Abstract

Friction capacity (fs) of driven pile in clay is key parameter for designing pile foundation. This study employs Gaussian Process Regression (GPR), and Minimax Probability Machine Regression (MPMR) for determination of fs of driven piles in clay. GPR is a Bayesian nonparametric regression model. MPMR is a probabilistic model. Pile length (L), pile diameter (D), effective vertical stress (σ’v), undrained shear strength (Su) have been used as input variables of GPR and MPMR. The output of the models is fs. The developed GPR, MPMR models have been compared with the Artificial Neural Network (ANN). GPR also gives the variance of predicted fs. The results prove that the developed GPR and MPMR are efficient models for prediction of fs of driven piles in clay.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The determination of friction capacity (fs) of driven pile in clay is a challenging task for geotechnical engineers. The different methods are available for determination of fs of driven pile in clay (Chandler 1968; Tomlinson 1971; McClelland 1972; Burland 1973; Meyerhof 1976; Parry and Swain 1977a, b). The available methods are not reliable (Randolph et al. 1979). Randolph et al. (1979) has nicely explained the mechanism of driven pile in clay. Goh (1995) successfully adopted Artificial Neural Network (ANN) for determination of fs of driven pile in clay. However, ANN has some limitations such as black box approach, arriving at local minima, low generalization capability, absence of probabilistic output, etc. (Park and Rilett 1999; Kecman 2001).

The article uses Gaussian Process Regression (GPR) and Minimac Probability Machine Regression (MPMR) for determination of fs of driven pile in clay. GPR is a probabilistic non-parametric modeling approach. It estimates distributions over functions from training data. Researchers have successfully used GPR for solving different problems in engineering (Pal and Deswal 2010; Xia and Tang 2011; Ni et al. 2012). MPMR is developed based on Minimax Probability Machine Classification (MPMC) by constructing a dichotomy classifier (Strohmann and Grudic 2002). MPMR has been successfully used in the various filed of engineering (Yang et al. 2010; Zhou and Xia 2011; Zhou et al. 2013). This study uses the database collected by Goh (1995) (see Table 1). The dataset contains information about pile length (L), pile diameter (D), effective vertical stress (s’v), undrained shear strength (Su) and fs. The developed GPR and MPMR have been compared with the ANN (Goh 1995). This article is organized as follows. The details of GPR for prediction of fs of driven piles in clay are described in Sect. 2. Section 3 describes MPMR model. The results and discussion are provided in Sect. 4. In Sect. 5, the major conclusions are drawn.

2 Details of GPR

In GPR, the problem is to determine a function \(y = f\left( x \right)\) from the following dataset

where x is input, y is output, Rd is d-dimensional vector space and R is one dimensional vector space. In this study, L, D, σ’v, and Su are used as input variable. fs is output of the GPR. So, \(x = \left[ {L,D,\sigma^{\prime}_{v} ,S_{u} } \right]\) and \(y = \left[ {f_{s} } \right]\).

The joint distribution of y is given by

where \(K\left( {x_{i} ,x} \right)\) is kernel function and I is identity matrix.

For a new input xN+1, the distribution of yN+1 is Gaussian with mean and variance:

The optimum value of hyperparameters of the GPR for a particular data set can be derived by maximizing the log marginal likelihood using common optimization procedures.

In carrying out the formulation, the data has been divided into two sub-sets; such as:

-

(a)

A training dataset: This is required to construct the model. In this study, 45 out of the 65 cases of pile load test are considered for training dataset.

-

(b)

A testing dataset: This is required to estimate the model performance. In this study, the remaining 20 data is considered as testing dataset.

The data is normalized between 0 and 1. The normalization has been done by using the following equation.

where d = any data (input or output), dmin = minimum value of the entire dataset, dmax = maximum value of the entire dataset, and dnormalized = normalized value of the data.

Radial basis function (\(K\left( {x_{i} ,x} \right) = \exp \left\{ { - \frac{{\left( {x_{i} - x} \right)\left( {x_{i} - x} \right)^{T} }}{{2s^{2} }}} \right\}\), s is width of radial basis function) has been used as a kernel function. The program of GPR has been developed by using MATLAB.

3 Details of MPMR

This section will describe briefly MPMR for prediction of fs of driven piles in clay. MPMR has the following form.

where K(xi,x) is kernel function, x is input, y is output, N is number of data, βi and b are output of the MPMR algorithm.

In this study, \(x = \left[ {L,D,\sigma^{\prime}_{v} ,S_{u} } \right]\) and \(y = \left[ {f_{s} } \right]\).

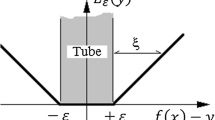

One dataset is obtained by shifting all of the regression data + ε along the output variable axis. The other dataset is obtained by shifting all of the regression data − ε along the output variable axis. A regression surface is the classification boundary between these two classes. More details about MPMR are given by Strohmann and Grudic (2002). MPMR uses the same training dataset, testing dataset, and normalization technique as used by GPR. Radial basis function has been used as kernel function. MATLAB has been used to develop the MPMR

4 Results and Discussion

The performance of GPR model depends on the value of Gaussian Noise (ε) and s. The design values of ε and s have been determined by trial and error approach. The developed GPR gives best performance at ε = 0.01 and s = 0.3. Figures 1 and 2 shows the performance of training and testing dataset respectively. The performance of GPR has been assessed in terms of Coefficient of Correlation (R) and variance account for (VAF). The value of R is calculated from the following equation.

where fsai and fspi are the actual and predicted fs values, respectively, \(\overline{f}_{sa}\) and \(\overline{f}_{sp}\) are mean of actual and predicted fs values corresponding to n patterns. For a good model, the value of R should be close to one.

