Abstract

One of the most important parameters specially in mining and oil drilling fields is the type of rocks. It is important to determine that rock structure is in which of the three categories of igneous, metamorphic, and sedimentary rocks. By identifying and determining the characteristics of the rocks with an accurate method, it is possible to complete the exploration information or selecting the appropriate operating parameters such as drill bit, ROP for real-time optimizing the drilling operation. One of the most accurate methods used in various engineering fields is the use of acoustic signals processing. The acoustic signals can be applied to get useful information about operating parameters. The purpose of this paper is rock type identification while drilling operation. For this purpose, 9 various rock samples with different types and properties were selected and prepared for laboratory-scale drilling tests. After the drilling tests, acoustic signals were analyzed and interpreted. The time domain, frequency and time–frequency spectrums of each acoustic signal were analyzed. Fast Fourier Transform and Short Time Fourier Transform algorithms used to determine the distinctions of dominant frequencies and selected frequency bands for the rock type determination. According to the results obtained from time–frequency Spectrum, it can be maintained that by investigating and analyzing the frequency behavior of different rocks, the rock type can be detected. This can be very useful and important for rock type identification in early phases of the projects, oil drilling, deep excavations, or projects without exploration information or to complete and update the geological data.

Graphic Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

One of the most useful techniques in engineering fields is using acoustic emission. In recent years, the use of acoustic waves has increased in various equipment or tools. Acoustic waves are produced in materials such as rock when stored strain energy is released. These elastic waves propagate in material and can be detected by different AE sensors. AE sensors can be directly attached to the surface of the monitored material. The study and signal processing of these elastic waves are known as Acoustic Emission Technique (AET) (Garate-Penaranda et al. 2016; Hampton et al. 2018). This technique is considered as a reliable and non-destructive technique. AET has different applications in various fields of engineering. as shown in Fig. 1, the applications of acoustic waves can be generally classified into three categories (Lu et al. 2017).

Three main groups of AE applications (Khoshouei and Bagherpour 2019)

The first application of acoustic waves is in prediction. So far, several studies have been carried out on the use of AE in the prediction of various properties such as the physical and mechanical properties of rocks. In this area, during an operation such as the drilling process, acoustic sensors are used to record the acoustic waves (Kumar et al. 2019). Subsequently, by using the signal processing methods, various parameters such as sound pressure level or dominant frequencies are extracted and analyzed to predict rock parameters. Table 1 shows 2 examples of studies in the prediction of the rock properties from dominant frequencies in mining engineering. The relations between dominant frequencies and rock properties with their R2 are shown. R2 or the coefficient of determination is a statistical measure in a regression model that determines the proportion of variance in the dependent variable that can be explained by the independent variable. In other words, this parameter shows how well the data fit the regression model (the goodness of fit) (Cameron and Windmeijer 1997).

One of the challenges of almost all engineering fields is how to find a low cost, accurate and reliable method for fast monitoring of equipment. There are various cases that have used AE analysis for monitoring. In these cases, AE sensors such as vibration or acoustic sensors installed, then by analyzing the collected signals, operation parameters can be extracted from the condition of different parts, which can be helpful for condition monitoring of different equipment (Chen et al. 2018; Kong et al. 2015; Susanto et al. 2018). One of the most important diagnostics that can be done during drilling operations is to identify the type and characteristics of the rocks during the drilling process. This can be helpful in the proper implementation of the drilling by selecting and using the correct drilling parameters, such as WOB, ROP, the completion or correction of exploration data, and the selection of extraction sequence or blasting materials. AET can be used as a powerful tool for assessing the optimal operating state or energy consumption of a process (Filipussi et al. 2015).

