Abstract

Pavement design in Senegal is based on a linear elastic behavior of pavement materials and the hypothesis of a static loading. However, previous works on the mechanical behavior of road materials showed that this one is reversible after several loading cycles and depends on the applied stress. The described behavior is from then on, purely nonlinear. One of the objectives of this research is to determine the parameters of response of lateritic pavement materials submitted to road traffic by using FEM. Therefore, experiments were made on gravel lateritic soils from Dougar, Sébikotane, Mont-Rolland, Pâ Lo and Ngoundiane. The Young’s modulus of the materials was defined in unconfined compression test while repeated load triaxial test was performed to determine the resilient modulus of the gravels and the appropriate model (Uzan model). An implementation was realized with Cast3M©. The importance of the nonlinearity was revealed in a very clear way and was crucial in the construction of the calculation algorithm. The observations for certain conditions showed that the values of the critical responses are more important for the linear model than for the nonlinear model. However, this trend should be validated by further studies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In Senegal, lateritic roads are affected by premature degradation. This phenomenon can be due to the absence of national standards for pavement design which still justifies the use of the specifications of the Cebtp (BCEOM-CEBTP 1971, 1972, 1984). In first approximation, the main hypothesis made on road materials is the hypothesis of a linear behavior which is based on static loading. Figure 1a shows that the stresses in a linear material is proportional to the strains, with a constant Young’s modulus E. However, several authors showed that the analysis of pavement response is not linear (Fig. 1b) and is characterized by a resilient modulus dependent on the level of stress (Lekarp et al. 2000).

Nonlinear material behavior (NCHRP 2004)

The importance of the nonlinear responses of road pavement materials in the determination of critical values was shown in an extensive way by some authors and tools (Harichandran et al. 1989; ILLI-PAVE© 1990; DAMA© 1991; Huang 1993; Zaghoul and White 1993; Chen et al. 1995; Dehlen 1969; Ullidtz 1998). These works showed that the nonlinearity of the base layer has an important effect on the calculation of the critical response parameters and significant differences were found with linear models (Samb 2014). Kim (2007) made a pavement modeling by using ABAQUS™ and showed that the tensile strains at the bottom of the asphalt layer, the vertical strains on top of the subgrade and on the surface deflection increase respectively with 29, 49 and 44% for the nonlinear model. The NCHRP (2004) makes a study based on the comparison between linear axisymmetric solutions and nonlinear solutions for a number of parameters of response by using the finite element program DSC2D©. For the structures of high traffic roads, the linear analysis predicted differences of about 30% for the tensile strain at the bottom of the asphalt layer and the compression strain on top of the subgrade. These variances decreases for both parameters, with the increase in stiffness of the asphalt layer. All these results confirm the importance of nonlinearity in pavement modeling. In Senegal, numerous studies include the mechanical behavior of lateritic gravels. Fall (1993) and Fall et al. (2007) worked on the monotonous and cyclic behavior of lateritic materials treated or not with cement. The aim of this study is to determine the critical parameters of response of lateritic pavements submitted to traffic loading. The question related to the impact of the nonlinearity on the behavior of untreated lateritic gravel soils and those treated with cement, remains a major stake. All the results will have to allow to pronounce better on the problem of road design in Senegal and to propose further studies that can lead to solutions. The determination of the input parameters of the FEM, particularly the parameters of the resilient modulus of Uzan model (1985) help to undertake a numerical modeling with Cast3M©. Developed by the Laboratoire de Mécanique Systèmes et Simulation within the Commissariat Français à l’Energie Atomique (CEA), Cast3M© is a computer code for the analysis of structures by the finite element method. It is characterized by the exceptional flexibility of the high level macro-language, GIBIANE, so that the user is able to adapt or extend the GIBIANE script to solve any kind of FE problem. The flexibility just referred to, is enhanced, for the programmer, by means of a programming language ESOPE (similar to Fortran) which is used to define new GIBIANE operators and data structures. For the nonlinear model, a calculation algorithm was built to take into account the nonlinearity of the mechanical behavior as well as the variation of the resilient modulus according to the level of stress (Samb 2014).

