Abstract

Feeding seaweeds and macroalgal products has been shown to reduce enteric methane emission from rumen fermentation. On Prince Edward Island, Canada, stormtoss shoreweed (SHW) consists of variable seaweed proportions of Chondrus crispus (Irish moss; IM), Laminaria longicruris, and Fucus vesiculosus. The impact of invasion by Furcellaria spp. (FF) and its increasing proportion in SHW harvests on feeding value has not been evaluated. The aim of this study was to determine effects of feeding SHW on ruminal fermentation and methane production. Effects were assessed in vitro using continuous culture with pooled rumen inocula from Holstein cows. In vitro cultures were maintained on 30 g day−1 of the dietary dry matter (DM) fed to donor cows and were supplemented with FF or IM at 0.14, or SHW at 0.14 (SHW1), 0.28 (SHW2), or 0.56 (SHW3) g DM day−1. There was little change in pH, total volatile fatty acids, or the acetate/propionate ratio due to seaweeds. The SHW mix and component seaweeds reduced the post-fermentation level of NH3-N suggesting decreased deamination of dietary and microbial amino acids. Methane emission was reduced on average 12 % with seaweeds and maximally by 16 % with SHW2. Reduction in methane production was not induced by impaired organic matter (OM) digestibility which averaged 46 %. North Atlantic SHW has potential based on in vitro screening at these doses to be fed to ruminants with beneficial effects on methane production at little cost to dietary digestibility.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Recent reports and studies have concluded that many types of macroaglae and macroalgal products have the environmentally beneficial effect of reducing methane (CH4) emissions from ruminant fermentations (Wang et al. 2008; Dubois et al. 2013; Machado et al. 2014b; Evans and Critchley 2014). The studies also demonstrated that CH4 reductions were accompanied by variable effects on overall fermentation. Macroalgae products are fed widely in the dairy sector in Atlantic Canada and are purported to improve cow health and productivity (Craigie 2011; Evans and Critchley 2014). Commonly referred to as seaweeds, marine macroalgae provide a source of organically bound mineral (Machado et al. 2014b) and bioactive metabolites (Holdt and Kraan 2011; Blunt et al. 2013). A natural stormtoss seaweed mix from Prince Edward Island (PEI), Canada, referred to as shoreweed (SHW) has been harvested with intention of commercialization and fed to ruminants at a rate of about 0.5 % of daily dry matter (DM) intake. However, SHW requires affirmation of effect and safety for official designation as a commercial nutritional supplement with potential novel environmental benefits. Feeding SHW to ruminants has been practiced for decades without reported ill effect on animals and with unanimous, however anecdotal, feeling among farmers that SHW is beneficial to animal health. This mix has originally contained a high proportion of the red macroalga Chondrus crispus, commonly known as Irish moss (IM), which has an economic benefit for North Atlantic coastal communities due to its alginate. Harvest for alginate from beds and stormtoss has been progressively reduced in economic viability due to intrusion of an invading species. The IM beds of the Gulf of St. Lawrence have a documented advancing invasion of another red macroalga from the genus Furcellaria with the species Furcellaria lumbricalis and Furcellaria fastigiata. Mathieson et al. (2008) reported that the Furcellaria species (FF) arrived from Europe via ballast water of past era trans-Atlantic ships and has been present in the Gulf region for over 150 years. Doty et al. (1987) described the presence of up to 5 % FF in commercial IM beds as recorded in surveys of the 1960s, and by 1987, stormtoss seaweeds of Atlantic Canada contained about 1:1 FF and IM, up from 1:8 in harvests of 1974. Bird et al. (1983) reported that on PEI, FF had become the prevalent species in IM beds at the typical harvesting depth which is reflected in FF contribution in stormtoss. Invaded beds exceeding 5 % FF are avoided by harvesters of IM resulting in economic loss to the region (Sharp et al. 1993). However, interest is expanding in utilizing FF as a commercial source of alginate, isolated feed ingredient, and as a component of a natural SHW mix livestock feed.

