Abstract

Identifying reduction dynamics in prehistoric retouched stone tools is important for understanding technological trends, as well as site function, raw material management and mobility of nomadic hunter-gatherers. In the absence of refits, the final state of the abandoned piece is the only remain that archaeologists have for the study of lithic reduction. The establishment of experimentally tested indexes providing strong correlations between estimated and real reduction are needed. In our work, we propose a new procedure for estimate reduction percentage. In this proposal, data are obtained from high resolution three-dimensional (3D) scans and manual measurements are avoided. The experimental test has been realized using distally retouched tools, the less suitable tools for reduction studies. The correlation levels obtained between the measured data and the estimated data increase substantially the original published from manual measurement, reaching a r 2 value of 0.81 and a correlation of 0.9. The main contribution of the proposed method is the very high correlation obtained in the volume estimation (r 2 = 0.89 and r = 0.94) using the 3D-based measurements. The 3D models of the unretouched and retouched flakes used in this work are free to use and accessible through an online repository.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Discussion concerning methods for quantifying reduction of lithic retouched tools has been one of the major questions in the artifact analyses of stone-tool-producing societies since, at least, the last 30 years (Dibble 1987; 1997; Kuhn 1990; Davis and Shea 1998; Hiscock and Attenbrow 2002; Clarkson 2002; Eren et al. 2005; Marwick 2008; Eren and Prendergast 2008; Eren and Sampson 2009; Hiscock and Clarkson 2009; Clarkson and Hiscock 2011 inter alia). The archaeologists' need to know how much tools have been reduced from their original morphology responds to the behavioral inferences that can be made through this kind of approach. Mobility patterns, occupational characteristics, raw material management, and typological variability are some of the main topics discussed in Paleolithic archaeology, and reduction quantification offers one way to study behavioral dynamics from static archaeological remains.

In lithic analysis, reduction could be adequately expressed as the amount of material removed from a retouched tool before it was abandoned. Its simplest expression is reduction index = original mass − abandoned mass, where mass is substituted for volume. In this equation, the abandoned mass or volume is known, so the aim is to estimate the original flake mass. The concept of original mass/volume has not always been considered as an absolute value (in grams or cubic millimeters) but rather as a morphological modification from an idealized original form. In Kuhn's original (1990) geometric index of reduction (GIUR) proposal, a higher deviation from a supposed (feather) original edge morphology involves a greater degree of reduction, and, indirectly a higher amount of mass lost. In more recent approaches (Eren et al. 2005), researchers have tried to transform relative reduction measures into absolute ones, giving scaled values to the original mass/volume estimation.

In general, coefficient of determination (r 2) and Pearson's correlation (r) have been used to define the degree of robustness of the different experimental approaches (Hiscock and Tabrett 2010). During the last decade, the link between these values and reduction, and also the utility of the constructed reduction indexes, has generated scientific controversy. Consequently, experimental protocols have been developed in order to test methods. Variables, measurement techniques, and samples have been modified or adapted in order to improve the correlation (Eren et al. 2005; Eren and Sampson 2009; Hiscock and Clarkson 2005, 2009). In a recent paper, Hiscock and Tabrett (2010) proposed a set of seven goals that a reduction index should ideally reach to become universally applied: (1) a high inferential power, (2) a proportional unidirectional growth of the index/reduction relation, (3) constant utility throughout all the reduction process, (4) sensibility to detect minor modifications, (5) versatility to different retouching modes, (6) adaptation to a wide range of blank morphologies, and (7) scale independence. Obviously, a reduction index that works well in all technological contexts should be the optimal to compare results. However, the high degree of variability between assemblages and their technologies makes the search for a universal reduction equation seem unrealistic. It may be difficult to compare standardized with nonstandardized industries, core-based with flake-based technologies, or unifacial with bifacial technologies because the concept and meaning of reduction intensity will vary according to typological, technological, cultural (and chronological) contexts. It appears more achievable to seek to establish broad reduction horizons, in which some kind of tool types converge in the same reduction laws independently of chronology or cultural context.

