Abstract

There is worldwide interest in developing algal biofuel. One main reason for the lack of success so far in producing a sustainable transport fuel from microalgae is the high cost of biomass processing, especially dewatering and oil extraction. There is also a significant cost involved in the energy content of the nutrient fertilisers required for biomass production. Non-destructive oil extraction or “milking” from algae biomass has the potential to bypass all of these hurdles. Using a “milking” strategy means that there would be no need for (a) biomass dewatering, (b) breaking cells for oil extraction and (c) addition of nutrients to the culture, resulting in a significant reduction in energy and fertiliser cost involved in production of biofuel from algae. We make use of the natural tendency of Botryococcus to produce external hydrocarbon in the extracellular matrix. In current study, we showed that external hydrocarbon from Botryococcus braunii BOT-22 can be non-destructively extracted using n-heptane (optimum contact time with n-heptane = 20 min). We were able to recover almost the entire de novo-produced external hydrocarbons at 5- and 11-day intervals when the culture was maintained with or without 1 % CO2 addition, respectively. This repeated non-destructive extraction of external hydrocarbon of B. braunii was possible for up to 70 days when 1 % CO2 was supplied to the culture. When CO2 was limited, a 70 % lower external hydrocarbon productivity was achieved using the same process. Although the productivity of external hydrocarbon of 9.33 mg L−1 day−1 of the “milked” culture is low in these un-optimised cultures, it was 1.3 ± 0.2-fold higher compared with that of a conventional semicontinuous culture, showing the potential of this method.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With the rapid decline in the reserves of crude fossil fuels and the need to reduce CO2 emissions, chemical energy from plants (i.e. biodiesel) is increasingly becoming an attractive source of energy (US DOE 2010; Borowitzka and Moheimani 2013a). Except for nuclear energy, the main source of all energies on this planet is derived directly or indirectly from the sun. In comparison with any potential source of renewable electrical energies such as solar, wind and tidal, chemical energy allows solar energy to be stored easily and, in most cases, to be used in existing engines. Currently, the main types of biofuels are bio-ethanol (mostly made from corn or sugar cane) and biodiesel (made from vegetable or animal oil). However, there are major sustainability issues with these sources of biofuels including that (a) there is a need for arable land to grow the crops, (b) there is a need for freshwater and (c) the overall lifecycle saving of energy and greenhouse gases may be less than anticipated (Li et al. 2012; Flesch et al. 2013). An alternative source of raw material for bioenergy production and CO2 bioremediation is the microalgae (Moheimani et al. 2012; Fon Sing et al. 2013).

The past decade has seen intense activity and investment in developing the production of microalgae for new commercial proposes, especially for bioenergy production. Commercial-scale microalgae production has a 60+-year history with the first algae product in the market being Chlorella tablets released in Japan in the late 1950s (Borowitzka 2013a). Since then, a number of microalgae-based industries producing high-value products such as health food, food additives and fine chemicals (e.g. β-carotene, astaxanthin, long-chain polyunsaturated fatty acids) and aquaculture feed products have been developed (Borowitzka 2013b). The perceived advantages of microalgae as a potentially attractive feedstock for bioenergy compared with terrestrial plants are their higher specific growth rate, the ability to use non-arable land and their ability to grow in hypersaline water, thus not competing with food crops for water and land (Fon Sing et al. 2013). Despite all of these advantages, to date, no large-scale production of algae for biofuel exists. One of the main reasons for this slow progress to commercialisation is the high cost of production of the algal biomass and of downstream processing (Stephens et al. 2010; de Boer et al. 2012). Triglycerides are the preferred type of lipids for conversion to biofuel such as biodiesel (Knothe 2013). Triglycerides are secondary metabolites stored intracellularly by the cells, and their content normally can be increased when algal growth is limited (Guschina and Harwood 2013). One of the challenges facing the potential algal biofuels industry is to extract this intracellular oil economically from the biomass. For example, a life-cycle analysis of biodiesel produced from Chlorella vulgaris grown in raceway ponds suggested that the extraction of the oil from the algae with solvent resulted in a significant energy penalty, especially if the biomass was dried before extraction (Lardon et al. 2009).

One potential method of improving the economics of microalgae as a source of renewable energy is to circumvent the need to extract the algal oil by “milking” or non-destructively extracting the oil from the microalgae (Frenz et al. 1989; Sim et al. 2001; Hejazi et al. 2004; Moheimani et al. 2013b). The concept is rather simple: Instead of growing the targeted algae in the presence of nutrients (i.e. nitrogen and phosphorous), followed by harvesting and dewatering the biomass and then extracting the oil from the cells, the non-destructive oil extraction process extracts the algal oils into a solvent from live algae cells without killing the cells. Furthermore, the algal cells can be maintained in a nutrient-limited state in which lipid production is enhanced (Hu et al. 2008; Griffiths et al. 2012). This would mean that, rather than growing new algae cells after extraction, the existing cells can be re-used for further oil production. This concept of harvesting the oil released while recycling rather than discarding the bio-catalytic algae cells is similar to milking, i.e. traditional algae production systems “kill the cow” (algae) to extract the “milk” rather than re-using the cow for many batches of milk. The concept of “milking” algae is not new and has been suggested previously by several investigators (Frenz et al. 1989; Sim et al. 2001; Hejazi et al. 2004). Botryococcus is an ideal organism to test this concept as this alga secretes hydrocarbons into the extracellular colony matrix (Metzger and Largeau 2005). Furthermore, these long-chain hydrocarbons are a more desirable fuel source than triglycerides. Moheimani et al. (2013b) showed the potential of milking Botryococcus braunii 807/2 using solvent or pressure (blotting). However, to date, no one has shown that the process can be repeatedly applied on the same cells. If milking is possible, the questions of for how long and at what frequency this process can be applied on the same cells are important. In this study, we aim to answer these questions.