Besides the red macroalgae IM and FF, SHW also contains variable proportions of the brown macroalgae Laminaria longicruris and Fucus vesiculosus, commonly known as kelp and rockweed, respectively. Ratios of the various component species tend to be dynamic, causing inconsistencies in the composition of SHW. Nutritional consequences of compositional variations of SHW including an increasing content of FF in a livestock supplement are unknown. In particular, the effect of SHW and its constituent seaweeds on ruminal fermentation may have importance regarding mitigation of enteric CH4 production by ruminants. The effects of treatments on products of metabolism that impact livestock productivity and the environment can be evaluated more rigorously in vitro than in cows. In vitro screening provides a rapid evaluation leading to more selective in vivo trials for evaluation of feed intake and animal productivity.

An example of beneficial seaweed application in livestock nutrition was early research on the brown macroalga Ascophyllym nodosum which demonstrated increased daily milk fat production in Scottish dairy cattle (Dunlop 1953). Recently, macroalgae have been identified as a beneficial and sustainable nutrition option to offset seasonal grazing quality in ruminant production (Machado et al. 2014a). From an environmental perspective, species of macroalgae from all the major categories (red, brown, green, and freshwater) are now being evaluated for their effects on ruminal fermentation with emphasis on the mitigation of enteric CH4 emission (Dubois et al. 2013; Machado et al. 2014b). The mitigation of enteric CH4 emission may improve availability of feed energy for the ruminant (Beauchemin et al. 2008) suggesting a possible mechanism for the increased productivity of cows fed antimethanogenic algae. In vitro studies have demonstrated strong CH4 mitigation potential from inclusion of small levels of brown and red macroalgae which differ in their bioactive components. Secondary metabolites including halogenated moieties produced by some red macroalgae are a natural antibacterial defense mechanism (Paul et al. 2006) some of which are antimethanogenic in rumen in vitro fermentations (Machado et al. 2014b). Comparatively, phlorotannins of A. nodosum induced reduction of CH4 and ammonia (NH3-N) production in rumen cultures (Wang et al. 2008). Phlorotannins are polyphenolic compounds exclusive to the brown macroalgae (Lee and Jeon 2013) but the red macroalgae also contain various polyphenolics (Cox et al. 2010). The effect of isolated polyphenolics of red algae on CH4 production in rumen cultures has not been described. However, CH4 reduction may simultaneously affect overall rumen fermentation efficiency, thus careful examination of the nature of this effect is required for all potential algae products as feed additives.

The aim of this study was to evaluate the effects of feeding North Atlantic SHW and its constituents FF and IM on in vitro rumen continuous culture fermentation (CCF) and CH4 emission. Specific parameters of evaluation were daily CH4 production, effluent ammonia-nitrogen and volatile fatty acids concentration, apparent fractional in vitro digestibility of feed organic matter, and fermentation pH.

Materials and methods

Rumen fluid inoculants

The source of pooled rumen inoculants for the CCF was five lactating Holstein cows (Bovidae, Bos taurus) fitted with 10 cm Bar Diamond Inc. (Parma, ID) rumen cannulas. The cows were housed and cared for at the Dalhousie University Faculty of Agriculture, Ruminant Animal Center and utilized in accordance with the Canadian Council on Animal Care (CCAC 2009). The same standard diet fed to the cows was applied as the basal ration for the CCF experiments. Rumen contents were collected from four quadrants of the rumen and hand squeezed through a 2-mm screen into a 6-L pre-warmed (39 °C) thermal jug. The fluid was transported and placed into the nitrogen-purged CCF units within 15 min of collection. A 2-mm screen was used to ensure representative collection from the rumen microbial biomass associated with the particulate fraction (Craig et al. 1987). The small quantity of rumen digesta particulates added with the rumen fluid is a diminishing fraction and is consumed or passes through the CCF during achievement of steady state.

Rumen in vitro continuous culture fermentations

Five anaerobic CCF fermentors based on Versatec water jacket chambers were employed based on protocols described by Muetzel et al. (2009) and Teather and Sauer (1988). Chambers were purged continuously with HP-N2. The basal total mixed ration (TMR) was added twice daily at 12-h intervals. The diet of the donor cows and CCF (Table 1) consisted of 60 % timothy/alfalfa forage (3:1), and 40 % concentrate balanced to meet the needs of a cow producing 35 kg milk day−1 (NRC 2001) and ground (2 mm). The diet chemical composition is described in Table 2. Dry matter was determined by achievement of constant weight at 105 °C, and organic matter (OM) was measured as loss on combustion at 600 °C for 8 h (Horwitz 2000). Neutral and acid detergent fiber (NDF and ADF) were determined using an Ankom (Macedon, NY) model 200 Fiber Analyzer. Crude protein (CP) content was determined using a LECO (USA) CHN628 series nitrogen analyzer. Calcium and phosphorus were determined by acid dissolving the substrate ash and analyzing the minerals in solution using a Thermo Jarrell-Ash (USA) model ICAP 9000 spectrophotometer.

