Abstract

We studied sintering temperature to enhance the piezoelectric and dielectric properties of 0.98(Na0.5 K0.5)NbO3-0.02Li(Sb0.17Ta0.83)O3 + 0.01wt%ZnO (hereafter NKN-LST+ZnO) lead free piezoelectric ceramics. The synthesis and sintering method were the conventional ceramic technique and sintering was executed at 1080 ∼ 1120°C. We found that optimal sintering temperature and NKN-LST+ZnO ceramics showed the highest piezoelectric properties and dielectric properties at the optimal sintering temperature. The NKN-LST+ZnO ceramics sintered at 1090°C show a superior performance with piezoelectric constant d 33 = 185 pC/N, k p = 0.36, ε T33 /ε0 = 491 respectively. These results reveal that NKN-LST+ZnO ceramics are promising candidate materials for lead-free piezoelectric application.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

At present, lead-based piezoelectric materials such as lead zirconate titanate (PZT) have been widely used for the piezoelectric and dielectric applications due to their superior piezoelectric and dielectric properties. Piezoelectric materials play important roles in aerospace, diagnostic ultrasound, energy harvesting fields. The most commonly employed piezoelectric materials are PbTiO3-PbZrO3 (PZT) based materials such as Pb(Ni,Nb)O3-Pb(Zr,Ti)O3 (PNN-PZT), Pb(Mg,Nb)O3-Pb(Zr,Ti)O3 (PMN-PZT), Pb(Ni1/3Nb2/3)O3-Pb(Zn1/3Nb2/3)O3 (PNN-PZN) have widely studied and employed in the various industries due to their superior piezoelectric, mechanical, and dielectric properties [1–3]. However, the industries of these materials may be restricted in the near future owing to the high volatilization of lead oxide. Therefore, it is required to find alternative lead-free piezoelectric materials with high piezoelectric coefficient, electromechanical coupling factor and high Curie temperature. In the past few years, many studies have reported barium titanate (BaTiO3) [BT] [4], bismuth sodium titanate (Bi,Na)TiO3 [BNT] [5] and sodium potassium niobate (Na,K)NbO3 [NKN] families for the lead free piezoelectric materials. Among those several candidates of lead-free piezoelectric materials, NKN system has been recently considered as promising candidate for a lead-free piezoelectric materials because of its high piezoelectric coefficient of 160 pC/N (Hot pressing process) [6]. However, difficulties in the sintering process of pure NKN ceramics have lead to a deviation from these excellent properties, for example, relatively low electrical properties (d 33 = 80pC/N, k p = 36%) [7]. So, many researchers have reported that the effects of dopants for NKN system such as LiNbO3, Ba(Zr,Ti)O3, SrTiO3 . It is inferred that these dopants can not only improve the densification but also can enhance the piezoelectric properties. Also ZnO was a good sintering aid which enhances the sintering ability of ceramics [8, 9]. The purpose of this paper is to obtain a well sintered (Na0.44 K0.52)Nb0.84O3-Li0.04(Sb0.06Ta0.1)O3 ceramics with high piezoelectric, dielectric properties. Moreover, the increased relative density and decreased sintering temperature are required to allow their application to various industries. In this work, ZnO was used to increase the relative density of NKN-LST ceramics and lower the sintering temperature of NKN-LST ceramics. Variations of structural and electrical properties of NKN-LST+ZnO ceramics were also investigated with a sintering temperature.

2 Experiment

The chemical molecular formulae used in this paper for the perovskite ceramics with (Na, K, Li) complex A-sites and (Nb, Sb, Ta) complex B-sites is NKN-LST ceramics. For NKN-LST+ZnO ceramics fabricated using a conventional ceramic technique using high-purity starting materials: Na2CO3, K2CO3, Nb2O5, Li2CO3, Sb2O3, Ta2O5 and ZnO. There is no excess addition of raw materials. These powders were separately dried in an oven at 100°C for 4 h. They were ball-milled for 24 h using ZrO2 balls in ethyl alcohol. After being dried at 110°C for 24 h, the powders were calcined at 850°C for 3 h. The calcined powders were pressed into the disk sample of 12 mm. The samples were sintered at 1080 ~ 1120°C for 4 h with heating rate of 5°C/min. After the samples were polished 1.0 mm thickness, silver paste was screen-printed surfaces as electrodes and then fired at 400°C for 10 min. We used X-ray diffraction (XRD) to analyze the crystallinity and microstructure. The dielectric properties were measured using an LCR meter (PM6306, Pluke). The polarization versus electric (P-E) hysteresis loops of the ceramics were measured by the Sawyer-Tower circuit. The samples were poled in oil bath at 120°C under a DC field of 4 kV/mm for 20 min. The piezoelectric constant d 33 was measured by a d 33 meter (Channel Product DT-3300). The electromechanical coupling factor k p was calculated by measuring the anti-resonance and resonance frequencies. The relative density of the NKN-LST+ZnO ceramics was measured by the Archimedes method.