Materials and methods

Culture maintenance

The non-axenic culture of Botryococcus braunii BOT-22 (race B) was obtained from the University of Tsukuba. B. braunii BOT-22 is deposited as Tsukuba-1 in NITE ((National Institute for Technology and Evaluation) International Patent Organism Depository, Japan) and was originally isolated by Dr. Kawachi, National Institute for Environmental Studies, Japan, from a dam in Ishigaki Island, Okinawa prefecture in Japan. The main oil product of this strain is a long-chain hydrocarbon (C34H58) called botryococcene (Ishimatsu et al. 2012). The cultures were maintained in AF6 medium (Kato 1982). The 6-L cultures were maintained in 12-L carboys aerated with a continuous stream of 1 % CO2 at 25 °C under continuous light at 70 ± 5 μmol photons m−2 s−1.

Total external hydrocarbon measurement

Cells were harvested by centrifugation (20 min at 2,246×g). The harvested B. braunii BOT-22 wet cake (10–12 % solid) was mixed with glass beads (0.5 mm diameter) and suspended by addition of n-heptane (algae/glass beads/heptane ratio of 1:0.1:0.2). The cells in heptane were mixed thoroughly for 10 to 15 min using an orbital shaker at 190 rpm providing a mixing time of 30 ± 3 s determined by measuring the time required for India ink to mix completely in the Erlenmeyer flask (Moheimani et al. 2011). Following this mixing, the growth medium was added to the mixture, resulting in rapid aqueous heptane two-phase partition. The lower aqueous phase contained the green cells, whereas the top heptane phase contained the extracted hydrocarbons. The heptane layer was removed and collected for measurement of the absorbance spectrum in a UV–visible spectrophotometer to monitor the extracted hydrocarbons and other chemicals. Prior to spectrophotometric analysis, samples were diluted so that absorbance at the peak wavelength did not exceed 0.5 absorbance units. The concentration of the extracted hydrocarbon was then measure at 190 nm against a known squalene standard prepared in n-heptane (Eroglu and Melis 2010). It is to be noted that only hydrocarbons with double bonds (C=C) can produce a UV-C absorbance signal (i.e. squalene). Not all of the hydrocarbons produced by B. braunii contain double bonds (Banerjee et al. 2002); however, the major hydrocarbon of B. braunii BOT22 is botryococcene (Ishimatsu et al. 2012) which has six double bonds and therefore can be detected easily by this method.

Growth, total lipid and photosynthesis measurements

Growth parameters (dry weight, cell counts) were determined using the methods described in Moheimani et al. (2013a). Total lipid was measured gravimetrically by the method of Folch et al. (1957). Quantitative measurements of the extracted hydrocarbon fraction were by the method of Eroglu and Melis (2010) described above. As a measure of the photosynthetic capacity of the cells, we measured the maximum photochemical efficiency F v/F m (Cosgrove and Borowitzka 2011) using an AquaPen-P AP-P (Photon Systems Instruments, Czech Republic) handheld fluorometer. Samples were dark-adapted for 20 min, and F v/F m was measured using the in-built protocols.

Solvent based non-destructive oil extractions

-

a.

Non-destructive hydrocarbon extraction: n-Heptane was used to extract external hydrocarbons non-destructively from B. braunii BOT-22. When the 6-L culture had reached stationary phase at 0.86 ± 0.07 g L−1, it was divided into six 100-mL cultures in 250-mL Erlenmeyer flasks. For external hydrocarbon extraction, 20 mL of n-heptane was added to the cultures (Moheimani et al. 2013b), mixed for 0 (control), 5, 10, 20, 40 and 60 min on an orbital shaker at a mixing rate of 30 ± 3 s−1. Using a 10-mL pipette, the solvent was then removed carefully. The extracted hydrocarbon contents in the solvent were then determined. Total oil (i.e. total lipids and hydrocarbons) and F v/F m were measured for the algal sample in the aqueous phase (see method 3).

-

b.

External hydrocarbon replacement (de novo) rate: For measuring the de novo hydrocarbon replacement rate of B. braunii BOT-22, 100 mL of n-heptane was added to 500 mL of B. braunii culture and mixed for 20 min, and external hydrocarbon and total lipids were then measured using the spectrophotometric method at time 0. The culture was then divided to six 50-mL cultures in 150-mL Erlenmeyer flasks. The external hydrocarbon and total oil of these samples were measured at days 1, 4, 8, 9, 11 and 15 independently to determine the rate of replacement (recovery) of the extracellular hydrocarbon.

-

c.