Steady state of fermentations was achieved over an adaptation period of 5 days and maintained at a feeding rate of 30 g DM day−1 of the TMR. The fluid volume in the CCF was controlled by infusion with fresh carbonate-phosphate buffer as simulated saliva of pH 6.8 (Muetzel et al. 2009; Teather and Sauer 1988) at a constant rate of 7.5 % h−1 of the 1100 mL fermentation volume using Pulse Instrumentation Ltd. (Canada) flow-rated tubing on a Technicon Instruments Corp. (USA) AutoAnalyzer Proportioning Pump III. Outflow was captured in N2 purged, and gas tight 2.5 L reservoirs in a refrigerator at 3 °C to terminate fermentation. Macroalgae supplements were introduced in augmented doses over a period of 4 days to gradually achieve full supplementation rate and held in this state during adaptation for another 3 days. The experimental SHW mix consisting of equal proportions of the macroalgae FF, IM, Laminaria, and Fucus was prepared from isolated species using the same processing as for the basal ration. To reflect the 114 g day−1 of SHW supplemented to dairy cows in PEI consuming 25 kg of dry weight, the 30 g of DM fed to the fermentations was supplemented equivalently and at doses two and fourfold to demonstrate effect at higher SHW supplementation rates. Thus, pure FF and IM were supplemented at 0.14 g DM day−1 and the SHW1, SHW2, and SHW3 mixtures were supplemented at 0.14, 0.28, and 0.56 g DM day−1, respectively. Table 2 defines the chemical composition of the FF, IM, and SHW.

Effects on fermentation parameters

To determine apparent in vitro digestibility of feed organic matter (IVD-OM), the total outflow of each fermentor was collected over the last four separate 24-h periods to minimize effects of daily variation. Dissolved components in the outflow were separated by centrifugation at 27,000 × g for 20 min in a Beckman Instruments Inc. (USA) J2-21M/E centrifuge. Outflow DM and OM components were determined (Horwitz 2000).

Production of fermentation gas was determined using UHP-N2 standardized with sulfur hexafluoride at 1.03 ppb (N2-SF6; Air Liquide Inc., USA) as a tracer gas infused at a constant rate of 15 mL min−1 into the headspace of the gas tight fermentors. Gas collections were made over the 12-h periods between feedings on the last day of each experimental period. The chamber was preconditioned for 12 h with the N2-SF6 prior to the gas collection period. Infusion rate of the N2-SF6 was controlled by Swageloc (USA) SS-4MG stainless steel metering valves calibrated with a Varian Inc. (USA) 90015–00 Digital Flow Meter. The gas sampling rate (5 mL min−1) remained consistent and well below the purge rate. The rate of gas collection was controlled by a Gilson (USA) Minipuls III peristaltic pump equipped with Pulse Instrumentation Inc. (Canada) flow-rated tubing. The sample gas stream was pumped into evacuated Tedlar bags directly from the gas draw-off pump. Gas subsamples were collected immediately from the Tedlar bags with a gas tight syringe and injected into evacuated Labco Inc. (UK) 10 mL Exetainer vials. Gas analysis was with a Varian Inc. (USA) Star 3800 gas chromatograph (GC) equipped with flame ionization (FID) and thermal conductivity detectors (TCD). Comparison of the N2-SF6 standard gas mix to the collected gas provides a difference in SF6 concentration directly attributable to dilution by produced fermentation gases.

The NH3-N concentration in fermentor outflow was determined immediately after sampling using Hach distillation method 8038 adapted from APHA method 4500-NH3 B-C (Clesceri et al. 1998), and measurement of change in absorbance after reaction with Nessler’s Reagent using a Hach Company (USA) DR2000 Colorimeter. The CCF pH was not regulated but was monitored regularly as the average of measurements taken in the digesta and fluid strata using an Extech Instruments Corp. (USA) pH meter with an Omega Engineering Corp. (Canada) PHE-1335 electrode. Final concentration of volatile fatty acids (VFA) was determined at the termination of each period when samples were collected after homogenization of the fermentation media and processed as described by García et al. (2007). Supernatant samples (50 mL) were acidified (1 mL 50 % H2SO4) and 10 mL of the stabilized sample was capped under N2 and stored at −20 °C. The VFA analysis was as described by Madrid et al.(1999) and García et al. (2007) using a Hewlett Packard (USA) 5890 series II plus GC equipped with a FID detector and a Phenomenex (USA) Zebron ZB-FFAP column (30 m × 0.25 mm × 0.25 μm).