In this work, we deal specifically with reduction in distally retouched tools. This approach has a concrete archaeological problematic since distal retouch has been considered as problematic (Kuhn 1990) for reduction estimations because of the morphological characteristics of its sagital section. On the contrary, other studies using allometry as a reduction indicator claim that useful data may be obtained from end-scrapers [see Blades' (2003) original work or the Eren's (2013) more robust approach]. In this case, the methodology is based on Eren et al. (2005) systematic for reconstructing original flake volume. In their proposal, a trigonometric reconstruction of the retouched edge/edges is performed in order to estimate the reduction percentage. Despite the fact that some aspects of this estimation has been questioned (Hiscock and Tabrett 2010), we consider that it might be useful if more precise measurements could be obtained. In this way, we have tried to improve it through the use of three-dimensional (3D) scan models on experimental samples and 3D-measurement techniques.

Archaeological Perspective

We are carrying out a research on technological variability and cultural evolution during the Late Upper Paleolithic/Mesolithic (ca. 14–8 ka cal. bp) in the Iberian Peninsula's Mediterranean basin. In comparison with previous Upper Paleolithic phases such as the Magdalenian (sensu stricto) or Solutrean, this time frame is locally characterized by a marked decrease in typological variability. In the most sites, bone or antler artifacts decrease or even disappear, lithic projectile variability is drastically reduced, and some typical domestic tools such as burins became scarce (Fullola et al. 2012). Thus, a very homogeneous assemblage composition is characteristic during the Bölling/Alleröd, Younger Dryas, and Early Holocene periods. With some variability in the percentages, the retouched assemblages are formed mainly by small backed blades and points comprising the hunting toolkit, with a late incorporation of abrupt-retouched microlithic triangles, and end-scrapers as the dominant “domestic tools.” Combined both typological groups frequently reach 70–80 % of the total retouched component (Morales et al. 2013). The presence of scrapers, denticulates, burins, truncations, or retouched flakes is therefore always low or nonexistent.

This typological homogeneity is observed both in coastal and mountain sites, and no seasonal or latitudinal variability is observed from the technological characteristics of the industries. Faunal studies show this homogeneity, too. In terms of Minimal number of individuals (MNI), rabbits are the most consumed prey, and there is some variability in the presence of ungulates between sites. In general terms, deer, ibex and wild boar are the most hunted preys. Land snails and mollusks were also collected (Vaquero 2004; Tejero et al. 2009; Allué et al. 2010; Martínez-Moreno and Mora 2011).

This apparent Late Pleistocene stasis does not seems to reflect high climatic instability and environmental change attested during this time period. However, changes must be observed through a different lens. Some studies consider variations in the intensity of recycling to result from raw material acquirement behavior (Vaquero et al. 2012), and we are sure that this kind of nonevident approach will be useful to reveal the hidden processes of change in site use, mobility, and activity dynamics.

Our approach deals with the most ubiquitous tool, i.e., end-scrapers, and focuses on a possible differential management of these tools over time. We have applied three lines of research, including (1) end-scraper raw material selection, (2) curation, and (3) use. The work presented here is a first step in observing if differences in the intensity of use could be detected through the combination of reduction intensity and the use–wear analyses. This differences, if exist, will help us to detect diachronic changes in mobility patterns through settlement duration characterization, raw material acquisition patterns, and in situ activities carried out.

Materials and Methods

Materials

To perform the experimental phase of this work, we prepared a set of 50 flint flakes. Nonspecific flaking strategies were used because one of the main desired characteristics was morphological heterogeneity of the sample. To select the flakes, no restrictions in terms of size and morphology were imposed. The only criterion used for selection was a minimum suitability for retouch. Some broken flakes or very atypical morphologies were eliminated. Retouch was implemented by direct, hardhammer freehand percussion. This phase consisted in configurating a potentially functional morphology at the distal end of each flake. No premise was established in order to control the amount of mass detached, the retouching phase finished when the end-scraper was typologically and functionally configured. All the knapping and retouch process was performed by a single knapper (J.I.M).

