Abstract

DuPont’s perfluoropolyether oil Krytox\(^{\textregistered }\) GPL 102 is a promising candidate for the high-temperature, high-pressure Deepwater viscosity standard (DVS). The preferred DVS is a thermally stable liquid that exhibits a viscosity of roughly 20 \(\hbox {mPa} \cdot \hbox {s}\) at 533 K and 241 MPa; a viscosity value representative of light oils found in ultra-deep formations beneath the deep waters of the Gulf of Mexico. A windowed rolling-ball viscometer designed by our team is used to determine the Krytox\(^{\textregistered }\) GPL 102 viscosity at pressures to 245 MPa and temperatures of 311 K, 372 K, and 533 K. At 533 K and 243 MPa, the Krytox\(^{\textregistered }\) GPL 102 viscosity is \((27.2 \pm 1.3)\,\hbox {mPa} \cdot \hbox {s}\). The rolling-ball viscometer viscosity results for Krytox\(^{\textregistered }\) GPL 102 are correlated with an empirical 10-parameter surface fitting function that yields an MAPD of 3.9 %. A Couette rheometer is also used to measure the Krytox\(^{\textregistered }\) GPL 102 viscosity, yielding a value of \((26.2 \pm 1)\,\hbox {mPa} \cdot \hbox {s}\) at 533 K and 241 MPa. The results of this exploratory study suggest that Krytox\(^{\textregistered }\, \hbox {GPL}\) 102 is a promising candidate for the DVS, primarily because this fluoroether oil is thermally stable and exhibits a viscosity closer to the targeted value of 20 mPa \(\cdot \) s at 533 K and 241 MPa than any other fluid reported to date. Nonetheless, further studies must be conducted by other researcher groups using various types of viscometers and rheometers on samples of Krytox GPL\(^{\textregistered }\) 102 from the same lot to further establish the properties of Krytox GPL\(^{\textregistered }\) 102.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

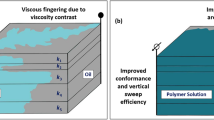

1 Introduction

On June 20, 2009, the International Association for Transport Properties (IATP) held its 9th meeting in Boulder, Colorado [1] and identified a short- and long-term high-temperature, high-pressure viscosity standard (HTHP VS). The short-term HTHP VS should have a dynamic viscosity of \(200\,\hbox {mPa} \cdot \hbox {s}\) at 473 K and 172 MPa with an uncertainty of 2 % and the long-term HTHP VS should have the same dynamic viscosity at 573 K and 241 MPa but now with an uncertainty of 1 %. Subsequently, during the HTHP Workshop initiated by Schlumberger and Cambridge Viscosity on January 22, 2010 [2], these specifications were changed to reflect interest in two types of petroleum viscosity standards, both of which have increasing importance as the search for domestic energy sources in increasingly harsh conditions escalates. One viscosity standard represents the properties of light oils found in ultra-deep formations typically accessed via offshore platforms in the deep waters of the Gulf of Mexico (the Deepwater viscosity standard or DVS). The other standard represents the properties of heavy oils produced from bitumen reserves found in shallower oil sands (the heavy oil viscosity standard or HOVS) [2]. The targeted DVS should have a dynamic viscosity of roughly \(20\,\hbox {mPa} \cdot \hbox {s}\) at 533 K and 241 MPa, while the HOVS should have a dynamic viscosity of \(1000\,\hbox {mPa} \cdot \hbox {s}\) at 473 K and 10.34 MPa. The desired uncertainty for both standards was set at 5 % to 10 % [3]. One of the conclusions of this meeting was that candidates for these standards should be assessed at multiple laboratories using different experimental techniques. For example, it was anticipated [3, 4] that the DVS and HOVS could be evaluated using oscillating-piston, rolling-ball, falling-object, torsional-crystal, vibrating-cylinder, oscillating-disk, vibrating-crystal, and capillary viscometers. A review of current viscometry laboratories [4] indicated, however, that these Deepwater standard conditions of 533 K and 241 MPa would be particularly challenging and would require modifications to existing viscometry equipment.

The objectives of the present study are to recommend a DVS, assess its viscosity at 533 K and 241 MPa using two different types of viscometers, and model the viscosity using nonlinear surface fitting. The desirable attributes [2, 4] of the candidate DVS include thermal stability, inertness, insensitivity to UV radiation, and ready availability throughout the world at a specified purity. Further, the candidate should be safe to use in the laboratory and it should be environmentally benign. To the best of our knowledge, no monodisperse or polydisperse hydrocarbon-based material has yet been identified that exhibits a viscosity close to the targeted value of 20 mPa \(\cdot \) s at the DVS conditions. Therefore we turned our attention to polyfluoroether oils, which are designed to exhibit remarkable thermal stability and are available over a fairly wide range of molecular weights and viscosity values.

