Abstract

For wood, water diffusivity is an important factor that influences its mechanical and physical properties. In this experimental study, the water absorption and desorption were investigated in linear directions for woods of two Eucalyptus clones; Eucalyptus grandis and Eucalyptus camaldulensis. The diffusion model based on Fick’s second law was applied to assess both water absorption and desorption processes on cubic wood samples of (20 × 20 × 20) mm3. The diffusion coefficient, absorption coefficient, surface emission and diffusivity resistance were estimated. The study of sorption kinetics was carried out at ambient temperature about 25 °C and desorption kinetics at 30 °C for 12 h. The obtained results indicate that the sorption and desorption kinetics as well as the diffused quantities of water in the wood of these two clones were greater in the longitudinal direction than in the radial direction and that they were the lowest in the tangential direction. Wood samples of E. grandis exhibit higher average values of diffusion coefficient, absorption coefficient, and surface emission coefficient in both absorption and desorption processes in the linear directions than those of E. camaldulensis. However, they display lower average values of resistance diffusivity in all directions than those E. camaldulensis in both absorption and desorption processes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Wood is a porous, hygroscopic, anisotropic and complex natural polymer; it has a layered structure. The wood moisture varies constantly with the environmental conditions due to absorption and/or desorption of humidity from the surrounding air [1,2,3,4]. Moisture content in wood has an important influence on its physical and mechanical properties, dimensional stability and durability, which limit its uses in construction and numerous applications of engineering [5,6,7,8,9].

Water can be present in two states in wood. The first state called bound water exists in cell walls. The second state or free water is located in the cell lumen and void spaces [10,11,12]. The water transfer in wood is a very complex process. The mechanism of water diffusion depends on wood density, type of wood, moisture content, relative humidity, temperature, anatomical direction (longitudinal, radial or tangential) and the duration of the exposure [13,14,15,16,17].

The water diffusion coefficient describes the rate of water transfer from the surface of the wood to the interior or vice versa. Thus, study and knowledge of the water diffusivity phenomenon in the wood is critical to control the drying rate and estimate the time required for lumber drying especially below the fiber saturation point (FSP) [18,19,20]. It also provides information concerning the effects of temperature, equilibrium moisture content, board thickness, air velocity, drying time and moisture gradients on the quality of the final product [21]. In addition, it contributes to the knowledge of storage conditions, life cycle of timber structures and the end-use of wood products.

Two types of resistances regulate the transfer of water between wood and air. The internal one, due to the boundary layer adjacent to the wood surface, is described by the diffusion coefficient (D). The external one, due to wood structure, is described by the surface emission coefficient (S) [22, 23].

The objectives of this research are (i) to study kinetics of water sorption and desorption in longitudinal, radial and tangential directions for two wood of clonal eucalyptus; (ii) to estimate the water diffusion, absorption and the emission surface coefficients in these woods; and (iii) to estimate diffusion resistance of water in the considered directions.

2 Materials and Methods

2.1 Materials

Four 9-year-old trees of clonal Eucalyptus wood were used in this study from the plantation established in the Maamora forest (North-West of Morocco): two trees of the E. camaldulensis clone (No 579) and two others of the E. grandis clone (No 3758). Their average circumferences and heights are respectively 76 cm and 19.4 m for E. camaldulensis and 84.5 cm and 18 m for E. grandis. They had good straightness; they were free from defects and carried minimum branches.

2.2 Experimental

2.2.1 Wood Samples’ Preparation

To investigate water diffusion in the clonal Eucalyptus wood, after wood drying to humidity about 11.5 %, three series of samples from each tree of each clone were prepared. These series consist of 18 samples taken from the heartwood along the same longitudinal bars of the first log from each tree. The wood specimens are cubes of the following dimensions L × R × T (20 × 20 × 20) mm3 (Fig. 1a) [24]. For both water sorption and desorption studies, six samples were used from each tree for the longitudinal, radial and tangential directions. For the sake of studying the linear diffusion of water; in the first, the sample’s faces were polished by abrasive paper before coated with varnish. Four sides of the test specimens were covered by five layers of wood protection varnish (Fig. 1b, c), to ensure the water diffusion in one direction (the two sides that remained open). To verify the effectiveness of the protective varnish, some samples of both clones were weighed and completely covered by five layers of wood varnish. They were afterward immerged in water for 24 h and then weighed again. It appeared that the weight of the samples only changes by 0.001 mg.