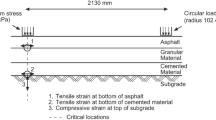

The discretization of the model consists of four layers:

-

Asphalt layer (HMA),

-

Base layer treated or no with cement;

-

Subbase layer with untreated gravel lateritic soils;

-

Subgrade layer with sandy material.

For the nonlinear model, a calculation algorithm was built and take into account the variation of the resilient modulus according to the level of stress. It is worth noticing that the configuration of the load allows us to considerably work with the 2D axisymmetric model since the 3D model gives results appreciably equal in case the load respects the axial symmetry. From there, all the simulations of our model were made with the 2D axisymmetric model.

2 Preliminary Test Results and Sample Preparation for Mechanical Tests

The preliminary tests (size distribution, plasticity, Proctor) were performed on five gravel lateritic soils collected in five sites (Sebikotane, Ngoundiane, Dougar, Pâ Lo and Mont-Rolland). For simple compression tests and repeated triaxial test, the test samples were realized on untreated soils and on gravel lateritic soils improved with 1% cement, 2% cement and 3% cement. The nomenclature is given at Table 1. The compaction was made in 95% of the OPM (Modified Optimum Proctor) with regard to the specifications of CEBTP (BCEOM-CEBTP 1991) for base layers. Figure 2 shows the results of gradations tests. According to the obtained results, the materials seem to contain a high percentage of gravels except the laterite of Pâ Lo which seems to have a high percentage of fine particles. The laterite of Mont-Rolland have a high percentage of fines particles while compared to the other lateritic soils. The laterite of Dougar present a spread and intermittent particle size distribution. All the materials have a spread particle size distribution. Among them, Dougar and Sebikotane show a more uniform particle size distribution. Besides, the plasticity of the lateritic soils have been studied by Atterberg’s Limits. The results are given in Table 2. It is showed that the laterite of Pa Lo has the higher limits of liquidity and plasticity, followed by the laterite of Ngoundiane, then by Mont-Rolland, then by Dougar, then by Sebikotane. The FEM was realized with the laterite of Ngoundiane which presents a uniform and spread particle size distribution and is classified as a Clayey gravel with high plasticity using USCS–LCPC classification method. The Proctor test results is also presented at Fig. 3. Table 3 presents the summary of the physical test results.

Particle size distribution of gravel lateritic samples (Samb 2014)

Optimum Proctor of the laterite of Ngoundiane (untreated, 1, 2 and 3% of cement) (Samb 2014)

To perform mechanical tests (simple compression tests and triaxial tests), test tubes were realized in the same conditions of compaction as the Proctor with 95% of Modified Optimum Proctor (OPM) and which corresponds to the same energy of compaction specified for gravel lateritic base layers. The energy conversion give us a five layers compaction with 8.5 blows by layer. The sample are 70 mm diameter and 180 mm in heights which corresponds 2φ + 40 mm. Mussels are established by pipes in PVC in the same dimensions as test tubes. After realizing the samples, the preservation is done by rolling up test tubes at first of aluminium paper and then of paraffin, to protect them from the ambient temperature as well as from the humidity. The tests are made for the 20 preparations. For each preparation, 28 tests tubes were realized. What makes a total of 560 test tubes. For triaxial tests, the test procedure was the NCHRP 1-37A for base and subbase materials. However, the samples dimensions were independent of those proposed by the test as the distribution size of the gravel lateritic soils give a middle material between fine soil and granular soil.

3 Resilient Modulus Concept and Implementation Model Determination from Cyclic Triaxial Test Results

Under cyclic loading, road materials are characterized by a fast increase in permanent strain from the first loading cycles, then, as the number of cycles increases, the behavior becomes reversible, allowing to define a resilient modulus (Fig. 4) (Yoder and Witczak 1975; Martinez 1982, 1990; Seed et al. 1967; Hicks and Monismith 1971; Uzan 1985; Witczak and Uzan 1988).

