control component, which means that if \(x_i =1\), then component i is selected as a control component. An intervention vector is defined as \({\varvec{w}}=\left( {w_1 ,w_2 ,\ldots ,w_{2^{n}} } \right) ,w_j \in \left\{ {0,1} \right\} ,\,\forall \,j\in \left\{ {1,2,\ldots ,\,2^{n}} \right\} \), where \(w_j =1\) or \(w_j =0\) indicates a change (or remaining) in state of a control component. The expression level of the control component can be determined by its current state and the status of the intervention vector. The intervention vector can be obtained following different methods, but here a control policy is established using a PM schedule. The state of the network under intervention is given by the control input, the state of the network prior to the intervention, and the intervention vector.

Simulations were performed to assess how the system’s model evolved, and how its individual components failed. Starting from an initial state, the probability of failure of the components was characterized, and it was established that a PM intervention would occur at the point closest to when the components reach 50 % probability of failure. The intervention resets the state of the component, equivalent to resetting the probability of failure of the component to zero. The simulation continues in order to determine the effects of the interventions in the system’s model through time. For each component, the interventions occur in different time steps.

In this research the authors propose the establishing the model of a system through its characterization as a PBN; identifying relevant genes/nodes, determining of the predictor functions, and calculating the selection probabilities of each predictor, constituent networks and cyclic/attractor states. This way, any manufacturing process/system can be modeled as a Markov decision process (MDP). The authors propose the use of a model checker such as PRISM (PRISM Model Checker, available at http://www.prismmodelchecker.org), to verify mathematical/formal correctness of the model through model checking, using probabilistic computational tree logic (PCTL). The use of PRISM permits identifying the system’s occurrence of failures and its behavior (the amount of reachable states, deadlocks, etc.), and can aid the identification of cyclic states/attractors. Deadlock states are reachable states that have no outgoing transitions. A manufacturing process can reach a deadlock state if, for example, a machine in a parts/goods production process fails and there is no product output. PCTL is a property verification language that permits analysis of a probabilistic model through the identification of one or more properties that can be evaluated allowing the researcher to see the time at which the maximum probability of failure of a machine has been reached. This can aid the designer in the task of creating a PM plan by intervening with the system before a failure is imminent. PM will prevent deadlock states, thus prolonging the normal operation of the process. Performing this analysis in the design phase permits obtaining from the conceptualization of the process the parts or components of the systems that can yield the best results.

PBN with interventions models of manufacturing processes

Modeling methodology

To illustrate the proposed approach, an automated manufacturing welding process composed of three machines: an off-the-shelf ultrasonic welding station and two off-the-shelf “pick and place” machines will be modeled. This process is taken from Rivera Torres et al. (2015b), and is reproduced here for reference. The welding station is composed of a 2500W power supply, and an actuator that houses a 3-inch air cylinder, a 20-micron converter, a 1:2.0 gain booster and a 20 kHz 1:1 gain horn. The welding station joins together two rigid parts. The “pick and place” is a mechanism that has movement in the x and y axes, and through a grip holds, places and removes the parts to and from the welding station in the assembly line. The pick and place loads the parts into the welding station. Once welded, a second pick and place removes the welded parts. Initially, designed features and requirements for each machine involved in the process and their components are identified according to their intended function and operation. A model of the manufacturing process has been developed to capture the dynamics and interactions of each of its components using PBNs in a high-level language. PBNs can model the selected manufacturing process because of its analogies with GRNs that are modeled using BNs and PBNs (state-based stochastic transition systems, with transitions based on probabilities of occurrence of certain factors, their components/nodes can assume binary states, relationships between nodes can be expressed using Boolean logic, and relevant nodes can be considered regulatory nodes, among others). Each node of the system is treated analogous to the gene abstraction in a GRN using binary quantization, where an expressed gene is assigned a value of 1 and an unexpressed gene a value of 0.

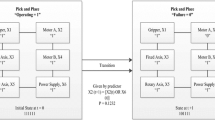

Figure 2 shows the finite state machine of the process modeled in this research, and is taken from Rivera Torres et al. (2015b).