In Fig. 1, we present the sagital section morphology of all the retouched flakes in order to show the intrasample variability. In the construction of reduction indexes, morphological features are, in some cases, a conditioning factor that must be taken into account. Any kind of bias or selection in sample composition probably affects the results in one way or another. In this scenario, we consider that it is fundamental to publish the main characteristics of the experimental sample in order to show the patterns used for method calibration. The development of this work has produced a collection of 3D models of both original flakes and retouched tools. This collection has been uploaded to an open-access online repository accessible to everyone who wants to test our results, or apply it to other scientific or educational purposes (http://sdrv.ms/157d5wQ).

3D extracted sections of the retouched tools. Those with very overestimated reduction values (Exp21 and Exp43) or the nonmeasurable morphologies (Exp30, Exp36, Exp38, Exp40, Exp41, Exp42, Exp43, Exp45, and Exp49) are shadowed. Values indicate an index of accuracy in which 1 is a perfect estimation of the reduction

Methods

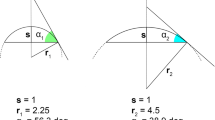

In the methodology published by Eren et al. (2005), they establish the trigonometric functions to obtain an ideal reconstruction of a tool's retouched edges. In this approach, two angles need to be measured (“a” and “b”). The first represents the real angle of the retouched edge; the second, the estimated angle of convergence of the dorsal and ventral planes. This joint is interpreted as the original angle of the unretouched edge. Both are measured with manual goniometers. In addition, two linear measurements are taken, too. The called “D” measurement is equivalent to Kuhn's GIUR “D” (extension of retouch scars), and the “L” measurement is the extension of the retouch in a tangent line. With these known values, it is possible to reconstruct the dimensions of the remaining sides of the triangle as observed in Fig. 2. Finally, the area of the constructed triangle is calculated. The volume is obtained by multiplying the area by the retouch length. This volume estimation is considered as the reduction equation (RE). In the experimental protocol developed by Eren et al. (2005), volume is calculated first before retouch using water displacement in a graduated beaker and later, after retouch, using the density equation. As density must be a constant, if density = mass/volume, so V = MD. In this way, the real volume of the retouched tool, and real volume of the retouch, can be compared with the estimated ones. To express results without size inferences, an estimated reduction percentage (ERP) is calculated as an index where ERP = RE/(RE + retouched tool volume). Index values ranges from 0 to 1, but only exceed 0.5 in highly overestimated cases. The higher value 1 is a nonreachable value because a tool cannot be reduced to 0. The published coefficient of determination (r 2) for this index with the Eren's et al. (2005) experimental sample was 0.4537 for all cases, and 0.799 avoiding the outliers.

Trigonometric method to obtain the simulated feathered termination of the flake and the area and volume values (modified from Eren et al. 2005)

In our test, we translate directly this methodology to the end-scraper sample. First, measurements were acquired using a precision weighing scale, manual goniometers, digital calipers, and a graduated beaker. Volume of the unretouched flake was measured by water displacement using the cylinder volume equation (V = πr 2 h) and registering water displacement with a digital caliper. The volume of the retouched tool was interpolated through the density equation. For calculating t and D 2, we created an Excel template with the formula. In order to simplify this template, the original formula was slightly modified in its trigonometrical reasoning without affecting the results. Then RE, ERP, and the difference between ERP and the measured reduction percentage (RP) were calculated.

