Abstract

Azospirillum sp. are plant growth promoting bacteria (PGPB) that increase grain yield in cereals and other species via growth promotion and/or stress alleviation. The PGPB beneficial effects have been partially attributed to bacterial production of plant hormones, especially growth promoters like auxins, gibberellins and cytokinins. This paper reports the characterization of the stress-like plant hormone abscisic acid (ABA) by GC-EIMS in cultures of A. brasilense Sp 245 after 120 h of incubation in chemically-defined media, and chemically-defined media with moderate stress (100 mM NaCl). Chemical characterization of ABA was done by gas chromatography-electron impact mass spectrometry (GC-EIMS) and quantification by selected ion monitoring (SIM) with a stable isotope of the hormone as internal standard in the media. A. brasilense cultures produced higher amounts of ABA per ml of culture when NaCl was incorporated in the culture medium. Inoculation of Arabidopsis thaliana with A. brasilense Sp 245 enhanced two-fold the plant’s ABA content. These results contribute to explain, at least to some extent, the beneficial effects of Azospirillum sp. previously found in inoculated plants placed under adverse environmental conditions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Plant growth-promoting bacteria (PGPB) are associated with many plant species and are commonly present in many environments. The most widely studied group of PGPB is those that colonize the root surfaces and the closely adhering soil interface, the rhizosphere (Patriquin et al. 1983). Some of these PGPB can also penetrate the root and establish endophytic populations (Kloepper et al. 1980; Gray and Smith 2005). The extent of endophytic colonization of host plant organs and tissues reflects the ability of the bacteria to selectively adapt to these specific ecological niches. Because of this reason, these bacteria have been inoculated to a wide range of cultivated species to enhance crop yield. Such enhancement may be obtained by seedling emergence acceleration and increasing plant weight (Okon and Hadar 1987), by disease control (Kloepper et al. 1980, 1991), and by conferring resistance to salt and water stresses to the infected plant (Creus et al. 1997; Mayak et al. 2004). In other words, PGPB are bacteria that can indirectly stimulate plant growth.

The mechanism that has been most often invoked to explain the various effects of PGPB on plants is the production of phytohormones (Bloemberg and Lugtenberg 2001; Bottini et al. 2004; Persello-Cartieaux et al. 2003). In effect, Azospirillum sp. produces and metabolizes plant hormones both in culture and in association with the plant (Piccoli and Bottini 1994; Bottini et al. 1989; Cassán et al. 2001a, b; Janzen et al. 1992; Lucangeli and Bottini 1996, 1997; Patten and Glick 1996; Piccoli et al. 1996; Timmusk et al. 1999).

The PGPB genus most widely studied is Azospirillum, a Gram-negative nitrogen-fixing soil bacterium that belongs to the α-subclass of proteobacteria group (reviewed by Kloepper 2003). Azospirillum sp. have been isolated all over the world from the rhizosphere of many grasses and cereals, particularly from economically important crops such as corn, wheat and rice, both in the tropical as well as in temperate climates (Patriquin et al. 1983). The Azospirillum sp. characteristic effect on inoculated plants is an enhanced root system with more lateral roots and enlarged root hairs, therefore occupying an enhanced soil volume (Bashan and Holguin 1997; Bertrand et al. 2000; Fulchieri et al. 1993). This enhanced root system confers to the plant a better ability for nutrient and water uptake (Okon 1994; Sarig et al. 1988) that augments the tissue turgor, which is the main factor that controls plant growth (Hsiao et al. 1970; Granier and Tardieu 1999; Sansberro et al. 2004).

Azospirillum sp. produces IAA (Crozier et al. 1988), indole-3-butyric acid (IBA; Martínez-Morales et al. 2003), cytokinins (Timmusk et al. 1999), and several gibberellins (GA, i.e., GA1, GA3, GA9, GA19, and GA20; Bottini et al. 1989; Janzen et al. 1992; Piccoli et al. 1996, 1997) in chemically-defined media. Several investigators have shown that inoculation with Azospirillum sp. or the application of the hormones induces the proliferation of lateral roots and root hairs (Fulchieri et al. 1993; Glick 1995; El-Khawas and Adachi 1999). It has also been demonstrated that Azospirillum sp. can metabolize GAs in vitro (Piccoli and Bottini 1994; Piccoli et al. 1996) as well as in vivo (i.e., in association with a higher plant; Cassán et al. 2001b), and in both situations Azospirillum sp. are able to hydrolyze ether and ester glycosides of GA20 (Cassán et al. 2001a; Piccoli et al. 1997). The beneficial effects of Azospirillum sp. on the inoculated plants however are not only restricted to direct growth promotion. In effect, alleviation of water and salt stresses have also been reported (Creus et al. 1997; Mayak et al. 2004).