Definition of the resilient modulus Mr (Hopkins et al. 2007)

The concept of resilient modulus was developed to allow for a better simulation of the traffic loads. In the traditional theories of elasticity (for an isotropic material), the elastic properties of a material are defined by a linear elastic modulus E and a Poisson’s ratio ν, which represent the constants of the material. However, road materials show a nonlinear behavior (with a modulus depending on the applied stress). To take into account this nonlinearity, the same approach is used by replacing the elastic modulus E with the resilient modulus Mr. Lekarp et al. (2000) reported considerable research since 1960 to characterize the resilient behavior of granular materials. Studies showed us that this behavior can be affected, with varying degrees of importance, by several factors such as the stress level, the effect of density, the grain size, the water content, the history, the number of loading cycles and the loading frequency. However, only the effects of stress-related parameters will be presented because of their preponderance in the resilient behavior. Several formulations were suggested by using various terms of stress (Lekarp et al. 2000; Kim 2007; Ba 2012; Fall et al. 2007; Taciroglu 1998; Samb 2014) (Table 4). It so ensures from observation that some generalized models allow us to take into account the behavior of the granular materials as well as those of the fine soils such as the Uzan model (Uzan 1985) and of the NCHRP one (NCHRP 2004) and combines the stiffening effect of the bulk stress and the soothing effect of the shear stress. These models were used for a correlation with the behavior of lateritic gravels of Senegal. Cyclic triaxial tests were conducted to determine the resilient modulus of these soils. The experimental procedure is described by the NCHRP 1-37A (2004). The axial deformations are measured by two external and two internal Linear Variable Differential Transformers (LVDT). Afterwards, the resilient modulus is calculated (NCHRP 1-37A 2004). It is important to notice that the results of the resilient modulus below are the ones obtained with the external deformation sensors.

For the modeling of the resilient behavior, two models were tested with the results of the triaxial tests:

-

The Uzan model (Uzan 1985) expresses the resilient modulus according to the bulk stress and the deviatoric stress what allows for taking into account the effect of the shear behavior (Eq. 1):

$$M_{r} = k_{1} \left( {\frac{\theta }{{p_{a} }}} \right)^{{k_{2} }} \left( {\frac{{\sigma_{d} }}{{p_{a} }}} \right)^{{k_{3} }}$$(1)with

\(\theta = \left( {\sigma_{1} + 2\sigma_{3} } \right) = \left( {\sigma_{d} + 3\sigma_{3} } \right) = bulk\;stress,\)

\(\sigma_{d} = \sigma_{1} - \sigma_{3} = deviatoric\;stress;\)

\(k_{1} , k_{2} \;et\;k_{3} :\;model\;parameters.\)

-

The NCHRP model (NCHRP 2004): the generalized model of Andrei (1999) was adopted in its simplified version (\(k_{6} = 0\) et \(k_{7} = 1\)) to characterize the resilient modulus of the pavement materials (Eq. 2):

$$M_{r} = k_{1} p_{a} \left( {\frac{\theta }{{p_{a} }}} \right)^{{k_{2} }} \left( {\frac{{\tau_{oct} }}{{p_{a} }} + 1} \right)^{{k_{3} }}$$(2)with

\(\tau_{oct} = \frac{1}{3}\sqrt {\left( {\sigma_{1} - \sigma_{2} } \right)^{2} + \left( {\sigma_{1} - \sigma_{3} } \right)^{2} + \left( {\sigma_{2} - \sigma_{3} } \right)^{2} } ;\)

\(k_{1} ,k_{2} ,k_{3}\) model parameters.

To determine the resilient modulus, correlations were made by using the NCHRP and Uzan models and give decisive results, which are presented below (Tables 5 and 6). The results show very good correlations. What permit to deduce that both models can be used in the characterization of the cyclic behavior of lateritic gravels. Thus, Uzan model had been selected for the implementation.