In addition to these “traditionally acquired” measurements, another methodology was employed in order to test the accuracy of the previous data and to obtain a higher accuracy. All the pieces were digitalized with a structured light Breuckmann's SmartScan 3D scan. The field of view used was a 250 mm one, and the process was automated with a scan-controlled rotation platform. Each flake was digitalized twice, once before retouching and again after retouch. The 100 resultant 3D meshes were carefully corrected using commercial 3D processing software in order to maintain the original morphology in the most complicated areas such as sharp edges. When the 3D models were polished and corrected, the exact volume was automatically calculated by the software.

Although some 3D processing software allows to measure angles directly, we consider this option somewhat imprecise and easily conditioned by subjective effects. In this case, we decided to develop an alternative method for the rest of the process. Sagital section were drawn using curve extraction options and creating a complete section. To extract highly equivalent sections for all the meshes, we defined the retouching plane as the base of the tool. The sections were then created using the most retouched point of the edge (normally a mid-point) and following the reduction direction perpendicularly (Fig. 3). In some cases, this coincided with the longitudinal technical axis, but generally, there was some degree of divergence.

Steps of the 3D methodological procedures. 1 Composition of non retouched and retouched flake; 2 measurement acquirement and differences between straight and surface measurements; 3 section extraction following the reduction axis; 4 dorsal and ventral planes projection, angle measurements, and surface used to compute area and volume

Once all the sections were created, we exported them as 2D slices into Corel Designer X5 software. The sections were scaled to the correct dimensions when necessary using this software. Then the angle “a” or retouch angle was measured. For the calculation of angle “b,” we extended the axis of the dorsal and ventral lines manually. To adjust the dorsal axis as much as possible, we fit it within the last unretouched straight surface orientation, interpreting it as the best remaining indicator of the original long-cross morphology. The angle was then measured at the intersection of both planes. Corel Designer automatically calculates the area of this new triangle and no trigonometric functions were needed.

The retouch length or “L” was measured in the 3D processing software, using the option of project distance of the surface. This option gives a more accurate extension of the retouched perimeter taking into account the surface morphology instead consider it as a straight line.

All the data were then introduced in a Microsoft Excel datasheet and real subtracted volume, RP, RE, ERP, and RP-ERP relation were calculated.

To assess the influence of the interobserver effect in the by-hand measurement, and to compare it with 3D obtained values, we performed a blind test with 11 randomly selected elements of the end-scraper sample. In this test, six researchers of the IPHES lithic technology department measured the two angles and the retouch length with some instructions about which data we wanted to acquire, but none about how to do it.

Results

Preliminary Test

A preliminary approach to the ERP was performed using the trigonometric reconstruction of the retouched edges in order to know its suitability to the characteristics of our sample (see Supplementary Materials Table 1). All the measurements were taken by-hand using the same methodology proposed in the original work as has been described in Eren et al. (2005).

Correlation values and coefficient of determination obtained gives unexpectedly extremely low results, indicating the absence of correlation between the real reduction values and the estimated ones (Fig. 4 and Table 1). Since higher correlation values had been published, we considered that two different sources of error were altering the correlation of the end-scraper sample. Firstly, morphological features, especially sagital section geometry, were less sensitive to the virtual flake portion reconstruction performed through trigonometry. Secondly, methods used to compute some variables, especially volume calculation, were very imprecise. Therefore, important errors in density estimations entailed faulty volume estimations for the retouched pieces. The use of manual goniometers is another way to introduce wrong estimations. Positioning a goniometer on irregular, convex, or concave surfaces leads to bad angle estimations; as is seen in Dibble and Bernard's (1980).

Measurement Uncertainty

Imprecision in by-hand measurements is a central problem concerning typometrical or morphometrical lithic analyses. Data comparison with measurements taken by-hand usually leads to false or very imprecise comparisons. Generally, the source of error could have two different origins. The first one is an intrinsic problem of the measuring instruments themselves. In volume calculations by water displacement using graduated beakers, measurers need to take into account that most graduated instruments have a fabrication uncertainty that can range from 0.5 to 10 % of the expressed volume. In this experiment, graduated beakers had a standard error of ±0.15 ml. Knowing this, the smaller the volume of the flake, the higher the influence of the error. Sometimes, this error could modify volumes by more than 100 %.

