Abstract

The ever increasing infrastructure development requires adequate and competent ground, which is becoming scarce at present. Thus, developing techniques for improving the weak soil (having low bearing capacity and/or likely to undergo excessive settlement) into a competent acceptable condition is a major task for geotechnical engineering practice. In this perspective, the concept of ‘reinforcing the soil’ is being widely appreciated and extensively practiced. For last few decades, the soil-reinforcement in various forms, such as planar and/or three-dimensional, has been vividly applied in several fields of civil engineering. As compared to the planar form, the three-dimensional ‘Geocell’ is comparatively new invention in soil-reinforcement. It is a honeycombing interconnected cellular confinement system, made of geosynthetics, such as geotextiles and/or geogrids. It has been observed that ‘Geocells’ significantly enhances the load-bearing capacity of soils and reduces settlement of the concern geotechnical structure. Apart from load-bearing (especially in pavements and foundations), it has also been extensively used in various slope stabilization, embankment construction and railway track applications. With increasing trend and demand, the performance of geocell-reinforcement has rigorously been studied for its betterment and optimum parametric configurations. Studies have revealed a large numbers of parameters, such as reinforcement geometry, interaction with filled soil, etc., largely influencing the performance of geocell-reinforced systems. In view of that, this paper aims to present a critical review of the parametric behavior of geocell-reinforced systems which would be a very useful document for various applications and further research.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The ever increasing demand of competent land for urbanization has been a challenge for geotechnical engineers to develop an optimized methodology of transforming comparatively week soil into an acceptable condition. In most of the cases, the inadequacy arises in terms of unsatisfactory bearing capacity of the soil, and/or, excessive settlement of concern geotechnical-structure. In view of this, different techniques are invented which enhances the strength and stiffness of soil, reduces compressibility and vulnerability to liquefaction, prevent adverse physical or chemical changes upon environmental effects and minimize the natural unpredictability of soils. Amongst the various ground improvement methods, such as replacement with good-fill soil, preloading with vertical drains, different types of compactions, grouting, deep soil mixing, and various chemical treatments etc., the soil-reinforcement in different forms is being widely appreciated for its versatility in technical, economical, and environmental feasibility and simple applications.

The concept of ‘reinforcing the earth’ is being practiced since centuries in various forms: like straw, reed, bamboo, logs, timber planks etc. [1,2,3,4,5,6]. The credit of introducing systematic approach/concept of soil-reinforcement is with Vidal [7]. Over the time, soil-reinforcement has been modified as per requirements and inventions: in terms of material, shapes and sizes. The metallic strip-reinforcements of the beginning [8, 9] were replaced by sheet-type-reinforcements and afterwards, the versatile geosynthetics in different forms, such as geotextiles, geogrids, and geocells, have superseded them all [2,3,4,5,6].

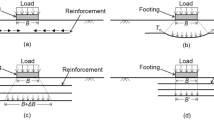

In last few decades, soil-reinforcements in planar forms were used in several fields of civil engineering applications, such as foundations, pavements, retaining walls, embankments etc. A typical foundation application for planar reinforcement is presented in Fig. 1a, showing different influencing parameters associated with it. The benefits of planar reinforcements considering several aspects, such as material-strength, geometry, placement depths, number of layers etc., has been demonstrated by several investigators [10,11,12,13,14,15,16,17,18]. A brief of few important studies on planar reinforcements is presented in Table 1.

Geocell is a three-dimensional honeycombing structure of interconnected cells, devised by Webster and Watkins [19], which contains and confines the soil within. Unlike other techniques, the development of geocell was initiated from field-application, and upon successful implementation it has been rigorously studied in-house for its optimum use (through physical models tests and/or numerical analyses). Geocells are, generally, made of thermally welded or mechanically bonded geosynthetics of various types. It can be made in-field using planar geotextiles or geogrids; however, readymade geocells are also available commercially. The readymade geocells are easy to transport (in collapsed form) and can be stretched into mattress at site. The commercially available geocells are, generally, having invariable and shorter in heights (thickness) as compared to the in-field constructed geocells; in which case, height of the geocells can be selected as per design-requirements. In field, geocells are constructed with ‘bodkin joints’ [20,21,22] through ‘dowel bars’ (as per required length and strength) and filled with soil of required quality and quantity. At site, the ‘dowels’ are mostly made of metals, such as steel bars, as compared to mechanical or thermally welded joints for commercial ready-made geocell-mattresses. As the planar reinforcements, geocells are also used in foundations, pavements, railways, embankments, slopes etc., to improve the load-bearing capacity and stability of geo-structures. In last few decades, the benefits of geocell-reinforcements, considering several aspects, such as material, geometry, placement depths, filled-soil etc., have been demonstrated by several investigators. In Table 2, a few field applications and laboratory studies are summarized which have highlighted the benefits of three-dimensional geocell-reinforcements.

This paper presents a critical review on ‘parametric influences’ of the geocell-reinforced systems; in terms of, mostly, a foundation-application. A typical geocell-reinforced foundation is shown in Fig. 1b, for a circular footing of diameter D. The ‘h’, ‘b’, and ‘d’ are representing the height, width, and pocket size of the geocell mattress, respectively. The placement depth of geocell-mattress below the footing (or the thickness of ‘soil-cushion’) is depicted as ‘u’. In Fig. 1b, two types of soils can be noticed: soil-1 is the native soil underneath; while, the geocell-reinforced fill-soil is indicated as soil-2. In general, geocells are placed directly over the native soil (or a base-geogrid may be provided in between) and pockets are filled with soil. As per general practice, geocell-pockets are filled with granular materials, like sand or gravel, for its better interfacial properties and higher control over the ‘in-filling’ process.