In previous results Cohen et al. (2001) demonstrated that the inoculation with A. lipoferum partially reversed the effect of fluridone in blocking abscisic acid (ABA) synthesis of maize seedlings, therefore suggesting the bacterial capacity to synthesize the hormone. In effect, inoculation with the bacteria increased the ABA levels of maize seedlings, which showed enhanced growth with respect to those treated with the inhibitor (Fluridone) and in turn kept a better water status. Since the synthesis of GA and ABA follow a common pathway, i.e., they operate in cell plastids through the MEP biosynthetic route of terpenes (Litchtentaler 1999); a feasible hypothesis is that bacteria can also synthesize ABA as part of their normal metabolism.

ABA plays a major role in plants responses to biotic and abiotic stresses; increases in ABA levels have been reported during salt, cold, drought and wounding (Zeevaart and Creelman 1988; Peña-Cortés et al. 1989; Shinozaki and Yamaguchi-Shinozaki 2000). ABA affects plant resistance to heat exposure (Robertson et al. 1994) and plant-pathogen interaction (Mohr and Cahill 2003). Although ABA is considered to be a “stress hormone” (Zeevaart and Creelman 1988), it is becoming clear that it also accomplishes important regulatory functions in the absence of stress (Cheng et al. 2002; Sharp 2002).

This paper reports the characterization of ABA in chemically-defined cultures of A. brasilense Sp 245 by gas chromatography-electron impact mass spectrometry (GC-EIMS). Quantification of ABA was done by selected ion monitoring (SIM) with a stable isotope of the hormone as internal standard, under mild saline stress in the media obtained by addition of NaCl. Also ABA content was measured in Arabidopsis thaliana plants inoculated or not with the bacterium.

Material and methods

Bacterial cultures

Azospirillum brasilense strain Sp 245 (gift of Dr. Carlos Barassi, EEA-INTA, Balcarce, Argentina) was used. Bacteria were first activated in Luria Broth (LB, Sigma Chem Co, St. Louis, MO, USA) medium and then cultured in 250 ml Erlenmeyer flasks containing 100 ml of specific and selective chemically-defined NFb medium (Bottini et al. 1989) pH 5.8 plus NH4Cl (1.25 g l−1) as N source. NaCl 100 mM was added to some flasks in order to generate a Ψw of ca. −0.7 MPa. Two sets of three flasks each containing only incubation medium alone or with NaCl were used as controls, while the other two sets were sown with 100 μl of an A. brasilense Sp 245 culture containing 108 cells ml−1 alone or with NaCl. The flasks were incubated in a water bath with orbital shaking (Shaker Pro, Viking, BIO-CONTROL, Buenos Aires, Argentina) at 120 r.p.m., in darkness and 30°C, until stationary phase as determined by OD620 (biomass production).

Arabidopsis thaliana (ecotype Columbia) seeds were surface sterilized, incubated for 72 h at 4°C in darkness, then allowed to germinate and grow for 30 days at 24°C and 16 h light and 8 h darkness on Petri dishes with MS medium. After germination (148 h from sowing) the root seedlings were inoculated with 10 μl of PBS medium alone (control), or 10 μl of a PBS suspension containing 106 CFU ml−1 of Azospirillum brasilense strain Sp 245. The bacteria have been grown as stated above, centrifuged and further re-suspended in PBS at the desired concentration.