Long-term hydrocarbon productivity following non-destructive extraction: The B. braunii BOT-22 culture was divided into three 100-mL cultures in 250-mL Erlenmeyer flasks. The 20 mL of n-heptane was added to each culture and mixed for 10 and 20 min. The external hydrocarbon and total lipids were then measured using the methods described above. After non-destructive hydrocarbon extraction, the algae samples were then kept in the same growth conditions as previously described and with either continuous air or 1 % stream of CO2. The non-destructive hydrocarbon extractability of the samples was re-tested every 11th day when only aeration was applied and every fifth day for the culture with added CO2. In the repeated non-destructive solvent extraction experiments, the culture, after removal of the solvent, was incubated under the same growth conditions until the next extraction.

Conventional biomass and oil productivity

The B. braunii BOT-22 was also grown in 100 mL volume using 250-mL flasks using the conventional semicontinuous culture method (Moheimani et al. 2011), mixed and aerated with either continuous air or 1 % CO2 in air. The biomass, total oil and external hydrocarbon productivity were measured using the methods described in Moheimani et al. (2013a).

Solvent-free non-destructive hydrocarbon extraction

Blotting (physical pressure) was used to non-destructively extract external hydrocarbons from B. braunii BOT-22 using the method previously described by Moheimani et al. (2013b). B. braunii samples (50 mL) from the cultures were concentrated from 0.95 to 30–35 g of dry weight L−1 by centrifugation at pH 7 (the growth pH) or pH 11 (elevated pH using NaOH) for 30 min at 2,246×g. The algae paste was then gently filtered at 10 kPa onto a 47 mm, 3 μm pore size Whatman polycarbonate filter (Nucleopore or Cyclopore). Another filter of the same type was then placed on the algae side of the filter, and a 47 mm diameter GF/C Whatman glass-fibre filter was placed on top and bottom of the polycarbonate filter pack. This “algae pack” was then placed between two glass plates and a pressure of 0–20 kPa was applied, a process we have termed “blotting”. After a certain time (0–4 h), the filters were separated; the B. braunii cells were washed gently from the polycarbonate filters using the filtrate medium, and the blotted oil fraction in the glass fibre filter was extracted with 8 mL n-heptane in a 10-mL glass vial by vortexing for 2 min. The amount of hydrocarbon was then measured at 190 nm against squalene standard (see above). The n-heptane was then evaporated using a stream of pure N2 gas. The oil fraction in the glass vial was redissolved in 120 μL chloroform and spotted on a pre-activated TLC plate and chromatographed (Fried and Sherma 1982; Ackman 1991). Standard silica TLC plates (MERK, TLC Silica Gel 60 F254) were used with a solvent mixture of 25 % (v/v) diethylether 75 % (v/v) hexane with 0.1 % acetic acid (v/v) added to facilitate phase separation (Moheimani et al. 2013b).

In the repeated blotting experiment, the polycarbonate filter containing the algae was resuspended in fresh medium after “blotting” so that the algae could continue to grow.

Results

Solvent-based non-destructive oil extraction

The first question to be answered was whether the external hydrocarbon of B. braunii BOT-22 can be extracted non-destructively using solvents. Experiments were carried out on suspended B. braunii colonies at stationary phase. The cell density was 0.87 ± 0.07 g DW L−1 and the cells contained 29 ± 3 % total oil (% of DW) of which up to 49 ± 4 % hydrocarbon, and the F v/F m of the cells was 0.60 ± 0.05.

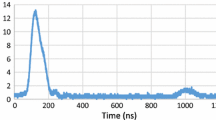

To be able to use a solvent for non-destructive hydrocarbon extraction, the solvent must not be harmful to cell metabolism. Therefore, we studied the effect of n-heptane contact time with the algal cells on both external hydrocarbon extraction and photosynthetic efficiency (F v/F m). Between 5 and 20 min n-heptane contact time reduced F v/F m by 8 ± 1 % (Fig. 1). However, after 24 h incubation of the cells placed in fresh medium following n-heptane extraction, the F v/F m recovered and showed no significant difference with the control (one-way ANOVA P > 0.05, Fig. 1). Any longer contact time with n-heptane resulted in a significant reduction in F v/F m which did not recover after 24 h incubation post-extraction (one-way ANOVA P < 0.05, Fig. 1). Visible and UV spectra of the extracts indicated no traces of any other chemicals than hydrocarbon (C34H58-botryococcene) in the n-heptane when the contact time was less than 20 min. However, at 40 and 60 min contact time with n-heptane, traces of pigments absorbing at 440–470 and 630–650 nm (most likely chlorophyll a) were observed. Therefore, the optimum contact time for non-destructive hydrocarbon extraction using n-heptane was between 5 and 20 min (Fig. 1).

Extraction of external hydrocarbons from B. braunii BOT-22 with n-heptane: Effects of time of contact with solvent on hydrocarbon extraction, and photosynthetic efficiency (F v/F m) of the algae cells. Data are: mean ± range, n = 3, for total oil in the cells and extracted oil measurements; mean ± SE, n = 5 for F v/F m (black circles and white circles are 0 min and 24 h post-extraction, respectively)

Rate of replacement of external hydrocarbon

Experiments were carried out on suspended B. braunii colonies at stationary phase with a cell density of 0.89 ± 0.06 g DW L−1, containing 30 ± 2 % of DW total oil of which 49 ± 4 % hydrocarbon, and an F v/F m of 0.59 ± 0.07.