Studies on Geocell-Reinforced Foundation Systems

Figure 1b has depicted the general configuration of geocell-reinforced foundation system indicating various influencing parameters. In either of the applications, such as foundation, embankment, or pavement etc., performance of geocell-reinforced systems was investigated, mostly, in terms of improvement in load-settlement behavior under different combinations of configurations. It has been studied through physical model tests, analytical and/or numerical analyses, considering various combinations of influencing parameters. Following sections present brief discussions on selected studies on geocell-applications.

Physical Model Studies

In field, geocell-soil-mattress is formed by filling the geocell-pockets with granular material, such as gravel or sand, overlying soft subgrades of sand and/or clay. As per the conditions, rigorous experiments were performed in laboratory on geocell-reinforced foundations overlying soft/very soft clay subgrades [23,24,25,26,27,28,29]. Performances of geocell-reinforced embankment on soft clay was investigated by Krishnaswamy et al. [30] and Zhang et al. [31]; while, the suitability of geocell-reinforcements in pavement application over soft clay were reported by Emersleben and Meyer [32], Tanyu et al. [33]. Leshchinsky and Ling [34, 35], Indraratna et al. [36], Biabani et al. [37] have investigated benefits of geocell-reinforced ballast under cyclic loading, simulating the railway track conditions. Biswas et al. [27, 38] investigated the effect of subgrade strength on the performance of geocell-sand mattress resting on clay subgrades. In Fig. 2, typical laboratory model test set ups for geocell-reinforced foundation [27] and embankment [30] are presented.

A number of investigations have considered physical model tests on geocell-sand mattress overlain loose and/or dense sand subgrade. Dash et al. [39,40,41,42,43,44], Dash [45, 46], Tafreshi and Dawson [13] have reported detail parametric studies investigating the effect of geocell-geometry, formation pattern, placement depth, geocell-stiffness and relative density of in-filled sand etc. Pokharel et al. [47] investigated the effect of shape, type, embedment depth of footing, geocell-height and quality of in-filled material on sandy subgrades. Investigations in very small scale, in triaxial set-ups, were also performed [48,49,50]. These investigations mostly focused on the influence of confinement, packing of geocell-systems, pattern of failure, and compared the relative performance of geocell systems with the other variations (such as, planar and randomly distributed fibers). Figure 3 presents a typical triaxial set-up [48] for geocell-reinforced sample. The figure also indicates the confinement effect in terms of development of apparent cohesion. Few laboratory model tests were also performed on geocell-reinforced foundations, in-filled with clay overlying the clay subgrade [51, 52].

Multiple geocell-system in triaxial test and development of apparent cohesion: Rajagopal et al. [48]

Analytical Studies

Different analytical models are developed for estimating the behavior of geocell-reinforced systems. Rajagopal et al. [48], Latha et al. [53,54,55] assumed that the enhanced load-bearing capacity is due to generation of apparent cohesion through geocell-confinement (Fig. 3). This approach considered ‘hoop stresses’ and lateral strain to estimate the induced cohesion (c r ) [56, 57]. Hence, in determining the geocell-behavior, the generated membrane stiffness was replaced by ‘equivalent soil-stiffness’ and analyzed as ‘layered-soil of different strengths’ [55, 56, 58]. A different approach proposed by Dash et al. [43] considering load dispersion through the geocell-reinforced soil layer. Zhang et al. [31] proposed similar, but, a detailed and more realistic mechanism by discretizing different mechanisms, such as lateral restrain (confinement), stress dispersion, and membrane action (Fig. 4). This approach approximated the geocell-reinforced-soil as a ‘layer with higher flexural rigidity’. Similar concept was also reported by Fabymole et al. [59] based of the result of instrumented physical model tests.

Discretized geocell-mechanism: confinement, membrane action and stress distribution: Zang et al. [31]

Numerical Studies

Considerable numbers of numerical simulations are also performed on geocell-reinforced systems, which were capable of rigorous parametric variations. Han et al. [60], Sireesh et al. [61,62,63], Yang et al. [64], Fabymole et al. [59], Hegde and Sitharam [65, 66] used FLAC3D for analyzing the behavior of geocell-reinforced foundation systems in varying conditions. Finite element analysis (in GEOFEM) considering the equivalent stiffness of geocell-reinforced layer, was reported by Latha et al. [54, 67]. The results indicated considerably good predictability of the foundation behavior, as observed in laboratory physical model tests. Similar approach was also reported by Buthurst and Kight [68], Latha and Somwanshi [55], Sitharam and Hegde [69], Mehdipour et al. [70]. In these studies, the confinement and interfacial resistances of geocells were replaced by a ‘stiffer-soil layer’ having ‘equivalent strength and stiffness’ that of the reinforced-soil. However, it is not a very realistic approach as it avoids the uncertainties involved in parametric variations. Therefore, though it produced good predictability of foundation performance, but, results were mostly limited to specific study and are not efficient enough to generalize the behavior. A more realistic approach, by modeling the geocell-mattress as multiple-cell system, was reported by Sireesh et al. [63] and Hegde and Sitharam [28]. Figure 5 presents the numerical model developed by Hegde and Sitharam [28] for geocell and geocell with base-geogrid. The performance of single-cell-geocell was also investigated few occasions [35, 64]; but, the behavior differs considerably to that of a multiple cell geocell-system actually used.