The second and the most common source of error, and the most usual, is related with human imprecision and strongly affects nonlinear measurements, conditioned by the morphology or sensitive to subjectivity. Equally, the wrong use of some measuring instruments, like goniometers, or errors in tool orientation in caliper captured measurements can affect the results in very different ways. Interobserver variability also has a determinant role in the definition of data, and greater precision and homogeneity is needed to measure lithic tools variables.

In the next section, we compare 3D and by-hand values of some of the fundamental measurements of this methodology. Furthermore, we show the consequences of assuming this error in the calculated relations.

Volume and Density

The imprecision of the volume measurement method converts this variable into an important source of error. In general, a marked overestimation of the real volume exists in the unretouched flake volume calculation. Error percentages achieve values higher than 80 % of the 3D measured value, and the mean calculated error for the total assemblage is 21.4 ± 21 % (Fig. 5).

On the contrary, in the retouched tools volume calculation, the general pattern reveals an underestimation of the 3D measured volume. Mean error for retouched tools against 3D measured volume is 21.2 ± 21 %.

In the by-hand measurements, retouched tool volume has been obtained using the density equation. The individual density of the flakes is calculated through known mass and volume values, so the volume of retouched tools is worked out using this existent density value and the weighted mass. One kind of material density is constant, so, despite some variability such as individual cortex percentages or impurities, the density value should be the same in all the samples. In Fig. 6, it is possible to observe density estimations compared to the volume using the 3D volume calculations and water displacement methods. While 3D estimation may be used to interpret density as a constant, the water displacement method is not. Especially, small volume flakes show evident density underestimations. In this way, the smaller the flakes are, the higher the density imprecision is. This error strongly affects the post-retouch volume calculation and the final ERP calculation.

Angle and Retouch Length

The computing of angles “a” and “b” and retouch length are the basis of edge reconstruction in the trigonometric method. In this case, wrong estimations will result in bigger or smaller triangles and, as a result, miscalculation of the area and extracted volume values. The ERP index is very sensitive to these variables and by-hand measurement introduces a high degree of uncertainty. For example, an error in caliper or goniometer positioning is easily produced due to the morphological complexity of the flakes. In addition, the subjectivity of the observers can create noncomparable samples.

Results plotted in Fig. 7 show high variability in the results of the interobserver test, especially in the angle measurements. If ERP is computed using each one of the different measurements sets, results will be completely different, and the interpretation of the reduction carried out will vary substantially.

3D-Based Method

The use of 3D reconstruction and measurement in the ERP index calculation (see Supplementary Material Table 2) increases in a very significant way the inferential power of the index compared with the one obtained using the trigonometric method for the end-scraper sample (Fig. 8). Statistical indicators “r” and “r 2” range between 0.8 and 0.9, respectively, indicating a very strong correlation of the known and estimated value (Table 2).

In the same way, the measurement methodology has demonstrated a higher degree of accuracy than the manual one. If 3D obtained measures are introduced into the trigonometric formulation, the correlation strength in volume and ERP/RP contrast increases substantially (r 2 = 0.5426 and 0.2727), raising levels of moderate correlation.

One of the most important index qualities in reduction is the directionality (Hiscock and Tabrett 2010) or the unidirectional growing of the index with increasing reduction values. This pattern was confirmed in the original ERP work (Eren et al. 2005), and our modification does not affect this character. In the same sense that the RP increases linearly when the percentage of removed volume is higher, the ERP also increases linearly when the estimated percentage is higher (Fig. 9).

No correction for the outliers has been applied because the measuring mechanism of this methodology entails a discrimination of non measurable cases. The final ERP values have been calculated for 42 of 50 elements of the sample. The morphology-based projection of the dorsal and ventral planes involves that highly parallel or divergent planes will never meet, so its ERP will be infinite. The only specimen that can be considered as an outlier and is not a parallel/divergent one is the case of a very atypical hinged termination that creates a high underestimation effect (specimen 43).

