Abstract

The shear behaviour of rock discontinuities is a key factor affecting the stability of rock engineering. To study the effect of heterogeneity on the shear behavior of rock joints, laboratory tests were performed on heterogeneous rock joints with different joint roughness coefficient (JRC). As a comparison, two groups of tests were also conducted on the corresponding homogeneous rock joints. Test results showed that, the shear stress–displacement curves of low strength rock joints, heterogeneous rock joints and high strength rock joints with low roughness are all in line with the trend of the typical single peak value curve, while the curves of high strength rock joints with JRC greater than 12–14 accord with the trend of strain hardening curve. The shear displacement corresponding to the peak shear strength of heterogeneous rock joints is smaller than that of the homogeneous rock joints. The shear strengths of the three types rock joints all grow exponentially with the increase of roughness. The shear strength and its growth rate of heterogeneous rock joints were between those of two corresponding homogeneous rock joints. The surface damage of rock joints increases with the increase of JRC and the damage degree of high strength rock joints is more serious than that of low strength rock joints with the same JRC. The surface damage of heterogeneous rock joints presents obvious heterogeneous characteristics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Rock discontinuities, such as faults, joints, beddings, fractures and broken zones, are widely developed in natural rock masses (He et al. 2018; Sun et al. 2014; Zhang et al. 2017a, b; Zhao and Feng 2018). The existence of rock discontinuities weakens the strength of rock mass (Wan et al. 2018; Jiang and Yang 2018; Shrivastava and Rao 2015; Su and Pan 2018), which may causes the failure of rock engineering, resulting in huge casualties and economic losses (Haftani et al. 2014; Grenon et al. 2017; Zhang et al. 2012). For instance, the rock bursts in the Jinping II Hydropower Station caused casualties among construction workers and damage to many sets of equipment; the 2012 major mining slope failure of the East wall of the LAB Chrysotile mine in Canada caused the loss of the local highway (Road 112), the main commercial link between the region and the Northeast USA. Actually, the stability of rock masses is dominantly controlled by the shear strength of discontinuities. Therefore, the study of rock discontinuity shear behavior has remained an important research theme in the past decades (Singh and Basu 2018). Cao et al. (2011) conducted shear tests of natural rock joint under different normal stresses and obtained the relationships between shear stress and shear displacement under different normal stresses. The 3D scanning images of joint surface are obtained and the relationships between shear strength of joint under different normal stresses and morphology characteristic evolution of joint surface are analyzed. Lei et al. (2017) conducted acoustic emission (AE) experiment of red sandstone samples and obtained the curves of the stress-strains about acoustic emission characteristics, stress, strain and time. Wang et al. (2015) carried out shear test with different shear velocities of four groups of rock-like joints with different roughness coefficients by using JAW-600 coupled shear-flow machine and proposed a new shear strength criterion considering shear velocity for rough rock joints based on the experimental data and Barton’s criterion for shear strength. Zhang et al. (2016a, b) performed shear tests on replicas of fresh, mated, and unweathered natural rock joint with different morphology under different normal stress levels and established a new peak shear strength criterion on the basis of the analysis of shear mechanism and the new model of peak dilatancy angle. Meng et al. (2018) carried out shear test on tensile granite joints under a constant normal load, investigated the damage characteristics of asperity based on the AE technique and discussed the influences of asperity damage on post-peak behavior and dilatation. Zhou et al. (2012) performed the numerical simulation of rock joint shear test by using the particle flow theory based on particle flow code (PFC) and deeply discussed the mechanical evolution law and failure mechanism during the shear test process from macro and meso-scale perspectives. Bewick et al. (2014a, b) used the PFC2D program based on discrete element method to simulate the shear behavior of intact (non-jointed) low-porosity brittle rock. The simulations are compared to the laboratory-generated ruptures and used to investigate rupture at various normal stress magnitudes. Bahaaddini et al. (2015) investigated the effect of the microscale properties of the smooth joint model on the shear behaviour of rock joints under various shearing mechanisms using the particle flow code PFC2D. Oh et al. (2017) employed DEM code with Voronoi tessellation to investigate the influence of important parameters such as joint strength, applied normal stress and asperity on magnitude of rock joint dilation during shear.