Behaviour of geocell-reinforced foundations in FLAC3D (Hegde and Sitharam [28]): a geocell only and b with base geogrid

Reinforcing Mechanism

The primary reinforcing action for geocell is to confine the in-fill soil from shearing away upon applied load. In addition, the perforated (and/or textured) geocell-walls derive anchorage (and/or interfacial friction; Fig. 6) through surrounding soil in resisting the incoming load [23, 39, 45, 48]. Besides, geocell-walls cut the potential failure planes (as would develop in unreinforced condition) and force it to go deeper in to the soil [23, 30, 38] to increase the stability and bearing capacity of soil (Fig. 7). The interconnected pockets provide all-round confinement to in-filled soil and behaves as a semi-rigid composite slab. It redistributes the applied load to a wider area with lesser intensity to improve the load-bearing capacity of underlying soil. The semi-rigid-slab configuration improves the performance by resisting differential settlement of concerned structure and generates membrane resistance. The soil-confinement is developed by the ‘hoop strength’ of geocells, in combination with the passive resistance of surrounding soil (and/or cells) [23, 48]. Together, it induces a significant apparent cohesion to the in-filled soil, even for dry sand [48]. The interconnected geocell-soil composite mattress, having high shear and bending rigidity, can support significant load even after squeezing of ‘in-filled soil’. Overall, the mechanism of geocell-reinforcements can be discretized as ‘confinement’, ‘membrane action’, and ‘stress distribution’ (Fig. 4; [31]).

Development of slip surfaces in unreinforced and geocell-reinforced foundations: Biswas et al. [38]

Influencing Parameters

A variety of studies have revealed various influences of several parameters on the performance of geocell-reinforced systems. Significant number of laboratory model tests, physical and/or analytical studies, indicated that the variance of effects are largely depended on the configurations of geocell-reinforced structures. A brief discussion on the influencing parameters and their effects are presented in following sections, mostly in perspective of a foundation (or load bearing) application.

Formation Pattern

Generally, geocell-mattress is formed either in ‘Chevron’ or ‘Diamond’ patterns (Fig. 8). Studies have indicated that the formation pattern is having marginal influence on the performance of geocell-reinforced systems. It is found that ‘chevron pattern’ is comparatively more beneficial over diamond pattern. The higher efficiency is the result of greater structural rigidity of geocell-mattress, comes with more number of joints per unit area. For example, in Fig. 8, it may be noticed that, in the same mattress area, the ‘chevron pattern’ is having 20 joints as compared to only 12 joints for the ‘diamond pattern’. Thus, the ‘chevron pattern’, having higher shear and bending rigidity, can sustain greater load and redistribute it more efficiently to the underlying subgrade [30, 39, 71, 72]. Besides, for greater structural rigidity, it can sustain for longer duration, even after shearing away of in-filled soil. Pokharel et al. [47] reported that the circular pocket provides higher improvement than the elliptical-shaped geocells, through a single-cell system. However, the interaction is different for multiple-cell-system as compared to the single-geocell [48, 73, 74]. Thus, it may be conclude that the ‘chevron pattern’ would be better configuration to follow for geocell-reinforced structures.

Pocket Size

Geocell-pocket-size is generally expressed as the diameter (d) of an equivalent circular area of geocell-pocket opening (Figs. 8, 9). It is found that the smaller the pocket-size, the higher is the load-bearing capacity of geocell-reinforcement. This is attributed to increased stiffness of geocell-soil composite structure. Smaller geocell-pockets provide higher confinement to in-filled soil and increases shear and bending rigidity through more number of joints per unit area. Moreover, the smaller the pockets are, the higher is the effective surface area for geocell-soil interfacial resistances. This can derive a very high anchorage/frictional resistances through geocell-walls against possible incoming loads. Combining the above, the geocell-soil-composite mattress behaves as a semi-rigid slab which redistribute the load to underlying subgrade more efficiently with lesser intensity to enhance overall performance. However, in field, construction of very small pockets is difficult; so as the compaction of in-filled soil. It has been found that the pockets of geocell-mattress should be smaller than the footing (or loading) area in such a way that the footing can cover, at least, one full pocket opening [23, 24, 39, 41]. Based on laboratory model studies, the optimum pocket size is recommended as 0.8D [41, 72], where ‘D’ is the footing (or loading) diameter.

Width and Height of Geocell Mattress

Laboratory model studies, physical and/or analytical, have indicated that performance of geocell-reinforced system is highly depended on the geometry of geocell-mattress, which includes width (or length) and height (or thickness). A schematic diagram of geocell-mattress is presented in Fig. 9, indicating geometric features of geocell-mattress. It is found that, with increase in width of geocell-mattress, the load distribution becomes more uniform and it can transfers the incoming load with much lesser intensity to underlying subgrade. Larger geocell-mattress produces significant interfacial resistance through surrounding soil and derives high membrane resistance to support greater load for better stability. The optimum width of geocell mattress is found to be 4–6D, where ‘D’ is the footing diameter [24, 51, 62]. Beyond this, improvement was insignificant with respect to increased dimension (Fig. 10a). It is attributed to development of farthest rupture planes for a shallow foundation, which, as per Chummar [75], is expected to be well within 3D at either sides of the footing.

Similar to the width of geocell-mattress, the height (or thickness) of geocell-mattress is equally important in influencing the behavior of geocell-reinforced structures. Through rigorous research, the optimum value of geocell-height was found to be in the range of 1.5–2.0D. The ‘range’ is depended on subgrade strength [27, 38], stiffness of geocell-materials [27, 39] and density of in-filled soil [39, 48, 72]. Figure 10b shows the effect of geocell height on the performance of model foundations [62]. It is found that with increase in geocell-height, the rigidity of geocell-mattress enhances. The enhancement is attributed to increased number of joint-layers (bodkin joint) which increases flexural rigidity of geocell-mattress to behave like a semi-rigid slab [39, 43]. Dash et al. [39] similitude this behavior with ‘deep beam action’. In addition, the increased height generates supplementary interfacial resistances through enhanced surface area. It is observed that a part of thick geocells, just under the footing bottom, are prone to buckle under high load. It is due to stiffness of the top of geocell-mattress, which was ‘not affected’ by increase in geocell-heights. Therefore, bending takes place at the top of geocell-mattress at high stress and resulted in greater footing-settlement to reduce overall performance [27, 38, 72]. The effect was very prominent for thicker geocells (h > 2D) and stiffer subgrades [38, 76] (Fig. 11); however, it was slightly reduced by dense in-filled soil through passive resistance.