Boness et al. (1991) used acoustic waves for the examination wear properties. The results of this study showed that the time-dependent components of acoustic signals can be used to distinguish the effect of wear (Boness and McBride 1991). Another notable work in this area is the analysis of acoustic signals in the drilling process. After recording the acoustic signals, signals were evaluated and analyzed, and the dependencies between the input parameters and the acoustic signal characteristics were illustrated (FUTÓ et al. 2005). Zborovjan et al. studied the acoustic signals for identification of rocks during the drilling process (Zborovjan et al. 2003). They maintained that since drilling is a high-energy operation, it is essential to optimize the drilling rate for minimum energy consumption. They added that knowing the rock type is important for this optimization as it determines the ROP that is more suitable for optimizing energy consumption. One way to determine the type of rocks is to analyze the acoustic signal generated during the different operations. Hence, this study attempted to identify the specific acoustic effects that can be related to the type of rocks. Williams and Hagan investigated how the type of acoustic signal changes with the rock cutting conditions. In this study, they observed changes in the signal nature depending on the use of worn or new tools, the depth of cutting, and the damping of the acoustic signal with distance. It was also found that any change in cutting conditions had significant impacts on AE signals (Williams and Hagan 2006). In 2007, Vardhan and Murthy conducted laboratory research that examined the acoustic effects of drilling with a jackhammer drill in rocks with different strengths. This research concluded that sound level variations depend on several properties such as UCS and abrasion of the rock. In this research, five different rock samples were used to examine the variations of the sound level nearby the drill bit (Vardhan and Murthy 2007). Karakurt et al. conducted an empirical and statistical analysis on the noise level generated during rock cutting with diamond saw blades. In this research, the effect of operating variables and rock properties on the noise properties was investigated. In this study, it is showed that higher cutting speeds and cutting depths correspond to higher noise levels. Also, the noise level decreased with the increase of the cooling fluid flow rate (Karakurt et al. 2013). Kawamura (2017) used the AE to determine the button bits break in hard rock drilling. In this study, this analysis was performed using time series analysis, FFT, and WT. The experimental results of this study showed that the WT provided a better estimation of the button bit breaking moment than FFT. Ultimately, it was suggested that the noise generated during drilling operations can be applied for the evaluation of drill bit condition (Kawamura et al. 2017). Qin (2018) investigated the relationship between rock properties and the features of vibration and acoustic signals. For this purpose, they used a rock drilling vibration system and used it to perform a series of drilling tests. This study found that vibration and acoustic sensors can be used to identify the characteristics that can be related to the type of rock in the drilling operation. Qin et al. also demonstrated that the acoustic signals collected from drilling in four different types of rock had different spectral characteristics. This study also reported that the acoustic sensor offers a better signal-to-noise ratio than the vibration sensor, which makes it more useful for the analysis of spectrum properties (Qin et al. 2018). In 2017 and 2018, Yari et al. studied the application of the acoustic signals in small scale drilling for determining the relationship between physical and mechanical properties of various rock samples and the dominant frequencies of acoustic signals. After performing the drilling tests, acoustic signals were analyzed to predict UCS, TS, P-wave and S-wave velocity, and porosity. These studies demonstrated the existence of an acceptable relationship between the physical and mechanical properties of rocks and the dominant frequencies of acoustic waves (Yari and Bagherpour 2018a, 2018b). In 2018, Buj-Corral et al. used FFT and HHT for spectral analysis of signals obtained from the cutting machine. After extracting the frequency-based characteristics, AE analysis was used for real-time assessment of the cutting machine. The results of this study suggest that the optimal cutting condition can be achieved using the signal characteristics (Buj-Corral et al. 2018). Khoshouei and Bagherpour in 2020 predicted 3 mechanical properties of hard rocks during the laboratory scale drilling process. They investigated the relationship between Uniaxial Compressive Strength (UCS), Brazilian Tensile strength (BTS) and Schmidt rebound number (SRN) and acoustic parameters include Sound Pressure Level (SPL), First Dominant Frequency (FDF), and Vibration Level (VL). Results of statistical analysis showed that there is an acceptable correlation coefficient between rock properties and properties of acoustic and vibration signals of the rock drilling operation (Khoshouei and Bagherpour 2020).

