Abstract

For improving the stability and load carrying capacity of weak subgrade, strengthening methods are to be followed in the field. Among the various approaches, geocells have been identified as an effective soil reinforcement technique for improving soft subgrade behaviour. The three-dimensional honeycomb structure of geocell offers more lateral confinement to the infill soil resulting in improved load carrying capacity. This led to the widespread use of geocells for different geotechnical applications like pavements, foundations, embankments, slope protection, erosion control etc. Many researchers in the past have confirmed the suitability of geocell reinforcement through their experimental, numerical and field studies. In this paper, a comprehensive review of the reinforcement mechanisms, design aspect and numerical modelling techniques of geocell reinforced soil is provided. In addition, this paper highlights the various field application scenarios where different types of geocells have been used and explores the research challenges and scope for further research in this field.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Construction over weak foundation soil is a challenging task for engineers because of its poor bearing capacity, and high compressibility. Such soils need treatment prior to the superstructure construction. Evolution of different techniques for improving the properties and behaviour of soil arise from these challenges. The selection of a method is based on the type of soil, design requirement of structure etc. Among the different techniques, the soil reinforcement is popular worldwide because of its simplicity and economic aspects (Vidal 1969; Binquet and Lee 1975; Paul 1988). Here load-bearing elements with good tensile strength and stiffness are embedded in the soil as reinforcements. Though the soil is weak in tension, the large tensile stress coming in the soil can be taken up by these reinforcing materials. Straws, reeds, bamboo etc. were used as soil reinforcements in the beginning.

The effective use of geosynthetic products as reinforcement has been identified since the 1970s. Geosynthetic products are usually manufactured from polymeric materials like HDPE. Different forms of reinforcement like planar, bars, strips etc. are effective as soil reinforcements (Jones 1996). With regards to the effectiveness, the more attractive are cellular systems owing to their 3D structure compared to planar geosynthetic reinforcements (Mhaiskar and Mandal 1996; Latha and Vidya 2007; Sireesh et al. 2009b; Tafreshi et al. 2013; Biswas et al. 2013; Tanyu et al. 2013). Geocell is a honeycomb structured polymeric cellular system, connected by joints (Bush et al. 1990; Dean and Lothian 1990; Cowland and Wong 1993; Lambert et al. 2011). Combination of two parts- “geo” means soil or earth and “cell” means a cellular type of shape for infill material such as soil, formed the word geocell.

The geocells enclose weaker materials like soil, stones etc. and their 3D structure provides all-round confinement. The combination of geocell and the fill material which acts as a reinforced composite is characterised by improved stiffness and strength to that of unreinforced soil. The composite system also ensures better distribution of the incoming load to a wider area by preventing lateral material spread.

Geocells are now widely used for different geotechnical applications like earthen embankments, retaining walls, slope stability etc. because of its simplicity and effectiveness as a soil reinforcement (Bathrust and Jarrett 1988; Dash et al. 2003). Geocells exist in various dimensions, and facia colours suiting different project needs, materials used are eco-friendly and offer high strength to weight ratio and durability. Studies have shown that geocells offer an enhancement in structure reliability and life, high degree of protection for the impermeable layers, cost-effectiveness compared to other products, serves as a working platform and saves construction time, enhances the soil bearing capacity and facilitates gradual settlements and reduces lateral deformations, functions as embankment base with improved stiffness and rigidity enhancing the stability(Latha 2000; Latha et al. 2006; Pokharel et al. 2010; Dash and Bora 2013; Sitharam and Hegde 2013; Tafreshi et al. 2013; Hegde and Sitharam 2015a). The long term performance of the resin which is used to make the geocell and the additives added, should be appropriately tested. Also, quality control must be assured to handle, store, and install geocells in the field (IGS 2018).

2 History of Geocells

To construct bridge approach roads over weak subgrade, for the smooth movement of military vehicles, different studies were carried out by U. S. Army Engineer Waterways Experiment Station on soil reinforcement methods in the late 1970s (Webster and Watkins 1977; Webster 1979).

Webster and Watkins (1977) placed different types of materials such as crushed stone, wire gabions with rock, sand confinement system, pervious polyester fabric, impervious coated nylon membrane as base reinforcement over clay subgrade in unpaved roads and compared the rut depth after traffic loading with that of the unreinforced base. The studies concluded that the sand base course reinforced by isolated plastic tubes performed better than the conventional base course with crushed stones. Square shaped grids filled with sand, called “grid cell confinement system” were developed after this study. Laboratory experiments were conducted (Rea and Mitchell 1978; Webster 1979) to investigate different parameters such as material, size and shape of the grid, subgrade stiffness, sand-grid layer thickness, properties of sand, compactive effort, loading etc. that can affect the performance of reinforced soil. Analytical formulas were developed based on the experimental results to predict the capacity of a reinforced base course (Mitchell et al. 1979) by considering different failure modes. Initially, paper and aluminium were used to make grid cells, and later Webster (1979) suggested plastic as grid material due to the many drawbacks of these materials. Polymeric materials, generally known as “geocell” were introduced in cellular confinement system in the 1980s. Later, materials like HDPE (high-density polyethylene) with low-temperature flexibility came into being (Pokharel et al. 2010; Yang et al. 2010).

3 Reinforcement Mechanism of Geocell

Many researchers tried to explain the reinforcing mechanism of geocells based on their experimental and numerical studies. Predominantly, geocell reinforcements were used to support loads besides improving the performance of soft soil.

The three-dimensional honeycomb structure of geocells confines the soil present in the pockets. The applied load will induce pressure inside each cell of the geocell. Induced stress causes lateral movement of the confined soil, which will exert pressure on the geocell walls. Thus, deformation of the geocell membrane takes place. Due to the circumferential deformation, the stress in the geocell membrane gets mobilised and therefore, confinement pressure of soil increases (Bathurst and Karpurapu 1993). The three-dimensional confinement restricts the lateral movement of the infill soil that results in more stable and stiffer composite structure (Fig. 1).

The stiffer composite structure redistributes the load to a wider area, resulting in decreased stress on the weak subgrade (Dash et al. 2007). This triaxial state of confinement results in increased shear strength and resistance to deformation. The interlocking and frictional resistance between the surrounding soil and geocell wall also leads to higher load carrying capacity.

Geocell walls cut the potential failure plane and push it to a greater depth into the soil due to its rigidity (Krishnaswamy et al. 2000; Dash 2012; Biswas et al. 2016). The position of the failure plane after loading for both unreinforced and geocell reinforced foundation bed is shown in Fig. 2. The geocell induces apparent cohesion to the soil which is responsible for the strength increment (Rajagopal et al. 1999). The geocell contributes to the increased confining stress onto the fill material which is influenced by the tensile modulus of the geosynthetic material from which geocell is formed.

Position of failure surface on load application for a unreinforced and b reinforced foundation beds (After Biswas et al. 2016)

4 Installation of Geocell Mattress in the Field

Bush et al. (1990) described the procedure for construction and installation of geocells in the field as described below. Before the construction of the geocell mattress, the ground has to be cleared and levelled. After that, basal geotextile material is laid on the ground by keeping minimum overlapping distance between adjacent rolls. Over the basal layer, another geogrid sheet is laid in a transverse direction with one end stitched to the bottom layer. The transverse member is rotated about the stitched end to make it vertical and temporarily tensioned with the help of timber posts. The procedure is repeated to cover the entire area. In between two transverse members, another layer of geogrid was positioned, and it connected with a transverse sheet with hooked steel bars known as bodkin joints (Carroll Jr. and Curtis 1990; Simac 1990). The cellular structure is formed by the bodkin joints, and a suitable material is filled inside the pockets.

Different types of readymade geocells are presently available, and based on the design requirements they can be suitably selected and stretched in the ground as a geocell mattress. Geocells can be manufactured from solid or perforated high-density polyethylene sheets and welded together to form the honeycomb structure typically of 100–200 mm height (Bathurst and Rajagopal 1993). If the height required is more, they are fabricated directly at the site using planar geogrids connected by bodkin joints (Bush et al. 1990).

5 Applications of Geocell

Yadav et al. (2014) reviewed different applications of geocell in the field of geotechnical engineering. They reported the mechanism, field installation and the various applications of geocell reinforcement. Geocells have been used for different type of structures such as embankment, foundation, reinforced wall, slope stability and erosion control. They also mentioned the necessity of further studies to evaluate the application of geocells in other fields. Dhane et al. (2015) discussed the importance of geocells in civil engineering field from the studies conducted by various researchers. They reported different applications and basic mechanisms of geocells and confirmed the cost-effectiveness and versatility of geocells.