The previous experiment indicated that n-heptane was suitable as a compatible solvent for non-destructive extraction of external hydrocarbon from B. braunii BOT-22. The second experiment was carried out to show if the B. braunii cells are capable of replacing (de novo) the extracted hydrocarbon (Fig. 2). In this experiment, we also tested the effect of CO2 addition to the culture on the external hydrocarbon replacement rate by maintaining the cultures with and without addition of a 1 % continuous CO2 stream after non-destructive hydrocarbon extraction. When no CO2 was added, B. braunii had replaced almost all of the extracted external hydrocarbon after 11 days (Fig. 2). The external hydrocarbon recovery rate gradually increased from 0.62 ± 0.25 to 2.93 ± 0.4 mg hydrocarbon recovered g−1 Botryococcus day−1 between days 1 and 11. Addition of 1 % CO2 to the culture after the initial extraction resulted in faster replacement of the external hydrocarbon (Fig. 2) with over 90 % of the B. braunii external hydrocarbon replaced by day 4 (Fig. 2). This resulted in rates of up to 4.84 ± 0.3 mg hydrocarbon recovered g−1 Botryococcus day−1 between days 1 and 5 after the initial non-destructive hydrocarbon extraction. No differences were found in the recovery of F v/F m after extraction between treatments with and without 1 % CO2 (Fig. 2). The visible and UV spectra of the extract indicated no traces of any other chemicals but only hydrocarbon in the n-heptane.

Hydrocarbon recovery rate of B. braunii BOT-22 after 20 min non-destructive extraction with n-heptane, when culture was gown with (white circles) and without (black circles) 1 % CO2. Data are: mean ± range, n = 3, for total oil in the cells and extracted hydrocarbon measurements; mean ± SE, n = 5 for F v/F m

Long-term repetitive non-destructive hydrocarbon extraction

The results so far indicated that external hydrocarbon from B. braunii BOT-22 can be extracted non-destructively. The previous experiments also showed that this alga is capable of replacing the extracted external hydrocarbon in about 5 days when not carbon limited. We then examined the possibility of repetitive long-term “milking” of this B. braunii. This is an important step towards potential future developments of a repetitive milking methodology to recover the external hydrocarbon from the algae.

Experiments were carried out on suspended B. braunii BOT-22 colonies at stationary phase with a cell density of 0.91 ± 0.05 g DW L−1, containing 30 ± 2 % of DW total oil (% of DW) of which 43 ± 6 % was hydrocarbon, and a F v/F m of 0.58 ± 0.05. To test the potential of repetitive milking, external hydrocarbon of the B. braunii was extracted using n-heptane (20 min contact time). Based on the previous experiment, the extractions were carried out every 11 days in cultures without 1 % CO2 addition and every 5 days in cultures with CO2 addition (Fig. 3a and b). Without additional CO2 supply to the culture, the external hydrocarbon was extractable for up to six times (55 days). The seventh non-destructive extraction (on day 66) resulted in a 60 ± 5 % reduction in the hydrocarbon yield and a 70 % reduction in F v/F m (Fig. 3a). Addition of 1 % CO2 to this culture on day 67 led to a gradual recovery of the F v/F m which increased by 30 % in 5 days and also a recovery of the external hydrocarbon yield of the culture (Fig. 3a).

B. braunii BOT-22 hydrocarbon yield (black circles) and F v/F m (black squares) using non-destructive hydrocarbon extraction (a and b). Cultures aerated a without CO2 and b with 1 % CO2. The cultures were grown parallel with the semi-continuous cultures of B. braunii BOT-22 with aerated c without CO2 addition (dilution rate = 30 ± 7 %), d with 1 % CO2 added (dilution rate = 58 ± 8 %) and e B. braunii culture kept as a control with no dilution with (black upright triangles) and without (white upright triangles) CO2 addition. Data are mean ± range, n = 4 for external hydrocarbon extraction, mean ± SE, n = 5 for semicontinuous growth, and mean ± SE, n = 12 for F v/F m

In the culture supplied with 1 % CO2, the external hydrocarbon was extractable repeatedly for 15 times (70 days, Fig. 3b). The 16th (day 75) and 17th (day 80) extractions showed a reduction in both external hydrocarbon yield (51 ± 4 %) and F v/F m (reduced by over 30 %) (Fig. 3b). Visible and UV spectra indicated no traces of any other chemicals than hydrocarbon in the n-heptane of the extracts.

B. braunii BOT-22 was also grown in semi-continuous culture with and without 1 % CO2 (Fig. 3c and d). Both cultures were stable for the duration of cultivation. However, a higher dilution rate could be achieved when the culture was not carbon-limited (Fig. 3c and d). The culture with CO2 showed a 4.9-fold fold increase in external hydrocarbon in the non-destructively extracted cultures and a 4.3-fold increase in the semicontinuous cultures, respectively, when compared with the culture with no external CO2 (Table 1). Addition of CO2 also resulted in a 2.5-, 3.5- and 5.1-fold increase in total biomass, lipid and hydrocarbon content, respectively (Table 1). Repeated non-destructive hydrocarbon extraction also resulted in a statistically significant 1.3 ± 0.2-fold higher external hydrocarbon productivity compared with the semicontinuous cultures (Table 1; T test, P < 0.05). The F v/F m of the post-harvest cultures stayed unchanged during semicontinuous growth in both growth conditions (Fig. 3c and d; repeated-measure one-way ANOVA P > 0.05).