Bending of geocell-wall just under the footing: Biswas et al. [38]

Placement Depth

Usually, the geocell-pockets are slightly overfilled by same in-filled soil. The overfilling serves in two ways: it distributes the load uniformly to a wider area which helps in reducing the stress intensity on geocell-mattress. In addition, the soil-cushion compensates constructional settlement [13, 20, 27, 38, 39, 77] and increases the density of in-filled soil. This, eventually, enhances load-bearing capacity and improves overall performance of geocell-reinforced systems. In most of the studies, the optimum thickness of soil cushion (u) (or the placement depth of geocell-mattress below the footing) was in the range 0.1–0.33D. Beyond the thickness, the unreinforced soil squeezed out under shear leading to early settlement of footing. In case of clay-filled geocell, the optimum performance noticed at u = 0; i.e., when the footing directly placed on geocell-mattress [51, 52]. Figure 12a shows a typical performances for geocell-reinforced foundations at different placement depths [39].

Density of In-Fill Soil

Dash et al. [39], Dash [45], Pokharel et al. [47], Latha et al. [67] and Rai [72] observed that the performance of geocell-foundations improves with increase in density (or relative density, D r ) of the in-filled soil (Fig. 12b). This was attributed to stiffness of encased soil which itself can carry sufficiently higher load, and being more compacted it could attract greater load by enhancing shear parameters. In other hand, it causes reduction in load transfer to the geocell-walls. This, eventually, affect the stain mobilization on geocell-wall which results in developing less interfacial (or anchorage) resistance [39]. The increase in in-filled soil density also help in reducing the early bending in geocell-wall, by providing high confinement. Considering the facts, it is recommended that the in-filled soil-density should be kept as high as possible for better performance of geocell-systems.

Geosynthetics Properties

The properties of geocell-making materials (geogrids and/or geotextiles), such as stiffness, textures, orientation of ribs, and aperture opening size (d a ) etc., imparts significant influence on the reinforcing mechanism of geocell-systems [30, 39, 46, 48]. It is seen that in case of larger aperture openings (such as geogrid) better interlocking and anchorage is developed as compared to solid walled or perforated walled geocells. On other side, geosynthetics having smaller apertures contributes in higher confinement and greater surface area towards deriving higher degree of wall-friction. It is reported that the optimum performance is derived when aperture size (d a ) is about 80 times of mean grain size (D 50 ) of the in-filled soil (Fig. 13a). Dash [46] found that the geogrid having horizontal and vertical orientation of ribs (square and/or rectangular aperture; Fig. 14) gives better resistance against incoming load and possible settlement than the inclined orientation (diamond openings; Fig. 14). It is also reported that not the tensile strength of geogrid, but the stiffness of overall geocell-mattress delivers higher impact on geocell-reinforced foundation system [39]. The performance was attributed to high confinement that a stiffer geogrid yields, as compared to geogrid having higher tensile strength but less stiffness.

Effect of aperture openings of geogrid: Dash [46]

Subsoil Strength

The subsoil strength, probably, is the most important influencing factor for the overall performance of geocell-reinforced foundation system. As seen in Fig. 1b, it may be understood that the entire geocell-reinforced foundation is supported and depends on the behavior of underlying subgrade (i.e. soil-2) [27, 38]. Figure 15 presents the effect of subgrade strength in terms of ‘pressure-settlement’ and ‘improvement in pressure-settlement responses’ reported by Biswas et al. [27, 38] and Biswas [72]. Though, the influence of subgrade strength has not been exploded fully, but, it is noticed that stiffer geocell-mattress can derive much higher support from stiff subgrades [27, 38, 72]; whereas, significantly high improvement can be derived in case of softer subgrades [27, 38]. It was found that the effect of bending in geocell-walls, just under the footing, were very prominent for stiffer subgrades which results in high localized settlement causing reduction in overall performances. In addition, the stiff subgrade offers higher support against possible settlement of geocell-mattress which results in reduced interfacial and membrane resistances.

Additional Base-Geogrid

In general practice, a layer of planar geosynthetics is laid over the native soil before constructing (or placing) the geocell-mattress (Figs. 16, 17). The base-geogrid serves in two ways: it creates a temporary platform to the geocell-mattress and supports constructional movement. Besides, it enhances the overall performance by providing membrane-resistance. Eventually, the base-geogrid causes the subgrade being stiffer as compared to the native ground. However, in case of stiffer subgrade, the same results in adverse effect as localized bending in geocell-walls (for high stress concentration) and reduces the performance [25, 27, 38, 51]. It has also been reported that the base-geogrid reduces the ‘tilting (or rotation)’ of geocell-mattress [39].

Construction of geocell-mattress: Bush et al. [20]

Construction sequence of geocell-mattress: Cowland and Wong [84]

A summary of reported optimum values of influencing parameters of geocell-reinforcement is presented in Table 3. In the table, the dimensional parameters are expressed in non-dimensional form with respect to diameter of the footing (D).

Field Applications (Case Studies)

Geocell-reinforcement was introduced in field much earlier than the parametric studies started in laboratories. Webster and Watkins [19] and Webster and Alford [78] pioneered this technology and led to the development of commercial geocells of present days. They used sand-filled interconnected thin-walled aluminum cells, overlying soft subgrade, against full-scale traffic load. It was observed that the reinforced-sand provided significantly greater load-carrying capacity and reduced about 60% of the unreinforced materials. Johnson [79] used geocells in construction of Greatham Creek Bridge, England (Fig. 18). Robertson and Gilchrist [80] mentioned geocells as the best alternative, in terms of cost effectiveness and overall performance, for construction of a 4 m high embankment over a deep soft clay.