5.1 Waste Containment System

Nowadays application of geosynthetic products in waste containment system as liners, cover systems, leachate collection system, cut off wall systems, etc. became common practice (Giroud and Cazzuffi 1989; Koerner 1990; Daniel and Bowders 1996; Rowe 1998). Hendricker et al. (1998) and Bouazza et al. (2002) investigated the effectiveness of geocell mattress as a cover system for hazardous waste containment system in Southern California. They reported that by means of stiffness, geocells could distribute loads to a wider area and also chemical compatibility of geocells proved its stress resistance to the waste exposure.

5.2 Pavement and Road Construction

Many researchers have stated the successful application of geocell mattress in road construction and pavements (Dash et al. 2008; Rajagopal et al. 2014; Pokharel et al. 2015). The ability of geocells to transfer vertical stresses to a wider area makes construction possible even over soft soil subgrade. Moreover, they raise the layer modulus, thereby lowering the surface deflection.

The suitability of geocell in Asphalt pavement was investigated by Thakur et al. (2012) and reported that their enhanced performance compared to unreinforced base layers, and Emersleben et al. (2008) enumerated that the presence of geocell layer in the gravel base reduces the vertical stresses on the subgrade to be around 30 percent of traffic.

Culverts were structures used in drainage and road works. Successful application of geocells in the construction of box culverts was reported by Gupta and Somnath (1994) in Bombay. A marine clay layer of 6 m was reported on the site. First tubular gabions, resting on hard mooram layer were constructed. Over the gabion layer, a geocell mattress was placed. With this arrangement, considerable improvement in the load carrying capacity of the clay bed was obtained.

5.3 Foundation

In the present scenario, the construction of the foundation over weak, soft soils is highly challenging. The construction of foundations can be done either by conventional methods like piles, rafts, etc., or by improving soil properties. Also, geosynthetic materials were used to stabilize the weak soil deposits (Alawaji 2001; Basudhar et al. 2007; Sitharam and Sireesh 2004). Compared to unreinforced soil base, footing on geocell reinforced soil exhibits higher bearing capacity and reduced settlement. 3D confinement action of geocells forms a rigid composite that has a higher load-bearing capacity (Latha et al. 2008, 2009; Latha and Somwanshi 2009; Hegde and Sitharam 2013, 2015a, 2017; Moghadas et al. 2015b). Many researchers have substantiated it through laboratory model tests over different types of footings (Mandal and Gupta 1994; Dash et al. 2001a, b; Sitharam and Sireesh 2005; Sitharam et al. 2005; Sithram and Sireesh 2006; Sitharam et al. 2007; Sireesh et al. 2009a; Dash et al. 2010; Pokharel et al. 2010; Dash 2012; Sitharam and Hegde 2013).

5.4 Embankment

Embankment construction over weaker subgrades suffers several flaws, which can be either during pre-construction (incapability of the soils to support the construction equipment) or post-construction (excessive settlement of the weaker soil after construction). Considering the above-mentioned problems, the usual remedial actions involve the removal of the topsoil and their replacement with stronger and stiffer material. But the method of removal and replacement is suitable only for thickness 2 to 3 m. If the thickness of soft soil is more, other ground improvement techniques like chemical treatment or soil reinforcement will be effective and economical.

The unique features of geocells, like their ability to act as a stiff, rigid base and incoming load distribution to a wider area, make it suitable for countering the inconveniences faced during the construction of embankments over soft soil. Johnson (1982), Bush et al. (1990), Zheng (2009), Zhang et al. (2010) and Latha (2011) have reported the successful application of geocells in embankment construction.

Bush et al. (1990) evaluated the suitability of the geocell mattress for embankment construction over soft soil. The geocell mattress was formed by placing geogrid diagonally between two transverse diaphragms and connected with a hooked steel bar, and granular soil was used as infill material. The geocell mattress load carrying capacity was improved, and the differential settlement was reduced. They reported that geocell mattress not only acts as reinforcement but also as drainage blanket, which helps in the consolidation of soft soil present below. Compared to various traditional construction techniques, this method was found to be most economical. They observed that due to the increased stiffness, a 30 percent cost reduction could be possible with geocells.

5.5 Railway

Many studies were conducted on geosynthetic reinforced railway ballast (Indraratna et al. 2006, 2013; 2015; Indraratna and Nimbalkar 2013; Sireesh et al. 2013; Biabani et al. 2016b). Indraratna et al. (2006) assessed the performance of geosynthetic stabilized ballast in the coastal region of Australia and confirmed the suitability and cost-effectiveness of the reinforcement. The geocell confinement of railway ballast displayed a significant reduction of the vertical deformations, which enabled low-quality material to be used as ballast. Leshchinsky et al. (2012) verified the effectiveness of geocell reinforcement through numerical modelling. From the studies, they found out that geocells effectively confines ballast and thus reduces vertical deformation.

5.6 Slope Protection and Erosion Control

Vegetation is the usual method adopted for slope stability and erosion control. But in steep slopes and high rainfall areas, this method fails to bind the soil particles as a single entity. In such cases, geocells can be used as reinforcement (Boyle and Robertson 2007). They are capable of retaining the soil particles by retarding the surface runoff and subsequently control the soil erosion. The confining effect of geocells in soil erosion control and slope stability was studied by many researchers. Mehdipour et al. (2013) considered both bending and membrane stresses in geocell and modeled geocell as a beam element. They found out that the main parameters of geocell reinforcement responsible for the decrease in the lateral displacements and the increased factor of safety of the slopes were bending moment and tensile strength. Geocell reinforcements mainly control the advancing of failure surfaces and reallocate the loads over a wider area and thus provide slope stability.

5.7 Reinforced Walls

Ling et al. (2009), Chen et al. (2013), Soude et al. (2013), Latha and Manju (2016) reported the use of geocells in retaining structures. The geocells were successfully used as reinforcement layers in gravity walls as well as the facial units in geosynthetic reinforced walls. The geocell reinforced walls constructed over soft compressible foundation soil tolerates large deformation and differential settlement due to the flexible nature of polymeric material. Also, the cell pockets can be used for growing vegetation, which gives a better aesthetic appearance and erosion control. The cellular structure provides lateral confinement to the infill soil by which a stable three-dimensional geocell soil composite structure was formed. The reinforcement mechanism can be explained by the increased confining pressure or the apparent cohesion induced by the geocell. The strength and stiffness of geocells play an important role in the performance of retaining structures.

The geocell reinforcement used in the facia of reinforced walls improves the resistance to the shear failure of soil and provides formwork for placement and compaction of the retained soil. The geocell soil composite structure effectively prevents the unwinding of facial units and provides additional stability (Bathrust and Crowe 1994). Ling et al. (2009) found out that geocell reinforced walls can resist earthquake loading to some extent through their experimental studies using five large-scale retaining walls. Geocells were used for both reinforcing and retaining the soil. The retaining wall performance under seismic load was the maximum when geocell layers were used as reinforcement layers. Also, they reported that in retaining structures, the gravel was best suited as infill material than the sandy soil. The confining effect of geocells was responsible for performance improvement, and it also prevents the structure from collapse.

6 Effect of Different Parameters on the Geocell Reinforcement Performance

Influence of the various parameters on the response of Geocell reinforcement for supporting foundations and for the construction of embankments was briefly reviewed in the following sections. The properties of geocells, as well as properties of native and infill soil, counts for the performance of reinforcement. The effect of various geocell parameters is summarised below.

6.1 Properties of Geocell

6.1.1 Geocell Dimensions

Cell height and width are the two parameters which are used to express the geocell dimensions. According to Rea and Mitchell (1978), the optimum footing diameter is 1.5 to 2.0 times cell width, and the optimum cell height to cell width ratio was 2.25, above which considerable improvement was not observed. Based on laboratory experiments, Mitchell et al. (1979) proved geocell height to width ratio was in between 2 to 3.

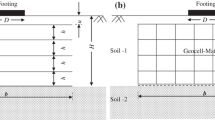

Dash et al. (2001a) performed laboratory model tests on strip footings supported by geocell sand beds with additional planar reinforcement, as shown in Fig. 3. Poorly graded river sand and 35 × 35 mm biaxial geogrid was used for the test with plain strain condition in the test set up.