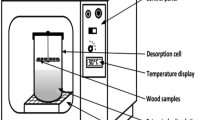

2.2.2 Experimental Equipments

The water diffusion study in clonal Eucalyptus wood was carried out using a climatic chamber to preserve the moisture of the samples at 11.5 % (Fig. 2a). Water bath at ambient temperature (25 °C) for the sorption study (at constant temperature) (Fig. 2b) and oven-dried at temperature 30 °C for the desorption process (Fig. 2c). To follow the gain or loss in the mass of the samples, an electronic balance was used (Fig. 2d). To maintain the moisture of the samples at the reached saturation level in the absorption process, the samples were kept in the desiccator until their use in the desorption process (Fig. 2e). To measure the samples dimensions, an electronic comparator was used (Fig. 2f).

2.2.3 Measurement Method

To track water sorption in the wood samples, the initial moisture content was about 11.5 %. The samples were completely immerged in the water basin at ambient temperature (about 25 °C). To measure the quantity of absorbed water, the changes in the weight of the specimens were recorded at regular time intervals (each 5 min) until equilibrium in 12 h.

For desorption study in the linear directions, the moisture content in the wood samples was at the level it had reached in the sorption process in each direction. The wood samples were placed in the oven at 30 °C, and their weights were measured at regular time intervals during 12 h until equilibrium state.

Water diffusion in the wood is the process of its transferring through the capillaries, vessels and cell walls. According to Fick’s second law, the water diffusion equation in the wood samples is given by the following formula [8]:

where c is water concentration, t time and Di diffusion coefficient in i direction (i = x,y,z).

For the one-dimensional transfer (i = x), the previous equation becomes:

Using the initial and final conditions as the following:

-

C(x,0)= Ci initial water concentration in the wood samples,

-

C(0,t)= C(e, t)= Cf final water concentration in the samples.

The dimensionless water concentration is defined by

where c is water concentration at time t.

The Eq. 2 becomes

The initial and the boundary conditions become

-

C*(0,0) = 0;

-

C*(0,t) = C* (e,t) = 1.

The partial differential Eq. 4 can be solved by the variables separation method; it expressed by the product of two functions: one depends on the position (x), while the other depends on the time (t), such as [25, 26]:

The general solution of the previous equation is

The analytical solution of Eq. 6 gives by the relation:

Integration of Eq. 7 over the thickness e gives the water concentration at the time t, and expressed by the equation [27,28,29]:

Thus, we obtain the infinite series as

The quantity \(C^{*} \left( t \right)\) varies between 0 and 1 (the initial and the final state), and the first term of the previous series is [29]

At the half time t0.5 which corresponds to C*(t) = 0.5, Eq. 10 becomes [29, 30]

Thus, the diffusion coefficient is determined as

For the values C*(t) are greater than 0.50, the diffusion coefficient is given by the relation [30]:

Thus, the water concentration is given by the equation [31]

The gain or loss of the dimensionless mass is indicated by equation:

where m(t) is the samples mass at time t (g), mi the initial samples mass (g), and meq the samples mass at equilibrium (g).

The experimentally measured magnitude m*(t) and the calculated analytically C*(t) being dimensionless. Thus, C*(t) can be written C*(t) ≡ m*(t); Eq. 12 becomes

where Δm(t) is the sample mass variation at time t (g), and Δmmax the sample mass at equilibrium (g).

The curve in Fig. 3 represents the variation of m*(t) depending on \(\sqrt {\text{t}}\). From this curve, it is possible to derive D. The diffusion coefficient is also calculated from results of the diffusion experiments from Eq. 5 which is given by the following equation:

where e is sample thickness (m).

The diffusion resistance of water (R) in the wood sample is given by the following relation [30]:

where S is the absorbent and/or desorbent surface of the sample.

The water absorption coefficient Aw is calculated from the equation [32, 33]:

where Δm is variation of the sample mass (mass at the time t − initial mass), S contact surface of the specimen and t time.