DuPont’s Krytox\(^{\textregistered }\) perfluoropolyether oils are excellent candidate DVS that meet the requirements mentioned here. Krytox\(^{\textregistered }\) oils are not susceptible to photochemical decay and they exhibit remarkable chemical and thermal stability [5–7]. While eight polydisperse Krytox\(^{\textregistered }\) oils (GPL 100 to 107) are commercially available, it is unlikely that any one of these would exhibit the targeted value of precisely \(20\,\hbox {mPa}\cdot \hbox {s}\) at 533 K and 241 MPa. It is anticipated, however, that two of the oils will exhibit viscosity values that are close to 20 mPa \(\cdot \) s, and either of these oils could serve as the DVS. The lots of these oils can sell out within several months; therefore, if a Krytox\(^{\textregistered }\) GPL oil is recognized as a viable HTHP DVS by the rheology community in the near future, a coordinated attempt will be made by various researchers to purchase material from the same lot in order to eliminate any lot-to-lot variations in chemical composition. Further, Krytox oils can be fractionated with supercritical \(\hbox {CO}_{2}\) [8, 9] thereby enabling more monodisperse perfluoropolyether oils to be obtained.

In the present work we demonstrate that Krytox\(^{\textregistered }\) GPL 101 has a viscosity slightly less than the targeted value, while Krytox\(^{\textregistered }\) GPL 102 exhibits a viscosity slightly above the 20 mPa \(\cdot \) s value. Although we also demonstrate that Krytox\(^{\textregistered }\) GPL 102 can be fractionated to obtain several fractions with viscosity values intermediate to those of Krytox\(^{\textregistered }\) GPL 101 and Krytox\(^{\textregistered }\) GPL 102, the primary focus of our work involves the study of a single oil, Krytox\(^{\textregistered }\) GPL 102. Two different apparatuses are used to determine the viscosity of this fluid over a wide range of temperature and pressure and to ascertain how closely this oil matches the target viscosity of \(20\,\hbox {mPa} \cdot \hbox {s}\) at 533 K and 241 MPa. One is an HTHP Couette rheometer designed to measure the viscosity of drilling fluids with viscosity values in the range of \(3\,\hbox {mPa} \cdot \hbox {s}\) to \(300\,\hbox {mPa} \cdot \hbox {s}\) [10]. The other viscometer is a novel windowed, variable-volume, rolling-ball viscometer based on the view cell apparatus used for HTHP solution studies in our group [11]. The viscosity results for Krytox\(^{\textregistered }\) GPL 102 are fit to an empirical 10-parameter surface fitting function that correlates viscosity to temperature and pressure.

2 Experimental

2.1 Materials

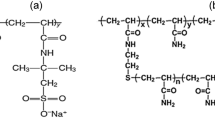

The full Krytox\(^{\textregistered }\) GPL 100 series of fluorinated lubricating oils are obtained from the DuPont Company. Table 1 lists the molecular-weight estimates of these perfluoropolyethers, whose structure is shown in Fig. 1. These oils have a “fairly broad” molecular-weight distribution [12]. Krytox\(^{\textregistered }\) GPL 100-107 oils are additive-free, non-reactive, non-flammable, thermally stable materials that are resistant to oxidation. Thus, they are typically used in general purpose applications, such as lubricating bearings that come into contact with chemicals and oxygen. Krytox\(^{\textregistered }\) GPL 101 (99.9 % purity) and 102 (99.9 % purity, lot K 1537) perfluoropolyether oils are used as received from Miller-Stephenson Chemical Company.

A Cannon certified viscosity standard (Chandler Engineering, Aqua 200, a silicone polymer with a viscosity of \(215\,\hbox {mPa}\cdot \hbox {s}\) to \(43.8\,\hbox {mPa}\cdot \hbox {s}\) over the 283 K to 393 K range, lot 913803), is used to calibrate the HTHP Couette rheometer.

Bis(2-ethylhexyl) phthalate, DEHP [99 % purity, Sigma Aldrich], is used to calibrate the rolling-ball viscometer. A reliable source of lubricating fluids viscosity data at temperatures from 273 K to 491 K and pressures to 1000 MPa is available including data on DEHP [13]. DEHP viscosity data at temperatures between 273 K and 348 K and pressures to 371 MPa are also available [14]. In the current study it is demonstrated that an extrapolation of the data [13] yields a DEHP viscosity of 3.1 mPa\(\cdot \)s at the DVS conditions; a value that is too low for DEHP to be a viable DVS candidate.

2.2 Viscometers

2.2.1 Rolling-Ball Viscometer

A novel windowed, variable-volume, rolling-ball viscometer is used for the collection of high-temperature, high-pressure viscosity data. Figure 2 shows an expanded view of the viscometer, which is very similar to our group’s densimeter [11]. The cell is constructed from Inconel 718, has an outside diameter of 7.6200 cm, an inside diameter (ID) of 1.5875 cm in the portion of the viscometer where the ball rolls, an ID of 1.9050 cm in the segment that retains the movable piston and a maximum working volume of 50 cm\(^{3}\). The spheres of various diameters (e.g., 1.5716 cm \(\pm \) 0.0005 cm) are also made of Inconel 718 (Industrial Tectonics Inc.) to minimize the effects of temperature and pressure on the calibration constant.