No extra nitrogen and phosphorous were added to the cultures during the repeated non-destructive hydrocarbon extraction (Table 1). On the other hand, both the semicontinuous cultures required nutrient addition for growth. The required nitrogen and phosphorous additions during cultivation are summarised in Table 1. Addition of CO2 resulted in an up to 100 % increase in nutrient requirements (Table 1).

The control cultures of B. braunii maintained at stationary phase, with and without 1 % CO2 addition, showed no significant changes in biomass yield over the culture period (repeated-measure one-way ANOVA P > 0.05) (Fig. 3e). However, the culture with 1 % CO2 had a slightly higher biomass yield compared with the CO2 limited culture (Fig. 3e).

Solvent-free non-destructive hydrocarbon extraction

A series of experiments was carried out to investigate the use of pressure (blotting) to non-destructively extract the external hydrocarbon of B. braunii BOT-22 as an alternative to repeated extraction with n-heptane. These experiments were carried out on colony-forming B. braunii BOT-22 cells in stationary phase with a cell density of 0.90 ± 0.03 g DW L−1, containing 30.5 ± 1 % of DW total oil of which 47 ± 2 % was hydrocarbon. As a simple means of applying physical pressure, B. braunii colonies were placed between stacks of filter paper with a defined pressure applied (blotting) for various time intervals (Fig. 4). The external hydrocarbon was successfully extracted by blotting between 0 and 20 kPa (Fig. 4). As expected, at the beginning, an increase in the pressure resulted in increasing the maximum external hydrocarbon collected (Fig. 4). The same maximum amount of blotted oil was collected at 5 min at 20 kPa, 30 min at 10 kPa, 45 min at 5 kPa and 120 min 0 kPa (Fig. 4). The blotting experiments also showed that F v/F m was reduced by blotting under all conditions (Fig. 5). Increasing pressure and blotting time resulted in an increased reduction of F v/F m indicating that the B. braunii cells might have been damaged by the blotting process. Furthermore, the F v/F m of the blotted samples after 12 and 24 h showed no signs of recovery (Fig. 5); however, UV and visible spectra of the blotted hydrocarbon extract showed no traces of chlorophyll or other pigments even after 240 min blotting at 20 kPa. Microscopic observation indicated that any blotting, even under no pressure, resulted in disintegration of the B. braunii BOT-22 colonies (Fig. 6). Further microscopic studies on the blotted samples indicated no re-formation of colonies in the following week. All of the blotted B. braunii BOT-22 samples died 2 weeks post-blotting. Interestingly, preliminary microscopic studies showed no colony disintegration for colonies kept between a slide and cover slip for up to 2 h (data not shown).

Discussion

In current study, we clearly demonstrated that n-heptane is a compatible solvent for non-destructive hydrocarbon extraction from B. braunii BOT-22. n-Heptane has been previously used for other strains of B. braunii (Sim et al. 2001; Moheimani et al. 2013b). Obviously, it would be more economical if n-hexane could be used instead of n-heptane as the bulk price of n-hexane (AU$ 2.20 L−1) is significantly lower than n-heptane (AU$ 2.78 L−1) (based on the quote received from Redox Pty Ltd, Australia, in May 2013). However, our preliminary results indicated that n-hexane was not a suitable solvent for non-destructive oil extraction of B. braunii BOT-22 (data not shown). Moheimani et al. (2013b) also found that n-hexane was not a compatible solvent for non-destructive oil extraction of B. braunii CCAP/2. Frenz et al. (1989) showed that botryocococcene recovery yields from B. braunii depend on the physiological state of the algae and the total hydrocarbon content of the biomass. They attempted non-destructive oil extraction with hexane showing yields ranging from 7.4 to 14 % and up to 38 % of the total hydrocarbons. However, evidence of cell survival was not provided. Kleinegris et al. (2011) also showed that toxic long-carbon-chain solvents such as hexane can disrupt the plasma membrane of Dunaliella salina and rupture the cells, causing lipids or other compounds such as carotenoids to leak into the medium.

Moheimani et al. (2013b) demonstrated that pressure (blotting) could be used for non-destructive oil extraction from B. braunii CCAP 807/2 (race A). However, several attempts using the same procedure on B. braunii BOT-22 (race B) were unsuccessful. The external hydrocarbon of B. braunii could be collected using blotting, but any small amount of pressure or filtration resulted in a breaking-up of the colonies. The blotting also markedly reduced the F v/F m of B. braunii BOT-22, and the broken-up colonies did not recover from the stress caused by the blotting. The fact that these two strains behave differently is not surprising as there is a wide range of differences between strain and the races of Botryococcus. For instance, Berkaloff et al. (1984) found that, although the general internal structure of several laboratory-grown and field-collected Botryococcus strains was rather constant, the organisation of the outer walls forming the hydrocarbon-rich matrix of the colonies differed greatly from one sample to another. They found that, in the majority of cultivated strains, the colonies were rather small, and the different successive external walls remained distinct with all strains containing dienic or trienic hydrocarbons. On the other hand, most of the collected samples possessed large colonies with a rather compact matrix formed by the hydrocarbon-rich part of the successive closely appressed external wall layers (Berkaloff et al. 1984).