Construction of the process’ PBN

As per Rivera Torres et al. (2015b), the process is characterized as a PBN, and the constituent networks, attractor states and selection probabilities are determined. The process is modeled as a PBN in the form of Sys \(= G(V, F)\), where \(V = \{x_{1},\, x_{2},\, x_{3}\}\), and \(F=\left\{ {f_1^{\left( 1 \right) } ,\,f_2^{\left( 1 \right) } ,\,f_3^{\left( 1 \right) } ,f_1^{\left( 2 \right) } ,f_2^{\left( 2 \right) } ,f_3^{\left( 2 \right) } } \right\} \). The nodes are: \(x_{1} =\) pick and place 1, \(x_{2} =\) pick and place 2, and \(x_{3} =\) Welding Station. Predictors are Boolean functions, estimated through component relationships and connectivity. Rivera Torres et al. (2015b) details the characterization of the process as a PBN, the determination of its failure modes, relevant nodes, constituent network, steady states, predictor functions and selection probabilities. Data on MTBF for each of the key components of the modeled process was obtained from technical data sheets from manufacturers. Based on the MTBF, their failure occurrence was calculated in terms of their annualized failure rate (AFR) using the formula:

which is a form of the equation \(F(t) = 1 - exp (-{\lambda } t)\) from (Ebeling (1997)), where \({\uplambda }\) is the failure rate of each component, and t is time. Table 1 details the Reliability, AFR and MTBF of each of the process’ components.

Table 2 details the predictors of the process, along with the selection probabilities for each.

The Ultrasonic welding process is a three gene PBN, where l(i) is the number of possible predictors per node. This means that \(l\left( i \right) ,\,i=1,\ldots ,3\) is \(l\left( 1 \right) =2,\,l\left( 2 \right) =2,\,l\left( 3 \right) =2\). The total number of realizations D is: \(D=\prod _{i=1}^3 l\left( i \right) =2\cdot 2\cdot 2=8\). There are 8 possible BNs, characterized by 8 vector functions, listed in Table 3 below.

The probability of selecting the \(i{\mathrm{th}}\) realization that has the vector function is given by \(u_i =\prod _{k=1}^3 c_{i_k }^{\left( i \right) } \). Table 3 lists the selection probability for each constituent BN.

Model semantics

In the proposed model, when a particular machine is operating properly, is analogous to an expressed gene while an unexpressed gene is analogous to a machine that is experiencing a failure. Understanding this relationship between the states of the machines and states of the system, a transition probability matrix is calculated. The transition matrix describes correlated machine states constructed through the application of predictor functions that are stochastically selected. Each realization of the network is a BN that has a set of transitions that represent the possible states of the system that can be achieved by applying the selected predictors. The transitions probability matrices that compose each realization of the system lead to attractor or cyclic states. These states are reached though the combined effect of machine failures and operation. These are then interpreted as states of the system. Some of the states of the system that are described in the transition matrix of each realization are states that equate to a system failure, and some are healthy states that translate to normal operation of the system. Figure 3 illustrates the key concept of a probabilistic Boolean network, a transition from state to state.

Each circle shows a state of the system at different times. At t = 0, the state of the system is in normal operation (represented by a ‘1’) as all individual machines or nodes are functioning (111), these nodes are denoted as x1 ... x3. The arrow between boxes denote a transition of the system from an operating state at \(t = 0\) to failure state (011) at \(t + 1\). This particular transition occurred based on a predictor function given by \(\hbox {x1}(t+1)=[\hbox {x1}(t)\hbox { OR x2}(t)\hbox { OR x3}(t)]\). In physical terms, the predictor function tells that at \(t + 1\) the system will be in failure because either Pick and Place 1 or Pick and Place 2 or the Welding Station failed, which can occur with a probability equal to 0.93236. At time \(t + 1\), an intervention is applied changing the state of the Pick and Place 1 from “false” or failure to operating (true) instead of transitioning according to predictor function. The probabilistic Boolean network, then:

-

Is a collection Boolean networks that consist of a grouping of nodes/genes, such as each components of the system (welding station, pick and place 1, and pick and place 2).

-

Transitions from state to state in time based on a set that contains the group of Boolean functions or predictors that govern the network in that specific time, such as the transition shown on Fig. 3 on which the system transitioned from (111) to (011).

-

Consists of 8 different constituent BNs for the system, and each has a specific group of predictors. At every time step, a stochastic decision is made on whether or not to continue with the same BN or switch to a new realization.

-

Contains realizations, each of which has a different transition probability matrix.

-

Can be subjected to an intervention, which is a vector that affects the inputs to the next state. The transition interrupts the sequence of state transitions to guide the next state to the expected output or desirable future state.

According to Zhang and Van Luttervelt (2011), a manufacturing system has two layers: infrastructure and substance. In the context of this research, the infrastructure is the manufacturing machines that compose the process and the substance is the parts that compose it. However, the PBN modeling scope is delimited to the infrastructure of the system.