Schematic of geocell foundation for approach embankment of Greatham Creek, Cleveland: Johnson [79]

Paul [81] reported use of geocells to support an embankment over deep soft deposits in Scotland. Application of geocell was found to be the most economical, convenient, and rapid method of construction. Settlement pins were installed in embankment, on top of geocell-mattress, for monitoring the performance which indicated insignificant differential settlement even after a long period of time. Bush et al. [20] described a detail construction of geocell-mattresses supporting embankments over soft ground. In this case, geocells were constructed with a polymer grid sheet, joined through ‘bodkin joint’ (Fig. 19). The bodkin-joints were formed by pulling the ribs of transverse geogrids through the longitudinal geogrid and inserting a dowel through the loop created. The construction was performed in sequence: initially, a series of interlocking cells (connected to a biaxial geogrid at base) was constructed using uniaxial polymer geogrids and filled with granular material. The filling was done by filling first two rows of cells to half height, before filling the first row to full height (Fig. 20). This method was followed to avoid distortion of cells. The cells were over-filled by 150 mm to encounter compaction settlement due to constructional traffic. It was reported that it saved 1/3rd of the cost compared to the conventional solutions. Dean and Lothian [82] reported construction of an embankment with uniaxial geogrid-made-geocell and filled with crushed rock over a deep soft deposit. Amongst the other alternatives, like construction of a viaduct, replacement of soft deposit with rock or pre-consolidation of soft soil etc., the geocell-reinforcement was found to be the most convenient, rapid, and economical method. Boyle and Robertson [83] used geocells in constructing flexible gravity walls and steepened slopes.

Cowland and Wong [84] presented a field investigation and construction process with performance monitoring of a geocell-reinforced road embankment over soft clay (Fig. 17). The embankment was fully instrumented with piezometers, inclinometers, profile gauges, settlement plates, surface settlement markers and lateral movement blocks. The monitoring was performed at regular intervals just after the instrumentations was over. Vane shear tests were carried out after 1-year of completion of construction and found an average increased in shear strength as about 2–3 times (depending on soil-types). Gupta and Somnath [85] used geocells in construction of box-culverts over marine clay deposits (more than 6 m depth) in New Bombay. The tubular gabions were constructed over soft soil, with their ends resting on hard moorum, before constructing the geocell-mattress. In this arrangement, the gabions were served as granular piles and the geocell-mattress was as flexible pile-cap. Koerner [86] reported a field study on geocell-reinforced pavement filled with compacted sand over soft subgrade. The pavement was tested under tandem-axle truck for 10,000 passes. The reinforced system resulted in slight rutting, as compared to deep ruts occurred only after ten passes over the unreinforced subgrade. Forsman et al. [87] reported a study on the performance of a geocell-reinforced road over deep peat deposit. The geocells were fabricated using geogrids and filled with light expanded clay aggregate. Such ‘fill’ was used because of expected large settlements in the peat deposit. The tests were instrumented using vertical extensometers, profile gauges, settlement plates, and strain gauges. Plate load test and falling weight deflectometer tests were conducted to measure the modulus of subgrade. The geocell layer was found to be effective in increasing the bearing capacity and reducing settlements. Even after a year and half, no significant settlement was observed on road surface. Emersleben and Mayer [32] performed model tests on circular footing and compared the results with in-situ test on geocell-reinforced subgrade (Fig. 21). A special type of soil, Glyben, was used to simulate the soft subgrade (c u = 15 kPa). In model tests, about 1.5-fold improvement in bearing capacity and about 30% reduction in vertical stresses was noticed. The in-situ tests, such as ‘vehicle crossing and vertical stress measurements’ and ‘falling weight deflectometer’, showed reasonably good agreements with the model test results.

Schematic of laboratory model set up and field test with falling weight deflectometer measurements [32]

Conclusions

This paper discussed the parametric behavior of various geocell-applications. The developments and detail mechanism of geocell-reinforced systems are briefly explained. Besides, attempts were also made to establish the inter-relationships between parameters for optimum results in varying configurations for maximum benefits. As per the findings, followings should be the critical considerations for designing a geocell-reinforced systems:

-

Primarily, the design and behavior of geocell-reinforced systems is depended on subgrade strength. The initial selection of geocell-geometry (height, width, pocket size etc.) has to be as per type and/or quantity of improvement required and available subgrade strength.

-

According to the desired intensity of load transfer (or bearing capacity of subgrade soil) and loading (or footing) diameter (or width), the width and height of geocell-mattress has to be designed. However, the density (or relative density) of the in-filled soil is preferable to be at maximum possible.

-

The type (interfacial properties), stiffness and tensile strength of geocell-making material (i.e. geogrid and/or geotextiles) has to be according to degree of confinement and rigidity of the geocell-soil mattress desired. This will effect in overall stiffness and slab-like-behavior of geocell-soil composite mattress (i.e. load transfer to underlying subgrades).

-

A base geogrid may be placed below the geocell-soil matrix, but, need to verify the applicability with respect to geocell-height and subgrade strength.

In general, it is found that the ‘Chevron’ pattern of geocell-formation with 0.8D pocket opening, having 6D width and 1.5–2D height may be adopted, when placed at 0.1D depth below the footing (of diameter ‘D’) and in-filled with granular soil of densest possible state. However, it is always suggested that for every individual application, one must consider all other influencing parameters as per the subgrade strengths, for the optimum combinations of configurations. At present, the application of geocell-reinforcement is mostly guided by experience and design of geocell-reinforced soil structures is yet to be fully explored. In view of this, this paper may be used as a preliminary guide for researchers and practitioners.