Two tables mounted on each other are used to tilt the viscometer, Fig. 3. A digital protractor (Model Pro 3600, Applied Geomechanics, \(0.1^{\circ }\) resolution) is employed to measure the inclination angle. The top table tilts the cell to a desired angle and the bottom table tilts the cell in the opposite direction to let the ball roll back to the starting position at the front sapphire window. Once the ball arrives at the front window, a magnetic pin is released and falls behind the ball to hold it in place. A borescope (Model Hawkeye\(^{\textregistered }\) Pro Hardy 6.35 mm, Gradient Lens Corporation) is positioned against the window at the front end of the cell to verify that only a single fluid phase is present during the experiment, and to confirm that the ball is rolling, rather than sliding, down the bore of the viscometer. The cell also has three sets of small opposing sapphire windows arranged a fixed distance of 3.81 cm apart along the sides of the viscometer. The ball velocity is determined from the time it takes the ball to roll past each of the three sets of small opposing sapphire windows, or the time it takes the ball to roll between two sets of windows. The O-rings used in conjunction with the windows and piston are composed of Viton or, for higher-temperature studies, FF 200 (Parker Seals Company).

The technique used to detect the ball position is similar to that used by Sawamura and Yamashita [15]. The detection system is composed of a fiber optic light source (Model LSX 24B, InterTest) and three pairs of glass fiber optic cables (Model IF23SM900, Banner Engineering Corporation) attached to the small sapphire windows. The three glass fiber optic sensors (Model R55FVWQ, Banner Engineering Corporation) are interfaced with a computer through a LabVIEW program.

The liquid sample and overburden fluid (water) are separated in the viscometer by a movable piston (3.175 cm long, 1.895 cm diameter) that retains an O-ring around its perimeter. A small pressure gradient of \(\sim \) 0.1 MPa is required to move the piston. The liquid sample is compressed to the desired operating pressure using a high-pressure generator (Model 37-5.75-60, High Pressure Equipment Company) that compresses the overburden fluid. System pressure is measured on the overburden fluid using a pressure transducer (Model 245-BZS, Viatran Corporation) that is calibrated against a Heise pressure gauge (Model CM, 414 MPa \(\pm \) 0.40 MPa, Heise Corporation). The viscometer cell is jacketed with band heaters (1000 W, Rama Corporation) and fiberglass insulation paper. A type-K thermocouple (Omega Corporation) is used to measure the temperature of the fluid in the view cell. The thermocouple is calibrated (293 K to 533 K) against a high precision thermometer (Medicus Health, \(0.01\,^{\circ }\hbox {C}\) resolution, accurate to \(0.05\,^{\circ }\hbox {C}\)). The temperature of the viscometer is controlled with a precision temperature controller (Oakton Digi-Sense, \(0.1\,^{\circ }\hbox {C}\) resolution, calibrated by InnoCal using methods traceable to NIST standards). More details on this viscometer can be found in the dissertation of Hseen Baled [16].

2.2.2 Couette Rheometer

A high-temperature, high-pressure Couette rheometer [10], which establishes a drag-induced laminar flow in a thin slit, is available for the measurement of the drilling mud viscosity at conditions associated with ultra-deep petroleum. The design of this apparatus is the product of a joint venture between the Society of Petroleum Engineers, Baker Hughes Drilling Fluids, and Ametek Chandler Engineering. This viscometer is rated for pressures to 276 MPa, temperatures to 589 K, and shear rates to \(\sim \!\!1100\,\hbox {s}^{-1}\). A more detailed description of the development and testing of this apparatus, with illustrations, is given elsewhere [10]. The viscometer [Chandler Model 7600 XHP/HT] consists of two coaxial cylinders. The recommended range of fluid viscosity for this model is approximately \(3\,\hbox {mPa}\cdot \hbox {s}\) to \(300\,\hbox {mPa} \cdot \hbox {s}\); for lower viscosity fluids, the drag between the rotor and stator becomes significant as the rotation rate decreases, while for higher viscosity fluids, the torque becomes too high. The Couette rheometer was calibrated with a Cannon viscosity standard. DEHP is not used for calibration of the Couette rheometer because only 8 of the 28 data points along the 4 isotherms in the 1 MPa to 260 MPa, 298 K to 491 K pressure–temperature range [13] exhibit viscosity values within the \(3\,\hbox {mPa}\cdot \hbox {s}\) to \(300\,\hbox {mPa}\cdot \hbox {s}\) bounds recommended for the Couette rheometer.

3 Experimental Results and Discussion

3.1 Rolling-Ball Viscometer Calibration with DEHP

The governing equation for determining the calibration constant, \(k\), of a rolling-ball viscometer is

where \(k\) has units of (\(\hbox {cm}^{4}\cdot \hbox {m}^{-1}\cdot \hbox {s}^{-2}), \mu \) is the viscosity in \(\hbox {mPa}\cdot \hbox {s}, v\) is the terminal velocity of the rolling ball in \(\hbox {cm}\cdot \hbox {s}^{-1}\), and \(\rho _\mathrm{b}\) and \(\rho _\mathrm{fl}\) are the ball density and fluid density, respectively, in \(\hbox {g}\cdot \hbox {cm}^{-3}\). The tilt angle is set at \(40\,^{\circ }, 40\,^{\circ }, 15\,^{\circ }\), and \(10\,^{\circ }\) for the isotherms 298 K, 311 K, 372 K, and 491 K, respectively. The viscosity and density of DEHP are taken from an ASME viscosity report [13]. Twenty-eight viscosity data points in the 2 \(\hbox {mPa}\cdot \hbox {s}\) to 3400 \(\hbox {mPa}\cdot \hbox {s}\) range along the 298 K, 311 K, 372 K, and 491 K isotherms between 1 MPa and 260 MPa are used for calibration. Although the DEHP density values are inexplicably not listed in the tabular results for the 491 K isotherm, the values are determined by rearranging the viscosity expression used in [13] to solve for \(\rho _\mathrm{fl}\) at 491 K, and the results are in good agreement with DEHP density data recently reported by Bamgbade et al. [17]. An Inconel 718 ball with a ball diameter, \(d\), to viscometer ID diameter, \(D\), ratio of 0.990 is used for the calibration of the viscometer at temperatures between 298 K and 491 K. Larger spheres (e.g., \(d/D = 0.995\) and 0.998) roll too slowly and yield calibration results inferior to those shown in Fig. 4 for \(d/D=0.990\). Smaller balls (e.g., \(d/D = 0.980\)) roll too quickly to obtain precise data.