The surface emission coefficient (E) describes the rate at which moisture is emitted from the surface of drying wood; it is given by the equation [34]:

where a is half of the specimen thickness, t0.5 half-drying time (the time when the fraction of average moisture in wood H* = 0.5), and D diffusion coefficient.

The porosity of wood (Φ) can be calculated from the relation follows [35, 36]:

where ρ is the density of the material and ρS the density of the wood cell wall (constant for all wood species and almost constant for all plant fibers) which equals to 1530 kg·m−3.

The wood density is defined as the ratio of the mass and the sample volume, and it is given by the equation:

where m is sample mass and V sample volume.

The wood moisture content denoted (MC) is equal to the quantity of water contained in the wood, expressed as a percentage of dry weight:

where mh is wet wood mass (g), and mo dry wood mass (g).

2.2.4 Statistical Analysis

The mean values of the diffusion, absorption and surface emission coefficients and water diffusion resistance for the two clones Eucalyptus wood were compared using T test for independent samples.

3 Results and Discussion

3.1 Absorbed and Desorbed Moisture Profile

In general, the profiles of water absorption and desorption behavior in the linear direction of both clones are similar (Fig. 4a–d). These figures give a clear vision of water transfer in clonal eucalyptus wood, the sorption and desorption behavior to be represented as of Fickian behavior.

The pattern of water diffusivity indicates two possible stages. In the first, the wood samples for both clones exhibited a high ratio of water diffusivity in each direction, followed by a period of very slow and continuous diffusivity until it reaches an equilibrium state. The axial direction exhibited the highest water diffusivity; followed by the radial direction then the tangential direction. The pattern (style) of the water sorption process indicates that more than half of the absorbed water occurred in the first 3 h after immersion of the wood samples in water. In the end of the sorption process, the moisture of samples in longitudinal, radial and tangential directions respectively reached 45.3; 29.2 and 23.7 % for E. grandis. While it reached 39.9; 24.4 and 19.7 % for E. camaldulensis samples.

In the desorption process, the moisture of the samples for both clones in each direction decreased from the maximum values which it reached in the sorption process to lower than 11.5 % within 3 h. After that, it gradually decreased until the equilibrium state. The E. grandis samples exhibited the greatest decrease. By comparing the curves of sorption and desorption kinetics in the three directions, we can deduce that the E. grandis and E. camaldulensis wood are more diffusive in the longitudinal direction [37]. In this direction, the capillary transfer and the vascular rays are the main sources of water diffusion. Indeed, in the longitudinal direction, the capillary flow is important; while in the radial and tangential directions the water diffusion is lower, but in the radial direction it is slightly more diffusive than in the tangential direction. In the radial direction, the vascular rays are the primary source of the water diffusion; especially their structure, arrangement and status, which supports the phenomenon of diffusivity. In the tangential direction, the early-wood and late-wood layers are arranged in parallel, which more supports the diffusion in the radial direction.

3.2 Water Quantity Absorbed and Desorbed

The variation of water quantity absorbed by the surface unit of the wood sample increased progressively and reached an equilibrium state (Fig. 5a, b). The absorbed water quantity is higher in the longitudinal direction, followed by the radial direction then the tangential direction for both clones. Four hours after the wood samples were placed in the water basin, the amounts of absorbed water in the longitudinal, radial and tangential directions were, respectively, 0.124; 0.055 and 0.034 g·cm−2 for E. grandis compared to those of E. camaldulensis which are 0.101; 0.041 and 0.024 g·cm−2.

In the desorption process (Fig. 5c, d), the quantity of desorbed water decreased progressively and achieved equilibrium for both woods. After 4 h, the quantity of water desorbed in the longitudinal, radial and tangential directions was 0.040; 0.049 and 0.055 g·cm−2 respectively for E. grandis. While for E. camaldulensis it reached 0.049; 0.056 and 0.064 g·cm−2.

The values of water absorption and surface emission coefficients calculated from Eqs. 18 and 19 for the two eucalyptus clones woods are reported in Table 1. This table shows that the longitudinal direction has the largest average values of the parameters calculated. While the radial and tangential directions have the smallest values in both the absorption and desorption processes. On the other hand, the radial direction has slightly more average values than those obtained for the tangential direction. Also, the E. grandis wood has greater average values of water absorption and surface emission coefficients in each direction for both absorption and desorption processes than those of E. camaldulensis wood.