Experimental results

This section discusses the results of the experiments performed to test the adequacy of the proposed model. In order to quantitatively validate the proposed model, PRISM model checker (Kwiatkowska et al. 2011) was used to generate the data required to conduct inferential statistical tests to determine the level of correspondence. While the use of PBNs to model industrial systems, predict failures and serve as a risk assessment and reliability analysis tool has been validated in Rivera Torres et al. 2015a; b, there is a remarkable opportunity to expand the extent of the model. It will predict failure, assess risk or analyze the reliability of the system, and will implement interventions that may adjust the outcome of the systems based on PBNs, delaying their time to failure when compared to the PBN model without interventions.

A Control group was established by simulating the system’s relevant components with their corresponding MTBFs obtained from actual technical data sheets. Control group data was compared against the PBN model of the system. Starting from a healthy state, such as all nodes operating correctly (pick_and_place1 = true, pick_and_place2 = true, welding_station = true), the maximum probability of reaching an unhealthy state, such as all nodes in failure (pick_and_place1 = false, pick_and_place2 = false, welding_station = false), is determined. Statistically significant difference between the control group and the PBN group was tested. The null hypothesis is that there is no difference between the data from Control and PBN or Ho: \({\upmu }\) control = \({\upmu }\) PBN. The alternative hypothesis is finding a difference between Control and PBN, or Ho: \({\upmu }\) control \(\ne {\upmu }\) PBN. Given \({\upalpha }\)-level of 0.05 for the test, it is concluded that there are no significant differences in probabilities of failure between the groups (p value \(> 0.05\)). In practical terms, there is no difference between control (expected value) and the PBN model observed values. Results of the two-sample T test are shown in Fig. 4.

Once it was established that there is no difference between the PBN model and the expected values from a real manufacturing system, interventions were modeled and their effects on the system were compared against the behavior of the PBN. For example, interventions for the pick and place machines are performed every 23 h, and for the welding station every 25 h, which is the time at which each of these machines reaches 50 % of failure, per section 3.5. Property verification in PRISM was used to determine the maximum probability that at least one of the system’s machine components fails through verification of the following property:

The element pick_and_place1, pick_and_place2, and welding_station are variables representing the system’s machine components that assume a value of true when the specific machine is operating normally, and false if the machine is in failure. The property verifies the maximum probability that in the future, when time reaches a certain value, either of the machines in the system is in failure. The results are plotted and shown on Fig. 5.

A 2-sample T test performed using Minitab 16 to verify if there were statistically significant differences among the means of the two groups. The null hypothesis for the test is that population means are the same (for both groups: PBN and PBN with interventions means) or \(H_o: \mu _{control} = \mu _{EPBN + intervention}\). The alternative hypothesis is that population means differ from each other or \(H_1 :\mu _{control} \ne \mu _{EPBN+intervention} \). The p value for the T test is 0.001. Given \({\upalpha }\)-level of 0.05 for the test, it is concluded that there are significant differences in probabilities of failure between the groups. In practical terms, there is a difference between the probabilities of failure between the Control and the PBN with intervention groups. This means that the control group (the process left unaltered) reaches a state of failure faster than the experimental (PBN with Interventions) group. By using intervention in this model, the system takes longer to fail. Results of this test are shown on Fig. 6.

Model checking was used to determine the time to failure of in both groups: PBN and PBN with Interventions. Various experiments were run using the model checker to determine the time to failure as expressed on the property. For each group, ten runs were performed on the model checker until the maximum probability reached 1. Then, for each property, the time at which the model checker allowed collecting modeling data to determine time to failure were used to determine the time of failure in both groups for comparison purposes. Time to failure values per group are depicted on an individual value plot on Fig. 7.

The individual value plot serves to show that the time to failure of the PBN with Interventions is larger, therefore, interventions in a PBN have the same effect as preventive maintenance in machines in a manufacturing system; they delay the failures.

Additionally, the statistical differences in time to failure between the PBN and the PBN with Intervention groups were determined. A Two-sample t-confidence interval and test procedure was used to make inferences about the difference between two population means based on data from two independent, random samples. The null hypothesis states that there is no difference between the time to failure in PBN and PBN with Intervention group, or \(Ho:\,\mu _{control} = \mu _{PBN\,with\,Interventions\,group}\). The alternative hypothesis states that the difference between time to failure in the PBN group is less than the time to failure in Control PBN with Intervention group, or \(Ho:\, \mu _{control} < \mu _{PBN\,with\,Interventions\,group}\). The p value for the hypothesis test is 0.000 and given \({\upalpha }\)-level of 0.05, therefore, the null hypothesis is rejected. This means the time to failure observed in the PBN group is statistically significantly less than the time to failure observed in the PBN with Interventions group. The proposed model of PBN with Interventions provides time to failure values greater than the PBN; consequently, interventions modeled increase time to failure in the system. Results of the two-sample T test are shown in Fig. 8.