The studies mentioned above were mainly concerned with the shear behavior and failure mechanism of homogeneous rock joints (the lithology on both sides of the joint is same). However, heterogeneous rock joints (the lithology on both sides of the joint is different) are also widely developed in natural rock masses which can cause geological disasters and affect the stability of engineering structures (Mandrone 2006; Wang et al. 2014). For example, the sandstone and mudstone interbedded strata in the Three Gorges Reservoir is typical representatives of the heterogeneous joints and the landslide in the Three Gorges reservoir is mostly developed between the heterogeneous interbed and between the strata with weak intercalated layer; the typical Northern Apennine flysches are characterized by rhythmic alternations of ‘hard’ layers of sandstone and ‘weak’, fine-grained pelitic layers. Their poor geomechanical properties are also one of the main causes of landslide. It can be seen that the existence of heterogeneous joints brings great challenges to the stability of rock mass engineering, and its influence can’t be ignored. To solve this problem, the shear test is performed on heterogeneous rock joints with different joint roughness coefficient (JRC) in this study. As a comparison, two groups of tests were also conducted on corresponding homogeneous rock joints. Through the comparative analysis of the shear behavior between heterogeneous rock joints and homogeneous rock joints with different JRC, this study aims to reveal the effect of heterogeneity on the shear behavior of rock joints and provide the basis for the evaluation of rock mass stability.

2 Experimental Methods

2.1 Specimen Preparation

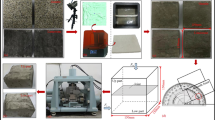

To investigate the shear behavior of homogeneous joints and heterogeneous joints with different JRC, three kinds of rock joints are considered in the test: joints with low strength rock on both sides (LSRJ), joints with low–high strength rock on both sides (LHSRJ), and joints with high strength rock on both sides (HSRJ), respectively. Homogeneous joints are used for comparison. In order to obtain the rock joints with different strength, the orthogonal design was used to determine the material proportions of two different rocks. The first type is the low strength sample made of white cement, fine sand, water and water superplasticizer at the weight ratio of 1:1:0.3:0.005; The second type is the high strength sample made of ash cement, fine sand, water and water superplasticizer at the weight ratio of 1:0.5:0.25:0.005; Standard profiles published by Barton and Choubey (1977) and Barton (1973) were selected to simulate the joint surface. The steel mould with different JRC was maked by Laser Cutting Technology according to the Barton curve, as shown in Fig. 1. Each kind rock joints consists of smooth joints and joints with JRC of 0–2, 4–6, 8–10, 12–14, 16–18, as shown in Fig. 2. The dimensions of the samples are 200 × 100 × 100 mm.

2.2 Test Apparatus and Procedure

Direct shear tests were performed using JAW-600 coupled shear-flow testing system as shown in Fig. 3. The apparatus consists of four main units, namely vertical load unit, horizontal load unit, data acquisition and servo-control unit. The shearing device consists of normal and tangential loading cylinders, and the maximum output force is 600 KN. Both normal and tangential loading can be controlled by force and displacement.

In this paper, the normal stress is not taken as an important factor, which is uniformly selected as 1 MPa and the shear rate is chosen as the static limit value of joints of 0.01 mm/s. In the test, the normal load is first applied to a predetermined value and keep constant until the end of the test, and then the shear load is applied. The normal load and shear load are controlled by force and displacement, respectively. All shear tests were carried out until the shear displacement reached to 8 mm. The shear stress and shear displacement were recorded automatically during each shear test through a digitized data acquisition system until the end of direct shear test.