According to the T tests (Table 2), there are statistically significant differences between the mean values of absorption and surface emission coefficients in the three directions for the two Eucalyptus clones in the sorption and desorption processes with 95 % confidence based on T test analysis.

3.3 Water Diffusivity

The diffusion is one factor that determines fast water movement through the wood. It describes the movement of water between the interior and the wood surface. The water diffusion coefficients of wood samples for two clones in both sorption and desorption processes were calculated from Eq. 12.

Experimental results obtained for water diffusion in the linear directions are reported in Table 3. This table shows that the water diffusion coefficients in two clones of Eucalyptus wood depend on the wood anatomical directions; it is an important factor that affects the diffusion coefficient. The longitudinal direction has the largest average values of water diffusion coefficient, followed by the radial direction. While the tangential direction has the lowest average values. Also, the water diffusion coefficient in the Eucalyptus wood depends on the wood density. The wood samples with high density have a small diffusion coefficient for the two clones in each direction for both sorption and desorption processes.

In the absorption and desorption processes, the wood samples of E. grandis have the greatest average values of the diffusion coefficient in all directions, due to their higher porosity and lower density compared to E. camaldulensis (Table 3).

In Table 4, we observe that there are statistically significant differences between the mean values of the diffusion coefficient for the two Eucalyptus clones in the longitudinal and tangential directions in both sorption and desorption processes at a confidence level P < 0.05. While there are no statistically significant differences between the averages of the diffusion coefficient values for the radial direction in both the absorption and desorption processes for both clones of Eucalyptus.

3.4 Resistance of Water Diffusion

The water transfer resistance in wood depends on anatomical direction and wood density. The obtained results in Table 5 show that the water diffusivity resistance increases with the rise of wood density, which implies that the wood density is the main parameter that influences the water diffusivity resistance. The tangential direction has a greatest average value of water transfer resistance, followed by radial directions. However, the longitudinal direction has the lowest average value of transfer resistance in the absorption and desorption processes for both woods, where the water moves toward the fiber easier than other directions. The E. grandis wood has a lower average value of diffusion resistance in both processes compared to E. camaldulensis wood.

Table 6 shows that there are statistically significant differences between the mean values of the water diffusion resistance for the two Eucalyptus clones in the longitudinal and tangential directions for both sorption and desorption processes (P < 0.05). But there are no statistically significant differences between the average of the diffusion coefficient values for the radial direction in both the absorption and desorption processes for both clones of eucalyptus.

The water diffusivity resistance in wood varies in a significant way as a function of the absorbent or desorbent surface of wood specimens (Figs. 6 and 7). The obtained results indicate a strong negative linear correlation between water diffusivity resistance and the absorbent and/or desorbent surface.

In the absorption process, according to the values of R2 the correlations between water transfer resistance and the absorbent surface of the wood samples in longitudinal and radial directions of E. camaldulensis are greater than those of E. grandis. While in the tangential direction it was higher for E. grandis than that of E. camaldulensis. Also, in the desorption process, this correlation is higher for E. grandis than that E. camaldulensis in radial and tangential directions, while it is the opposite in the longitudinal direction.

4 Conclusion

The study of the diffusivity of water in the linear directions was carried out for two clones of eucalyptus wood from the Maamora forest (North-West of Morocco). Based on the results of this study, the following conclusions can be drawn:

-

the quantity of water absorbed and/or desorbed is higher in the longitudinal direction. While its lowest in the tangential direction for two clones in both sorption and desorption processes;

-

the clone of E. grandis has the greater average values of water diffusion, absorption and surface emission coefficients in the longitudinal, radial and tangential directions for both sorption and desorption processes compared to those of E. camaldulensis clones;

-

the wood of E. camaldulensis clones has higher water diffusivity resistance in the linear directions studied compared to those of E. grandis clones;

-

the permeability of clonal Eucalyptus wood in the transverse direction is very low compared to the longitudinal direction. In longitudinal direction, the vessels, fibers and woody rays are the main source of the water diffusion.