Schematic view of strip footing supported by Geocell Reinforced foundation bed (After Dash et al. 2001a)

Effect of parameters such as (i) height of the geocell layer (h) and (ii) placement position of planar reinforcements was studied by keeping the pocket size of geocells (d), the width of the geocell layer (b), and depth to the top of the geocell layer from the base of the footing (u) constant. The pressure-settlement response for different width and height of geocell mattresses are depicted in Fig. 4 and 5. Beyond h/ B ratio 2 and b/B ratio 4, bearing capacity change is marginal, where h and b geocell mattress height and width, B is the width of footing.

Pressure-Settlement response for different width of geocell mattress (After Dash et al. 2001a)

Pressure-Settlement response for different height of geocell mattress (After Dash et al. 2001a)

From the test results, they concluded that the presence of basal geogrid under geocell mattress increases the load carrying capacity of the footing. But the effect of planar geogrid becomes marginal at large heights of the geocell mattress. Maximum performance increment was obtained for geocell height which is twice the footing width.

In continuation to the above studies, they varied the following parameters-formation of the geocell mattress, pocket-size of geocells (d), the height of geocell layer (h), the width of the geocell mattress (b), depth to the top of the geocell layer below the footing (u), the relative density of soil and type of reinforcement used to form the geocell. It was observed that, though the sand filled in the cell pockets fail, the geocell mattress act as a beam due to its shear and bending rigidity and support footing. Geocell reinforcement enabled the soil to resist failures even at a settlement equal to 50% of the footing width and load as high as 8 times the ultimate bearing capacity of the unreinforced sand. From Figs. 4 to 5, the maximum performance can be obtained with geocell height equal to twice the footing width, geocell layer width around 4 times the footing width, top of geocell mattress at a depth of 0.1B from the bottom of the footing and by filling the geocells with denser soils. Based on the experimental works on geocell reinforced circular footing, the maximum performance of the foundation in load carrying was observed for geocell layer width equal to the diameter of footing (Dash et al. 2003).

The ratio of geocell height to geocell diameter (h/D), known as the aspect ratio, is a primary factor contributing to the performance of the geocell layer. Higher aspect ratio results in improved bearing capacity of geocell supported embankments, and the improvement is less significant when the aspect ratio is greater than unity (Latha and Rajagopal 2007). Flexural strength of geocells increases with increase in cell height to cell width ratio (Tang and Yang 2013).

When the height of the geocell increases, the number of bodkin joint layers also increases, which in turn makes the geocell mattress a semi-rigid slab with high rigidity (Dash et al. 2001a, 2007). Thus the load can be distributed to a wider area, and the overall performance of the structure improves (Hegde and Sitharam 2015a).

6.1.2 Pattern of Arrangement

Pokharel et al. (2010) performed lab tests on single geocell reinforced bases in pavement and found out that in comparison with an elliptical-shaped geocell, a circular-shaped one has higher stiffness and bearing capacity. Chen et al. (2013) also reported that the highest apparent cohesion was induced by circular-shaped geocells and lowest by hexagonal shape.

Transverse and diagonal geogrids were arranged in different patterns and connected by Bodkin joints to form geocells. Amongst the different patterns, Chevron pattern and diamond pattern are more popular and are shown in Fig. 6. Chevron pattern was found to be more efficient than the diamond pattern of arrangement (Dash et al. 2001b; Rai 2010). The number of joints per area is more for the Chevron pattern; thus, the bending and shearing rigidity is more. Higher rigidity geocell pattern helps to distribute large loads uniformly to the soft foundation soils.

Various geocell configurations a Handmade geocell diamond pattern; b Handmade geocell chevron pattern (After Dash et al. 2003)

6.1.3 Pocket Size of Geocells

Though the actual shape of geocell is triangular, pocket size is expressed in terms of equivalent diameter. To allow for axial symmetry conditions, the triangular area is transformed into a circle of the same cross-sectional area to get the equivalent diameter. The behaviour of reinforced foundation bed is highly depended on the pocket size of geocells.

Rai (2010) reported that a smaller pocket size geocell gives better performance. Confinement per unit volume is more for smaller size pocket, which results in bearing capacity improvement (Hegde and Sitharam 2015b). As per Dash et al. (2003) and Rai (2010), the optimum pocket size was identified as 0.8 D, where D is the footing diameter.

6.1.4 Properties of Geocell Material

Properties of geogrid from which geocell has been formed have a major influence on the performance of the reinforced system. The orientation of geogrid ribs and stiffness were some of the significant parameters. Compared to diamond openings, the square or rectangular openings geogrid give better performance improvement. Also, the bearing capacity of reinforced foundation bed increases with an increase in geocell elastic modulus (Hegde and Sitharam 2015b). It is explained as a higher elastic modulus of geocell material exerts higher confining pressure on infill soil, which leads to bearing capacity increment.

Compared to confined geocell, unconfined geocell has lower stiffness and higher ultimate load capacity (Pokharel et al. 2010). In plate load tests, the geocell that is fully embedded in to the sand is referred to as confined geocell and exposed to air is termed as unconfined.

6.2 Soil Parameters

6.2.1 Interface Friction angle

Textured geocells were found to perform better compared to the smooth-walled geocells as the textured surface provided a higher degree of frictional interaction between the geocell wall and the infill material. The increase in the friction angle caused an only marginal increment in the load carrying capacity for reinforced foundation bed (Hegde and Sitharam 2015b).

6.2.2 Properties of Infill Soil

Granular soils are preferred over cohesive soils as geocell fill material since the confinement effect is more significant in these soils, which leads to a reduction in settlement (Latha and Rajagopal 2007). The relative density of infill material was found to be directly affecting the bearing capacity of footing (Rai 2010; Dash et al. 2001b). Maximum efficiency of geocell can be obtained with denser infill soil.

6.2.3 Embedment Depth

Davarifard and Moghaddas (2015) conducted plate load tests on multi-layered geocell reinforced beds in the field. Most of the experimental works related to geocell reinforcement have been carried out for surface footings, and only a few have considered embedment depth of footing. The influence of the embedment depth on the load carrying capacity of the footing was investigated through a large-scale model test on an embedded square footing. It was observed that the bearing capacity of the footing increased proportionally with an increase in embedment depth ratio (Df/B) [Df is the embedment depth; B is the footing width].

6.2.4 Properties of Native soil

The properties of subsoil have an influence on the performance of the geocell reinforced foundation. The stiffness of the foundation bed is a major factor which determines the percentage of improvement obtained through geocell reinforcement. Higher stiffness subgrade provides more support against settlement to geocell soil composite, which results in reduced membrane resistances and less improvement factor (Biswas 2015). Also, Geocell reinforcement is more effective in soft clay beds than sand beds (Hegde 2013).

6.3 Review of the Optimum Parameters of Geocell for Maximum Performance

Various researchers have reported optimum parameters of the geocell mattress, which gives the maximum performance, and above which improvement is marginal, as summarised in Table 1. The different parameters of the geocell mattress were expressed in terms of either footing diameter or width depends upon type footing.

Properties of geocell as well as infill soil have an influence on the performance of the reinforced foundation system. Various factors like height of the geocell mattress, width of the geocell mattress, pocket-size of geocell, the placement depth below the footing, the pattern of formation, density of infill soil, properties of geosynthetic material from which geocell has formed, etc. have discussed in this section to obtain optimum parameters for effective and economical design, and construction of geocell reinforced system. The type of construction, economy, type of subgrade and its stiffness, etc., affects the quantification of improvement. Geocells can be effectively used as reinforcement both in the case of clay as well as a sand bed. Based on previous studies it can be concluded that the most effective geocell reinforced foundation was obtained with Chevron pattern with 0.8D pocket size, 0.1D placement depth, (4–6)D of geocell width and (1.5–2)D of geocell height, denser infill soil, and textured geocell material, where D is the footing diameter same values can be used for strip footing also by replacing footing diameter by footing width.

7 Design Aspects of Geocell

Geocell was designed as an equivalent material with cohesion greater than the infill soil and friction angle same as that of the infill. Membrane stress in the geocell walls confines the soil particles, which results in apparent cohesion in the soil. The geocell membrane stress caused additional confining stress (∆σ3), which was given by (Henkel and Gilbert 1952),

where εa = axial strain of soil at failure, εc = circumferential strain of soil at failure, Do = initial diameter of geocell pocket, D = diameter of the sample at an axial strain of εa, M = modulus of the membrane, obtained from the load-strain curves of wide-width tensile strength test on geogrids.