The main reason for the negative effect of colony disintegration due to blotting on the survival of B. braunii BOT-22 remains to be determined. The absence of any pigmentation or membrane lipids in the blotted hydrocarbon is indicative of minimum cell damage. However, there may have been some undetected cell damage due to filtration or pressure that resulted in the death of the cultures. Therefore, our results clearly indicated that while solvent-based (n-heptane) non-destructive hydrocarbon extraction is possible, blotting is not an appropriate process for non-destructive hydrocarbon extraction from B. braunii BOT-22.

When the target is long-term non-destructive hydrocarbon extraction from a particular Botryococcus strain, one needs to identify if the cells are capable to replace (de novo) the extracted external hydrocarbon and, if they do so, what is the rate (per day) of external hydrocarbon recovery post the original non-destructive extraction. Here, we demonstrated that B. braunii BOT-22 can replace its external hydrocarbon after 11 days in cultures without 1 % CO2 addition. Moheimani et al. (2013b) showed that B. braunii CCAP 807/2 can replace 33 % of the external hydrocarbon after 11 days when cells were non-destructively extracted with n-heptane for 20 min. Addition of 1 % CO2 to the culture of B. braunii BOT-22 reduced the time for replacement of the extracted hydrocarbon to 5 days. This was not surprising considering that the main component of hydrocarbon is carbon. The reduction of C-limitation in algal cultures by the addition of CO2 or bicarbonate has been shown to increase growth and lipid production in many algae, including B. braunii (e.g. Ranga Rao et al. 2007; Moheimani 2013; White et al. 2013).

The idea of milking algae cells repeatedly by non-destructive solvent extraction is not new, and Botryococcus is not the only alga for which non-destructive oil extraction has been attempted. A number of algae species (i.e. Dunaliella and Nannochloropsis) and also the halophilic bacterium Halomonas elongata have been tested for the potential of non-destructive extraction of high-value products or biofuel (Sauer and Galinski 1998; Sim et al. 2001; An et al. 2004; Hejazi et al. 2004; Eroglu and Melis 2010). However, if the targeted chemical for the process is not excreted by the cells, the current process of non-destructive extraction is most likely not applicable. For instance, Hejazi et al. (2004) reported milking yields of 0.06 mg L−1 day−1 for β-carotene from D. salina. However, Kleinegris et al. (2011) showed that direct contact between the D. salina cells and an organic solvent such as dodecane in a two-phase system used by Hejazi et al. (2004) resulted in cell death and that the β-carotene recovery by this method can destroy the cells.

As mentioned above, there have been previous studies on non-destructive oil extraction from B. braunii. However, none of these tested long-term repetitive extraction, and development of any sustainable non-destructive oil extraction (milking) from B. braunii requires the ability to extract the oil/hydrocarbon over a long period both repetitively and reliably. In this study, we clearly showed that external hydrocarbon from B. braunii BOT-22 can be extracted non-destructively repeatedly for up to 70 days using n-heptane when the culture is not carbon-limited. The external hydrocarbon from carbon-limited B. braunii BOT-22 could only be repeatedly extracted for 50 days, and the productivity was less. The overall external hydrocarbon productivity using non-destructive extraction was at least 20 % higher compared with B. braunii grown in conventional semi-continuous culture. It should be noted that, when B. braunii BOT-22 was grown semicontinuously, the total lipid was over 52 % higher than the external hydrocarbon extracted by milking. However, no nutrient addition is required during repeated hydrocarbon extraction by milking whereas, in order to maintain the semicontinuous culture, regular nutrient addition to the culture is required. Based on the nutrient uptake rate (calculated using the Redfield ratio), the production of 1 t of Botryococcus biomass (including 170 kg of hydrocarbon) in semicontinuous growth requires at least 69 kg of “N” (= 418 kg of NaNO3) and 10 kg of “P” (= 43 kg of KH2PO4). This is in a scenario where the medium is recycled after harvesting and no nutrients go to waste. On the other hand, to produce the same amount of hydrocarbon by repeated milking, there would be no need for nutrient addition. Furthermore, in the milking process used in this study, there is no need to dewater the biomass for milking. As mentioned earlier, dewatering is the most energy-expensive step of the conventional algae to biofuel production methodology. Thus, milking provides a saving of both nutrients and energy.

Our results indicate that even in a best-case scenario (non-carbon-limited culture), the process of non-destructive external hydrocarbon extraction (milking) is only possible for a certain period of time. This is acceptable as even cows cannot be milked forever. However, we clearly showed that B. braunii BOT-22 is a suitable strain for repetitive non-destructive hydrocarbon extraction. Although the reason why the cells can be repeatedly milked for only a limited time is not known, it should be possible to extend this time. It is possible that the cells eventually do become critically nutrient limited and require addition of a limited amount of specific nutrients to stabilise the culture, and this is the topic of ongoing work. The other challenge is to design a continuous milking bioreactor.