This bio-inspired, stochastic methodology uses PBNs with interventions to a model manufacturing process under Preventive Maintenance schedule and guides the evolution of the network. This methodology also provides a new mechanism for the study and prediction of a process future behavior at the design phase assessing future performance and identifying areas to improve design reliability and system resilience. This research demonstrated that PBNs modeling of the behavior of an automated assembly process can be performed through the study of the relationship between the state of the system and its main components, i.e. machines; therefore, the methodology can be applied to a variety of manufacturing process or systems.

Conclusions

This paper presented how intervention in a bio-inspired, stochastic modeling methodology for a manufacturing process can be used to guide the system’s evolution. The methodology aids the development and validation of a bio-inspired model from which statistically valid predictions about its behavior were obtained. The intervention was used to model an automated assembly process in preventive maintenance and was coupled with validation and verification. Experiments were conducted to perform empirical predictions of system behavior. Their results were congruent with expected observable events. A two-sample T test was used to validate statistically significant differences between the probabilities of failure of the PBN and the PBN with intervention, \((\textit{p}\;\hbox {value} = 0.001,\,{\upalpha }= 0.05)\). An individual box plot shows that time to failure between PBN and experimental groups is greater for PBNs with interventions. Another two-sample T test demonstrates statistical differences in time to failure between the control and the experimental groups (p value = 0.000, \({\upalpha } = 0.05\)). This shows that PBN models with interventions have a longer time to failure than PBN models without interventions. Findings from this research suggest that the proposed approach can be repeated for larger manufacturing systems with multiple machines, which can afterwards be characterized as PBNs with interventions. This research also suggests that this methodology can be applied to different processes or systems given that the relationship between the state of the system and its main components is known. The predictors for the system can be determined in a similar way, studying the relationship between the nodes to determine relevant nodes, logical equations, among others. The predictor selection probability is also determined from a probability analysis. These deliberate perturbations of a network allow it to achieve a desired response, in order to identify those conditions that can attract “healthy” system states, thus improving its reliability and efficiency. Future research should concentrate in optimizing the control of the network such that the optimal solution to the PM schedule for the system. Optimizing the control of the PBN in a manufacturing process may contribute to designing more resilient systems and processes (Zhang and Van Luttervelt 2011). In Wang et al. (2014a; 2016), the authors discuss a unified definition of the service system and its identity, distinguishing it from other systems. The authors believe that PBNs can be useful to model a general service system, and this can be a future research.

Change history

03 April 2017

An erratum to this article has been published.

References

Arnosti, D. N., & Ay, A. (2012). Boolean modeling of gene regulatory networks: Driesch redux. Proceedings of the National Academy of Sciences, 109(45), 18239–18240.

Bane, V., Ravanmehr, V., & Krishnan, A. R. (2012). An information theoretic approach to constructing Robust Boolean gene regulatory networks. IEEE/ACM Transactions on Computational Biology and Bioinformatics, 9(1), 52–65.

Banerjee, A., & Burton, J. (1990). Equipment utilization based maintenance task scheduling in a job shop. European Journal of Operations Research, 45(2–3), 191–202.

Batun, S., & Azizoglu, M. (2009). Single machine scheduling with preventive maintenances. International Journal of Production Research, 47(1), 1753–1771.

Bittner, M. L., Meltzer, P., Chen, Y., Jiang, Y., Seftor, E., Hendrix, M., et al. (2000). Molecular classification of cutaneous malignant melanoma by gene expression profiling. Nature, 406(6795), 450–536.

Burton, J., Banerjee, A., & Sylla, C. (1989). A simulation study of sequencing and maintenance decisions in a dynamic job shop. Computers and Industrial Engineering, 17(1), 447–452.

Carlson, J. G. H., & Yao, A. C. (2008). Simulating an agile, synchronized manufacturing system. International Journal of Production Economics., 112, 714–722.

Cassady, C., & Kutanoglu, E. (2003). Minimizing job tardiness using integrated preventive maintenance planning and production scheduling. IIE Transactions, 35(6), 505–513.