Bathurst and Karpurapu (1993) conducted triaxial compression tests on a single cell reinforced granular soil sample. Construction of Mohr circle for both reinforced and unreinforced soil and apparent cohesion estimation is shown in Fig. 7. Because of the confinement effect of geocell, cell pressure σ3 increased to (σ3 + ∆σ3), and normal stress σ1 increased to σr1.

Mohr circles for both reinforced and unreinforced soil and apparent cohesion estimation (After Bathurst and Karpurapu 1993)

Rajagopal et al. (1999) conducted a triaxial test on a single cell, and multi-cell reinforced sand samples and concluded that among different samples, the more accurate value of apparent cohesion was obtained for samples with at least three interconnected cells.

The apparent cohesion induced by the geocell layer (Rajagopal et al. 1999) was given as

here Kp is the passive earth pressure coefficient and \(\Delta {\upsigma }_{3}\) is the additional confining stress due to the geocell membrane stress. The apparent cohesion was added with the original cohesion of infill soil to get the cohesive strength of the reinforced layer.

Mitchell et al. (1979) carried out the first analytical work on geocell reinforced soil. Analytical solutions were developed for obtaining the load carrying capacity of base course reinforced with a grid cell. The method considered a different type of failures such as (a) bearing capacity (b) bending (c) durability failure (d) excessive rutting (e) cell penetration of subgrade (f) cell bursting (g) cell wall buckling. Due to the complex structure of geocell and stress-dependent nature of sand stiffness, the estimation of the modulus of geocell is difficult.

Latha (2000) proposed an empirical relation between modulus numbers of soil:

where Kr and Ke are the modulus number of geocell-soil composite and unreinforced soil, respectively. The Young's modulus parameter (Ke) is the modulus number in the hyperbolic model (Duncan and Chang 1970), and M corresponds to the tensile stiffness of the geocell material.

The equivalent stiffness of geocell reinforced soil is a function of the stiffness of unreinforced soil, secant modulus of geocell material and an interaction parameter in case of multiple cells. A nonlinear empirical equation to express Young’s modulus of geocell-reinforced sand (Eg) is given by (Latha 2000; Rajagopal et al. 2001):

here Pa = atmospheric pressure in kPa,M = secant modulus of geocell material in kN/m. The value of M was obtained from the value corresponding to an average strain of 2.5% in the load elongation curve of geocell material. σ3 = confining pressure in kPa, Ku = Young’s modulus parameter of the unreinforced sand, it’s a dimensionless quantity. n = Modulus exponent of unreinforced soil, dimensionless quantity, determines the rate of variation of Eg with σ3.

Various design methods for geocell supported embankments includes slip line method (Jenner et al. 1988), a method based on Bishop’s slope stability analysis (Latha et al. 2006) and a method based on plane strain finite element analysis (Latha 2011).

Jenner et al. (1988) considered the plastic bearing failure of embankments, which can be expected for embankments with a width of more than four times the foundation soil depth. With the help of a non-symmetric slip line field, the contribution of geocell in bearing capacity was determined. Construction of the slip line makes this method complex.

Koerner (1998) proposed a method for bearing capacity estimation based on plastic limit equilibrium mechanism. He observed that the shear strength between geocell and infill soil was responsible for the strength improvement and considered the geocell as a soil layer with improved strength parameters due to the confinement.

Latha et al. (2006) developed a computer program based on Bishop’s slope stability method for the design of geocell reinforced embankments. In this method, a geocell layer was treated as a soil layer with additional cohesion due to confinement. Input parameters were slope geometry, depth of foundation soil, the height of geocell, shear strength parameters of soil and geocell layer, foundation soil properties, pore pressure coefficients, surcharge pressure on the embankment crest. If all the parameters are known, slope stability analysis can be carried out with a trial height of the geocell layer to get its cohesive strength corresponding to the required factor of safety. After getting the cohesion value, modulus of geocell for a particular geocell size and axial strain can be determined by back-calculation.

Later Zhang et al. (2010) proposed a bearing capacity calculation method for the geocell supported embankments on soft foundation soil. They considered three functioning aspects of the geocell layer which are (a) lateral resistance effect (b) vertical stress dispersion effect as shown in Fig. 8 and (c) membrane effect as in Fig. 9. The increase in bearing capacity can be obtained by summing up all the three mechanisms.

-

(a)

Lateral resistance effect.

Schematic diagram of Lateral resistance effect and Vertical stress dispersion effect (After Zhang et al. 2010)

Membrane effect in the reinforcement (After Zhang et al. 2010)

The shear strength between the geocell wall and the infill soil imparts the lateral resistance component as shown in Fig. 8.

-

(b)

Vertical stress dispersion effect.

Wider distribution of load can be possible because of the three-dimensional structure of geocells which improves the load carrying capacity of foundation soil. The interconnected cells form a panel which acts as a slab and redistribute the applied load. This is known as vertical stress dispersion effect. Due to the vertical dispersion effect, the load per unit area increases from ps to pr, as shown in Fig. 8. The contribution of vertical dispersion effect on bearing capacity, \(\Delta P_{1}\) is given by:

hc and θ are the height and the dispersion angle of geocell reinforcement, respectively, bn = width of the uniform load ps.

-

(C)

Membrane effect.

Due to the loading geocell deflects and generates additional tension force. This force reduces pressure on the foundation soil and thus decreases the vertical deformation and increases the bearing capacity. Membrane effect is due to the vertical component of the mobilized tensile strength (Zhao et al. 2009). The contribution of membrane effect on bearing capacity, \({\mathrm{\Delta P}}_{2}\) is given by:

here, T = tensile strength geosynthetic material. α = Horizontal angle of tensile force T as shown in Fig. 9, bn = width of the uniform load ps as shown in Fig. 8

The sum of above mechanisms gives the bearing capacity increment due to the placement of geocell reinforcement, and the increment in bearing capacity (Δp) was added with the bearing capacity of unreinforced foundation soil (ps) to get the bearing capacity of reinforced foundation soil bed (Prs)

For larger settlements, the method proposed by Zhang et al. (2010) showed better results than the Koerner’s method.

8 Experimental Studies on Geocell Reinforced Soil

Based on various experimental studies conducted by many researchers, the behaviour of geocell reinforced soil was analysed.

Marto et al. (2013) reviewed experimental tests conducted by various researchers on geosynthetic reinforced soils. In geotechnical engineering, conventional building materials are effectively replaced by geosynthetic products in various aspects. They made the following conclusions from their review studies.

-

1.

Efficiency of reinforcement decreases with an increase in height and width of geocell.

-

2.

Optimum width of cellular mattress in the sand is five times the footing width.

-

3.

Geocell reinforcement is more efficient than planar reinforcement in settlement reduction and load carrying capacity.

-

4.

Compared to unreinforced footing geocell supported footings have very less mobilised shear stress ratio.

Mitchell et al. (1979) conducted model laboratory tests on footings resting on sand beds with square-shaped paper grid cells as reinforcement. Influence of parameters such as diameter and height of geocells were investigated. From the experimental results, it was concluded that the substantial increment in elastic modulus of soil could be obtained with geocell reinforcement.

Dash et al. (2004) conducted laboratory model tests to compare the performance of different geosynthetic materials as reinforcements in sand beds under a strip footing. They considered geocell, planar biaxial polypropylene geogrid and randomly distributed mesh elements as reinforcing materials. Plain strain condition was maintained for testing. Based on the experimental results, they concluded that among different geosynthetic materials, geocells were the most effective reinforcement. Geocell reinforced soil was able to resist failures at settlement values equal to about 45% of footing width and the applied load equal to eight times the ultimate capacity of the unreinforced soil while geogrid reinforced soil was able to withstand settlement of around 15% of the footing width and a load equalling four times the ultimate capacity of the unreinforced soil.

Zhou and Wen (2008) studied the problematic soft soil condition for the foundation of Qin-Shen Railway (from Qinhuangdao to Shenyang) in China. The laboratory model test results showed that the provision of geocell reinforced cushion improves the subgrade reaction coefficient corresponds to 30 cm diameter plate, (K30) by 3000%, and reduces deformation by 44%.