ABA analysis

The whole procedure was performed in darkness or dim light to avoid ABA photodestruction. For ABA quantification in the bacterial culture 100 ng of [2H6]-ABA, (gift of J. D. Cohen, Department of Horticulture, University of Minnesota, Saint Paul, MN, USA) were added to half volume of the cultures at the end of the incubation period as internal standard, and the mixture allowed to stand 3 h in darkness and 4°C for isotope equilibration. The other half of the cultures was processed without internal standard in order to perform mass spectra characterization of the purported ABA. Bacterial cultures (or culture media controls) were grown as described above then sonicated twice for 6 min and centrifuged 10 min at 10 000g and 4°C. The cells were discarded and the supernatant was adjusted to pH 3.0 with acetic acid and partitioned three times with an equal volume of ethyl acetate (saturated with 1% acetic acid) pH 2.8–3.0. The ethyl acetate fraction was evaporated and the residue dissolved in 1 ml of a mixture of methanol: water: acetic acid (79/20/1; v/v/v), filtered and submitted to HPLC purification with a μBondapack C18 reverse phase (Waters Associates, Parker Ltd., Milford, MA, USA) column. Elution was performed with a KONIK 500 apparatus (Konik Instruments, Barcelona, Spain) at a flow rate of 2 ml min−1 using the following gradient: from 0 to 10 min 10% methanol in 1% acetic acid, from 10 to 40 min 10–73% methanol in 1% acetic acid, from 40 to 50 min with 73% methanol in 1% acetic acid, from 50 to 60 min with 100% methanol. The fraction from 34 to 40 min (co-chromatographying with authentic ABA, Sigma Chem Co, St Louis, MO, USA) was collected. After solvent evaporation in vacuum at room temperature the sample was derivatized for capillary gas chromatography-electron impact mass spectrometry-selected ion monitoring (GC-MS-SIM) analysis. For methyl-ester (Me) derivatization 2–4 ml of methanol and 50–100 μl of fresh CH2N2 were added, and left for 30 min at room temperature. After solvents had been eliminated under N2 the extract was dissolved in 5 μl hexane and 1 μl was injected in the split-split less mode in a GC-MS system (PerkinElmer Clarus 500, Atlanta, GA, USA). The GC column was a PerkinElmer Elite-5MS, cross-linked methyl silicone capillary column (30 m length, 0.25 mm internal diameter, and 0.25 μm film thickness) eluted with He (1 ml min−1). The GC temperature program was 100–190°C at 15°C min−1, then from 190 to 260°C at 5°C min−1. ABA characterization was performed in full scan mode and the spectra obtained matched with authentic ABA (Sigma Chem. Co., St Louis, MO, USA). The amount of ABA in the medium was calculated by comparison of the peak areas of the parent ions for the Me derivative of the deuterated internal standard (194/166), and the Me derivative of the endogenous ABA (190/162). All analyses were performed from three biological replicates.

For ABA quantification in A. thaliana seedlings, approximately 100 mg FW of shoot + leaf tissues were homogenized in 1 ml of ice-cold methanol: water: acetic acid (79:10:1; v/v) along with 100 ng of [2H6]-ABA. After filtration and methanol evaporation in vacuum, the aqueous was loaded to Sep-Pack C18 cartridges (Waters Associates, Milford, MA, USA), washed with hexane and eluted with methanol: water: acetic acid (79:10:1; v/v). After methanol evaporation in vacuum aqueous was partitioned 4× with water (pH 3.0) saturated ethyl acetate. The acidic ethyl acetate fraction was evaporated in vacuum and re-dissolved in a mixture of methanol:water:acetic acid (79/20/1; v/v/v), and from this point on the extracts were processed as stated above for the bacterial cultures.

Statistical analysis

Data were analyzed by analysis of variance (ANOVA) followed by Turkey’s t test at P ≤ 0.05 (Graph Pad Software, San Diego, CA, USA).

Results and discussion

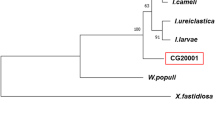

Figure 1 shows the mass spectra of Me-ABA identified from the HPLC extract, and that of authentic Me-ABA. Clearly, both spectra overlapped sufficiently to demonstrate A. brasilense Sp 245 produced ABA in chemically-defined media.

Table 1 shows bacterial growth after 120 h of incubation in the different culture media compared with NFb and NFb plus NaCl culture medium. The addition of 100 mM of NaCl into NFb culture medium generated an extra osmotic pressure of 0.5 MPa, giving a final Ψw of ca. −0.7 MPa, thus resembling a situation of mild saline/osmotic stress usually found in plant tissues. This salt concentration affected scarcely either the final pH and bacterial growth assessed as OD620 (total biomass) of both A. brasilense Sp 245 cultures conditions. However, the saline condition reduced to 1/3 the CFU ml−1 (cells alive) of A. brasilense Sp 245 cultures as compared with the treatment without NaCl.