The terminal velocity of the rolling ball is the same whether the viscometer is tilted \(+\theta \) or \(-\theta \). In all cases, the ball rolls at its terminal velocity and no sliding is observed. The calibration results are shown in Fig. 4, which presents the calibration constant values, \(k\), as a function of pressure for each isotherm. The pressure dependence reflects the decrease in the ball diameter and the simultaneous increase in the cell internal diameter with increasing pressure, an effect enhanced at elevated temperatures [18].

It is necessary to extrapolate the viscometer calibration to 533 K, the temperature associated with the DVS, since the DEHP calibration only extends to 491 K. Two alternative approaches are available. In the first approach, linear temperature-dependent expressions for the intercept (\(a\), Fig. 5) and slope (\(b\), Fig. 6) of the four linear isotherms in Fig. 4 were used to estimate the intercept and slope of a 533 K calibration constant isotherm. The results (\(a\) = 0.536 \(\hbox {cm}^{4}\cdot \hbox {m}^{-1}\cdot \hbox {s}^{-2}\) at 533 K, \(b~=~1.944~\times 10^{-3}\,\hbox {cm}^{4}\cdot \hbox {m}^{-1}\cdot \hbox {s}^{-2}\cdot \hbox {MPa}^{-1}\) at 533 K) are used to generate the solid gray line in Fig. 4.

A linear fit (\(R^{2~}=~0.98\)) of the intercept, \(a\), values of the 298 K to 491 K linear isotherms in Fig. 4. When extrapolated to 533 K, \(a = 0.536\,\hbox {cm}^{4}\cdot \hbox {m}^{-1}\cdot \hbox {s}^{-2}\)

A linear fit (\(R^{2} =0.99\)) of the slope, \(b\), values of the linear isotherms in Fig. 4. When extrapolated to 533 K, \(b = 1.944 \times 10^{-3}\,\hbox {cm}^{4}\cdot \hbox {m}^{-1}\cdot \hbox {s}^{-2}\cdot \hbox {MPa}^{-1}\)

In the second approach shown in Fig. 7, \(k\) is determined using DEHP viscosity data at 533 K as estimated by extrapolating \(TP\mu \) data [13] using a surface fitting correlation, Eq. 2 [18].

where the viscosity, \(\mu \), is in \(\hbox {mPa}\cdot \hbox {s}\), temperature, \(T\), is in K, and pressure, \(P\), is in MPa. The unitless coefficients of the surface fitting correlation are given in Table 2. The mean absolute percentage deviation (MAPD) obtained with the surface fitting correlation of the DEHP viscosity is 0.91 %. (At DVS conditions of 533 K and 241 MPa, the DEHP viscosity is estimated to be 3.1 \(\hbox {mPa}\cdot \hbox {s}\).)

Surface fitting of the DEHP viscosity data at 298 K, 311 K, 372 K, and 491 K [13] (black data markers) and extrapolated DEHP viscosity values at 533 K (gray dashed line)

DEHP density values at 533 K are obtained with the modified Tait equation [19],

The parameters \(\rho _{0}\), \(B\), and \(C\) are determined by fitting Eq. 3 to new HTHP DEHP density data recently reported by Bamgbade et al. [17]. Table 3 lists the extrapolated parameter values at 533 K.

The results for the calibration constant, \(k,\) based on this technique are represented by the dashed gray line in Fig. 4. The solid and dashed gray lines shown in Fig. 4 differ by 1.2 %.

The effects of temperature and pressure on the viscometer dimensions must be considered when determining the calibration constant at the desired conditions. To the best of our knowledge, there is no analytic solution for the viscometer constant of a rolling-ball viscometer, which consists of a spherical object rolling along the bottom edge of a cylindrical volume of confined fluid, as a function of ball and tube diameter. Therefore semi-empirical expressions such as the following equation are used to describe the calibration constant as a function of temperature and pressure [20, 21]:

where \(k_{0}\) is the calibration constant at the reference condition (\(T_{0~}\)= 311 K, \(P_{0~}\)= 1.4 MPa), \(r_{0}\) is the diameter ratio (\(d_{0}/D_{0})\) of the sphere to the tube at the reference condition, \(\alpha \) and \(\kappa \) are the linear thermal expansion and isothermal compressibility of the ball and tube material (Inconel 718) [22], and the parameter \(\beta \) is fitted to the experimental data and can be expressed as a linear function of temperature, Fig. 8.

Fitting parameter \(\beta \) in Eq. 4 as a function of temperature

Figure 9 shows a comparison of the calculated calibration constant using Eq. 4 with the experimental data. The MAPD values are 1.73 %, 0.63 %, 1.94 %, 1.88 %, and 2.85 % for the isotherms 298 K, 311 k, 372 K, 491 K, and 533 K, respectively.