Sireesh et al. (2009b) examined the effect of geocell sand mattress provided over clay subgrade with voids. Influence of various parameters such as the thickness of unreinforced sand layer above clay bed, width and height of the geocell mattress, the relative density of the infill soil in the geocells and influence of basal geogrid were studied through laboratory model tests. Clay subgrade was prepared by using natural silty clay of low plasticity (CL). The circular footing was used for loading. Biaxial geogrid with square shape aperture opening size 0.035 × 0.035 m in chevron pattern was used to form geocells and cell pockets were filled by poorly graded sand (SP). From the test results, it was clear that the provision of the geocell mattress improves the load carrying capacity and reduces the settlement of clay subgrade with the void. Geocells are effective only when it spreads beyond the void to a distance equal to the diameter of the void. The load carrying capacity of the foundation is directly proportional to geocell width, geocell layer height, the density of infill soil. Performance improves with increase in geocell width only up to a value of 4.9 times footing diameter, and critical height of geocell layer was found to be 1.8 times footing diameter beyond which performance reduces. If geocell reinforcement were provided with basal geogrid in the granular soil layer overlying soft subgrade with a void, a 3.4-fold improvement in performance could be obtained. The overall load carrying capacity of the footing with a reinforced foundation increased by about 40 times compared to the case of clay subgrade with void alone.

Pokharel et al. (2010) investigated the factors such as elastic modulus of geocell, type of the geocell, the thickness, embedment of the geocell and the infill material quality etc. that influence the performance of single geocell reinforced bases in the pavement. Plate load tests were conducted on a single geocell under static load with two types of infill material. It was observed that higher stiffness and bearing capacity was exhibited by circular-shaped geocell compared to elliptical-shaped geocell and by geocells with higher elastic modulus. Also compared to confined geocell, unconfined geocell has lower stiffness and higher ultimate load capacity.

Tafreshi and Dawson (2010) carried out laboratory model tests on strip footing supported on a reinforced sand bed. Experiments were conducted by using both geocells and geotextiles of same characteristics as reinforcements, and their performances were compared. Parameters such as reinforcement width, the number of planar layers of geotextile and height of the geocell below the footing base were also studied. It was concluded that with the increase of these parameters, the efficiency of reinforcement decreases. They suggested an optimum depth of the topmost geocell layer as 0.1 times footing width. They confirm the suitability of geocell over conventional planar geosynthetic materials. Also, they pointed out the necessity of large scale field tests to identify the actual behaviour in the field.

Chen et al. (2013) examined the confining effect of geocell reinforced sand by both triaxial compression tests and theoretical analysis. Effect of various parameters such as shape, size and number of cell, sample size etc. on the behaviour of samples were also studied. It was found that the confining effect of geocells was influenced by the size and shape of the geocell, cell pressure and multiple cell effect. Among circular, rectangular, and hexagonal cross-sections, highest apparent cohesion was induced by circular-shaped geocells and lowest by hexagonal shape. Lower confining pressure makes the reinforcement more effective. They also concluded that at higher confining pressure, the sample behaves like stiff column under axial compression.

Dash and Bora (2013) conducted a series of strain-controlled experiments to understand the behaviour of foundation beds reinforced by stone column-geocell mattress. They found out that the composite system is more efficient than other planar reinforcement systems. Clay with low plasticity (CL) was used as the foundation bed and poorly graded crushed granite aggregates of size 2–10 mm were used to form the stone columns. The diameter of geocell was taken as 0.8D (where D is the diameter of footing) and followed the chevron pattern. The load-bearing capacity of soft clay beds improved by 3.7 times when stone columns alone were used and 7.8 times improvement was observed with geocell alone. But the combined system improved the load carrying capacity by 10.2 times. Use of stone column-geocell system also increased the stiffness of the clay bed, which resulted in the reduction of footing settlement. Maximum performance improvement was observed with stone column length and spacing as 5 times and 2.5 times the column diameter, respectively. Also, the critical height of the geocell mattress was identified as the diameter of footing, above which the improvement was less significant.

Biswas et al. (2015) carried out several model studies on geocell supported embankments with and without basal reinforcements. A scale factor of 10 and side slope of 1H: 1 V was assumed for testing. 50 mm × 50 mm geocells with height 25 mm and diamond pattern were used. The test results revealed that geocell supported embankments have more bearing capacity than the unreinforced embankments and geogrid supported embankments. A non-dimensional term called improvement factor, If was introduced, which is the ratio between pressure over the embankment with reinforcement to that without reinforcement. The provision of basal reinforcement below geocells increases the improvement factor.

Tafreshi et al. (2015) conducted cyclic plate load test on unreinforced, one and two layers of geocell reinforced soil beds. They used a circular plate of diameter 300 mm for the test. It is observed that the surface settlement decreases with an increase in the number of geocell layers. Also, the vertical spacing between geocells and optimum depth of the first layer was obtained as 0.2 times plate diameter.

Pancar (2016) evaluated the suitability of geocell and geotextile reinforcement for pavement in clayey subgrade with optimum moisture content and higher water contents through the plate load test. They examined eight different cases with optimum moisture content as high as 25% and water content as high as 35%. Test results were summarised, and they confirmed the efficiency of geocells over geotextiles in bearing capacity improvement and further observed that, the combination of these two materials gave the most effective soil reinforcement. Also, it was found that in order to keep highway standards, water content should be kept optimum in this treatment.

Lekshmi et al. (2016) put forward an alternative method to reduce the base thickness of pavements owing to the unavailability of aggregates. Plate load tests were carried out in the laboratory for both unreinforced and geocell reinforced base layer under repeated loading. Permanent and resilient deformations have been examined from results. It was observed that the geocell reinforced layer offered greater resilience than an unreinforced layer. Thus they confirmed the suitability of the geocell layer in unpaved roads as it reduced deformation by reinforcing the unbound aggregates, thereby reducing the thickness of the base layer. Also, for the prediction of permanent deformation in the base layer due to the higher number of cycles, they proposed a numerical model.

9 Numerical Studies on Geocell Reinforced Soil

Most of the early researchers adopted Equivalent Composite Approach for modelling geocells. Equivalent composite approach, ECA (Bathrust and Knight 1998; Latha 2000; Latha and Somwanshi 2009; Mehdipour et al. 2013; Hegde and Sitharam 2015a) uses a 2D framework for modelling. In this approach, geocell reinforced soil was modelled as a composite material with the equivalent parameters determined by Eqs. (1)–(4). Though ECA is simple, it is unrealistic to model a 3-dimensional honeycomb structure as a two-dimensional soil layer. Also, the ECA model cannot accurately simulate the interaction between geocell and infill material which is responsible for the development of additional load-bearing capacity. Duncan-Chang model was commonly used to simulate stress dependency of infill soil. The shortcomings of ECA led to the advancement in the three-dimensional modelling of geocell with the help of 3D software like FLAC 3D, ABAQUS etc. Mhaiskar and Mandal (1996) modelled axisymmetrically the geocell-soil composite system using ANSYS 3D. Eight noded isoparametric solid elements which had anisotropic and plasticity capabilities were used to model geocell and clay subgrade. The geocell reinforced sand layer was modelled as an isotropic, elastic-perfectly plastic, non-dilatant material, and Drucker Prager yield criterion was applied. But here also the stress-strain relationship of the soil-geocell composite system could not be modelled properly. So the geocell layer was considered as a soil layer with equivalent stiffness.

Han et al. (2008) may be the first researcher to model geocell and soil separately in a three-dimensional workspace. By modelling geocell and the soil separately, the confining effect of geocell on the infill, interface friction between geocell and the infill, contribution of geocell on strength improvement of the reinforced composite etc. can be evaluated. They studied the behaviour of single-cell reinforced sand under vertical loading and modelled single-cell geocell as a square box in FLAC 3D software, as shown in Fig. 10. The model adopted was Mohr-Coulomb for soil and linearly elastic membrane model for geocell. Since the Mohr-Coulomb model does not consider the stress dependency of soil, bearing capacity increment due to geocell cannot be stimulated in the modelling.

Numerical model of single-cell reinforced sand (Han et al. 2008)

Yang et al. (2010) proposed a three dimensional model for geocell reinforced soil. Geocell and infill soil was modelled separately using FLAC 3D, and the results were checked with plate load test results. 80 cm × 80 cm × 60 cm test box was used for experiments. A single cell was used to reinforce 12 cm thick sand layer and 15 cm dia steel plate was used for loading. The Duncan and Chang model was used to model the fill material in order to account for stress dependency. Nowadays, manufacturers use stronger and stiffer polymers for making geocells. Thus a thin geocell strip can carry considerable bending load. Therefore the geocell was modelled by the linearly elastic plate elements which can carry both membrane and bending stress. The actual shape of geocell can be simulated by using digitisation of photographs taken from the top of geocell. The curvature of the digitized geocell was approximated by a sinusoidal curve. The axisymmetric model was used with vertical and horizontal movements restrained. At the joint of geocell, special boundary conditions were applied for soil. The compaction effect was taken into consideration by keeping lateral earth pressure coefficient, k0 as 1. In order to simulate circular loading, velocity boundary was applied on the top of the sand layer.