Differences between A. brasilense Sp 245 alone and A. brasilense Sp 245 plus NaCl cultures were also found in the ABA bacterial production. In Table 2 it is shown the difference in ABA production by A. brasilense in normal and under NaCl conditions. According to isotope dilution calculations (SIM data from samples containing [2H6]-ABA), A. brasilense cultures produced higher amounts of ABA per ml of culture when NaCl was incorporated in the culture medium (i.e., 235 ng ml−1 vs. 73 ng ml−1, Table 2). These results were comparable to previous ones by Piccoli et al. (1999) where the quantity of GA3 produced in vitro by Azospirillum sp. was reduced only 50% in the presence of PEG (Ψw = −1.21 MPa), despite a 90% reduction in the number of cells alive per ml of culture medium. Such results imply a compensatory mechanism in the ability of the bacterium to produce phytohormones (i.e., ABA) under drought conditions. In effect, it is well known that the cell secondary metabolism increases under stressful conditions, as it is the case of GA biosynthesis by the fungus Gibberella fujikuroi that begins when N supply is limited in the culture medium (Candau et al. 1992). Hence, the positive effects of Azospirillum sp. inoculation on to plants submitted to water and salt stresses previously found (Cohen et al. 2001; Creus et al. 1997; Mayak et al. 2004) may be explained not only by production of growth promoting-like hormones (i.e., GAs and IAA) by the bacteria, but also by release of the stress-related hormone, ABA. Indeed, under mild stress conditions Azospirillum improved approximately 8-folds the ABA production (167.9 ng per 108CFU ml−1, Table 2) calculated as per the number of live cells.

When A. thaliana root seedlings were inoculated with A. brasilense Sp 245, the ABA content of 30-days-old plants was doubled with respect to the control non-inoculated ones (Table 3). Indeed, A. lipoferum was able to infect A. thaliana and the augmentation of ABA content in the plants may be, at least partially, ascribed to bacterial production.

Conclusion

Azospirillum brasilense produces ABA in vitro in a chemically-defined medium, i.e., with malic acid as the sole C source, demonstrating that the bacteria posses the whole biochemical machinery to perform such work. In higher plants it is known that the biosynthetic pathway for ABA proceeds through cleavage of carotenes (namely neoxanthin, Schwartz et al. 2003), while in some fungi it has been proposed that the biosynthesis occurs in a more direct way from farnesyil diphosphate (Siewers et al. 2006). However, there are no reports in the literature regarding possible pathways for ABA synthesis in bacteria.

Since saline soils are one of the most problematic aspects in world agriculture nowadays; the results presented encourage the possibility that PGPB with improved capacity of ABA production may help in plant-stress alleviation.

Abbreviations

- ABA:

-

Abscisic acid

- CFU:

-

Colony forming units

- GA(s):

-

Gibberellin(s) as a class

- GC-EIMS:

-

Capillary gas chromatography-electron impact mass spectrometry

- LB:

-

Luria Broth

- Me:

-

Methyl ester

- OD:

-

Optical density

- PGPB:

-

Plant growth promoting bacteria

- SIM:

-

Selected ion monitoring

References

Bashan Y, Holguin G (1997) Azospirillum-plant relationships: environmental and physiological advances (1990–1996). Can J Microbiol 43:103–121

Bertrand H, Plassard C, Pinochet X, Touraine B, Normand P, Cleyet-Marel JC (2000) Stimulation of ionic transport system in Brassica napus by a plant growth-promoting rhizobacterium (Achromobacter sp.). Can J Microbiol 46:229–236

Bloemberg GV, Lugtenberg BJ (2001) Molecular basis of plant growth promotion and biocontrol by rhizobacteria. Curr Opin Plant Biol 4:343–350

Bottini R, Fulchieri M, Pearce D, Pharis RP (1989) Identification of gibberellins A1, A3 and iso-A3 in cultures of Azospirillum lipoferum. Plant Physiol 90:45–47

Bottini R, Cassán F, Piccoli P (2004). Gibberellin production by bacteria and its involvement in plant growth promotion and yield increase. Appl Microbiol Biotech 65:497–503

Candau R, Avalos J, Cerdá-Olmedo E (1992) Regulation of gibberellin biosynthesis in Gibberella fujikuroi. Plant Physiol 100:1184–1188

Cassán F, Bottini R, Schneider G, Piccoli P (2001a) Azospirillum brasilense and Azospirillum lipoferum hydrolyze conjugates of GA20 and metabolize the resultant aglycone to GA1 in seedlings of rice dwarf mutants. Plant Physiol 125:2053–2058