3 Results Analysis

3.1 Characteristics of Shear Stress–Displacement Curve

Figure 4 shows the shear stress–displacement curves of LSRJ, HSRJ and LHSRJ with different JRC after shearing, respectively. By comparing the characteristics of the curves, it can be seen that:

-

(1)

The shear stress–displacement curves of LSRJ, LHSRJ and HSRJ with low JRC are all in line with the trend of the typical single peak value curve, while the curves of HSRJ with JRC greater than 12–14 accord with the trend of strain hardening curve, as shown in Fig. 4, the shear stress increases gradually with the occurrence of shear deformation, but no obvious peak value appears until reaches a constant value.

-

(2)

In the same group of tests, the trend of the shear stress–displacement curve of joints under different JRC is basically the same. In other words, the influence of the increase of JRC on the shear stress–displacement curve of the rock joints is not obvious. With the increase of JRC, the shear strength and its growth rate of joints increases (Gu et al. 2003). The shear strength of LHSRJ with smooth joint is 2.91 MPa which is not different from that of homogeneous rock joints, because the rock surface on both side of the joints are relatively smooth at this time, and there is almost no inter embed phenomenon on the joint. The shear strength mainly depends on the cohesion of the joints, and has no significant relationship with the strength of the rock on both sides of the joints.

-

(3)

The shear stiffness, which is defined as the ratio of the peak shear strength to the horizontal displacement, increases with the increase of homogeneous rock joints roughness and is not significantly affected by heterogeneous rock joints roughness.

From the shear stress–displacement curves of homogeneous rock joints and heterogeneous rock joints with the same JRC shown in Fig. 5, it can be seen that the peak strength and residual strength of the HSRJ are the largest. The peak strength and residual strength of LHSRJ are between those of LSRJ and HSRJ (Zhang et al. 2016a, b). The shear displacement corresponding to the shear peak strength of heterogeneous rock joints is smaller than that of homogeneous rock joints, and the shear displacement corresponding to the shear peak strength of the LSRJ is the largest. The reason is that the strength of the rock on both sides of LHSRJ is different. The high strength rock is more easily pressed into the low strength rock under the action of initial normal load, which leads to the higher closure degree of LHSRJ and the smaller shear displacement. The shear stiffness of LHSRJ is closer to that of HSRJ, while the shear stiffness of LSRJ is the least.

3.2 Characteristics of Shear Strength

Table 1 shows the peak shear strength of three kinds of rock joints with different JRC. The shear strength data of joints shown in Table 1 are fitted, and the relationship curves between shear strength and JRC of three kinds of rock with different strength are described and compared, as shown in Fig. 6.

It can be seen from Table 1 and Fig. 6 that the shear strength of three types rock joints increases exponentially with the increase of JRC, that is, with the increase of JRC, the shear strength of joints increases and the growth rate increases gradually.

The shear strength of smooth joint of LSRJ is 2.83 MPa. The shear strengths of rock joints increases to 3.38 MPa, 3.72 MPa, 4.20 MPa, 4.88 MPa, and 5.78 MPa and the growth rate is 19.43%, 31.45%, 48.41% and 104.24% when the JRC increases to 0–2, 4–6, 8–10 and 16–18, respectively. The shear strength of smooth joint of LHSRJ is 2.91 MPa. The shear strengths of rock joints increases to 3.59 MPa, 3.87 MPa, 4.63 MPa, 5.27 MPa and 6.31 MPa and the growth rate is 23.37%, 32.99%, 59.10%, 81.10% and 116.84% when the JRC increases to 0–2, 4–6, 8–10 and 16–18, respectively. The shear strength of smooth joint of HSRJ is 3.17 MPa. The shear strengths of rock joints increases to 3.98 MPa, 4.43 MPa, 5.34 MPa, 6.02 MPa and 6.97 MPa and the growth rate is 25.56%, 39.75%, 68.45%, 89.91% and 119.87% when the JRC increases to 0–2, 4–6, 8–10 and 16–18, respectively.

The fitting relation between the shear strength and JRC of three types rock joints is exponential, the fitting coefficients are 0.999, 0.997 and 0.995 respectively. The fitting relations are shown by Eqs. (1), (2) and (3), and the fitting accuracies are high.