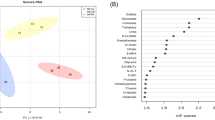

Experimental design and statistical analysis

The study was completed in four experimental periods such that a control and four of the five seaweed treatments appear in each period except in the last period where the control appears two times with three seaweed treatments. Thus, the control has n = 5 and was demonstrated in all five fermentors; however, the seaweed treatments have n = 3 from three different fermentors. Sample collection for effluent parameters of all treatments fermentations were carried out on the last 4 days of each period and gas collection on the final day. Statistical analysis was conducted using GenStat version 12.2 (VSN International 2006). Data were collected for NH3-N, pH, and IVD-OM as repeated measurements over 4 days. The measurements were summarized as the 4 days mean. Measures of CH4 and VFA were based on single measurement replicates at the end of each period. Means differences were assessed with a mixed model analyses of restricted maximum likelihood (REML) due to the random effects of treatment replications not being tested in all fermentors and periods. The fixed effects were macroalgae species and supplementation rate. Significance probabilities for statistical differences among treatments were assessed by approximate least significant difference (LSD; 5 %) with application of two times mean standard error of difference (2 × SED). Significant trends among controls and treatments were assessed using linear and quadratic contrasts. The model fitted was:

where μ = mean effect and ε = residual error; Y = observation (dependent variable) having the factors of (i) α = effect of macroalgae supplement with i th replicates (1,2,3); (ii) β = effect of the j th rate of SHW supplementation; (iii) δ = fermentation in k th fermentor units (1…5); and (m) denotes that the treatment is nested within the replicate-fermentor combination, so the treatment effect is estimated after any effects of replicate-fermentor are accounted for. Demonstrated response differences were considered significant when P ≤ 0.05.

Results

pH, ammonia, and VFA

There was no significant change induced by the seaweed treatments in pH measured in the fermentation effluent with an average pH of 6.29 as compared to the control at pH 6.23. However, the average NH3-N concentration of 29.6 mg dL−1 was a significant decrease of 9 % induced by the seaweed treatments compared to the control at 32.5 mg dL−1 (Table 3). The independent treatments all induced significant NH3-N reductions with the largest reduction of 12 % by SHW2. Although seaweeds reduced NH3-N in CCF, there were no differences between seaweed types or inclusion rates when the SHW inclusion rate was increased (two and fourfold; Table 4). The total VFA and the acetate species having concentration averages of 54.2 and 38.8 mM, respectively, were not different than the control with total VFA and acetate concentrations of 56.2 and 39.7 mM, respectively. Statistical contrasts indicate that compared to the control, a decrease in propionate of 3 % induced by the SHW treatments collectively was significant (Table 4) due to decrease of 5 and 4 % induced by SHW1 and SHW3, respectively. The FF, IM, and SHW2 treatments were not different than the control for propionate. Compared to control, reductions in butyrate concentration measured in CCF effluent were induced by FF, IM, and SHW1 at 13, 14, and 25 %, respectively, and collectively the treatments reduced butyrate concentration by 15 % which is reflected in the statistical contrasts.

In vitro organic matter digestibility and methane

There was little difference between the control and treatments for the proportion of feed OM added that was measured exiting the fermentation via outflow which is a function of total fermentative digestion (Tables 3 and 4). There was an average of 46 g (100 g)−1 of feed IVD-OM occurring in the fermentations. Tables 3 and 4 show that the seaweed treatment inclusions invoked a response of generalized reductions in daily production of CH4 for all the treatments compared to control, although there was little difference among seaweed treatments. Daily production of CH4 from the treatments amounted to an average of 0.44 g day−1 compared to the control producing 0.49 g day−1. The quantitative effect of CCF seaweed inclusion was significant reductions in production of CH4 demonstrating maximum abatement of 16 % invoked by SHW2, and no difference was observed between FF and IM.