Cassán F, Lucangeli C, Bottini R, Piccoli P (2001b) Azospirillum sp. Metabolize [17,17-2H2] Gibberellin A20 to [17,17-2H2] Gibberellin A1 in vivo in dy rice mutant seedlings. Plant Cell Physiol 42:763–767

Cheng WH, Endo A, Zhou L, Penney J, Chen HC, Arroyo A, León P, Nambara E, Asami T, Seo M, Koshiba T, Sheen J (2002) A unique short-chain dehydrogenase/reductase in Arabidopsis glucose signaling and abscisic acid biosynthesis and functions. Plant Cell 14:2723–2743

Cohen A, Travaglia C, Reinoso H, Piccoli P, Bottini R (2001) Azospirillum inoculation and inhibition of gibberellins and ABA synthesis in maize seedlings under drought. Proc Plant Growth Regul Soc Am 28:88-93

Creus C, Sueldo R, Barassi C (1997) Shoot growth and water status in Azospirillum-inoculated wheat seedlings grown under osmotic and salt stresses. Plant Physiol Biochem 35:939–944

Crozier AP, Arruda P, Jasmim JM, Monteiro AM, Sandberg G (1988) Analysis of indole-3-acetic acid and related indoles in culture medium from Azospirillum lipoferum and Azospirillum brasilense. Appl Environ Microbiol 54:2833–2837

El-Khawash H, Adachi K (1999) Identification and quantification of auxins in culture media of Azospirillum and Klebsiella and their effect on rice roots. Biol Fert Soils 28:377–381

Fulchieri M, Lucangeli C, Bottini R (1993) Inoculation with Azospirillum lipoferum affects growth and gibberellins status of corn seedling roots. Plant Cell Physiol 34:1305–1309

Glick BR (1995) The enhancement of plant growth by free living bacteria. Can J Microbiol 41:109–117

Granier Ch, Tardieu F (1999) Water deficit and spatial pattern of leaf development. Variability in responses can be stimulated using a simple model of leaf development Plant Physiol 119:609–619

Gray EJ, Smith DL (2005) Intracellular and extracellular PGPR: commonalities and distinctions in the plant-bacterium signaling processes. Soil Biol Biochem 37: 395–412

Hsiao TC, Acevedo E, Henderson DW (1970) Maize leaf elongation: continuous measurement dependence on water status. Science 168:590–591

Janzen R, Rood S, Dormar J, McGill W (1992) Azospirillum brasilense produces gibberellins in pure culture and chemically-medium and in co-culture on straw. Soil Biol Biochem 24:1061–1064

Kloepper JW Leong J, Teintze MN, Schroth MN (1980) Enhanced plant growth by siderophores produced by plant growth-promoting rhizobacteria. Nature 286:885–886

Kloepper JW, Zablotowiez RM, Tipping EM, Lifshitz R (1991) Inorganic plant growth promotion mediated by bacterial rhizosphere colonizer. In: Keister KL, Gregan PB (eds) The rhizosphere and plant growth. Kluwer, Dordrecht, pp 315–326

Klopper JW (2003) A review of the mechanism for plant growth promotion by PGPR. In: Proc. 6th International PGPR Workshop. Calcuta, India, pp 81–92

Litchtenthaler HK (1999) The 1-deoxy-d-xylulose-5-phosphate pathway of isoprenoid biosynthesis in plants. Annu Rev Plant Physiol Plant Mol Biol 50:47–65

Lucangeli C, Bottini R (1996) Reversion of dwarfism in dwarf-1 maize (Zea mays L.) and dwarf-x rice (Oryza sativa L.) mutants by endophytic Azospirillum spp. Biocell 20:223–228

Lucangeli C, Bottini R (1997) Effects of Azospirillum spp. on endogenous gibberellin content and growth of maize (Zea mays L.) treated with uniconazole. Symbiosis 23:63–72

Martínez-Morales LJ, Soto-Urzúa L, Baca BE, Sánchez-Ahédo JA (2003) Indole-3-butyric acid (IBA) production in culture medium by wild strain Azospirillum brasilense. FEMS Microbiol Lett 228:167–173

Mayak S, Tirosh T, Glick B (2004) Plant growth-promoting bacteria that confer resistance to water stress in tomatoes and peppers. Plant Sci 166:525–530

Mohr P, Cahill D (2003) Abscisic acid influences the susceptibility of Arabidopsis thaliana to Pseudomonas syringae pv. tomato and Peronospora parasitica Funct Plant Biol 30:461–469