This study provides a useful guideline for the treatment of the sorption and desorption isotherm and/or control of processes drying for this woods’ type.

References

B. Time, Hygroscopic Moisture Transport in Wood. PhD Thesis, Norwegian University (1998)

R. Baronas, F. Ivanauskas, I. Juodeikienė, A. Kajalavičius, Modelling of moisture movement in wood during outdoor storage. Nonlinear Anal. Model. Control 6, 3–14 (2001)

S.Q. Shi, Diffusion model based on Fick’s second law for the moisture absorption process in wood fiber-based composites: is it suitable or not. Wood Sci. Technol. 41, 645–658 (2007)

B. Franke, S. Franke, M. Schiere, A. Müller, Moisture diffusion in wood–Experimental and numerical investigations. In: World conference on Timber Engineering, 22–25 August, Vienna (2016)

S. Noorolahi, J. Khazaei, S. Jafari, Modeling Cyclic water absorption and desorption characteristics of three varieties of wood. In: World conference on agricultural information and IT. 24–27 August, Tokyo, Japan, (2008)

M. S. Sivertsen, Liquid water absorption in wood cladding boards and log sections with and without surface treatment. PhD Thesis, Norwegian University of Life Sciences (2010)

M. Sayar, A. Tarmian, Modification of water vapor diffusion in poplar wood (Populus nigra L) by steaming at high temperatures. Turk. J. Biol. 37, 511–515 (2013)

H.C. Aristide, A. Christophe, H. Sossou, A. Malahimi, V. Antoine, Mass diffusivity determination of teak wood (Tectonagrandis) used as building material. Procedia Eng. 127, 201–207 (2015)

M. Amer, B. Kabouchi, M. Rahouti, A. Famiri, A. Fidah, S. El Alami, Influence of moisture content on the axial resistance and modulus of elasticity of clonal eucalyptus wood. Mater. Today Proc. 13, 562–568 (2019)

K. Krabbenhøft, Moisture Transport in Wood a Study of Physical-Mathematical Models and their Numerical Implementation. PhD Thesis, Technical University of Denmark (2003)

K. El Mokhtari, M. El Kouali, M. Talbi, D. Boriky, A. El Brouzi, Moisture Transfer in Wood Packaging below the Fiber Saturation point. In: International Journal of Science and Research, 538–540 (2013)

L. Bennani, M. Elkouali, M. Talbi, T. Ainane, Modelling the absorption process of water in wood in the transient regime. Int. J. Chem. Sci. 15, 137 (2017)

W.T. Simpson, Determination and use of moisture diffusion coefficient to characterize drying of northern red oak (Quercus rubra). Wood Sci. Technol. 27, 409–420 (1993)

K. Krabbenhoft, L. Damkilde, A model for non–Fickian moisture transfer in wood. Mater. Struct. 37, 615–622 (2004)

W. Zillig, H. Janssen, J. Carmeliet, D. Derome, Liquid water transport in wood: Towards a mesoscopic approach. In: Proceedings of 3rd International Building Physics Conference, 27–31 August, Taylor French (2006)

S. Sandoval-Torres, E. Hernández-Bautista, J. Rodríguez-Ramírez, A.C. Parra, Numerical simulation of warm-air drying of Mexican Softwood (Pinus pseudostrobus): an empirical and mechanistic approach. Chem. Biochem. Eng. Q. 28, 125–133 (2014)

M. Campean, Influence of moisture diffusion rate of bound water upon the drying time of steamed and unsteamed beech wood. Pro. Ligno. 11, 31–38 (2015)

J.L. Nsouandélé, B. Bonoma, M.S. Tagne, D. Njomo, Determination of the diffusion coefficient of water in the tropical wood. Phys. Chem. News. 54, 61–67 (2010)

A. Tarmian, R. Remond, H. Dashti, P. Perre, Moisture diffusion coefficient of reaction woods: compression wood of Picea abies L. and tension wood of Fagus sylvatica L. Wood Sci. Technol. 46, 405–417 (2012)