Cavory, G., Dupas, R., & Gonçalves, G. (2001). A genetic approach to the scheduling of preventive maintenance tasks on a single product manufacturing production line. International Journal of Production Economics, 74(1–3), 135–146.

Chaouiya, C., Ourrad, O., & Lima, R. (2013). Majority rules with random Tie-breaking in Boolean gene regulatory networks. PLoS One, 8(7), e69626.

Chareonsuk, C., Nagarur, N., & Tabucanon, M. (1997). A multicriteria approach to the selection of preventive maintenance intervals. International Journal of Production Economics, 49, 55–65.

Chen, H., & Sun, J. (2014). Stability and stabilisation of context-sensitive probabilistic Boolean networks. IET Control Theory & Applications, 8(17), 2115–2121.

Chen, X., Jiang, H., & Ching, W.-K. (2012). On construction of sparse probabilistic Boolean networks. East Asian Journal on Applied Mathematics. https://doi.org/10.4208/eajam.030511.060911a.

Cheng, X., Sun, M., & Socolar, J. E. S. (2013). Autonomous Boolean modelling of developmental gene regulatory networks. Interface: Journal of the Royal Society, 10(78), 20120574.

Ching, W.-K., Zhang, S.-Q., Jiao, Y., Akutsu, T., Tsing, N.-K., & Wong, A.-S. (2009). Optimal control policy for probabilistic Boolean networks with hard constraints. IET Systems Biology, 3(2), 90–99.

Choudhary, A. (2006). Intervention in gene regulatory networks. http://txspace.di.tamu.edu/bitstream/handle/1969.1/4284/etd-tamu-2006B-ELEN-Choudha.pdf?sequence=1.

Datta, A., Choudhary, A., Bittner, M. L., & Dougherty, E. R. (2003). External control in Markovian genetic regulatory networks. Machine Learning, 52, 169–191.

Datta, A., & Dougherty, E. R. (2006). Introduction to genomic signal processing with Control. Boca Raton, Fl: CRC Press.

Datta, A., Pal, R., Choudhary, A., & Dougherty, E. R. (2007). Control approaches for probabilistic gene regulatory networks. IEEE Signal Processing Magazine, 24(1), 54–63.

Didier, G., & Remy, E. (2012). Relations between gene regulatory networks and cell dynamics in Boolean models. Discrete Applied Mathematics, 160(15), 2147–2157.

Ebeling, C. E. (1997). An introduction to reliability and maintainability engineering. New York: McGraw-Hill.

Gao, Y., Xu, P., Wang, X., & Liu, W. (2013). The complex fluctuations of probabilistic Boolean networks. Biosystems, 114(1), 78–84.

Ghanbarnejad, F. (2012). Perturbations in Boolean networks as model of gene regulatory dynamics (Doctoral Thesis). Leipzig, Germany: University of Leipzig.

Gu, J.-W., Ching, W.-K., Siu, T.-K., & Zheng, H. (2013). On modeling credit defaults: a probabilistic Boolean network approach. Risk and Decision Analysis, 4(2), 119–129.

Hopfensitz, M., Müssel, C., & Maucher, M. (2012). Attractors in Boolean networks: a tutorial. Computational Statistics. http://www.springerlink.com.ezproxy.library.wisc.edu/index/NR1671N55Q3365Q5.pdf

Hu, X., & An, R. (2011). Modeling and simulation of manufacturing systems in unstable environments. In Proceedings of the world congress on engineering (WCE). London, UK.

Kauffman, S. A. (1969). Homeostasis and differentitation in random genetic control networks. Nature, 224, 177–178.

Kauffman, S. A. (1993). The origins of order: self-organization and selection in evolution. NewYork: Oxford University Press.

Kobayashi, K., & Hiraishi, K. (2010). Reachability analysis of probabilistic Boolean networks using model checking (pp. 829–832). Proceedings of presented at the SICE annual conference 2010. http://library.uprm.edu:2055/stamp/stamp.jsp?tp=&arnumber=5604207.

Kumar, R. U. (2013). Simulation and modeling analysis in manufacturing process. International Journal of Recent Technology and Engineering, 1(6), 90–92.

Kwiatkowska, M. Z., Norman, G., & Parker, D. (2011). PRISM 4.0: verification of probabilistic real-time systems. In Lecture Notes in Computer Science, Vol. 6806 (pp. 585–591). Springer.

Law, A. M., & McComas, M. G. (1997). Simulation of manufacturing systems. In Proceedings of the 1997 winter simulation conference (pp. 86–89). Atlanta, GA.