In conclusion, as yet, there exists no suitable system for long-term non-destructive hydrocarbon extraction from Botryococcus. However, our results on testing various methods of non-destructive hydrocarbon extraction show that, in principle, such a process is possible. Despite the often-quoted very high oil and hydrocarbon content of B. braunii, we have shown that the total oil content of B. braunii is the same as other green algae (between 25 % and 35 % of dry weight) after the external hydrocarbon is extracted. Unfortunately, Botryococcus is a relatively slow-growing alga and, as it is a fresh water alga, it is not a serious candidate for biofuels production (Borowitzka and Moheimani 2013a, b). However, the unique feature of this alga, the release of hydrocarbon into the extracellular colony matrix, makes it a suitable species for developing and testing milking methods. Although the mechanism of hydrocarbon excretion is not known, it may be possible to enhance hydrocarbon formation and excretion from the cells either through improved culture conditions, targeted strain selection or by genetic manipulation. Other species also may be amenable to manipulation to enhanced production of extracellular fatty acids and lipids. Several microalgae have been reported to secrete fatty acids (e.g. Sushchik et al. 2001) and zooxanthellae (dinoflagellates) may also secrete lipids (Crossland et al. 1980; Patton and Burris 1983). Alternatively, it may be possible to genetically engineer another algae species (see, for example, Roessler et al. 2009), preferably one which can be grown in saline media, to secrete lipids and/or hydrocarbons which can then be milked by the non-destructive methods we have developed.

References

Ackman RG (1991) Application of thin-layer chromatography separation: neutral lipids. In: Perkins EG (ed) Analyses of fats, oils and lipoproteins. American Oil Chemists Society, Champaign, pp 60–82

An J-Y, Sim S-J, Kim B-W, Lee JS (2004) Improvement of hydrocarbon recovery by two-stage cell-recycle extraction in the cultivation of Botryococcus braunii. J Microbiol Biotechnol 14:932–937

Banerjee A, Sharma R, Chisti Y, Banerjee U (2002) Botryococcus braunii: a renewable source of hydrocarbons and other chemicals. Crit Rev Biotech 22:245–279

Berkaloff C, Rousseau B, Couté A, Casadevall E, Metzger P, Chirac C (1984) Variability of cell wall structure and hydrocarbon type in different strains of Botryococcus braunii. J Phycol 20:377–389

Borowitzka MA (2013a) Energy from microalgae: a short history. In: Borowitzka MA, Moheimani NR (eds) Algae for Biofuels and Energy. Springer, Dordrecht, pp 1–15

Borowitzka MA (2013b) High-value products from microalgae—their development and commercialisation. J Appl Phycol 25:743–756

Borowitzka MA, Moheimani NR (eds) (2013a) Algae for biofuels and energy. Springer, Dordrecht, 288 pp

Borowitzka MA, Moheimani NR (2013b) Sustainable biofuels from algae. Mitig Adapt Strat Glob Chang 18:13–25

Cosgrove J, Borowitzka MA (2011) Chlorophyll fluorescence terminology: an introduction. In: Suggett DJ, Prásil OJ, Borowitzka MA (eds) Chlorophyll a fluorescence in aquatic sciences: methods and applications. Springer, Dordrecht, pp 1–17

Crossland CJ, Barnes DJ, Borowitzka MA (1980) Diurnal lipid and mucus production in the staghorn coral Acropora acuminata. Mar Biol 60:81–89

de Boer K, Moheimani NR, Borowitzka MA, Bahri PA (2012) Extraction and conversion pathways for microalgae to biodiesel: a review focused on energy consumption. J Appl Phycol 24:1681–1698

Eroglu E, Melis A (2010) Extracellular terpenoid hydrocarbon extraction and quantitation from the green microalgae Botryococcus braunii var. Showa. Biores Technol 101:2359–2366

Flesch A, Beer T, Campbell PK, Batten D, Grant T (2013) Greenhouse gas balance and algae-based biodiesel. In: Borowitzka MA, Moheimani NR (eds) Algae for biofuels and energy. Springer, Dordrecht, pp 233–254

Folch J, Lees M, Sloane-Stanley GH (1957) A simple method for the isolation and purification of total lipids from animal tissues. J Biol Chem 226:497–509

Fon Sing S, Isdepsky A, Borowitzka MA, Moheimani NR (2013) Production of biofuels from microalgae. Mitig Adapt Strat Global Chang 18:47–72

Frenz J, Largeau C, Casadevall E (1989) Hydrocarbon recovery by extraction with a biocompatible solvent from free and immobilized cultures of Botryococcus braunii. Enzym Microb Technol 11:717–724

Fried B, Sherma J (1982) Thin-layer chromatography: techniques and applications. Marcel Dekker, New York, pp 105–122

Griffiths MJ, Hille RP, Harrison STL (2012) Lipid productivity, settling potential and fatty acid profile of 11 microalgal species grown under nitrogen replete and limited conditions. J Appl Phycol 24:989–1001

Guschina I, Harwood J (2013) Algal lipids and their metabolism. In: Borowitzka MA, Moheimani NR (eds) Algae for biofuels and energy. Springer, Dordrecht, pp 17–36