Comparison of the calculated calibration constant using Eq. 4 (lines) with the experimental data (symbols)

3.2 Rolling-Ball Viscometer Measurements of the Viscosity of Krytox\(^{\textregistered }\) GPL 102

The viscosity of Krytox\(^{\textregistered }\) GPL 102 is determined over a wide range of pressure at 311 K, 372 K, and 533 K using the expression,

The calibration constant, \(k\), derived from the DEHP surface fitting technique, is used here. The density of Krytox\(^{\textregistered }\) GPL 102, \(\rho _\mathrm{fl}\), is calculated with the modified Tait correlation, Eq. 3. The required parameters for the Tait equation, found in Table 4, are based on Krytox\(^{\textregistered }\) GPL 102 density data recently measured by our group [11]. The measured temperature, pressure, tilt angle, the Krytox\(^{\textregistered }\) GPL 102 density determined from the Tait equation, and the calculated viscosity for each experiment are provided in Table 5. The viscosity results are also illustrated in Fig. 10. At the conditions closest to those associated with the HTHP DVS, the viscosity of Krytox\(^{\textregistered }\) GPL 102 is 27.2 mPa \(\cdot \) s at 533 K and 242.9 MPa.

In order to verify that the flow is laminar in each of these experiments, a log–log plot of the resistance factor, \(f\), versus the Reynolds number, Re, is generated for all isotherms [23]. The results are shown in Fig. 11, where

where \(g\) is the gravitational acceleration at Pittsburgh, PA (9.80269 \(\hbox {m}\cdot \hbox {s}^{-2})\) [24]. The resistance factor and Reynolds number values are listed in Table 5. Turbulent flow is typically indicated by a gradual flattening of the log \(f\) versus log Re data at higher values of Re of any isotherm. If the data are linear for each isotherm, however, as shown in Fig. 11, then the nature of the fluid flow around the rolling ball is laminar in all experiments (note that the isotherms do not have to be coincident).

Unlike falling-cylinder viscometers that are characterized by a single shear rate at the surface of the falling cylinder as the fluid flows through the well-defined gap of fixed dimensions, the fluid flow around a close-clearance ball rolling through a tube experiences a range of shear rates. Therefore, an average shear rate, \(\bar{{\dot{\gamma }}}\) in units of \(\hbox {s}^{-1}\), is estimated for each experiment, using the expression below [25],

The average shear rates are provided in Table 5.

The standard uncertainties, \(u\), are \(u(T)\) = 0.30 K, \(u(P)\) = 0.07 MPa below 56 MPa and 0.35 MPa from 56 MPa to 241 MPa, \(u\)(t) = 0.05 s, \(u(\theta ) = 0.1^{\circ }\), and the estimated accumulated experimental uncertainty in the reported Krytox\(^{\textregistered }\) GPL 102 viscosity, \(U_\mathrm{c}\), calculated by applying the law of error propagation to Eq. 1, is \(U_\mathrm{c}(\mu ) = 2.4\,\% \mu \) (for 311 K and 372 K isotherms) and \(U_\mathrm{c}(\mu ) = 4.7\,\% \mu \) (for 533 K isotherm), at a confidence level of approximately 95 % (coverage factor, \(k \)= 2).

3.3 Couette Rheometer Measurements of Krytox\(^{\textregistered }\) GPL 101 and 102

After calibrating the Chandler Couette rheometer with a high-temperature silicone oil, the viscosity of Krytox\(^{\textregistered }\) GPL 101 and 102 was measured at \(\sim \)533 K over the 34 MPa to 276 MPa pressure range. In each experiment the pressure and temperature are fixed and the shear rate is increased from 85 s\(^{-1}\) to 1021 s\(^{-1}\), and then decreased to 85 s\(^{-1}\). Typical high-pressure results are shown in Figs. 12 and 13 for Krytox\(^{\textregistered }\) GPL 101 and 102, respectively. The rapid decrease in viscosity with increasing shear rate below 600 s\(^{-1}\) and the hysteresis of the data collected as the shear rate is increased compared to the data collection during the reduction of shear rate are not reflective of the fluid properties. Rather, it appears that there may be a source of drag, perhaps bearing friction, between the rotor and stator that becomes insignificant as the rotation rate increases for the Krytox oils. (This hysteresis did not occur during calibration.) Regardless of the source of these unsystematic results at low shear, these data were not considered reliable. The data collected at shear rates greater than 600 s\(^{-1}\), however, were reproducible and exhibited the expected Newtonian behavior of these relatively low molecular-weight polymers. In Table 6, viscosity data are reported only for shear rates of 1021 s\(^{-1}\). Results from two series of data collection separated by 6 months are presented in Table 6.