Okon Y (1994) Azospirillum/plant associations. CRC Press, Boca Raton, p 347

Okon Y, Hadar Y (1987) Microbial inoculants as crop yield enhancers. CRC Crit Rev Biotechnol 6:61–79

Patriquin DG, Döbereiner J, Jain DK (1983) Sites and processes of association between diazotrophs and grasses. Can J Microbiol 29:900–915

Patten CL, Glick BR (1996) Bacterial biosynthesis of indole-3-acetic acid. Can J Microbiol 42:07–220

Peña-Cortés H, Sánchez-Serrano JJ, Mertens R, Willmitzer L, Prat S (1989) Abscisic acid is involved in the wound-induced expression of the proteinase inhibitor II gene in potato and tomato. Proc Natl Acad Sci USA 86:9851–9855

Persello-Cartieaux F, Nussaume L, Robaglia C (2003) Tales from the underground: molecular plant-rhizobacteria interactions. Plant Cell Environ 26:189–199

Piccoli P, Bottini R (1994) Metabolism of 17,17-[2H2]gibberellin A20 to 17,17-[2H2]gibberellin A1 by Azospirillum lipoferum cultures. AgriScientia XI:13–15

Piccoli P, Masciarelli O, Bottini R (1996) Metabolism of 17,17[2H2]-Gibberellins A4, A9, and A20 by Azospirillum lipoferum in chemically-defined culture medium. Symbiosis 21:167–178

Piccoli P, Lucangeli D, Schneider G, Bottini R (1997) Hydrolysis of [17,17-2H2]Gibberellin A20-Glucoside and [17,17-2H2]Gibberellin A20-glucosyl ester by Azospirillum lipoferum cultured in a nitrogen-free biotin-based chemically-defined medium. Plant Growth Regul 23:179–182

Piccoli P, Masciarelli O, Bottini R (1999) Gibberellin production by Azospirillum lipoferum cultured in chemically defined medium as affected by water status and oxygen availability. Symbiosis 27: 135–146

Robertson AJ, Ishikawa M, Gusta LV, MacKenzie SL (1994) Abscisic Acid-induced heat tolerance in Bromus inermis leyss cell-suspension cultures. Heat-stable, abscisic acid-responsive polypeptides in combination with sucrose confer enhanced thermostability Plant Physiol 105:181–190

Sansberro P, Mroginski L, Bottini R (2004) Abscisic acid promotes growth of Ilex paraguariensis plants by alleviating diurnal water stress. Plant Growth Regul 42:105–111

Sarig S, Blum A, Okon Y (1988) Improvement of the water status and yield of field-grown grain sorghum (Sorghum bicolor) by inoculation with Azospirillum brasilense. J Agric Sci Camb 110:271–277

Schwartz SH, Qin X, Zeevaart JAD (2003) Elucidation of the indirect pathway of abscisic acid biosynthesis by mutants, genes, and enzymes. Plant Physiol 131:1591–1601

Sharp RE (2002) Interaction with ethylene: changing views on the role of ABA in root and shoot growth responses to water stress. Plant Cell Environ 25:211–222

Shinozaki K, Yamaguchi-Shinozaki K (2000) Molecular response to dehydration and low temperature: differences and cross-talk between two stress signaling pathways. Curr Opin Plant Biol 3:217–223

Siewers V, Kokkelink L, Smedsgaard J, Tudzynski P (2006) Identification of an abscisic acid gene cluster in the grey mold Botrytis cinerea. Appl Environm Microbiol 72:4619–462

Timmusk S, Nicander B, Granhall U, Tillberg E (1999) Cytokinin production by Paenibacillus polymyxa. Soil Biol Biochem 31:1847–1852

Zeevaart JAD, Creelman JA (1988) Metabolism and physiology of abscisic acid. Annu Rev Plant Physiol Plant Mol Biol 39:439–473

Acknowledgements

This research was supported with grants from CONICET and Secyt-UNCu to R.B and P.P.R. Bottini and P. Piccoli are fellows of CONICET. A. Cohen is recipient of a post-doc scholarship from CONICET.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cohen, A.C., Bottini, R. & Piccoli, P.N. Azospirillum brasilense Sp 245 produces ABA in chemically-defined culture medium and increases ABA content in arabidopsis plants. Plant Growth Regul 54, 97–103 (2008). https://doi.org/10.1007/s10725-007-9232-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10725-007-9232-9