References

Dewar S (1962) The oldest roads in Britain. Countryman 59(3):547–555

Jones CJFP (1996) Earth reinforcement and soil structures. Thomas Telford Publication, London

Shukla SK (2002) Geosynthetics and their applications. Thomas Telford, London

Shukla SK (2012) Handbook of geosynthetic engineering. 2nd edn. ICE Publishing, London

Shukla SK (2016) An introduction to geosynthetic engineering. CRC Press, Taylor and Francis, London

Saran S (2005). Reinforced soil and its engineering applications. I.K. International Pvt. Ltd., New Delhi

Vidal H (1969). The principle of reinforced earth. Highway Research Record, 282, Washington, D.C.

Binquet J, Lee KL (1975). Bearing capacity tests on reinforced earth slabs. J Geotech Eng Div ASCE 101(12):1241–1255

Binquet J, Lee KL (1975). Bearing capacity tests on reinforced earth slabs. J Geotech Eng Div ASCE 101(12), 1257–1276

Giroud JP, Noiray L (1981) Geotexti1e reinforced unpaved road design. J Geotech Eng Div ASCE 107(9), 1233–1254

Omar MT, Das BM, Yen SC, Puri VK, Cook EE (1993) Ultimate bearing capacity of rectangular foundations on geogrid-reinforced sand. Geotech Test J ASTM 16(2):246–252.

Kumar A, Walia BS, Saran S (2005). Pressure-settlement characteristics of rectangular footings resting on reinforced soil. J Geotechn Geol Eng 23:469–485

Tafreshi SNM, Dawson AR (2010) Comparison of bearing capacity of a strip footing on sand with geocell and with planar forms of geotextile reinforcement. Geotext Geomembr 28(1):72–84

Rajyalakshmi K, Madhav MR, Ramu K (2012) Bearing capacity of reinforced strip foundation beds on compressible clays. Indian Geotech J 42(4):294–308

Jha JN, Choudhary AK, Gill KS, Shukla SK (2013) Bearing capacity of a strip footing resting on reinforced fly ash slope: an analytical approach. Indian Geotech J 43(4):354–366

Kazi M, Shukla SK, Habibi D (2015) Effect of submergence on settlement and bearing capacity of surface strip footing on geotextile-reinforced sand bed. Int J Geosynth Ground Eng. doi:10.1007/s40891-014-0006-y

Kazi M, Shukla SK, Habibi D (2015) An improved method to increase the load-bearing capacity of strip footing resting on geotextile-reinforced sand bed. Indian Geotech J 45(1):98–109

Biswas A, Ansari MA, Dash SK, Krishna AM (2015) Behavior of geogrid reinforced foundation systems supported on clay subgrades of different strengths. Int J Geosynth Ground Eng 1(3):1–10

Webster SL, Watkins JE (1977) Investigation of construction techniques for tactical bridge approach roads across soft ground. Technical Report S-77-1, United States Army Corps of Engineers, Waterways Experiment Station, Mississippi, USA

Bush DI, Jenner CG, Bassett RH (1990) The design and construction of geocell foundation mattresses supporting embankments over soft ground. Geotext Geomembr 9(1):83–98

Simac MR (1990) Connections for geogrid systems. Geotext Geomembr 9(4):537–546

Carroll RG, Curtis VC (1990) Geogrid connections. Geotext Geomembr 9(4–6):515–530

Mandal JN, Gupta P (1994) Stability of geocell-reinforced soil. Constr Build Mater 8(1):55–62

Mhaiskar SY, Mandal JN (1996) Investigations on soft clay subgrade strengthening using geocells. Constr Build Mater 10(4):281–286

Dash SK, Sireesh S, Sitharam TG (2003) Behaviour of geocell reinforced sand beds under circular footing. Ground Improv 7(3):111–115

Zhou H, Wen X (2008) Model studies on geogrid or geocell-reinforced sand cushion on soft soil. Geotext Geomembr 26(3):231–238

Biswas A, Krishna AM, Dash SK (2013) Influence of subgrade strength on the performance of geocell-reinforced foundation systems. Geosynth Int 20(6):376–388

Hegde A, Sitharam TG (2015) 3-Dimensional numerical modelling of geocell reinforced sand beds. Geotext Geomembr 43:171–181

Hegde A, Sitharam TG (2015). Joint strength and wall deformation characteristics of a single-cell geocell subjected to uniaxial compression. Int J Geomech ASCE 15(5). doi:10.1061/(ASCE)GM.1943-5622.0000433

Krishnaswamy NR, Rajagopal K, Latha GM (2000) Model studies on geocell supported embankments constructed over a soft clay foundation. Geotech Test J 23(2):45–54

Zhang L, Zhao M, Shi C, Zhao H (2010) Bearing capacity of geocell reinforcement in embankment engineering. Geotext Geomembr 28(5):475–482

Emersleben A, Meyer N (2008) The use of geocells in road constructions over soft soil: vertical stress and falling weight deflectometer measurements. EuroGeo4, paper number 132, 2008

Tanyu BF, Aydilek AH, Lau AW, Edil TB, Benson CH (2013) Laboratory evaluation of geocell-reinforced gravel subbase over poor subgrades. Geosynth Int 20(2):47–61

Leshchinsky B, Ling H (2013) Effects of geocell confinement on strength and deformation behaviour of gravel. J Geotech Geoenviron Eng 139(2):340–352

Leshchinsky B, Ling H (2013) Numerical modelling of behavior of railway ballasted structure with geocell confinement. Geotext Geomembr 36:33–43

Indraratna B, Biabani M, Nimbalkar S (2015) Behavior of geocell reinforced subballast subjected to cyclic loading in plane strain condition. J Geotech Geoenviron Eng 141(1):04014081

Biabani MM, Indraratna B, Ngo NT (2016) Modelling of geocell-reinforced sub-ballast subjected to cyclic loading. Geotext Geomembr 44:489–503

Biswas A, Krishna AM, Dash SK (2016) Behavior of geosynthetic reinforced soil foundation systems of different configurations over a stiff clay subgrade. Int J Geomech ASCE doi:10.1061/(ASCE)GM.1943-5622.0000559