Discussion

A SHW product with variable component consistency is available as a stormtoss that otherwise would be left to decompose, and we demonstrated that SHW and specifically FF and IM did not impart any detrimental effects on extended rumen fermentation in vitro at the supplementation levels used in this study. There was no visual difference in stability for treatments compared to the control with visual stability defined as maintenance of stratification between the buoyant and fluid suspension.

Fermentation pH

The pH was consistently about 6.3 for all treatments due in part to continuous infusion of a weak artificial saliva buffer of pH 6.8. Saliva assists in counteracting the pH lowering effect of acid production in the rumen and was similarly stabilized by the buffer during CCF. Maintenance of rumen pH and prevention of rumen acidosis is important for efficient productivity, rumen function, and animal health (Owens et al. 1998). Duffield et al. (2004) measured ruminal pH from multiple sampling points and methods of measure, and their average ruminal pH of 6.3 in lactating Holstein cows fed with TMR was in agreement with our in vitro pH. In Table 4, the contrasts demonstrate that no significant pH differences were observed even with up to fourfold increase in SHW inclusion.

Ammonia-nitrogen

All the seaweeds demonstrated the effect of NH3-N reduction in CCF. Reduction of NH3-N suggests decreased deamination of dietary amino acids as reported by Wang et al. (2008) when A. nodosum phlorotannins reduced NH3-N during in vitro ruminal cultures. We may expect further reduction in NH3-N with increased inclusion of phlorotannins; however, increasing the rate of SHW did not further reduce NH3-N production. It would be valuable to elucidate the beneficial presence of phlorotannins, other polyphenolics, and consequences of dosage. Also, reduced ruminal amino acid deamination improves utilization of dietary protein and reduced excretion of excess N as urea to the environment (Mueller-Harvey 2006).

Volatile fatty acids

Maintenance of normal fermentation during seaweed inclusion in CCF was demonstrated with no significant change of total VFA accumulation compared to the control. However, the SHW1 treatment tended to moderately reduce propionate and butyrate. Contrasts confirm a decrease in these VFA between the control and seaweed groups but acetate levels were not significantly affected (Table 4). The decrease was not enough to significantly influence total VFA or the acetate to propionate ratio. All VFA are energy sources for maintenance, growth, and lipogenesis, and of importance in this study is the observed reduction in propionate which is a primary glucogenic precursor and butyrate which is a lipogenic precursor of longer chain fatty acids (Bergman 1990). Acetate, the primary precursor of short and medium chain fatty acids, remained relatively unchanged due to seaweed inclusion. Fluctuations in rumen propionate are normal and concentrations at high levels are not considered critical; however, 50–75 % of a ruminant’s glucose is derived from propionate (Bergman 1990), and increase in propionate increases the efficiency of acetate utilization, thus significant reduction is undesirable. Increased utilization of lactate, amino acids, and glycerol may offset some reduction in propionate glucogenesis. Only the SHW1 and SHW3 treatments reduced propionate, and FF, IM, and SHW1 reduced butyrate compared to the control. There was little difference between seaweed treatments for propionate or butyrate, and the reductions relative to control need confirmation while any consequences to production need quantification in vivo.

In vitro digestibility

The IVD-OM was not significantly affected by the SHW treatments, indicating a lack of effect on in vitro ruminal degradation of feed substrate with a fourfold increase in SHW inclusion (Tables 3 and 4). The FF and IM generated a response similar to that of SHW, indicating that the isolated constituents do not impart a different effect on IVD-OM compared to the SHW mix. This provides further evidence that these pure seaweed species were not toxic to the rumen ecosystem at the studied doses. Our IVD-OM average of 46 g (100 g)−1 was similar to the Holstein apparent rumen digestibility of 44 g (100 g)−1 reported by Berzaghi et al. (1996) for cows grazing pasture and supplemented with corn. A correlation between feed digestibility and enteric gas production has long been confirmed by others (Menke et al. 1979; r 2 = 0.67–0.96), and values have been used to predict feed utilization (Chenost et al. 2001; r 2 = 0.54–0.66). However, other recent macroalgae studies have demonstrated reduction of CH4 without significant depression in digestibility (Machado et al. 2014b).