Examples of Chandler Couette rheometer results for Krytox\(^{\textregistered }\) GPL 101 at 242 MPa and 275 MPa and 533 K; Run 1. “up” refers to the first part of the experiment when shear rate was increased from 85 \(\hbox {s}^{-1}\) to 1021 \(\hbox {s}^{-1}\) “down” refers to the subsequent data collection as shear rate was incrementally decreased to 85 \(\hbox {s}^{-1}\). The gray bar refers to the targeted DVS of 20 \(\hbox {mPa}\cdot \hbox {s}\) at 533 K and 242 MPa. The arrow indicates the difference between the viscosity at DVS conditions and the targeted value

Examples of Chandler Couette rheometer results for Krytox\(^{\textregistered }\) GPL 102 at 208 MPa and 242 MPa and 533 K, run 1. “up” refers to the first part of the experiment when shear rate was increased from 85 \(\hbox {s}^{-1}\) to 1021 \(\hbox {s}^{-1}\) “down” refers to the subsequent data collection as shear rate was incrementally decreased to 85 \(\hbox {s}^{-1}\). The gray bar refers to the targeted DVS of 20 \(\hbox {mPa}\cdot \hbox {s}\) at 533 K and 242 MPa. The arrow indicates the difference between the viscosity at DVS conditions and the targeted value

At the HTHP DVS conditions of 533 K and 241 MPa, the average viscosity average values of both runs of Krytox\(^{\textregistered }\) GPL 101 and 102 are 16.5 \(\hbox {mPa}\cdot \hbox {s}\) and 26.2 \(\hbox {mPa}\cdot \hbox {s}\), respectively, at a shear rate of 1021 \(\hbox {s}^{-1}\). The targeted viscosity value of 20 \(\hbox {mPa}\cdot \hbox {s}\) for the DVS is therefore intermediate to the viscosity exhibited by these fluids. Either of these fluids exhibit values close enough to the 20 \(\hbox {mPa}\cdot \hbox {s}\) target that either could be considered as a viable DVS candidate.

A comparison of the Krytox\(^{\textregistered }\) GPL 102 rolling-ball viscometer results (based on both 533 K calibration constant techniques) and the Chandler Couette rheometer results at 1021 \(\hbox {s}^{-1}\) are presented in Fig. 14, along with the targeted viscosity of the DVS. At DVS conditions, the viscosity of Krytox\(^{\textregistered }\) GPL 102 is 27.2 \(\hbox {mPa}\cdot \hbox {s}\) based on the rolling-ball viscometer, and 26.2 \(\hbox {mPa}\cdot \hbox {s}\) based on the Couette rheometer; a 3.7 % difference relative to the rolling-ball viscometer value. As shown in Fig. 14, these values are in good agreement given the extent of the error bars for the 241 MPa data.

A comparison of the 533 K viscosity values of Krytox\(^{\textregistered }\) GPL 102 based on the rolling-ball viscometer and the Couette rheometer at 1021 \(\hbox {s}^{-1}\). The error bars for the rolling-ball viscometer results based on the calibration constant derived from the surface fitting of the DEHP data are also shown. The targeted DVS viscosity value is also indicated

3.4 Alternative Krytox\(^{\textregistered }\) GPL-based DVS Candidates

Two methods are available for formulating a Krytox GPL\(^{\textregistered }\)-based DVS that exhibits a viscosity closer to \(20\,\hbox {mPa}\cdot \hbox {s}\) than Krytox\(^{\textregistered }\) GPL 101 (\({\sim }17\,{\hbox {mPa}} \cdot \hbox {s}\)) or 102 (\({\sim }26\,{\hbox {mPa}}\cdot \hbox {s}\)). The first is to blend Krytox\(^{\textregistered }\) GPL 101 and 102 such that the mixture exhibits a viscosity value close to \(20\,\hbox {mPa} \cdot \hbox {s}\) at 533 K and 241 MPa. Alternately, because Krytox\(^{\textregistered }\) GPL oil is a polydisperse mixture of perfluoropolyethers, this fluid can be fractionated into a series of more monodisperse fractions that will exhibit viscosity values greater than and less than the parent oil. For example, members of our team have previously fractionated perfluoropolyether oils using supercritical \(\hbox {CO}_{2}\) at varying pressures as the solvent [8, 9], and in one case, Krukonis and co-workers [9] demonstrated that the resulting fractions exhibited viscosity values greater than and less than the viscosity of the parent oil. In this work, Krytox\(^{\textregistered }\) GPL 102 was successfully fractionated into six fractions using \(\hbox {CO}_{2}\) at 333 K using the standard procedures described elsewhere [8, 9]. The fraction (1) extracted with the lowest pressure/density \(\hbox {CO}_{2}\) is the lower molecular weight constituents of the parent oil, while the last fraction recovered (6) with the highest pressure/density \(\hbox {CO}_{2}\) corresponds to the highest molecular weight fraction of the parent oil. 96.1 % of the Krytox\(^{\textregistered }\) GPL 102 charged to the fractionation vessel was recovered in the six fractions, Table 7.

A benchtop Brookfield cone-and-plate viscometer [Model LVDV-II+Pro, Brookfield Engineering Laboratories] with a small sample size adapter is used to demonstrate that at ambient pressure and temperatures between 298 K and 423 K, fractions 2, 3, and 4 exhibit viscosity values intermediate to those of Krytox\(^{\textregistered }\) GPL 101 and 102 at the same conditions. (The mass of each fraction was too small to evaluate in either high-pressure apparatus.) This result conceptually demonstrates that supercritical fluid fractionation of Krytox\(^{\textregistered }\) GPL 102 can produce a lower molecular weight, relatively monodisperse fraction that would likely exhibit a viscosity value at DVS conditions closer to \(20\,\hbox {mPa} \cdot \hbox {s}\) than either Krytox\(^{\textregistered }\) 101 or 102.