Chen et al. (2013) proposed a numerical model for analysing the behaviour of geocell reinforced retaining structures. They have used the finite difference program FLAC for analysis. The stability and the deformation of the retaining structures were examined using the proposed model. For different soils; backfill, foundation soil and geocell reinforced soils non-linear elastic stress-strain relationship with Mohr-Coulomb yield criteria was adopted. They did not model the geocell and infill separately, instead of that apparent cohesion was considered for modelling geocell reinforced soil. Cable elements were used to model different interfaces such as the interface between a reinforced zone with backfill and with foundation bed. Two-dimensional analysis using finite difference program FLAC 2D was carried out to study the stability of geocell reinforced slopes (Mehdipour et al. 2013). The geocell was modelled with the two-dimensional beam element that can carry both membrane and bending stress and with three degrees of freedom at each end node.

After reporting the limitations of ECA, Hegde and Sitharam (2015a, b and 2017) proposed a new modelling approach by considering the actual shape of geocells. Geocell and infill material were modelled separately with different constitutive models. The numerical model of geocell reinforced sand bed was validated with the plate load test results obtained from the laboratory. They digitised the photograph of an expanded single cell to get the actual curvature and with deduced coordinates and numerical analyses were carried out in FLAC 3D. The linear elastic geogrid element was used to model the geocell. The elastic-perfectly plastic Mohr-Coulomb model was used for foundation and the infill soil and the geocell- infill soil interface was linearly modelled with Mohr-Coulomb yield criterion. The bottom boundary was full constrained from movement, and the horizontal movement was restrained for side boundaries. They modelled four different cases: (i) unreinforced foundation bed (ii) geogrid reinforced (iii) geocell reinforced (iv) geocell and geogrid. Figure 11 shows the three-dimensional models adopted for the four cases. It was observed that a combination of geogrid and geocell increased the bearing capacity of the soil, which led to the decreased settlement of the footing. Combination of geocell and geogrid gave the maximum performance improvement among the four cases. The geogrid helps in accumulating stresses above the geogrid and thus transferring lesser stress intensity to the subgrade. Whereas in the case of geocells, the stresses are horizontally spread to the wider area and shallower depth. Though this 3D numerical modelling is more accurate than the ECA approach, the anisotropic behaviour of sand bed was not considered in the modelling.

Biabani et al. (2016a) studied the effectiveness of geocell reinforced soil as subballast which is subjected to cyclic loading, with the help of numerical model developed in ABAQUS. The numerical results were compared with the large scale prismoidal triaxial experiment and concluded that the numerical model of geocell reinforced subballast was able to successfully predict the deformations under cyclic loading in both vertical and lateral directions. For the numerical modelling, suitable material properties and boundary conditions were selected, the elastoplastic material with non-associative behaviour for subballast and linear elastic-perfectly plastic material for geocell mattress. The hexagonal shape was used to model geocell, as shown in Fig. 12. The movement was fully restricted at the bottom, and the lateral displacement was constrained in the direction parallel to tracks (Є2 = 0). Both monotonic load and cyclic load were superimposed at different confining pressures to simulate the loading condition. The model in ABAQUS has 9380 elements, and 12,624 nodes and eight noded reduced integration elements (C3D8R) were used for analyses.

3D modeling of geocells as hexagonal shaped pockets (Biabani et al. (2016a)

10 Scope for Further Research

After reviewing different works of literature, the authors listed the following limitations and future scope in studies related to geocell reinforced soil;

Researchers in the past have carried out many experimental studies on geocell reinforced soil and concluded that the geocell material added to the stability while being sustainable and economical. Majority of the works have been done either by using small scale triaxial compression tests or plate load tests in soft clay or sand. There is a lack of study using large scale tests as well as field tests, which can give more accurate and viable solutions to predict the actual behaviour of geocell reinforced soil in the field. The dimensional analysis needs to be carried out, which will be an indication of the response of footings or other load-bearing structures resting on the geocell reinforced foundation bed in the real field condition.

In the present construction scenario, these cellular confinement systems have a wide variety of geotechnical applications. The three-dimensional honeycomb shape of geocells contributes to the load carrying capacity and stiffness of the structure, and also surface characteristics play a major role in the strength improvement. So there is a need to do the surface roughness analysis of geocells. A limited number of publications are available in this aspect; hence it will be handy for the researchers if SEM analysis of different types of geocells and its effect on load carrying capacity is carried out.

Majority of earlier studies were concentrated on the behaviour of geocell reinforced soil used in foundation beds. But the effect of the shape of the footing on the performance of geocell reinforced subgrade requires more detailed study. Both experimental and numerical studies are required on other applications of geocells such as railway engineering where the geocell reinforced soils are exposed to the cyclic loading, landfills where geocells are exposed to the chemical constituents, embankments, pavements etc. The suitability of geocells as subballast, landfill liner, landfill cover etc. and its long term performance needs to be understood in detail. Geocell reinforced retaining structures and slopes became popular in the recent past, but only a few studies which include numerical analyses that give a better understanding of deformation and failure modes of the structures are available. Most of the numerical studies were based on the finite difference method and without considering the actual shape of geocells. The geocell reinforced soil was modelled as a composite material with improved properties. More realistic three-dimensional modelling with a finite element method and the response of various structures under dynamic and eccentric loading need to be explored further. Also, the present design methods followed to get the effective diameter, length and spacing between geocell layers should be re-evaluated based on further studies, which helps in the optimisation of geocell parameters.

Most of the early researchers adopted equivalent composite approach method for numerical analysis where two-dimensional modelling was done by considering geocell reinforced soil as an equivalent soil layer with modified parameters obtained from either theoretical calculations or experimental works. Few researchers modelled geocell and infill soil separately using the appropriate constitutive models. Review of numerical studies has shown that there is a paucity of the use of models like Modified Cam Clay (MCC), which can model volume changes in soft soils more realistically compared to Mohr-Coulomb or Drucker Prager. In order to accurately model geocells, it is required to study the suitability of using different elements available in various software programs by considering the actual stress-strain response of geocells under loading. By giving actual field conditions and stress state in the analysis, it is possible for geotechnical practitioners to implement the results directly in the field without scaling.

From the design point of view, more sophisticated design methods are needed for geocell reinforced soils by considering all the stresses developed within the cell, cell walls and the adjacent cells. Another area of interest is the analytical solutions for determining the exact stresses and strains in the geocell under the application of different types of load. It is required to develop a sophisticated laboratory method for finding the joint strength of geocells which is a key parameter in the design.

11 Conclusion

Geocell reinforcement is an effective and economic ground improvement technique for improving the behaviour of weak soils. Lateral confinement, tensioned membrane effect and wider vertical stress distribution are the main load transfer mechanisms of geocell reinforcement. A comprehensive review of literature by previous researchers on the reinforcement mechanisms, design aspects, experimental studies and numerical modelling techniques of geocell reinforced soil is discussed in this paper. The flowing conclusions were drawn based on the review:

-

1.

Geocells provide all-round confinement to the infill soil and prevents lateral spreading of soil on the application of load and thus increases the strength and stiffness of weak soil. The high bending and shear stiffness of the geocell mattress makes it suitable to support shallow foundations resting on clay subgrade. With the provision of geocell mattresses, punching failure is prevented, and the pressure-settlement relationship shows linear behaviour till settlement as large as 20% of footing diameter. Further improvement could be achieved by placing a basal geogrid below the geocell soil composite system.

-

2.

The reinforcing mechanism of geocell reinforced soil is explained by the development of apparent cohesion by the increased confining stress of geocell membrane on to the infill soil. The horizontal stress developed due to the applied vertical load generates hoop stress in the cell wall due to which adjacent cells offer passive resistance. This creates a triaxial state of confinement which is responsible for shear strength improvement. About 50% stress reduction and 3–4 times improvement in load carrying capacity could be achieved with the use of geocell reinforcement.

-

3.