From studies in various fields, it can be understood that the use of acoustic signals generated in different processes can be concluded that by employing a suitable method for signal processing and extracting their properties such as the dominant frequencies can be very useful. By using these methods, many of the work required in the operations can be eliminated, which can speed up decision making and increases the accuracy and reliability of the various operations. It can be concluded that the use of acoustic signals in different processes can be very useful by employing a suitable technique for signal processing and extracting their parameters such as the dominant frequencies.

2 Materials and Methods

2.1 Rock Samples and Their Physical and Mechanical Properties

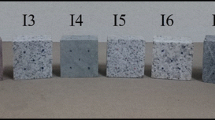

For determining the effect of rocks type and their properties on the acoustic signals at first, 9 different rock samples, including 3 igneous rock samples, 3 metamorphic rocks, and 3 sedimentary rocks or travertine, were prepared for drilling tests and determining their properties. Figure 2 shows the rock samples and Table 2 shows the type and properties of the rock samples used for laboratory-scale drilling tests. All rock samples are prepared in the form of cubes with dimensions of 9 × 9 × 9 cm for drilling tests. These dimensions are considered constant in all experiments.

2.2 Rotary Drilling Tests

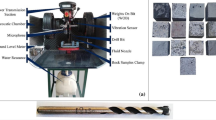

The drilling tests were performed on rock samples by a laboratory scale drilling machine. Figure 3 shows the laboratory scale drilling machine in details. As shown in Fig 3 parts as follows: the weights on the drill bit, the drill fluid inlet section with collection source, the main engine that performs the rotation of the drill bit, a rock clamp with an acoustic and a sensor section including a wideband acoustic condenser microphone and a sound level meter to measure the sound pressure level (SPL) of acoustic signals while drilling of each rock sample.

Table 3 describes signal measurement equipment and parameters of the drilling process performed on rock samples.

3 Results and Discussion

Since rock type determination is very important in mining and civil projects, and especially in processes such as drilling, in this paper, the possibility of using acoustic signals generated during the drilling operation is evaluated for determining the rock type. For this purpose, methods include the analysis and comparison of the distribution of sound pressure levels in the time domain, signal frequency analysis and 2D frequency analysis (STFT) have been used. The procedure for the proposed method is summarized in Fig. 4.

Initially, the sound level generated in the entire drilling process of each rock sample was recorded with a sound level meter. Figure 5 shows a comparison of the sound level distribution during the drilling process of each rock. The statistical characteristics of the sound pressure and the variables of the distribution functions are presented in Table 4.

It is observed from the sound level distributions that the intensity distribution of sounds is different in each rock type. In general with increasing with the hardness of rocks the sound level being highest, But this is not always the case. Distribution in sedimentary rock samples is highest, In this type of rock, a wider range of sound levels is observed. In metamorphic rocks, the distribution is medium and the other distribution is also related to igneous rocks, Which focuses on the level of sound in a narrow and high range. Comparison and analysis of the sound pressure level distribution of different rocks show that it is not possible to clearly express the type of rocks only with the time distribution graph or distribution function. After analyzing the time domain signals, the acoustic signal frequencies were compared to the dominant frequencies of each rock. The frequency spectrums of rocks is shown in Fig. 6.

The dominant frequencies were obtained from the frequency spectrum of each rock by using the FFT method. It was observed that the dominant frequencies or frequencies with the highest energy are varying in different rocks. Generally, It can be observed that the dominant frequencies of igneous rocks, are higher than metamorphic rocks and metamorphic rocks have a higher frequency than sedimentary rocks. Figure 7 shows the five dominant frequencies of the acoustic signals spectrums comparatively.