3 Result and discussion

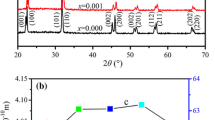

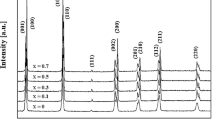

The X-ray diffraction (XRD) patterns for the NKN-LST+ZnO ceramics with various sintering temperature are shown in Fig. 1. All NKN-LST+ZnO ceramics sintered various sintering temperatures were well developed and none of the apparent secondary phases was found as shown in the Fig. 1. S. H. Park et al.[10] reported all NKN + xZnO ceramics have an orthorhombic structure. Although sintering temperature was increased, the peak shape did not change. Therefore, it can be inferred that all NKN-LST+ZnO ceramics with various sintering temperatures are considered to have an orthorhombic structure. The 2θ value of the mean diffraction peaks of (002) and (020) spaces for the samples sintered at 1080 ~ 1120°C, as highlighted in Fig. 2. As the sintering temperature was raised from 1080°C to 1090°C, the peak intensity of NKN-LST+ZnO ceramics increased and peak shape sharpened. It can be inferred that NKN-LST+ZnO ceramics sintered at 1090°C was crystallized well than 1080°C. However, NKN-LST+ZnO ceramics sintered above 1090°C, NKN-LST+ZnO ceramics lost their original well-crystallized perovskite structure. By comparing with other electrical properties, such as piezoelectric constant, electromechanical coupling coefficient, dielectric permittivity, we can infer that those properties of NKN-LST+ZnO ceramics decreased with increasing sintering temperature above 1090°C. Figure 3 shows, for examples, the scanning electron microscopy (SEM) micrographs of the NKN-LST+ZnO ceramics with various sintering temperatures. It has been observed that the NKN-LST+ZnO ceramics sintered at 1080°C has porous microstructure with small grain size. The grain size is significantly increased as sintering temperature reached 1090°C. According to the kinetic grain growth equation expressed as below [11].

Where G is the average grain size, n is the kinetic grain growth exponent, t is the sintering time, K0, Q, R and T are constant, apparent activation energy, gas constant, absolute temperature respectively. It can be explained that properly increasing sintering temperature enhances the grain growth. Therefore, cavities have been become smaller, NKN-LST-CuO ceramics turns into more dense structure and much more uniform. the grain boundary was clear with increased below 1090°C. However, further increasing sintering temperature of NKN-LST+ZnO ceramics exceed at 1090°C, the microstructure was inhomogeneous and the grain size of abnormal grain was observed. The fracture surface was the typical transgranular fracture mode for the sample sintered above 1090°C. Also we cannot even distinguish one grain from another over a wide area. These results prove to us that the NKN-LST+ZnO ceramics can not only artificially control of grain size but also can regulate the electrical properties.