By comparing and analyzing the variation of shear strength with JRC of LSRJ, LHSRJ and HSRJ, it can be seen that the shear strength of three types joints grow exponentially with the increase of JRC. However, the shear strength of the three types joints is different, which shows that the shear strength of HSRJ is the largest, that of LHSRJ is the second, and that of LSRJ is the least. With the increase of JRC, the growth rate of shear strength of HSRJ is the highest, that of LHSRJ is the second, and that of LSRJ is the lowest. The reason is that with the increase of JRC, the meshing of HSRJ is more obvious than that of LSRJ and LHSRJ under normal pressure, which made the growth rate of shear strength of HSRJ is higher than that of LSRJ and LHSRJ. It can be seen from Fig. 6 that when the JRC is low, the shear strength of LHSRJ is closer to that of LSRJ, and when the JRC increases to 8–10, the shear strength of LHSRJ is gradually closer to that of HSRJ. This is because when the JRC is low, the difference of strength on both sides of LHSRJ leads to a large number of bulges of low strength rock sheared off during shearing while the bulges on the surface of high strength rock is rarely damaged. The shear strength of low strength rock plays a dominant role in the shear strength of the joints at this time, so when the JRC is low, the shear strength of LHSRJ is closer to that of LSRJ. With the increase of JRC, the number of rock bulges and the degree of fluctuation on both sides of the joints will increase accordingly, and more high strength rock bulges with greater fluctuation degree will incise and even embed into the low strength rock surface, resulting in stronger plow effect, which will increase the damage degree of high strength rock. Therefore, the shear strength is closer to that of high strength rock joints.

3.3 Comparison of Shear Failure Characteristics

The shear failure characteristics of LSRJ and HSRJ with different JRC are as shown in Fig. 7a, b, respectively. From Fig. 7a, b, it can be seen that when the JRC of LSRJ and HSRJ is 0–2, the shear failure mode is mainly the wear of joint bulges. When the JRC of LSRJ and HSRJ exceeds 8–10, in addition to the wear of bulges of joints, the shear failure mode of joints is accompanied by the shearing off of a large number of joint bulges.

In summary, the failure mode of joints with low JRC is mainly surface wear of joints, and the resistance to shear of joints is mainly due to the surface adhesion effect. With the increase of JRC, the number of joint bulges and the degree of fluctuation will increase accordingly. The resistance to shear of joints mainly due to the surface adhesion effect and engaging effect and the failure mode of joints are surface friction and the shearing off of joint bulges.

By comparing Fig. 7a with b, it can be seen that the damage degree of HSRJ is more serious than that of LSRJ when the JRC is the same. This indicates that HSRJ still need to overcome the large friction resistance after the bulges sheared off. At the same time, it also explains the phenomenon that the reduction of shear stress of HSRJ in post-peak stage is small and the strain softening is not obvious.

The shear failure characteristics of heterogeneous rock joints are different from those of the homogeneous rock joints. In order to more clearly observe the wear degree of the specimen and the quantity and distribution of debris, it have been circumscribed in red contour, as shown in Fig. 7c. It can be seen that all joints were damaged to some extent and with the increase of JRC, the quantity of debris produced by wear on joints gradually increase, indicating that the damage degree of specimen increases with the increase of JRC. Moreover, the wear of joints has obvious heterogeneity, and the quantity of white (low strength) debris produced on gray (high strength) specimens is far more than gray debris produced on white specimens.

The resistance to shear of joints is mainly due to the surface adhesion effect, engaging effect and plow effect, correspondingly, the failure modes of joints are surface friction and the shearing off of joint bulges. The difference of strength on both sides of LHSRJ with low JRC leads to a large number of bulges of low strength rock sheared during shearing while the bulges on the surface of high strength rock is rarely damaged. Therefore, the quantity of white (low strength) debris produced on gray (high strength) specimens is more than gray debris produced on white specimens. With the increase of JRC, the number of rock bulges and the degree of fluctuation on both sides of joints increase accordingly, and more high strength rock bulges with greater fluctuation degree incise and even embed into the low strength rock surface, resulting in stronger plow effect, which will increase the damage degree of rock. Therefore, with the increase of JRC, the quantity of debris gradually increases.