Based on the comparison of the dominant frequencies of each rock, it can be observed that by comparing the dominant frequencies of each rock, no distinction can be seen between the different rock types. In general, the dominant frequencies of igneous rocks are greater than the metamorphic rocks and metamorphic rocks are more than sedimentary rocks. But the type of rocks cannot be detected only by examining the dominant frequencies. The effectiveness of a simple signal processing technique in a single domain, either the time domain or frequency domain, is not sufficient to provide reliable results for practical applications. The time–frequency methods can reflect the frequency variations of a non-stationary signal over time (Chen et al. 2019). To evaluate and identify the type of rocks, the frequency spectrum of the signals, the time and frequency domain of each signal and the time–frequency analysis were used. Figures 8,9 and 10 show the time spectrum, the frequency domain and the time–frequency spectrum of the rocks simultaneously. In these figures, the first part shows the acoustic signal in the time domain, which the horizontal axis is the time in seconds, and the vertical axis is the amplitude of sound pressure in Pascals. The second part of the graphs is the time–frequency spectrum of acoustic signals. To get the time–frequency spectrum, the Short-Time Fourier Transform or STFT was applied, finally, The third part is the frequency spectrum of the signal used by the Fast Fourier Transform (FFT). The FFT method is an estimate of the Fourier transform or FT. The Fourier transform method is a representation of a signal in the frequency domain (frequency spectrum) to estimate the power and identify the frequencies in the signal spectrum (Nussbaumer 2012). The FFT method is known as a more efficient and faster method than the FT method, which processes the signal at discrete times. In this way, the signal is divided into limited time intervals called frame or window, then each of these sections is independently converted to the frequency domain and processed. In normal signal processing, the signal must first be converted from analog to digital. For this purpose, Discrete Fourier Transform or DFT is used. Equation 1 shows the discrete fourier transform (Welch 1967).

Which in this equation: x(nT): the sampling time signal, ω: frequency, and nT: discrete-time (sampled time).

FFT method is one of the most useful methods for processing various signals such as vibration signals, acoustic signals, and biomedical signals, there are also disadvantages (Goyal and Pabla 2016). One of the disadvantages of this method is that, over time, signal changes can not show the frequency, which makes it impossible to simultaneously conduct many processes in this way. To solve these problems, using the time–frequency (or 2D spectrum) analysis method, which simultaneously displays the time and frequency, is considered. The time–frequency spectrum yields useful information about the frequency that can be useful for cases such as condition monitoring or detection.

By investigation of the time–frequency spectrum of each rock, it can be seen that each rock has significant frequency behaviour. In igneous rock samples, the dominant frequencies are mostly in narrow strips and are very much more intense than other frequencies and are spaced apart at specific intervals. Also, the dominant frequencies are stable, so they are present during the spectrum. In metamorphic rocks at the beginning of the collision of drill bit and rock, the intensity of the frequency is very high, and then, with the completion of the collision, the intensity of the frequencies is stabilized. There is also a cyclic behaviour that can be related to rocks with different mineral contents and particle size distributions during each cycle. In sedimentary rocks, the frequencies initially have more intensity and then become less frequent. Generally, in these rocks, energy is less intense than igneous rocks and metamorphic rocks, and the frequency reduction behaviour of metamorphic rocks is less. Table 5 Describes the frequency spectrums. As shown in this table, the frequency spectrum of the signals is divided into 5 frequency bands, and the time behaviour of the frequencies is analyzed in each band.