Hejazi MA, Holwerda E, Wijffels RH (2004) Milking microalga Dunaliella salina for β-carotene production in two-phase bioreactors. Biotechnol Bioeng 85:475–481

Hu Q, Sommerfeld M, Jarvis E, Ghirardi M, Posewitz M, Seibert M, Darzins A (2008) Microalgal triacylglycerols as feedstocks for biofuel production: perspectives and advances. Plant J 54:621–639

Ishimatsu A, Matsuura H, Sano T, Kaya K, Watanabe MM (2012) Biosynthesis of isoprene units in the C34 botryococcene molecule produced by Botryococcus braunii strain Bot-22. Proc Environ Sci 15:56–65

Kato S (1982) Laboratory culture and morphology of Colacium vesiculosum Ehrb. (Euglenophyceae). Jpn J Phycol 30:63–67

Kleinegris DMM, van Es MA, Janssen M, Brandenburg WA, Wijffels RH (2011) Phase toxicity of dodecane on the microalga Dunaliella salina. J Appl Phycol 23:949–958

Knothe G (2013) Production and properties of biodiesel from algal oils. In: Borowitzka MA, Moheimani NR (eds) Algae for biofuels and energy. Springer, Dordrecht, pp 207–221

Lardon L, Hélias A, Sialve B, Steyer J-P, Bernard O (2009) Life-cycle assessment of biodiesel production from microalgae. Environ Sci Technol 43:6475–6481

Li Y, Moheimani NR, Schenk PM (2012) Current research and perspectives of microalgal biofuels in Australia. Biofuels 3:427–439

Metzger P, Largeau C (2005) Botryococcus braunii: a rich source for hydrocarbons and related ether lipids. Appl Microbiol Biotechnol 66:486–496

Moheimani NR (2013) Inorganic carbon and pH effect on growth and lipid productivity of Tetraselmis suecica and Chlorella sp (Chlorophyta) grown outdoors in bag photobioreactors. J Appl Phycol: 25:387–398

Moheimani NR, Isdepsky A, Lisec J, Raes E, Borowitzka MA (2011) Coccolithophorid algae culture in closed photobioreactors. Biotechnol Bioeng 9:2078–2087

Moheimani NR, Webb JP, Borowitzka MA (2012) Bioremediation and other potential applications of coccolithophorid algae, a review. Algal Res 1:120–133

Moheimani NR, Borowitzka MA, Isdepsky A, Fon Sing S (2013a) Standard methods for measuring growth of algae and their composition. In: Borowitzka MA, Moheimani NR (eds) Algae for biofuels and energy. Springer, Dordrecht, pp 265–284

Moheimani N, Cord-Ruwisch R, Raes E, Borowitzka MA (2013b) Non-destructive oil extraction from Botryococcus braunii (Chlorophyta). J Appl Phycol. doi:10.1007/s10811-013-0012-9

Patton JS, Burris JE (1983) Lipid synthesis and extrusion by freshly isolated zooxanthellae (symbiotic algae). Mar Biol 75:131–136

Ranga Rao A, Sarada R, Ravishankar GA (2007) The influence of CO2 on growth and hydrocarbon production in Botryococcus braunii. J Microbiol Biotechnol 17:414–419

Redfield AC (1958) The biological control of chemical factors in the environment. Am Sci 46:230A–221

Roessler PG, Chen L, Liu B, Dodge CN (2009) Secretion of fatty acids by photosynthetic organisms. USA Patent Application 0298143A1

Sauer T, Galinski EA (1998) Bacterial milking: a novel bioprocess for production of compatible solutes. Biotechnol Bioeng 57:306–313

Sim S-J, An J-Y, Kim B-W (2001) Two-phase extraction culture of Botryococcus braunii producing long-chain unsaturated hydrocarbons. Biotechnol Lett 23:201–205

Stephens E, Ross IL, King Z, Mussgnug JH, Kruse O, Posten C, Borowitzka MA, Hankamer B (2010) An economic and technical evaluation of microalgal biofuels. Nat Biotechnol 28:126–128

Stumm W, Morgan JJ (1996) Aquatic chemistry: chemical equilibria and rates in natural waters. John Wiley and Sons, New York

Sushchik NN, Kalacheva GS, Gladyshev MI (2001) Secretion of free fatty acids by prokaryotic and eukaryotic algae at optimal, supraoptimal, and suboptimal growth temperatures. Microbiology 70:542–547

US DOE (2010) National Algal Biofuels Technology Roadmap. U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy, Biomass program. Washington DC, pp 1–124.

White DA, Pagarette A, Rooks P, Ali ST (2013) The effect of sodium bicarbonate supplementation on growth and biochemical composition of marine microalgae cultures. J Appl Phycol 25:153–165

Acknowledgments

This work was partly funded by the JSPS invitation fellowship program for research in Japan (long-term) to Navid R. Moheimani. The authors would like to thank Mr. Atsushi Nakazawa for his excellent technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moheimani, N.R., Matsuura, H., Watanabe, M.M. et al. Non-destructive hydrocarbon extraction from Botryococcus braunii BOT-22 (race B). J Appl Phycol 26, 1453–1463 (2014). https://doi.org/10.1007/s10811-013-0179-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-013-0179-0