M. Simo-Tagne, R. Rémond, Y. Rogaume, A. Zoulalian, P. Perré, Characterization of sorption behavior and mass transfer properties of four central Africa tropical wood: ayous, Sapele, Frake, Lotofa. Maderas, Ciencia y tecnología 18, 207–226 (2016)

W. Olek, J. Weres, Effects of the method of identification of the diffusion coefficient on accuracy of modeling bound water transfer in wood. Transp. Porous Med. 66, 135–144 (2007)

A. Herritsch, Investigations on Wood Stability and Related Properties of Radiata Pine. PhD Thesis, University of Canterbury 2007

Z. Perkowski, J. Świrska-Perkowska, M. Gajda, Comparison of moisture diffusion coefficients for pine, oak and linden wood. J. Build. Phys. 41, 135–161 (2016)

L. Passarini, R.E. Hernández, Effect of the desorption rate on the dimensional changes of Eucalyptus saligna wood. Wood Sci. Technol. 50, 941–951 (2016)

M.A.O. Sid Ahmed, C.S. Ethmane Kane, N. Bouaziz, M. Rhazi, M. Kouhila, Evaluation Par Méthode Inverse du Coefficient de Diffusion et du Nombre de transfert biot lors du Séchage en système continu. Revue des Energies Renouvelables. 12, 627–640 (2009)

E. Agoua, S. Zohoun, P. Perré, A double climatic chamber used to measure the diffusion coefficient of water in wood in unsteady-state conditions: determination of the best fitting method by numerical simulation. Int. J. Heat Mass Transf. 44, 3731–3744 (2001)

J. Crank, The mathematics of diffusion, 2nd edn. (Clarendon Press, Oxford, 1975)

A. C. Kouchade, Mass diffusity of wood determined by inverse method from electrical resistance measurement in unsteady state. Ph D Thesis, Ecole Nationale du Génie Rural, des Eaux et de Forêts (ENGREF), Centre de Nancy (2004)

T. A. Nguyen, Approches expérimentales et numériques pour l’étude des transferts hygroscopiques dans le bois. Ph D Thesis, Universite de Limonges (2014)

N. Mouchot, A. Wehrer, V. Bucur, A. Zoulalian, Détermination indirecte des coefficients de diffusion de la vapeur d’eau dans les directions tangentielle et radiale du bois de hêtre. Ann. For. Sci. 57, 793–801 (2000)

A.C. Houngan, C. Awanto, L. Fagbemi, M. Anjorin, A. Vianou, Mass diffusivity measurements of two cement based materials. J. Civil Eng. Constr. Technol. 6, 86–92 (2015)

W. Sonderegger, M. Glaunsinger, D. Mannes, T. Volkmer, P. Niemz, Investigations into the influence of two different wood coatings on water diffusion determined by means of neutron imaging. Eur. J. Wood Prod. 73, 793–799 (2015)

D. Konopka, E.V. Bachtiar, P. Niemz, M. Kaliske, Experimental and numerical analysis of moisture transport in walnut and cherry wood in radial and tangential material directions. BioResources 12, 8920–8936 (2017)

O. Söderström, J.G. Salin, On determination of surface emission factors in wood drying. Holzforschung 47, 391–397 (1993)

C. Delisée, J. Lux, J. Malvestio, 3D morphology and permeability of highly porous cellulosic fibrous material. Transp. Porous Med. 83, 623–636 (2010)

M. Plötze, P. Niemz, Porosity and pore size distribution of different wood types as determined by mercury intrusion porosimetry. Eur. J. Wood Prod. 69, 649–657 (2011)

T. C. Monteiro, J. T. Lima, J. R. M. da Silva, R. N. Rezende, R. J. Klitzke, Water flow in different directions in Corymbia citriodora wood. Maderas- Cienc. Tecnol. (2020)

Acknowledgements

This work is supported by the Forest Research Center in Rabat (High Commission for Waters, Forests and Fight against Desertification) in collaboration with Faculty of Sciences in Rabat (Mohammed V University), Morocco.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Amer, M., Kabouchi, B., Rahouti, M. et al. Experimental Study of the Linear Diffusion of Water in Clonal Eucalyptus Wood. Int J Thermophys 41, 142 (2020). https://doi.org/10.1007/s10765-020-02723-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-020-02723-7