The following equation has been used to determine VAF

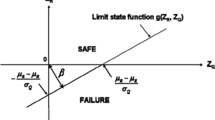

For a good model, the value of VAF should be close to 100 (Erzin and Cetin 2013). It is observed from Figs. 1 and 2 that the value of R and VAF is close to 1 and 100 respectively. So, the developed GPR predicts fs reasonable well. The variance is also obtained from the developed GPR. Figures 3 and 4 illustrates the variance of training and testing dataset respectively. These figures can be used to determine uncertainty. It can be also used to determine probability of failure.

The design values of σ and ε have been determined by trial and error approach for developing the MPMR model. The developed MPMR gives best performance at s = 0.8 and ε = 0.007. Figures 1 and 2 shows the performance of training and testing dataset respectively. The value of R and VAF is close to one and 100 respectively for training as well as testing datasets. Therefore, the developed MPMR proves his capability for prediction of fc of driven piles in clay. The developed GPR and MPMR have been compared with the ANN model developed by Goh (1995). The comparison has been carried out in terms of Root Mean Square Error (RMSE) and Mean Absolute Error (MAE). The values of RMSE and MAE have been determined by using the following relation.

where fsa and fsp are actual and predicted fs values respectively and n is the number of data. Figure 5 shows the bar chart of RMSE and MAE values of the ANN, GPR and MPMR models. It is observed from Fig. 5 that the developed GPR and MPMR outperform the ANN model. The performance of GPR and MPMR is almost same. The developed GPR produces variance of the predicted fs. However, the ANN and MPMR models do not give variance of the predicted fs. GPR assumes data distribution for developing the model. However, ANN and MPMR do not assume any data distribution.

5 Conclusion

This article describes GPR and MPMR for prediction of fs of driven piles in clay. 65 datasets have used to develop the GPR and MPMR models. The data division and normalization technique have been described in the manuscript. The developed GPR and MPMR give reasonable performance. The predicted variance is useful for determination risk. The performance of GPR and MPMR is better than the ANN model. This study gives excellent tools based on the developed GPR and MPMR for prediction of fs of driven piles in clay.

References

Burland JB (1973) Shaft friction of piles in clay-a simple fundamental approach. Ground Eng 6(3):30–42

Chandler RJ (1968) The shaft friction of piles in cohesive soil in terms of effective stress. Civil Eng Publ Works Rev 63:48–51

Erzin Y, Cetin T (2013) The prediction of the critical factor of safety of homogeneous finite slopes using neural networks and multiple regressions. Comput Geosci 51:305–313

Goh ATC (1995) Empirical design in geotechnics using neural networks. Geotechnique 45(4):709–714

Kecman V (2001) Leaming and soft computing: support vector machines, neural networks, and fuzzy logic models. The MIT press, Cambridge

Mcclelland B (1972) Design and performance of deep foundations in clay. General Rep Am Soc Civil Eng Spec Conf Perform Earth Earth Support Struct 2:111–114

Meyerhof GG (1976) Bearing capacity and settlement of pile foundations, Eleventh Terzaghi Lecture. J Geotech Eng Div Am Soc Civil Eng 102:195–228

Ni WK, Wang T, Chen WJ, Tan SK (2012) GPR model with signal preprocessing and bias update for dynamic processes modeling. Control Eng Pract 20(12):1281–1292

Pal M, Deswal S (2010) Modelling pile capacity using Gaussian process regression. Comput Geotech 37(7–8):942–947

Park D, Rilett LR (1999) Forecasting freeway link ravel times with a multi-layer feed forward neural network. Comput Aided Civil Infra Struct Eng 14:358–367

Parry RHG, Swain CW (1977a) Effective stress methods of calculating skin friction on driven piles in soft clay. Ground Eng 10(3):24–26

Parry RHG, Swain CW (1977b) A study of skin friction on piles in stiff clay. Ground Eng 10(8):33–37

Randolph MF, Carter JP, Wroth CP (1979) Driven piles in clay-the effects of installation and subsequent consolidation. Geotechnique 29(4):361–393

Strohmann TR, Grudic GZ (2002) A Formulation for minimax probability machine regression. In: Dietterich TG, Becker S, Ghahramani Z (eds) Advances in neural information processing systems (NIPS) 14. MIT Press, Cambridge

Tomlinson MJ (1971) Some effects of pile driving on skin friction Behaviour of piles. Inst Civil Eng 107(I):14

Xia Z, Tang J (2011) Characterization of structural dynamics with uncertainty by using Gaussian processes. In: Proceedings of the ASME design engineering technical conference, pp 1225–1239

Yang LL, Wang Y, Zhang R (2010) Simultaneous feature selection and classification via Minimax Probability Machine. Int J Comput Intell Syst 3(6):754–760

Zhou YR, Xia K (2011) Nonlinear prediction of fast fading channel based on Minimum Probability machine. In Proceedings of the 2011 6th IEEE conference on industrial electronics and applications ICIEA 2011 5975626:451–454

Zhou Y, Huan J, Hao H, Li D (2013) Video text detection via robust minimax probability machine. Int J Digital Content Technol Appl 7(1):679–686

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Samui, P. Determination of Friction Capacity of Driven Pile in Clay Using Gaussian Process Regression (GPR), and Minimax Probability Machine Regression (MPMR). Geotech Geol Eng 37, 4643–4647 (2019). https://doi.org/10.1007/s10706-019-00928-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-019-00928-8