Liang, R., Qiu, Y., & Ching, W.-K. (2014). Construction of probabilistic Boolean network for credit default data. In Proceedings of the seventh international joint conference on computational science and optimization. Presented at the seventh international joint conference on computational science and optimization.

Mosley, S., Teyner, T., & Uzsoy, R. (1998). Maintenance scheduling and staffing policies in a wafer fabrication facility. Transactions in Semiconductor Manufacturing, 11(2), 316–323.

Pal, R., Datta, A., Bittner, M., & Dougherty, E. (2005). Intervention in context-sensitive probabilistic Boolean networks. Bioinformatics, 21(7), 1211–1218. https://doi.org/10.1093/bioinformatics/bti131.

Pan, E., Liao, W., & Xi, L. (2010). Single-machine-based production scheduling model integrated preventive maintenance planning. International Journal of Advanced Manufacturing Technology, 54(2), 304–309.

Prokopenko, M. (2009). Guided self-organization. HFSP Journal, 3(5), 287–289.

Rivera Torres, P. J., Serrano Mercado, E.I., & Anido Rifón, L. (2015a). Probabilistic Boolean network modeling of an industrial machine. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-015-1143-4.

Rivera Torres, P. J., Serrano Mercado, E.I., & Anido Rifón, L.(2015b). Probabilistic Boolean network modeling and model checking as an approach for DFMEA for manufacturing systems. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-015-1183-9.

Shmulevich, I., & Dougherty, E. R. (2007). Genomic signal processing, 1st edn. Vols. 1–1, Vol. 1. Princeton: Princeton University Press.

Shmulevich, I., Dougherty, E., & Kim, S. (2002a). Probabilistic Boolean networks: a rule-based uncertainty model for gene regulatory networks. Bioinformatics. http://bioinformatics.oxfordjournals.org.ezproxy.library.wisc.edu/content/18/2/261.short.

Shmulevich, I., & Dougherty, E. R. (2010). Probabilistic Boolean networks: modeling and control of gene regulatory networks. Philadelphia, PA: SIAM.

Shmulevich, I., Dougherty, E. R., Kim, S., & Zhang, W. (2002b). From Boolean to probabilistic Boolean networks as models of genetic regulatory networks. Proceedings of the IEEE, 90, 1778–1792.

Smith, J. S. (2003). Survey on the use of simulation for manufacturing system design and operation. Journal of Manufacturing Systems., 22(2), 157–171.

Sortrakul, N., Nachtmann, H. L., & Cassady, C. R. (2005). Genetic algorithms for integrated preventive maintenance planning and production scheduling for a single machine. Computers in Industry, 56, 161–168.

Trairatphisan, P., Mizera, A., Pang, J., Tantar, A. A., Schneider, J., & Sauter, T. (2013). Recent development and biomedical applications of probabilistic Boolean networks. Cell Communication and Signaling, 11, 46.

Vahedi, Golnaz (2009). An engineering approach towards personalized cancer therapy. Doctoral dissertation, Texas A&M University. http://hdl.handle.net/1969.1/ETD-TAMU-2009-08-2941.

Verma, A., & Ramesh, P. (2007). Multi-objective initial preventive maintenance scheduling for large engineering plants. International Journal of Reliability Quality and Safety Engineering, 14(3), 241–250.

Wang, J., Wang, H., Zhang, W., Ip, W., & Furuta, K. (2014a). On a unified definition of the service system: What is its identity? IEEE Systems Journal, 8(3), 821–826.

Wang, X., Wang, H., & Qi, C. (2016). Multi-agent reinforcement learning based maintenance policy for a resource constrained flow line system. Journal of Intelligent Manufacturing, 27(2), 325–333. https://doi.org/10.1007/s10845-013-0864-5.

Yulan, J., Zuhua, J., & Wenrui, H. (2008). Multi-objective integrated optimization research on preventive maintenance planning and production scheduling for a single machine. International Journal of Advanced Manufacturing Technology, 39, 954–964.

Zhang, W. J., & Van Luttervelt, C. A. (2011). Toward a resilient manufacturing system. CIRP Annals-Manufacturing Technology, 39(1), 469–472.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rivera Torres, P.J., Serrano Mercado, E.I., Llanes Santiago, O. et al. Modeling preventive maintenance of manufacturing processes with probabilistic Boolean networks with interventions. J Intell Manuf 29, 1941–1952 (2018). https://doi.org/10.1007/s10845-016-1226-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-016-1226-x