Discussion

The 3D-based modification of the original ERP methodology has been demonstrated as a very powerful estimator of reduction percentages in distally retouched tools. This method needs a longer measuring protocol than other estimating methods because a 3D digitalization of the artifacts is required. In the past few years, the number of lithic studies that uses laser or structured light 3D scans has increased exponentially (Grosman et al. 2008; Lin et al. 2010; Shott and Trail 2010; Clarkson and Hiscock 2011; Bretzke and Conard 2012). Nevertheless, 3D scan is still a time-consuming procedure that complicates its systematic application to large archaeological or experimental samples. In our case, using trigonometry and Excel formulation ERP estimations produced immediate results, while the 3D method is longer and more fastidious. Nonetheless, previous 3D work was performed using a NextEngine 3D laser scan, and now, with structured light equipment, time cost has been reduced substantially. Laser acquirement needs an average time of 1 h per piece plus the mesh repairing process. With the structured light scanner, it is possible to get four to six models per hour depending on the complexity. It would be expected that upcoming 3D scan generation and processing software will reduce this time even more.

Concerning the 3D ERP proposal, we have demonstrated that it can be successfully applied to nontriangular sagital section. Although better correlations are obtained with more homogeneously decreasing sections, relatively parallel ones can be analyzed as well. In this way, we think that manual adjustment of dorsal and ventral planes can reduce the so-called flat-flake problem (Dibble 1995; Hiscock and Clarkson 2005). This limitation is something that must be evaluated for the archaeologist trying to apply this method to a given archaeological sample. In the case that we are working on, the Late Upper Paleolithic end-scraper assemblage, there is not a significant blade component, so the greatest part of the distally retouched tools was manufactured on simple flakes. In other cases, dismissing a certain percentage of the archaeological sample was not a strong handicap. A reduced and well-selected sample can provide more reliable results. When a large number of tools need to be eliminated, the ERP index should be interpreted as a minimum ERP index.

To complete the experimental testing of 3D ERP index, it is necessary to check its performance in a sequential chain of reduction; the quality that Hiscock and Tabrett (2010) called “comprehensiveness.” As morphological changes in the long cross-section will appear through the reduction sequence, we have considered that a new and more focalized experiment is needed. The introduction of a broader range of controlled morphologies, and also laterally retouched tools, would be necessary. Nevertheless, in comparison with ERP values of Eren et al. (2005), we think that correlation must increase as the reduction evolves because of the compensation of the outliers' load. Eren's experimentation reaches reduction values of 0.25, while ours only reaches 0.12. The inferential power of 3D ERP is higher for nonextensively reduced samples because Eren's correlation gets stronger when more distant isolated points (more reduced tools) force to a more linear relation. The linear pattern of that sample is not well defined in the lesser reduction zone of Eren's plot area.

As for the GIUR and ERP, multiple measurement average can be applied to the 3D ERP method. In this case, it is necessary to be very careful in computing the retouch length. Especially in end-scrapers, more lateral retouch is often marginal, so the reduction carried is lower than for the more centered ones. The computing of small marginal retouch in the “L” value will oversize the volume reconstruction. When the marginality of some lateral retouch could be observed, one could take the decision to avoid them in order to prevent overestimated volumes.

All the 3D models used in these experiments are accessible and free for researchers. Archaeological data sharing must be the basis for faster growth of the discipline. Massive incorporation of the new technologies will create large amounts of digital data in a short time. This data can be easily shared between archaeologists. In the same way, large databases can be created with the common aim of validating proposals and innovation, especially regarding to lithic analyses and new approaches to lithic technology.

References

Allué, E., Ibañez, N., Saladié, P., & Vaquero, M. (2010). Small preys and plant exploitation by late pleistocene hunter-gatherers. A case study from the Northeast of the Iberian Penisula. Archaeological and Anthropological Sciences, 2(1), 11–24.