Dash SK, Krishnaswamy NR, Rajagopal K (2001) Bearing capacity of strip footings supported on geocell-reinforced sand. Geotext Geomembr 9(4):235–256

Dash SK, Rajagopal K, Krishnaswamy NR (2001) Strip footing on geocell reinforced sand beds with additional planar reinforcement. Geotext Geomembr 19:529–538

Dash SK, Sireesh S, Sitharam TG (2003) Model studies on circular footing supported on geocell reinforced sand underlain by soft clay. Geotext Geomembr 21(4):197–219

Dash SK, Rajagopal K, Krishnaswamy NR (2004) Performance of different geosynthetic reinforcement materials in sand foundations. Geosynth Int 11(1):35–42

Dash SK, Rajagopal K, Krishnaswamy NR (2007) Behaviour of geocell-reinforced sand beds under strip loading. Can Geotech J 44(7):905–916

Dash SK, Reddy PD, Raghukanth TG (2008) Subgrade modulus of geocell-reinforced sand foundation. Ground Improv 161(12):79–87

Dash SK (2010) Influence of relative density of soil on performance of geocell reinforced sand foundations. J Mater Civ Eng ASCE 22(5):533–538

Dash SK (2012) Effect of geocell type on load carrying mechanism of geocell reinforced sand foundations. Int J Geomech ASCE 12(5):537–548

Pokharel SK, Han J, Leshchinsky D, Parsons RL, Halahmi I (2010) Investigation of factors influencing behavior of single geocell-reinforced bases under static loading. Geotext Geomembr 28(6):570–578

Rajagopal K, Krishnaswamy NR, Latha GM (1999) Behaviour of sand confined with single and multiple geocells. Geotext Geomembr 17(3):171–184

Latha GM, Murthy VS (2007) Effects of reinforcement form on the behaviour of geosynthetic reinforced sand. Geotext Geomembr 25(1):23–32

Wu CS, Hong YS (2009) Laboratory tests on geosynthetics-encapsulated sand column. Geotext Geomembr 27(2):107–120

Sitharam TG, Sireesh S, Dash SK (2005) Model studies of a circular footing supported on geocell-reinforced clay. Can Geotech J 42(2):693–703

Sitharam TG, Sireesh S, Dash SK (2007) Performance of surface footing on geocell-reinforced soft clay beds. Geotech Geol Eng 25(5):509–524

Latha GM, Rajagopal K, Krishnaswami NR (2006) Experimental and theoretical investigation on geocell supported embankment. Int J Geomech 6(1):30–35

Latha GM, Dash SK, Rajagopal K (2008) Equivalent continuum simulations of geocell reinforced sand beds supporting strip footings. Geotech Geol Eng 26(4):387–398

Latha GM, Somwanshi A (2009) Bearing capacity of square footings on geosynthetic reinforced sand. Geotext Geomembr 27(4):281–294

Henkel DJ, Gilbert GD (1952) The effect of the rubber membrane on the measured triaxial compression strength of clay samples. Geotechnique 3(1):20–29

Duncan JM, Seed HB (1967). Corrections for strength test data. J Soil Mech Found Div ASCE 93(5):121–137

Bathurst RJ, Karpurapu R (1993) Large-scale triaxial compression testing of geocell-reinforced granular soils. Geotech Test J 16(3):296–303

Fabymole PA, Sireesh S, Madhav MR (2014) Numerical modelling of strip footing on geocell reinforced beds. Ground Improv 168(3):194–205

Han J, Yang X, Leshchinsky D, Parsons RL (2008) Behaviour of geocell reinforced sand under a vertical load. Transp Res Rec J Transp Res Board 2045:95–101

Sireesh S, Puppala AJ, Sitharam TG, Gowrisetti S (2009) Numerical simulation of geocell-reinforced sand and clay. Ground Improv 162(4):185–198

Sireesh S, Sitharam TG, Dash SK (2009) Bearing capacity of circular footing on geocell-sand mattress overlying clay bed with void. Geotext Geomembr 27(2):89–98

Sireesh S, Sailesh P, Sitharam TG, Puppala AJ (2013) Numerical analysis of geocell reinforced ballast overlying soft clay subgrades. Geomech Eng 5(3):263–281

Yang X, Han J, Parsons RL, Leshchinsky D (2010) Three-dimensional numerical modelling of single geocell reinforced sand. Front Archit Civ Eng China 4(2):233–240

Hegde A, Sitharam TG (2013) Experimental and numerical studies on footings supported on geocell reinforced sand and clay beds. Int J Geotech Eng 7(4):347–354

Hegde A, Sitharam TG (2014) Effect of infill materials on the performance of geocell reinforced soft clay beds. Geomech Geoeng 10(3):1–11

Latha GM, Dash SK, Rajagopal K (2009) Numerical simulation of the behavior of geocell reinforced sand in foundations. Int J Geomech ASCE 8(4) 143–152

Bathrust RJ, Knight MA (1998) Analysis of geocell reinforced-soil covers over large span conduits. Comput Geotech 22(3):205–219

Sitharam TG, Hegde A (2013) Design and construction of geocell foundation to support embankment on soft settled red mud. Geotext Geomembr 41:55–63

Mehdipour I, Ghazavi M, Moayed RZ (2013) Numerical study on stability analysis of geocell reinforced slopes by considering the bending effect. Geotext Geomembr 37:23–34

Webster SL (1979) Investigation of beach sand trafficability enhancement using sand-grid confinement and membrane reinforcement concepts. Technical Report GL-79-20. US Army Corps of Engineers, Vicksburg, MS.