Properties of geocell and that of the native and infill soil have a major influence on the performance of the geocell soil composite system. It is found from the studies that the optimum parameters of geocells for economical and effective design of reinforced foundation can be summarised as Chevron pattern, pocket-size of 0.8D, geocell width of 4D to 6D, the geocell height of 1.5D to 2D, placement depth of 0.1D from footing bottom where D is the footing diameter. The relative density of infill material was found to directly affect the bearing capacity, and the maximum efficiency of geocell was obtained with denser infill soil. The subgrade stiffness was found to be inversely affecting the improvement factor, which, makes the geocell reinforcement more effective in soft clay bed than the sand bed.

-

4.

Geocell reinforcement acted as a wide slab and redistributed the load to a wider area, which restrained failure surface development. At large settlements (> 20% of footing width), tension developed in the curved geocell mattresses. This tensioned membrane effect of geocells was responsible for an increase in the bearing capacity. Studies indicated that 0. 3 m thick geocell reinforced base behaved as a beam whereas 0.15 m thick reinforced base behaved as a tensioned membrane.

-

5.

Numerical modelling of the three-dimensional honeycomb structure of geocell is complex. Equivalent Composite Approach (ECA) is the simplest and therefore, the most popular method to model the geocell soil composite system. The majority of the numerical studies were based on this approach with the equivalent system modelled with the Drucker- Prager or Duncan- Chang model. ECA treat the geocell reinforced soil in the two-dimensional framework without considering the actual curvature of the geocell. As a result, the stress distribution along the membrane and the circumferential strains due to the three-dimensional honeycomb structure cannot be fully accounted for in the analyses.

-

6.

Recently few studies were reported where the limitations of ECA method were overcome by considering the three-dimensional nature of the geocells. In one of the studies (Hegde and Sitharam 2005), digitisation technique was used to get the actual shape of geocells, and these points were uploaded to the software program FLAC 3D and analyses were carried out. Another work (Biabani et al. 2016a, b) was based on the finite element method using ABAQUS. In these studies, the geocell and the infill soil were modelled separately. There is a clear paucity of detailed 3D numerical simulations considering the geocell infill soil interaction as they are required to accurately study the stresses and strains developed in the geocell soil composite system.

References

Alawaji HA (2001) Settlement and bearing capacity of geogrid reinforced sand over collapsible soil. Geotext Geomembr 19(2):75–88

Basudhar PK, Saha S, Deb K (2007) Circular footings resting on geotextile reinforced sand bed. Geotext Geomembr 25(6):377–384

Bathrust RJ, Jarrett PM (1988) Large-scale model tests of geocomposite mattresses over peat subgrades, vol 1188. Transportation Research Record, Washington D.C, pp 28–36

Bathurst RJ, Crowe RE (1994) Recent case histories of flexible geocell retaining walls in North America. In: Tatsuoka F, Leshchinsky D (eds) Recent case histories of permanent geosynthetic-reinforced soil retaining walls. Balkema, Rotterdam, The Netherlands, pp 3–19

Bathurst RJ, Karpurapu R (1993) Large-scale triaxial compression testing of geocell-reinforced granular soils. Geotech Test J 16(3):296–303

Bathurst RJ, Knight MA (1998) Analysis of geocell reinforced soil covers over large span conduits. Comput Geotech 22(3/4):205–219

Biabani MM, Ngo NT, Indraratna B (2016a) Modelling of geocell reinforced subballast subjected to cyclic loading. Geotext Geomembr 44:489–503

Biabani MM, Indraratna B, Ngo NT (2016b) Performance evaluation of railway sub ballast stabilized with geocell based on pull-out testing. Geotext Geomembr 44:579–591

Binquet J, Lee LK (1975) Bearing capacity tests on reinforced earth slabs. J Geotech Eng Div ASCE 101(12):1241–1255

Biswas A, Murali Krishna A, Dash SK (2013) Influence of subgrade strength on the performance of geocell-reinforced foundation systems. Geosynth Int 20(6):376–388

Biswas S, Bhandari G, Sahu RB (2015) Embankment over geocell reinforced soft foundation soil. Proceedings of Indian geotechnical conference 2015

Biswas A, Krishna AM, Dash SK (2016) Behavior of geosynthetic reinforced soil foundation systems of different configurations over a stiff clay subgrade. Int J Geomech ASCE 16(5):04016007

Bouazza A, Zornberg JG, Adam D (2002) Geosynthetics in waste containment facilities: recent advances. Geosynthetics-7 ICG-Delmas ISBN 90 5809 523 1

Boyle S, Robertson K (2007) Geocell geogrid and reinforced-soil restoration of eroded steep slopes. Geosynthetics 25(2):20–26

Bush DI, Jenner CG, Bassett RH (1990) The design and construction of geocell foundation mattress supporting embankments over soft ground. Geotext Geomembr 9:83–98

Carroll RG Jr, Curtis VC (1990) Geogrid connections. Geotext Geomembr 9(4–6):515–530

Chen CPW, Huang FC, Shen CW (2013) Numerical analysis of geocell-reinforced retaining structures. Geotext Geomembr 39:51–62

Cowland JW, Wong SCK (1993) Performance of a road embankment on soft clay supported on a geocell mattress foundation. Geotext Geomembr 12(8):687–705

Daniel DE, Bowders JJ (1996) Waste containment by geosynthetics. Proceedings of 2nd international congress on environmental geotechnics, Vol 2. Osaka, pp 49–66

Dash SK (2010) Influence of relative density of soil on performance of geocell reinforced sand foundations. J Mater Civ Eng ASCE 22(5):533–538

Dash SK (2012) Effect of geocell type on load-carrying mechanisms of geocell-reinforced sand foundations. Int J Geomech 12(5):537–548

Dash SK, Bora MC (2013) Improved performance of soft clay foundations using stone columns and geocell-sand mattress. Geotext Geomembr 41:26–35

Dash SK, Rajagopal K, Krishnaswamy NR (2001a) Strip footing on geocell reinforced sand beds with additional planar reinforcement. Geotext Geomembr 19:529–538

Dash SK, Krishnaswamy NR, Rajagopal K (2001b) Bearing capacity of strip footings supported on geocell-reinforced sand. Geotext Geomembr 19:235–256

Dash SK, Sireesh S, Sitharam TG (2003) Model studies on circular footing supported on geocell reinforced sand underlain by soft clay. Geotext Geomembr 21:197–219

Dash SK, Rajagopal K, Krishnaswamy NR (2004) Performance of different geosynthetic reinforcement materials in sand foundations. Geosynth Int 11:1

Dash SK, Rajagopal K, Krishnaswamy NR (2007) Behaviour of geocell-reinforced sand beds under strip loading. Can Geotech J 44:905–916

Dash SK, Reddy PD, Raghukanth TG (2008) Subgrade modulus of geocell-reinforced sand foundation. Ground Improv 161(12):79–87

Davarifard S, Tafreshi M (2015) Plate load tests of multi-layered geocell reinforced bed considering embedment depth of footing. Procedia Earth Planet Sci 15:105–110

Dean R, Lothian E (1990) Embankment construction problems over deep variable soft deposits using a geocell mattress. Proceedings of performance of reinforced soil structures, British Geotechnical Society, London (UK). pp 443–447

Dhane G, Kumar D, Priyadarshee A (2015) Geocell: an emerging technique of soil reinforcement in civil engineering field. IOSR J Mech Civ Eng 59–63

Duncan JM, Chang CY (1970) Non-linear analysis of stress and strain in soils. J Soil Mech Found Div 96:1629–1653

Emersleben A, Meyer N (2008) Bearing capacity improvement of gravel base layers in road constructions using geocell. IACMAG 1–6 October, Goa, India

Giroud JP, Cazzuffi DA (1989) Uses of geosynthetics for environmental control. Proceedings of 12th international conference on soil mechanics and foundation engineering, vol 4. Rio de Janeiro, Brazil, pp 3119–3125

Gupta P, Somnath B (1994) Bearing capacity improvement using geogrids. J Civ EngConstr Rev 7:12–13

Han J, Yang X, Leshchinsky D, Parsons RL (2008) Behaviour of geocell reinforced sand under a vertical load. J Transp Res Board 2045:95–101

Hegde A, Sitharam TG (2013) Experimental and numerical studies on footings supported on geocell reinforced sand and clay beds. Int J Geotech Eng 7(4):346–354

Hegde A, Sitharam TG (2015a) 3-Dimensional numerical modelling of geocell reinforced sand beds. Geotext Geomembr 43:171–181

Hegde A, Sitharam TG (2015b) 3-Dimensional numerical analysis of geocell reinforced soft clay beds by considering the actual geometry of geocell pockets. Can Geotech J 52(9):1396–1407