Blades, B. S. (2003). End scraper reduction and hunter-gatherer mobility. American Antiquity, 68(1), 141–156.

Bretzke, K., & Conard, N. J. (2012). Evaluating morphological variability in lithic assemblages using 3D models of stone artifacts. Journal of Archaeological Science, 39(12), 3741–3749.

Clarkson, C. (2002). An index of invasiveness for the measurement of unifacial and bifacial retouch: A theoretical, experimental and archaeological verification. Journal of Archaeological Science, 29, 65–75.

Clarkson, C., & Hiscock, P. (2011). Estimating original flake mass from 3D scans of platform area. Journal of Archaeological Science, 38(5), 1062–1068.

Davis, Z. J., & Shea, J. J. (1998). Quantifying lithic curation: An experimental test of Dibble and Pelcin's original flake-tool mass predictor. Journal of Archaeological Science, 25(7), 603–610.

Dibble, H. L., & Bernard, M. C. (1980). A comparative study of basic edge angle measurement techniques. American Antiquity, 45(4), 857–865.

Dibble, H. L. (1987). The interpretation of Middle Paleolithic scraper morphology. American Antiquity, 52(1), 109–117.

Dibble, H. L. (1995). Middle Palaeolithic scraper reduction: Background, carification, and review of evidence to date. Journal of Archaeological Method and Theory, 2, 299–368.

Dibble, H. L. (1997). Platform variability and flake morphology: Comparison of experimental and archaeological data and implications for interpreting prehistoric lithic technological strategies. Lithic technology, 22(2), 150–170.

Eren, M. I., Dominguez-Rodrigo, M., Kuhn, S. L., Adler, D. S., Le, I., & Bar-Yosef, O. (2005). Defining and measuring reduction in unifacial stone tools. Journal of Archaeological Science, 32(8), 1190–1201.

Eren, M. I., Prendergast, M. E. (2008). Comparing and synthesizing unifacial stone tool reduction indexes. In Andrefsky, W. Jr (Ed.), Lithic technology: Measures of production, use and curation (pp. 49–84). Cambridge: Cambridge University Press.

Eren, M. I., & Sampson, C. G. (2009). Kuhn's geometric index of unifacial stone tool reduction (GIUR): Does it measure missing flake mass? Journal of Archaeological Science, 36(6), 1243–1247.

Eren, M. I. (2013). The technology of Stone Age colonization: An empirical, regional-scale examination of Clovis unifacial stone tool reduction, allometry, and edge angle from the North American Lower Great Lakes region. Journal of Archaeological Science, 40(4), 2101–2112.

Fullola, J. M., Mangado, X., Tejero, J.-M., Petit, M.-À., Bergadà, M.-M., Nadal, J., García-Argüelles, P., Bartrolí, R., & Mercadal, O. (2012). The Magdalenian in Catalonia (northeast Iberia). Quaternary International, 272–273, 55–74.

Grosman, L., Smikt, O., & Smilansky, U. (2008). On the application of 3-D scanning technology for the documentation and typology of lithic artifacts. Journal of Archaeological Science, 35(12), 3101–3110.

Hiscock, P., & Attenbrow, V. (2002). Morphological and reduction continuums in eastern Australia: measurements and implications at Capertee 3. Tempus, 7, 167–174.

Hiscock, P., & Clarkson, C. (2005). Experimental evaluation of Kuhn's geometric index of reduction and the flat-flake problem. Journal of Archaeological Science, 32(7), 1015–1022.

Hiscock, P., & Clarkson, C. (2009). The reality of reduction experiments and the GIUR: Reply to Eren and Sampson. Journal of Archaeological Science, 36(7), 1576–1581.

Hiscock, P., & Tabrett, A. (2010). Generalization, inference and the quantification of lithic reduction. World Archaeology, 42(4), 545–561.