Methane

Methane emissions from the CCF’s were lower with inclusion of the seaweed treatments (Tables 3 and 4) as determined cumulatively over the entire period between feeding events. The interaction between substrate protein content and in vitro ruminal gas production was described by Cone and van Gelder (1999) who reported that protein contributed to total fermentation gases and was responsible for approximately 32 % of gas compared to carbohydrates. Thus, the observed reduction in amino acid degradation may have contributed to a lower observed CH4 production from the seaweed-treated CCF’s.

Beauchemin et al. (2008) report that for dairy cows about 10 % of total feed energy can be lost when converted to CH4 and emitted into the environment. Therefore, mitigation of ruminal CH4 emissions is favorable in several ways including improved utilization of feed expenses, reduced contribution to green house gas inventories, and is helpful to the dairy industry image in the marketplace. With the nonsignificant reduction in IVD-OM, the reasoning for reduced methane emissions with seaweeds inclusion remains unclear; however, recent studies suggest red and brown macroalgae have bioactive components with antimethanogenic properties (Wang et al. 2008; Dubois et al. 2013; Machado et al. 2014b). Further investigation into microbial population changes and daily gas dynamics is required, as well as demonstration of these effects in vivo.

Conclusions

The CCF functionality was not negatively affected by FF, IM, or SHW. The fermentation stability was maintained, and there was no indication of impaired passage of digesta through the CCF. Inclusion of SHW and isolated seaweeds were found to reduce NH3-N, emissions of CH4, and in some cases propionate and butyrate. Reduction in CH4 was not associated with lower IVD-OM, and in vivo trials are needed to confirm this observation extrapolates to animals. Seaweeds are suitable for applications in organic agriculture, and the lack of impairment to in vitro fermentation by these seaweeds at the studied doses suggests that there is utility for SHW and its components as supplements for ruminants. Our observations corroborate years of anecdotal evidence that no negative impact results from feeding of North Atlantic SHW to dairy cows.

References

Beauchemin KA, McGinn SM, Grainger C (2008) Reducing methane emissions from dairy cows. WCDS Adv Dairy Technol 20:79–93

Bergman EN (1990) Energy contributions of volatile fatty acids from the gastrointestinal tract in various species. Physiol Rev 70:567–590

Berzaghi P, Herbein JH, Polan CE (1996) Intake, site, and extent of nutrient digestion of lactating cows grazing pasture. J Dairy Sci 79:1581–1589

Bird CJ, Greenwell M, McLachlan J (1983) Benthic marine algal flora of the north shore of Prince Edward Island (Gulf of St. Lawrence), Canada. Aquat Bot 16:315–335

Blunt JW, Copp BR, Keyzers RA, Munro MH, Prinsep MR (2013) Marine natural products. Nat Prod Rep 30:237–323

CCAC (Canadian Council on animal Care) (2009) CCAC guidelines on: the care and use of farm animals in research, teaching, and testing. CCAC, Ottawa, http://www.ccac.ca/Documents/Standards/Guidelines/Farm_Animals.pdf

Chenost M, Aufrére J, Macheboeuf D (2001) The gas-test technique as a tool for predicting the energetic value of forage plants. Anim Res 50:349–364

Clesceri LS, Greenberg AE, Eaton AD (eds) (1998) Standard methods for the examination of water and waste water. 20th edn. Amercian Public Health Association (APHA). Washington, DC

Cone JW, van Gelder AH (1999) Influence of protein fermentation on gas production profiles. Anim Feed Sci Technol 76:251–264

Cox S, Abu-Ghannam N, Gupta S (2010) An assessment of the antioxidant and antimicrobial activity of six species of edible Irish seaweeds. Int Food Res J 17:205–220

Craig MW, Broderick GA, Ricker DB (1987) Quantitation of microorganisms associated with the particulate phase of ruminal ingesta. J Nutr 117:56–62

Craigie JS (2011) Seaweed extract stimuli in plant science and agriculture. J Appl Phycol 23:371–393

Doty MS, Caddy JF, Santelices B (eds) (1987) Case study of seven commercial seaweed resources. Chondrus crispus Stackhouse. Section 5.0. FAO Fish. Tech Pap T281, pp 311

Dubois B, Tomkins NW, Kinley RD, Bai M, Seymour S, Paul NA, de Nys R (2013) Effect of tropical algae as additives on rumen in vitro gas production and fermentation characteristics. Am J Plant Sci 4:34–43

Duffield T, Plaizier JC, Fairfield A, Bagg R, Vessie G, Dick P, Wilson J, Aramini J, McBride B (2004) Comparison of techniques for measurement of rumen pH in lactating dairy cows. J Dairy Sci 87:59–66