4 Conclusion

The deformation and strength properties of heterogeneous rock joints have an important influence on the evaluation and control of rock mass stability. In this paper, shear tests of heterogeneous rock joints and corresponding homogeneous rock joints with different JRC are carried out. According to the experimental results, the following conclusions are drawn:

-

(1)

The shear stress–displacement curves of LSRJ, LHSRJ and HSRJ with low JRC are all in line with the typical single peak value curve, while HSRJ with JRC greater than 12–14 accord with the strain hardening curve.

-

(2)

The shear displacement corresponding to the peak shear strength of heterogeneous rock joints is smaller than that of the homogeneous rock joints. The reason is that the high strength rock is more easily pressed into the low strength rock under the action of initial normal load, which leads to the higher closure degree of heterogeneous rock joints and the smaller shear displacement.

-

(3)

The shear strengths of the three types rock joints all grow exponentially with the increase of JRC. The shear strength and its growth rate of heterogeneous rock joints were between those of two corresponding homogeneous rock joints.

-

(4)

The surface damage of rock joints increases with the increase of JRC and the damage degree of HSRJ is more serious than that of LSRJ with the same JRC. The surface damage of heterogeneous rock joints presents obvious heterogeneous characteristics.

Through the comparative analysis of the shear behavior between heterogeneous rock joints and homogeneous rock joints with different JRC, this study revealed the effect of heterogeneity on the shear behavior of rock joints and provided the basis for the evaluation of rock mass stability.

References

Bahaaddini M, Hagan PC, Mitra R, Hebblewhite BK (2015) Parametric study of smooth joint parameters on the shear behaviour of rock joints. Rock Mech Rock Eng 48(3):923–940

Barton N (1973) Review of a new shear-strength criterion for rock joints. Eng Geol 7(4):287–332

Barton N, Choubey V (1977) The shear strength of rock joints in theory and practice. Rock Mech 10(1–2):1–54

Bewick RP, Kaiser PK, Bawden WF (2014a) DEM simulation of direct shear: 2. Grain boundary and mineral grain strength component influence on shear rupture. Rock Mech Rock Eng 47(5):1673–1692

Bewick RP, Kaiser PK, Bawden WF, Bahrani N (2014b) DEM simulation of direct shear: 1. Rupture under constant normal stress boundary conditions. Rock Mech Rock Eng 47(5):1647–1671

Cao P, Fan X, Pu C, Chen Y, Zhou H, Zheng X, Zhang C (2011) Shear test of joint and analysis of morphology characteristic evolution of joint surface. Chin J Rock Mech Eng 30(3):480–485

Grenon M, Caudal P, Amoushahi S, Turmel D, Locat J (2017) Analysis of a large rock slope failure on the east wall of the LAB chrysotile mine in Canada: back analysis, impact of water infilling and mining activity. Rock Mech Rock Eng 50(2):403–418

Gu XF, Seidel JP, Haberfield CM (2003) Direct shear test of sandstone-concrete joints. Int J Geomech 3(1):21–33

Haftani M, Gheshmipour AA, Mehinrad A, Binazadeh K (2014) Geotechnical characteristics of Bakhtiary dam site, SW Iran: the highest double-curvature dam in the world. Bull Eng Geol Env 73(2):479–492

He D, Yang W, Cheng Y (2018) Surface morphology of structural plane and effects of the shear strength parameters. Adv Civ Eng 2018:1–7

Jiang Q, Yang B (2018) Manufacturing of natural rock joints by engraving and analysis of wearing damage of natural rock joints under shear tests. Chin J Rock Mech Eng 37(11):2476–2488