Hegde A, Sitharam TG (2017) Experiment and 3D-numerical studies on soft clay bed reinforced with different types of cellular confinement systems. Transp Geotech 10:73–84

Hendricker AT, Fredianelli KH, Kavazanjiam E, McKelvey JA (1998) Reinforcement requirements at a hazardous waste site. Proceedings of the 6th international conference on geosynthetics, Atlanta. pp 465–468

Henkel DJ, Gilbert GD (1952) The effect of the rubber membrane on the measured triaxial compression strength of clay samples. Geotechnique 3(1):20–29

IGS (2018) Guide to the specification of geosynthetics

Indraratna B, Nimbalkar S (2013) Stress-Strain degradation response of railway ballast stabilized with geosynthetics. Geotech Geoenviron Eng 139(5):684–700

Indraratna B, Khabbaz H, Salim W, Christie D (2006) Geotechnical properties of ballast and the role of geosynthetics in rail track stabilization. Ground Improv 10(3):91–101

Indraratna B, Nimbalkar S, Neville T (2013) Performance assessment of reinforced ballasted rail track. Ground Improv 167:24–34

Indraratna B, Biabani MM, Nimbalkar S (2015) Behaviour of geocell-reinforced subballast subjected to cyclic loading in plane-strain condition. J Geotech Geoenviron Eng 141(1):04014081

Jenner CG, Bush DI, Bassett RH (1988) The use of slip line fields to assess the improvement in bearing capacity in bearing capacity of soft ground given by a cellular foundation mattress installed at the base of an embankment. Proc. Int. Geotech. Sym., Balkema, Rotterdam, Netherlands. pp 209–214

Johnson JE (1982) Bridge and tidal waters. Munic Eng 109:104–107

Jones CJFP (1996) Earth reinforcement and soil structures. Thomas Telford Publication, London

Koerner RM (1990) Preservation of the environment via geosynthetic containment systems. Proceedings of 4th international conference on geosynthetics, vol 3. The Hague, pp 975–988

Koerner RM (1998) Designing with geosynthetics. Prentice Hall, New Jersey

Krishnaswamy NR, Rajagopal K, Latha GM (2000) Model studies on geocell supported embankments constructed over a soft clay foundation. Geotech Test J 23(2):45–54

Lambert S, Nicot F, Gotteland P (2011) Uniaxial compressive behaviour of scrapped tire and sand filled wire netted geocell with a geotextile envelop. Geotext Geomembr 29:483–490

Latha GM (2000) Investigations on the behaviour of geocell supported embankments. Ph.D Thesis, Indian Institute of Technology Madras, Chennai, India

Latha GM (2011) Design of geocell reinforcement for supporting embankments on soft ground. Geomech and Eng 3(2):117–130

Latha GM, Manju GS (2016) Seismic response of geocell retaining walls through shaking table tests. Int J Geosynth Ground Eng 2:7

Latha GM, Rajagopal K (2007) Parametric finite element analyses of geocell supported embankments. Can Geotech J 44(8):917–927

Latha GM, Somwanshi A (2009) Effect of reinforcement form on the bearing capacity of square footing on sand. Geotext Geomembr 27:409–422

Latha GM, Vidya SM (2007) Effects of reinforcement form on the behaviour of geosynthetic reinforced sand. Geotext Geomembr 25(1):23–32

Latha GM, Rajagopal K, Krishnaswamy NR (2006) Experimental and theoretical investigations on geocell supported embankments. Int J Geomech 6(1):30–35

Latha GM, Dash SK, Rajagopal K (2008) Equivalent continuum simulations of geocell reinforced sand beds supporting strip footings. Geotech Geol Eng 26:387–398

Latha GM, Dash SK, Rajagopal K (2009) Numerical simulation of the behaviour of geocell reinforced sand foundations. Int J Geomech 9(4):143–152

Lekshmi S, Prabhu SS, Pratibha R, Babu GS (2016) Behavior of geocell-reinforced granular base under repeated loading. Transp Geotech 9:17–30

Leshchinsky B, Ling HI (2012) Numerical modelling of behaviour of railway ballasted structure with geocell confinement. Geotext Geomembr 36:33–43

Ling HI, Leshchinsky D, Wang JP, Mohri Y, Rosen A (2009) Seismic response of geocell retaining walls: experimental studies. ASCE J Geotech Geoenviron Eng 135:515–552

Mandal JN, Gupta P (1994) Stability of geocell reinforced soil. Constr Build Mater 8:55–62

Marto A, Oghabi M, Eisazadeh A (2013) Effect of geocell reinforcement in sand and its effect on the bearing capacity with experimental test; a review. EJGE 18:3501–3516

Mehdipour GM, Reza ZM (2013) Numerical study on stability analysis of geocell reinforced slopes by considering the bending effect. Geotext Geomembr 37:23–34

Mhaiskar SY, Mandal JN (1996) Investigations on soft clay subgrade strengthening using geocells. Constr Build Mater 10(4):281–286

Mitchell JK, Kao TC, Kavazanijiam E (1979) Analysis of grid cell reinforced pavement bases. Technical report GL-79-8, U.S. Army waterways experiment station, Vicksburg

Moghaddas T, Shaghaghi T, Mehrjardi T, Dawson AR (2015b) A simplified method for predicting the settlement of circular footings on multi-layered geocell-reinforced non-cohesive soils. Geotext Geomembr 43:332–344

Pancar EB (2016) Geosynthetic reinforcement of pavement subgrade with optimum and high water content. Int J Eng Trends Tech (IJETT) 38(1)

Paul J (1988) Reinforced soil system in embankments-construction practices. In: Proceedings of the international geotechnical symposium on practice of earth reinforcement, Fukuoka, Japan, October, pp 461–466

Pokharel SK, Jie H, LeshchinskyDov PRL, Halahmi I (2010) Investigation of factors influencing behavior of single geocell-reinforced bases under static loading. Geotext Geomembr 28:570–578

Pokharel SK, Martin I, Norouzi M, Breault M (2015) Validation of geocell design for unpaved roads. Proceedings of Geosynthetics 2015, 15–18 February 2015, Portland, Oregon

Rai M (2010) Geocell-sand mattress overlying soft clay subgrade: behaviour under circular loading. PhD thesis, IIT guwahati, India.-Dought

Rajagopal K, Krishnaswamy NR, Latha GM (2001) Finite element analysis of embankments supported on geocell layer using composite model. Proceedings of 10th international conference on computer methods and advances in geomechanics, Arizona, USA

Rajagopal K, Krishnaswamy NR, Latha GM (1999) Behaviour of sand confined with single and multiple geocells. Geotext Geomembr 17:171–184

Rajagopal K, Krishnaswamy NR, Latha GM (2001) Finite element analysis of embankments supported on geocell layer using composite model. Proc. of 10th International conference on computer methods and advances in Geomechanics, Arizona, USA

Rajagopal K, Chandramouli S, Parayil A, Iniyan K (2014) Studies on geosynthetic reinforced road pavement structures. Int J Geotech Eng 8(3):287–298

Rea C, Mitchell JK (1978) Sand reinforcement using paper grid cells. Reprint 3130, ASCE spring convention and exhibit, pp 24–28

Rowe RK (1998) Geosynthetics and the minimization of contaminant migration through barrier systems beneath solid waste. Proceedings 6th international conference on geosynthetics, vol 1. Atlanta pp 27–102

Simac MR (1990) Connection for geogrid system. Geotext Geomembr 27:89–98

Sireesh S, Gowrisetti S, Sitharam TG, Puppala AJ (2009a) Numerical simulations of sand and clay. Ground Improv 162:185–198

Sireesh S, Sitharam TG, Dash SK (2009b) Bearing capacity of circular footing on geocell–sand mattress overlying clay bed with void. Geotext Geomembr 27:89–98

Sireesh S, Sailesh P, Sitharam TG, Puppala AJ (2013) Numerical analysis of geocell reinforced ballast overlying soft clay subgrades. Geomech Eng 5(3):263–281

Sitharam TG, Hegde A (2013) Design and construction of geocell foundation to support the embankment on settled red mud. Geotext Geomembr 41:55–63

Sitharam TG, Sireesh S (2004) Model studies of embedded circular footing on geogrid reinforced sand beds. Ground Improv 8(2):69–75

Sitharam TG, Sireesh S (2005) Behaviour of embedded footings supported on geocell reinforced foundation beds. Geotech Test J ASTM 28(5):452–463