Dunlop G (1953) Feeding of seaweed meal to lactating cows. Nature 171:439–440

Evans FD, Critchley AT (2014) Seaweeds for animal production use. J Appl Phycol 26:891–899

García V, Catalá-Gregori P, Madrid J, Hernández F, Megías MD, Andrade-Montemayor HM (2007) Potential of carvacrol to modify in vitro rumen fermentation as compared with monensin. Animal 1:675–680

Holdt SL, Kraan S (2011) Bioactive compounds in seaweed: functional food applications and legislation. J Appl Phycol 23:543–597

Horwitz W (ed) (2000) Official methods of AOAC international. 17th edn. Association of Official Analytical Chemists (AOAC) International. Gaithersburg

Lee SH, Jeon YJ (2013) Anti-diabetic effects of brown algae derived phlorotannins, marine polyphenols through diverse mechanisms. Fitoterapia 86:129–136

Machado L, Kinley RD, Magnusson M, de Nys R, Tomkins NW (2014a) The potential of macroalgae for beef production systems in Northern Australia. J Appl Phycol. doi:10.1007/s10811-014-0439-7

Machado L, Magnusson M, Paul NA, de Nys R, Tomkins N (2014b) Effects of marine and freshwater macroalgae on in vitro total gas and methane production. PLoS One 9(1):e85289

Madrid J, Megías MD, Hernández F (1999) Determination of short chain volatile fatty acids in silages from artichoke and orange by-products by capillary gas chromatography. J Sci Food Agric 79:580–584

Mathieson AC, Pederson JR, Neefus CD, Dawes CJ, Bray TL (2008) Multiple assessments of introduced seaweeds in the Northwest Atlantic. ICES J Mar Sci 65:730–741

Menke KH, Raab L, Salewski A, Steingass H, Fritz D, Schneider W (1979) The estimation of the digestibility and metabolizable energy content of ruminant feeding stuffs from the gas production when they are incubated with rumen liquor in vitro. J Agric Sci 93:217–222

Mueller-Harvey I (2006) Unraveling the conundrum of tannins in animal nutrition and health. J Sci Food Agric 86:2010–2037

Muetzel S, Lawrence P, Hoffmann EM, Becker K (2009) Evaluation of a stratified continuous rumen incubation system. Anim Feed Sci Technol 151:32–43

NRC (National Research Council) (2001) Nutrient requirements of dairy cattle, 7th edn. National Academy of Sciences, Washington, DC

Owens FN, Secrist DS, Hill WJ, Gill DR (1998) Acidosis in cattle: a review. J Anim Sci 76:275–286

Paul NA, de Nys R, Steinberg PD (2006) Chemical defence against bacteria in the red alga Asparagopsis armata: linking structure with function. Mar Ecol Prog Ser 306:87–101

Sharp GJ, Têtu C, Semple R, Jones D (1993) Recent changes in the seaweed community of Western Prince Edward Island: implications for the seaweed industry. Hydrobiologia 260(261):291–296

Teather RM, Sauer FD (1988) A naturally compartmented rumen simulation system for the continuous culture of rumen bacteria and protozoa. J Dairy Sci 71:666–673

VSN International (2006) GenStat Release 12.1 statistical software. VSN International Limited, Hemel Hempstead

Wang Y, Xu Z, Bach SJ, McAllister TA (2008) Effects of phlorotannins from Ascophyllum nodosum (brown seaweed) on in vitro ruminal digestion of mixed forage or barley grain. Anim Feed Sci Technol 145:375–395

Acknowledgments

This study was completed at the Dalhousie University Agricultural Campus (Dal-AC) in Truro, Nova Scotia, Canada. The authors thank Elizabeth Gnemmi and the Dal-AC Ruminant Animal Center, Joe Dorgan (North Atlantic Organics), and Mark Grimmitt (Agriculture Canada) for their input into this study. This study was made possible by grants from the Prince Edward Island Adapt Council and North Atlantic Organics, PEI, Canada.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kinley, R.D., Fredeen, A.H. In vitro evaluation of feeding North Atlantic stormtoss seaweeds on ruminal digestion. J Appl Phycol 27, 2387–2393 (2015). https://doi.org/10.1007/s10811-014-0487-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-014-0487-z