Lei N, Zhang X, Zhong Y, Ke R, Li S (2017) Experimental investigation on acoustic emission of red sandstone in Wuyishan scenic area under shear force condition. Chin J Geol Hazard Control 28(2):85–91

Mandrone G (2006) Engineering geological mapping of heterogeneous rock masses in the Northern Apennines: an example from the Parma Valley (Italy). Bull Eng Geol Environ 65(3):245–252

Meng F, Zhou H, Wang Z, Zhang C, Li S, Zhang L, Kong L (2018) Characteristics of asperity damage and its influence on the shear behavior of granite joints. Rock Mech Rock Eng 51(2):429–449

Oh J, Li Y, Mitra R, Canbulat I (2017) A numerical study on dilation of a saw-toothed rock joint under direct shear. Rock Mech Rock Eng 50(4):913–925

Shrivastava AK, Rao KS (2015) Shear behaviour of rock joints under CNL and CNS boundary conditions. Geotech Geol Eng 33(5):1205–1220

Singh HK, Basu A (2018) A comparison between the shear behavior of ‘real’ natural rock discontinuities and their replicas. Rock Mech Rock Eng 51(1):329–340

Su F, Pan P (2018) Experimental study on failure process and mechanism of marble containing natural hard structural plane. Chin J Rock Mech Eng 37(3):611–620

Sun S, Sun H, Wang Y, Wei J, Liu J, Kanungo DP (2014) Effect of the combination characteristics of rock structural plane on the stability of a rock-mass slope. Bull Eng Geol Env 73(4):987–995

Wan W, Liu J, Liu J (2018) Effects of asperity angle and infill thickness on shear characteristics under constant normal load conditions. Geotech Geol Eng 36(4):2761–2767

Wang J, Li C, Yong R, Liang D (2014) Comparison study on shear strength parameters of Jurassic different rock discontinuities in Three Gorges Reservoir region. Coal Geol Explor 5:61–66

Wang G, Zhang X, Jiang Y, Zhang Y (2015) New shear strength criterion for rough rock joints considering shear velocity. Chin J Geotech Eng 8:1399–1404

Zhang C, Feng X, Zhou H, Qiu S, Wu W (2012) Case histories of four extremely intense rockbursts in deep tunnels. Rock Mech Rock Eng 45(3):275–288

Zhang X, Jiang Q, Chen N, Wei W, Feng X (2016a) Laboratory investigation on shear behavior of rock joints and a new peak shear strength criterion. Rock Mech Rock Eng 49(9):3495–3512

Zhang Y, Wang D, Tang H, Li C, Yi X (2016b) Study of shear strength characteristics of heterogeneous discontinuities using PFC2D simulation. Rock Soil Mech 37(4):1031–1041

Zhang P, Zhao Y, Zhang M, Wu S, Ma R, Kan Z (2017a) Experimental study on stress variation law of roof, floor and nearby aquifer induced by coal seam mining under large dip fault. J Shandong Univ Sci Technol (Nat Sci) 36(6):60–65

Zhang W, Wang C, Chen X (2017b) Sand inrush mechanism influenced by secondary faults in working face under alluvium mining. J Shandong Univ Sci Technol (Nat Sci) 36(6):90–95

Zhao L, Feng J (2018) Interrelationship study between rock mechanical stratigraphy and structural fracture development. J Shandong Univ Sci Technol (Nat Sci) 37(1):35–46

Zhou Y, Misra A, Wu S (2012) Macro- and meso-analyses of rock joint direct shear test using particle flow theory. Chin J Rock Mech Eng 31(6):1245–1256

Acknowledgements

This work is supported by the National Natural Science Foundation of China (No. 51379117) and Natural Science Foundation of Shandong Province, China (ZR2019BEE065 and ZR2017PEE018).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiang, Y., Wang, Y., Yan, P. et al. Experimental Investigation on the Shear Properties of Heterogeneous Discontinuities. Geotech Geol Eng 37, 4959–4968 (2019). https://doi.org/10.1007/s10706-019-00955-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-019-00955-5