However, there remains a general consensus [27] that any processing of a DVS is undesirable, and fluids such as Krytox\(^{\textregistered }\) GPL 101 or 102 that exhibit viscosity values of approximately \(10\,\hbox {mPa} \cdot \hbox {s}\) to \(30\,\hbox {mPa} \cdot \hbox {s}\) would be considered as suitable candidates. We propose using Krytox\(^{\textregistered }\) GPL 102 because extensive HTHP density data have been recently published by our team [11]. We also suggest that in the immediate future an effort should be made to eliminate variance of the molecular weight, which would induce variance in the viscosity. The first such effort is currently underway under the sponsorship of the US DOE NETL; this agency is purchasing many small containers of Krytox\(^{\textregistered }\) GPL 102 from the same lot for distribution to interested parties at no cost via requests sent to the corresponding author of this study.

4 Viscosity Modeling Results

The viscosity data are modeled with the surface fitting correlation, Eq. 2. The unitless coefficients of the surface fit are given in Table 8. The MAPD obtained with the surface fit of Krytox\(^{\textregistered }\) GPL 102 is 3.9 % which is within experimental uncertainty. The results are presented in the semi-log plot of viscosity versus pressure, Fig. 15. Figure 16 shows the comparison of the experimental viscosity versus calculated viscosity with Eq. 2.

Semi-log plot of Krytox\(^{\textregistered }\) GPL 102 (lot K 1537) viscosity versus pressure. Lines represent viscosity results obtained with the surface fitting, filled markers represent viscosity results obtained with the rolling-ball viscometer, and open markers represent viscosity results obtained with the Couette rheometer

Experimental Krytox\(^{\textregistered }\) GPL 102 (lot K 1537) viscosity versus viscosity determined with surface fitting correlation, Eq. 2

5 Conclusions

DuPont’s Krytox\(^{\textregistered }\) perfluoropolyether oils are promising candidates for a high-temperature, high-pressure (HTHP) Deepwater viscosity standard (DVS). The preferred DVS is a thermally stable liquid that exhibits a viscosity of roughly 20 \(\hbox {mPa}\cdot \hbox {s}\) at 533 K and 241 MPa.

A novel, windowed, variable-volume, rolling-ball viscometer is designed by our team [16] and used to determine viscosity values of Krytox\(^{\textregistered }\) GPL 102. The rolling-ball viscometer is calibrated with bis(2-ethylhexyl) phthalate, and used to determine the viscosity of Krytox\(^{\textregistered }\) GPL 102 over a wide range of pressure (up to 245 MPa) at 311 K, 372 K, and 533 K. At 533 K and 24 MPa, the Krytox\(^{\textregistered }\) GPL 102 viscosity is found to be \((27.2 \pm 1.3)\,\hbox {mPa} \cdot \hbox {s}\).

A high-temperature, high-pressure Chandler Couette rheometer, calibrated with a silicone oil viscosity standard, is also used to measure the Krytox\(^{\textregistered }\) GPL 102 viscosity, yielding a value of \((26.2 \pm 1)\,\hbox {mPa} \cdot \hbox {s}\) at 533 K and 241 MPa. The Couette rheometer is also used to determine that the viscosity of Krytox\(^{\textregistered }\) GPL 101 is \(16.5\,\hbox {mPa} \cdot \hbox {s}\) at 533 K and 243 MPa. These viscosity results for Krytox\(^{\textregistered }\) GPL 102 and 101 are the closest values to the desired DVS viscosity value of 20 mPa \(\cdot \) s that have been reported to date.

The 20 mPa \(\cdot \) s DVS target is an approximate value, therefore either Krytox\(^{\textregistered }\) GPL 101 or 102 can be considered as a viable DVS candidate. We propose the use of Krytox\(^{\textregistered }\) GPL 102 because of the availability of extensive Krytox\(^{\textregistered }\) GPL 102 density data [11], which is often required for determination of viscosity. Although supercritical \(\hbox {CO}_{2}\) fractionation of Krytox\(^{\textregistered }\) GPL 102 can be employed to yield fractions with properties intermediate to those of Krytox\(^{\textregistered }\) GPL 101 and 102, the additional processing of a viscosity standard is generally considered to be undesirable.

The rolling-ball viscometer viscosity results for Krytox\(^{\textregistered }\) GPL 102 are correlated with with an empirical 10-parameter surface fitting function, which yields an MAPD of 3.9 %.

References

Minutes of the 9th IATP Meeting. (IATP Meeting, June 20, 2009, Boulder, CO), http://transp.cheng.auth.gr/mja/iatp/09_Boulder_Min.pdf. Accessed Dec 2012

HTHP Viscosity Standards Workshop Executive Summary. (HTHP Viscosity Standards Workshop, Jan 22, 2010), https://www.slb.com/~/media/Files/core_pvt_lab/other/hpht_viscosity_standards_workshop_2010_summary.pdf. Accessed Dec 2012

R. Kasameyer, D. Airey, J. Cole, Viscometer State-of-the-Art (HTHP Viscosity Standards Workshop, Jan 22, 2010), https://www.slb.com/~/media/Files/core_pvt_lab/other/high_pressure_viscometers.pdf. Accessed Dec 2012