Kuhn, S. L. (1990). A geometric index of reduction for unifacial stone tools. Journal of Archaeological Science, 17(5), 583–593.

Lin, S. C. H., Douglass, M. J., Holdaway, S. J., & Floyd, B. (2010). The application of 3D laser scanning technology to the assessment of ordinal and mechanical cortex quantification in lithic analysis. Journal of Archaeological Science, 37(4), 694–702.

Martínez-Moreno, J., Mora, R. (2011). In the kingdom of Ibex: continuities and discontinuities in Late Glacial hunter-gatherer lifeways at Guilanyà (south-eastern Pyrenees). Hunting Camps in Prehistory. Current archaeological approaches. Proceedings of the International Symposium, 13–15 May 2009, University Toulouse II, Le Mirail. Palethnology, 3, 211–227

Marwick, B. (2008). What attributes are important for the measurement of assemblage reduction intensity? Results from an experimental stone artefact assemblage with relevance to the Hoabinhian of mainland Southeast Asia. Journal of Archaeological Science, 35(5), 1189–1200.

Morales, J. I., Vergès, J. M., Fontanals, M., Ollé, A., Allué, E., & Angelucci, D. E. (2013). Los niveles B y Bb de La Cativera (El Catllar, Tarragona). Procesos técnicos y culturales durante el Holoceno inicial en el noreste de la Península Ibérica. Trabajos de Prehistoria, 70(1), 54–75.

Shott, M. J., & Trail, B. W. (2010). Exploring new approaches to lithic analysis: Laser scanning and geometric morphometrics. Lithic Technology, 35(2), 195–220.

Tejero, J. M., Estrada, A., Nadal, J., Fullola, J.M., Mangado, X., Petit, M.A., Bartrolí, R., Calvo, M. (2009). Hunters and craftsmen of the Late-Glacial period. The exploitation of animal resources at Parco Cave (Lleida, Spain) during the Magdalenian. In Search of Total Animal Exploitation. Case Studies from the Upper Palaeolithic and Mesolithic. Proceedings of the XVth UISPP Congress, Session C61, vol. 42, Lisbon, 4–9 September 2006. L. Fontana, F. X. Chauvier and A. Bridault. Oxford, BAR International Series, 2040, 91–99.

Vaquero, M., (coord.). (2004). Els darrers caçadors-recolectors de la Conca de Barberà: el jaciment del Molí del Salt (Vimbodí). Excavacions 1999-2003. Montblanc, Museu Arxiu de Montblanc i Comarca.

Vaquero, M., Alonso, S., García-Catalán, S., García-Hernández, A., Gómez de Soler, B., Rettig, D., & Soto, M. (2012). Temporal nature and recycling of Upper Paleolithic artifacts: the burned tools from the Molí del Salt site (Vimbodí i Poblet, northeastern Spain). Journal of Archaeological Science, 39(8), 2785–2796.

Acknowledgments

This research has been partially supported by the Spanish Ministerio de Economia y Competitividad (The Ministry of Economy and Competitiveness) project numbers CGL2009-12703-C03-02/03, CGL2012-38434-C03-01/03, and HAR2012-32548/HIST, and the AGAUR from Generalitat de Catalunya—AGAUR SGR324 project. J.I. Morales is a beneficiary of a predoctoral research fellowship (FI) from the AGAUR of Generalitat de Catalunya (FI-DGR 2013). Authors also want to thank A. Bargalló and D. Barsky for his comments on the previous versions of the draft and language corrections and the two anonymous reviewers for their comments and suggestions.

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 46 kb)

Rights and permissions

About this article

Cite this article

Morales, J.I., Lorenzo, C. & Vergès, J.M. Measuring Retouch Intensity in Lithic Tools: A New Proposal Using 3D Scan Data. J Archaeol Method Theory 22, 543–558 (2015). https://doi.org/10.1007/s10816-013-9189-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10816-013-9189-0