Rai M (2010) Geocell-sand mattress overlying soft clay subgrade: behaviour under circular loading. Ph.D. thesis, IIT Guwahati

Wesseloo J (2004) The strength and stiffness of geocell support packs. Ph.D. thesis, Univesity of Pretoria, Pretoria

Wesseloo J, Visser AT, Rust E (2009) The stress-strain behavior of multiple cell geocell packs. Geotext Geomembr 27(1):31–38

Chummar AV (1972) Bearing capacity theory from experimental results. J Soil Mech Found Div ASCE 98(12):1311–1324

Biswas A (2016) Influence of subsoil strength on performance of geosynthetic-reinforced foundations. Ph.D. thesis, IIT Guwahati

Yoon YW, Heo SB, Kim KS (2008) Geotechnical performance of waste tires for soil reinforcement from chamber tests. Geotext Geomembr 26(1):100–107

Webster SL, Alford SJ (1978) Investigation of construction concepts for pavements across soft ground. Technical Report S-78-6, United States Army Corps of Engineers, Waterways Experiment Station, Mississippi, USA

Johnson JE (1982) Bridge and tidal waters. Munic Eng 109:104–107

Robertson J, Gilchrist AJT (1987) Design and construction of a reinforced embankment across soft lakebed deposits. In: Proceedings of the International Conference on Foundations and Tunnels, London, M. C. Forde, vol 2. Engineering Technics Press, Edinburgh, pp 84–92

Paul J (1988) Reinforced soil system in embankments-construction practices. In: Proceedings of the International Geotechnical Symposium on practice of Earth Reinforcement, Fukuoka, Japan, October, pp 461–466

Dean R, Lothian E (1990) Embankment construction problems over deep variable soft deposits using a geocell mattress.In: McGown A, Yeo KC, Andrawes KZ (eds) Performance of reinforced soil structures. Thomas Telford Ltd., London, pp 443–447

Boyle S, Robertson K (2007) Geocell, geogrid and reinforced-soil restoration of eroded steep slopes. Geosynthetics 25(2):20–26

Cowland JW, Wong SCK (1993) Performance of a road embankment on soft clay supported on a geocell mattress foundation. Geotext Geomembr 12(8):687–705

Gupta P, Somnath B (1994) Bearing capacity improvement using geogrids. J Civ Eng Constr Rev 7:12–13

Koerner RM (1997) Designing with geosynthetics 3rd edn. Prentice Hall Inc., New Jersey

Forsman J, Slunga E, Lahtinen P (1998). Geogrid and geocell reinforced secondary road over deep peat deposit. In: Proceedings of the 6th International Conference on Geosynthetics, vol 2. Atlanta, pp 773–778

Biswas A, Dash SK, Krishna AM (2012) Parameters influencing the performance of geocell-reinforced foundation system: a brief review. In: Proceedings of Indian Geotechnical Conference. IIT Delhi, vol 1, pp 365–368

Akinmusuru JO, Akinbolade JA (1981) Stability of loaded footings on reinforced soil. J Geotech Eng Div ASCE 107(6):819–827

Fragaszy RJ, Lawton E (1984). Bearing capacity of reinforced sand subgrades. J Geotech Eng Div ASCE 110(10):1500–1507

Guido VA, Chang DK, Sweeney MA (1986) Comparison of geogrid and geotextile reinforced earth slabs. Can Geotech J 23:435–440

Love JP, Burd HJ, Milligan, G.W.E., Houlsby GT (1987) Analytical and model studies of reinforcement of a layer of granular fill on soft clay subgrade. Can Geotech J 24(4):611–622

Kim SI, Cho SD (1988) An experimental study on the contribution of geotextiles to bearing capacity of footings on weak clays. In: Proceedings of the International Geotechnical Symposium on Theory and Practice of Earth Reinforcement, Fukuoka, Japan, pp 215–220

Samatani NC, Sonpal RC (1989) Laboratory tests of strip footing on reinforced cohesive soil. J Geotech Eng ASCE 115(9):1326–1330

Huang CC, Tatsuoka F (1990) Bearing capacity of reinforced horizontal sandy ground. Geotext Geomembr 9(1):51–82

Mandal JN, Sah HS (1992) Bearing capacity tests on geogrid- reinforced clay. Geotext Geomembr 11(3):327–333

Shin EC, Das BM, Puri VK, Yen SC, Cook EE (1993) Bearing capacity of strip foundation on geogrid reinforced clay. Geotech Test J ASTM 16(4):534–541

Khing KH, Das BM, Puri VK, Cook EE, Yen SC (1993) The bearing capacity of a strip foundation on geogrid-reinforced sand. Geotext Geomembr 12(4):351–361

Khing KH, Das BM, Puri VK, Yen SC, Cook EE (1994) Foundation on strong sand underlain by weak clay with geogrid at the interface. Geotext Geomembr 13(3):199–206

Das BM, Omar MT (1994) The effects of foundation width on model tests for the bearing capacity of sand with geogrid reinforcement. Geotech Geol Eng 12(3):133–141

Michael AT, Collin JG (1997) Large model spread footing load tests on geosynthetic reinforced soil foundations. J Geotech Geoenviron Eng ASCE 123(1):66–72

Alawaji HA (2001) Settlement and bearing capacity of geogrid reinforced sand over collapsible soil. Geotext Geomembr 19(2):75–88

Sitharam TG, Sireesh S (2004) Model studies of embedded circular footing on geogrid reinforced sand beds. Ground Improv 8(2):69–75

Basudhar PK, Saha S, Deb K (2007) Circular footings resting on geotextile reinforced sand bed. Geotext Geomembr 25(6):377–384

Sawwaf ME, Nazer A (2005). Behaviour of circular footings resting on confined granular soil. J Geotech Geoenviron Eng ASCE 131(3):359–366

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Biswas, A., Krishna, A.M. Geocell-Reinforced Foundation Systems: A Critical Review. Int. J. of Geosynth. and Ground Eng. 3, 17 (2017). https://doi.org/10.1007/s40891-017-0093-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40891-017-0093-7