4 Conclusions

One of the most important material properties in mining and civil projects is the type of materials. This parameter is also vital in exploitation and in oil drilling fields. By detecting the characteristics of the rocks with high speed and reliability, during the drilling operation (real-time process), it is possible to complete the exploration information, selecting the appropriate operational parameters, selecting the best operation conditions such as drill bit speed, ROP, type of cooling fluid. This paper describes the use of acoustic signals to detect the type and estimate material properties while drilling operations. For processing and extracting the acoustic signal characteristics, a wideband acoustic condenser microphone and a sound level meter were used and acoustic signals were recorded during the laboratory scale drilling operation. Evaluations were conducted in three steps. The first step was to compare the time distribution of sound pressure levels of each rock. The results of this part showed that it is not possible to determine the type of rocks with drilling sound pressure level. The next process was about frequency analysis of signals. The frequency spectrum of each signal was obtained and the dominant frequencies with the highest energy intensities were extracted. Typically, the dominant frequencies of igneous rocks are higher than metamorphic rocks and metamorphic rocks are higher than sedimentary rocks, but with the dominant frequencies of a single rock, it is hard to identify its type. The next part for distinction of the rocks was the Time–Frequency spectrums (STFT method) of drilling operation. The results show that the spectrum of each rock is distinct from the other rocks, but in each rock type, the states of the spectra are like each other. For example, in igneous rocks, the frequencies are very intense and they are striped and strong at equal intervals. Also, frequencies with the highest sound intensity are sustained throughout the drilling. In metamorphic rocks, the intensity of frequencies is less than igneous rock, and they appear only at the beginning of drilling. After the full collision of drill bit and rock, they are cyclic, which can indicate the heterogeneity of the rock texture, in other words, there are minerals with different particle size and properties in the rock texture. In sedimentary rocks, the behaviour of decreasing frequency intensities is also observed. The dominant frequencies of each rock are distinct from other rock types that can be used to determine and predict the properties of rocks but can not be classified by comparing the dominant frequencies of each of the rocks. The results of this paper show that it is possible to install acoustic sensors on drilling machines and process the propagated acoustic signals to detect type of rocks. This detection can be useful in operations with little information about drilling materials, or choosing the appropriate operation parameters. This method, in addition to being a novel method, with high accuracy, reliability and low cost, can accelerate and improve decisions during the drilling process. This eliminates human error and increases operational efficiency. One of the researches that can be done in the future is to evaluate more rock samples with wide properties to get a comprehensive understanding of the acoustic behavior of different rocks. It is also recommended to use this method in field drilling machines, which requires the identification and detection of environmental noise factors, which are sometimes high ambient noise. In this case, it is necessary to identify and detect the signals produced by the collision of the drill bit with the rock, using signal processing techniques, to identify the rock type.

Abbreviations

- 2D :

-

Two-Dimensional

- AE :

-

Acoustic Emission

- BTS :

-

Brazilian Tensile Strength

- FFT :

-

Fast Fourier Transform

- H :

-

Hardness

- ROP :

-

Rate of Penetration

- STFT :

-

Short Time Fourier Transform

- UCS :

-

Uniaxial Compressive Strength

- Vp :

-

P- wave Velocity

- Vs :

-

S- wave Velocity

- WT :

-

Wavelet Transform

- WOB :

-

Weights on Bit

- ρ :

-

Density

References

Boness R, McBride S (1991) Adhesive and abrasive wear studies using acoustic emission techniques. Wear 149:41–53

Buj-Corral I, Álvarez-Flórez J, Domínguez-Fernández A (2018) Acoustic emission analysis for the detection of appropriate cutting operations in honing processes mechanical systems. Signal Process 99:873–885

Cameron AC, Windmeijer FA (1997) An R-squared measure of goodness of fit for some common nonlinear regression models. J Econ 77:329–342

Chen J, Chen H, Xu J, Wang J, Zhang X, Chen X (2018) Acoustic signal-based tool condition monitoring in belt grinding of nickel-based superalloys using RF classifier and MLR algorithm. Int J Adv Manuf Technol 98:859–872

Chen Y, Li H, Hou L, Bu X (2019) Feature extraction using dominant frequency bands and time-frequency image analysis for chatter detection in milling. Precis Eng 56:235–245

Filipussi DA, Guzmán CA, Xargay HD, Hucailuk C, Torres DN (2015) Study of acoustic emission in a compression test of andesite rock Procedia. Mater Sci 9:292–297

Futó J, Kostúr K, Kačur J (2005) Control and optimisation of rock disintegration based on acoustic background of drilling machine. Ann Univ Craiova 1:40–42

Garate-Penaranda K, Pretz T, Nienhaus K (2016) Pattern recognition, classification and diagnosis of acoustic emission signals in applications for mining. vol RWTH-2016–03619. Institut für Maschinentechnik der Rohstoffindustrie

Goyal D, Pabla B (2016) The vibration monitoring methods and signal processing techniques for structural health monitoring: a review. Arch Comput Methods Eng 23:585–594