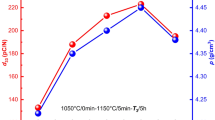

Figure 4 shows the polarization vs electric field curves of the NKN-LST+ZnO ceramics sintered at 1080 ~ 1120°C. As shown in the Fig. 4, 70 kV/cm was applied to the samples. For all samples, the remnant polarization increase with increasing sintering temperature below 1090°C. This indicates that sufficient grain growth was not happened sintered at 1080°C. When sintering temperature reach at 1090°C, it may assume that grain sufficiently grow and show the highest remnant polarization (P r ) of 19.8μC/cm2 at an applied electric field of 70 kV/cm. This high polarization value of 19.8μC/cm2 in the NKN-LST+ZnO ceramics comes from the samples forming of strong orthorhombic structure as discussed in Fig. 2. The change in value of P r could be associated with an increase in the relative density of samples. Therefore, it can be inferred that as sintering temperatures increase, grain growth of samples occurred. Variation of the relative density, electromechanical coupling coefficient, piezoelectric constant, dielectric permittivity was shown in Fig. 5. All results show the average values which was obtained by measuring 5 times of each 5 samples. The relative density increased with increasing sintering temperatures but it decreased as the sintering temperature exceed 1090°C and the formation of a dense microstructure through the liquid-phase sintering was ascribed the increase in relative density of samples. However, when excessive sintering temperature increased, grain was melted whereupon relative density of samples decreased. The d 33, k p and ε T33 /ε0 exhibited a similar tendency of relative density. The increase in d 33, k p and ε T33 /ε0 could be explained by the increase in relative density. However since excessive sintering temperature made grain melt in NKN-LST+ZnO ceramics, the d 33, k p, ε T33 /ε0 are expected to decrease with increased sintering temperature above 1090°C. The NKN-LST+ZnO ceramics sintered at 1090°C shows superior piezoelectric and dielectric properties of d 33 = 185pC/N (SSD = ±0.02), k p = 0.36 (SSD = ±5), ε T33 /ε0 = 491 (SSD = ±4) dielectric loss = 0.16 (SSD ± 0.03), respectively. (Each statistical standard deviation (SSD) shows in parenthesis). The electromechanical coupling factor (k p) is calculated by the following equation [12].

Where fr is resonance frequency, fa anti-resonance frequency, a = 0.395 and b = 0.674 for planar (k p) mode.

4 Conclusion

In this paper, Lead-free NKN-LST+ZnO piezoelectric ceramics with different sintering temperature were prepared by using a conventional ceramic technique and their piezoelectric, ferroelectric, dielectric properties have been studied. The XRD results show that NKN-LST+ZnO ceramics were crystallized and they had a orthorhombic structure. When sintering temperature was 1090°C, NKN-LST+ZnO ceramics were well crystallized than others. The P-E hysteresis loops for the NKN-LST+ZnO ceramics sintered at 1090°C shows the highest remnant polarization of 19.8μC/cm2 while the NKN-LST+ZnO ceramics sintered at shows the lowest remnant polarization of 10.1μC/cm2 under an applied electric field of 70 kV/cm. Also, NKN-ST + ZnO ceramics sintered at 1090°C have the highest piezoelectric constant (d 33) of 185pC/N, and electromechanical coupling coefficient (k p) of 0.36, dielectric permittivity (ε T33 /ε0) of 491. These results indicate that the sintering temperature considerably influence the sinterbility, structural and electrical properties of NKN-LST+ZnO ceramics. NKN-LST+ZnO ceramics can not only artificially control of grain size but also improve the electrical properties. These superior electrical, structural properties make NKN-LST+ZnO ceramics for a wide range of electromechanical transducers and energy harvesting.

References

S.H. Lee, K.S. Lee, J.H. Ryu, Y.H. Jeong, H.S. Yoon, Trans. Electr. Electron. Mater. 12(2), 72 (2011)

P. Zhao, B.P. Zhang, J.F. Li, Appl. Phys. Lett. 91, 172901 (2007)

K. Wang, J.F. Li, N. Liu, Appl. Phys. Lett. 93, 092904 (2008)

S.H. Lee, Y.H. Lee, J. Ceram. Process. Res. 12(4), 416 (2011)

S.H. Lee, Y.H. Lee, Elec. Mat. Lett. 7(3), 205 (2011)

M.S. Kim, D.S. Lee, E.C. Park, S.J. Park, S.J. Jeong, J.S. Song, J. Eur, Ceram. Soc. 27, 4121 (2007)

D. Lin, K.W. Kwok, Int. J. Appl. Ceram. Technol 8(3), 684 (2011)

Y. Yang, S.H. Ding, X. Yao, Ceram. Int. 30, 1335 (2004)

C.L. Huang, M.H. Weng, Mater. Res. Bull 35, 1881 (2000)

S.H. Park, C.H. Ahn, S. Nahm, J.S. Song, Jpn. J. Appl. Phys 43(8B), L1072 (2004)

T.Y. Chen, S.Y. Chu, Y.D. Juang, Sens. Actuator A Phys. 102, 6 (2002)

M. Matsubara, T. Yamaguchi, K. Kikata, S. Hirano, Jpn. J. Appl. Phys. 44, 6136 (2005)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, SH., Lee, SG., Kim, HJ. et al. Effect of sintering temperature on piezoelectric and dielectric properties of 0.98(Na0.5K0.5)NbO3-0.02Li(Sb0.17Ta0.83)O3+0.01wt%ZnO ceramics. J Electroceram 28, 101–104 (2012). https://doi.org/10.1007/s10832-012-9686-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10832-012-9686-7