A. Goodwin, Plausible Industrial Reference Fluids for Viscosity (HTHP Viscosity Standards Workshop, Jan 22, 2010), https://www.slb.com/~/media/Files/core_pvt_lab/other/industrial_reference_fluids_viscosity.pdf. Accessed Dec 2012

K.J.L. Paciorek, R.H. Kratzer, J. Kaufman, J.H. Nakahara, J. Appl. Polym. Sci. 24, 1397 (1979)

www.krytox.com. Accessed June 2013

R. Fix, ChemPoint. Private communication (2013)

R. Enick, E. Beckman, A. Yazdi, V. Krukonis, H. Schonemann, J. Howell, J. Supercrit. Fluids 13, 121 (1998)

M.E. Paulaitis, V.J. Krukonis, R. Kurnik, R. Reid, Rev. Chem. Eng. 1, 179 (1983)

W. Gussler, M. Pless, J. Maxey, P. Grover, J. Perez, J. Moon, T. Boaz, SPE Drill Complet. 22, 81 (2007)

B.A. Bamgbade, Y. Wu, W.A. Burgess, M.A. McHugh, Fluid Phase Equilib. 332, 159 (2012)

K. Selby, DuPont performance lubricants. Private communication (2010)

R.V. Kleinschmidt, D. Bradbury, M. Mark, in Viscosity and Density of over Forty Lubricating Fluids of Known Composition at Pressures to 150,000 psi and Temperatures to 425 F (ASME Report, New York, 1953)

K. Harris, J. Chem. Eng. Data 54, 2729 (2009)

S. Sawamura, T. Yamashita, Rolling-ball viscometer for studying water and aqueous solutions under high pressure, in Proceedings of the 14th International Conference on the Properties of Water and Steam (Kyoto, 2004), p. 429

H.O. Baled, Density and viscosity of hydrocarbons at extreme conditions associated with ultra-deep reservoirs-measurements and modeling. Dissertation, University of Pittsburgh, 2012

B.A. Bamgbade, Y. Wu, H.O. Baled, R.M. Enick, W.A. Burgess, D. Tapriyal, M.A. McHugh, J. Chem. Thermodyn. 63, 102 (2013)

H. Baled, R. Enick, W. Burgess, J. Jain, B. Morreale, Y. Soong, D. Tapriyal, Y. Wu, B. Bamgbade, M.A. McHugh, in A windowed, variable-volume, rolling-ball viscometer rated to \(260^{\circ }\text{ C }\) and 275 MPa, presented at 18th Symposium on Thermophysical Properties (Boulder, CO, 2012)

J.H. Dymond, R. Malhotra, Int. J. Thermophys. 9, 941 (1988)

Y. Sato, H. Yoshioka, S. Aikawa, R.L. Smith Jr, Int. J. Thermophys. 31, 1896 (2010)

M. Izuchi, K. Nishibata, Jpn. J. Appl. Phys. 25, 1091 (1986)

Inconel\(^{\textregistered }\) alloy 718, http://www.specialmetals.com/products/inconelalloy718.php. Accessed June 2013

R.M. Hubbard, G.G. Brown, Ind. Eng. Chem. Anal. Ed. 15, 212 (1943)

Wolfram Alpha, http://www.wolframalpha.com/. Accessed May 2013

J. Šesták, F. Ambros, Rheol. Acta 12, 70 (1973)

E.W. Lemmon, M.O. McLinden, D.G. Friend, in Thermophysical Properties of Fluid Systems, NIST Chemistry Webbook, NIST Standard Reference Database Number 69, ed. by P.J. Lindstrom, W.G. Mallard (National Institute of Standards and Technology, Gaithersburg, MD), http://webbook.nist.gov/chemistry/fluid/. Accessed Dec 2012

H. Baled, R.M. Enick, W. Burgess, D. Tapriyal, B.D. Morreale, Y. Wu, B.A. Bamgbade, M.A. McHugh, S. Bair, V. Krukonis, in Perfluoropolyether oils as Candidates for the Deepwater Viscosity Standard of 20 cP at \(500^{\circ }\text{ F }\) and 35000 psia, Presented at 12th IATP Meeting (June 24, 2012, Boulder, CO), Minutes of the 12th IATP Meeting, http://transp.eng.auth.gr/index.php/iatp/2012. Accessed Aug 2013

Acknowledgments

This technical effort was performed in support of the National Energy Technology Laboratory’s Office of Research and Development support of the Strategic Center for Natural Gas and Oil under RES contract DE-FE0004000, which supported the doctoral studies of Hseen Baled [16]. We would like to express our gratitude for the numerous insights and helpful suggestions provided by Arno Laesecke of the National Institute of Standards and Technology (NIST), Thermophysical Properties Division, Boulder, CO, and Scott Bair of the George W. Woodruff School of Mechanical Engineering, Georgia Tech, Atlanta, GA. Laesecke and Bair were the first to suggest that DuPont’s Krytox\(^{\textregistered }\) perfluoropolyether oils are excellent DVS candidates.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baled, H.O., Tapriyal, D., Morreale, B.D. et al. Exploratory Characterization of a Perfluoropolyether Oil as a Possible Viscosity Standard at Deepwater Production Conditions of 533 K and 241 MPa. Int J Thermophys 34, 1845–1864 (2013). https://doi.org/10.1007/s10765-013-1500-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10765-013-1500-5