Hampton J, Gutierrez M, Matzar L, Hu D, Frash L (2018) Acoustic emission characterization of microcracking in laboratory-scale hydraulic fracturing tests. Los Alamos National Lab.(LANL), Los Alamos, NM (United States)

Karakurt I, Aydin G, Aydiner K (2013) Predictive modelling of noise level generated during sawing of rocks by circular diamond sawblades. Sadhana 38:491–511

Kawamura Y, Jang HD, Hettiarachchi D, Takarada Y, Okawa H, Shibuya T (2017) A case study of assessing button bits failure through wavelet transform using rock drilling induced noise signals. J Powder Metall Min 6:1–6

Khoshouei M, Bagherpour R (2019) Application of acoustic emission (AE) in mining and earth sciences: a review. Rudarsko-geološko-naftni zbornik 34:19–31

Khoshouei M, Bagherpour R (2020) Predicting the geomechanical properties of hard rocks using analysis of the acoustic and vibration signals during the drilling operation. Geotech Geolog Eng 39:1–13

Kong X, Wang E, Hu S, Li Z, Liu X, Fang B, Zhan T (2015) Critical slowing down on acoustic emission characteristics of coal containing methane. J Nat Gas Sci Eng 24:156–165

Kumar BR, Vardhan H, Govindaraj M (2010) Estimating rock properties using sound level during drilling: field investigation. Int J Min Miner Eng 2:169–184

Kumar CV, Vardhan H, Murthy CS, Karmakar N (2019) Estimating rock properties using sound signal dominant frequencies during diamond core drilling operations Journal of Rock Mechanics. Geotech Eng 11:850–859

Lu W, Zhang Y, Yan P, Chen M, Wang G, Leng Z, Hu H (2017) The influence of flowing water coupling condition on the result of rock mass acoustic test. Bull Eng Geol Env 76:1449–1459

Nussbaumer HJ (2012) Fast fourier transform and convolution algorithms. Springer Science & Business Media, Berlin, p 2

Qin M, Wang K, Pan K, Sun T, Liu Z (2018) Analysis of signal characteristics from rock drilling based on vibration and acoustic sensor approaches. Appl Acoust 140:275–282

Susanto A, Liu C-H, Yamada K, Hwang Y-R, Tanaka R, Sekiya K (2018) Application of Hilbert-Huang transform for vibration signal analysis in end-milling. Precis Eng 53:263–277

Vardhan H, Murthy CS (2007) An experimental investigation of jack hammer drill noise with special emphasis on drilling in rocks of different compressive strengths. Noise Control Eng J 55:282–293

Welch P (1967) The use of fast Fourier transform for the estimation of power spectra: a method based on time averaging over short, modified periodograms. IEEE Trans Audio Electroacoustics 15:70–73

Williams E, Hagan P (2006) Observations on the variation in acoustic emissions with changes in rock cutting conditions. Paper presented at the coal operators' conference

Yari M, Bagherpour R (2018a) Implementing acoustic frequency analysis for development the novel model of determining geomechanical features of igneous rocks using rotary drilling device. Geotech Geolog Eng 36:1805–1816

Yari M, Bagherpour R (2018b) Investigating an innovative model for dimensional sedimentary rock characterization using acoustic frequency analysis during drilling. Rudarsko-Geolosko-Naftni Zbornik 33:17–25

Yari M, Bagherpour R, Khoshouei M (2019) Developing a novel model for predicting geomechanical features of carbonate rocks based on acoustic frequency processing during drilling. Bull Eng Geol Env 78:1747–1759

Zborovjan M, Lesso I, Dorcak L (2003) Acoustic identification of rocks during drilling process. J Acta Montan Slov 8:91–93

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khoshouei, M., Bagherpour, R. & Jalalian, M.H. Rock Type Identification Using Analysis of the Acoustic Signal Frequency Contents Propagated While Drilling Operation. Geotech Geol Eng 40, 1237–1250 (2022). https://doi.org/10.1007/s10706-021-01957-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-021-01957-y