4 Model Calibration

To make the model calibration which will be used in Cast3M©, an axisymmetric model and a three-dimensional model tested by Kim (2007) were recalculated. The axisymmetric model consists of a pavement structure with an asphalt concrete layer, a base and a subgrade layer. The size of the domain were set 20-times the loading radius in the radial direction and 140-times the loading radius in the longitudinal direction. The characteristics of the various layers are given in Table 7. Axisymmetric and three-dimensional meshes were chosen by getting as close as possible to the comparison model. The results of the simulations are given in Table 8 and show, for the axisymmetric calculation, the same values of critical response for the surface deflection, the radial stress on the bottom of the asphalt layer, the vertical stress on the subgrade and a certain difference for the vertical strain on top of the subgrade. In addition, for the three-dimensional model, the values of critical responses are appreciably equal to those of the comparison model for the vertical strain on top of the subgrade where a bigger difference than that of the axisymmetric model is observed. Indeed, the simulations showed that the definition of the mesh (number of elements, number of nodes, mesh refinement) can make the results vary in a very sensitive way, which can be the cause of the difference of the comparison values. Due to the fact that it is very difficult to obtain exactly the same configuration of the mesh, especially for the density, equivalent meshes are reconstituted until obtaining the closest values. This calibration was very important for the elimination of the programming errors and the constitution of a reference model for later simulations.

5 Input Parameters

5.1 Geometry and Mesh

The structure consists of a 80 mm thick bituminous concrete, a 200 mm thick base layer of lateritic gravels treated or not, a 250 mm thick subbase of untreated lateritic gravels and of a sandy subgrade of infinite thickness. The materials of the asphalt and subgrade layer are considered elastic linear. The base and the subbase has a nonlinear elastic behavior. The parameters of the Uzan model (1985) are chosen for the gravel lateritic soils of Ngoundiane. For the limits conditions, the horizontal movements are blocked in the transverse directions (flexible boundary) and the vertical and horizontal movements are blocked in the bottom of the subgrade (stiff boundary). The number of nodes and used elements is given in Table 9. The corresponding geometrical configuration is shown in Fig. 5.

5.2 Loading and Boundary Conditions

In Senegal, the axle load is 130 kN (13 tons) for a single axle with dual-wheels (BCEOM-CEBTP 1984). The reference load is uniformly distributed on two circles whose centers are from 37.5 cm away from each other. The calculation of the stresses and the strains is done for a typical load of 6.5 tons exercising a vertical pressure q uniformly distributed on two circles with: a = 12.5 cm; l = 3 × a = 37.5 cm and q = 6.62 bars. The reference load for the calculations is represented by the Fig. 6. In this work, the effect of a single wheel was tested with a tire pressure of 0.662 MPa.

Schematization of the loading (Samb 2014)

5.3 Material Parameters

The hypothesis of a linear behavior and that of a nonlinear behavior were studied to estimate the impact of the non-consideration of the nonlinearity in road design. In the case of a nonlinear axisymmetric modeling, a linear behavior is considered for the asphalt layer and the subgrade and a nonlinear behavior for the base and subbase layer. The parameters of the lateritic gravels are those of the lateritic career of Ngoundiane. For the base layer, untreated gravels and those improved in 2 and 3% of cement are considered. For the subbase, the untreated material is considered. For the Young’s modulus, the maximal values of the unconfined compression tests are chosen, by considering that the gravel lateritic soils are compacted in 95% of the modified optimum Proctor. For the parameters (Young’s modulus and Poisson’s ratio) of the asphalt layer and the subgrade, the values are chosen in reference to Fall et al. (2002) who estimated the influence of the input parameters in the codes of calculation for pavements reinforcement. For every case, the corresponding parameters are given in Table 10.

5.4 Algorithm of Calculation

For nonlinear analysis, an incremental iterative procedure is used and the tangent constitutive matrix is updated after and during each load increment. As illustrated in Fig. 7, an initial tangent stiffness is determined for every element at the beginning of each load increment. This tangent stiffness is used to determine the first estimation of the incremental nodal displacements (and element strains and stresses) for the load increment. Unbalanced nodal loads are determined from the differences between the current estimated total stresses and the element stresses predicted for the current strains by the constitutive law. The tangent stiffnesses for all elements is then updated whereas the program iterates on the unbalanced nodal loads until convergence (NCHRP 2004). The Table 11 summarized the NCHRP method of implementation of resilient modulus.

Schematic of incremental iterative nonlinear solution technique (NCHRP 2004)

For algorithm’s setup, a direct incremental method of the resilient modulus with very small time steps, is used. A first test showed that for the linear method, 24 times steps were sufficient to obtain a constant result. In addition, for the nonlinear model, the tests showed that the results vary very widely according to the compulsory number of steps. From 300 steps, the values stabilize, which explains that the value of the number of steps n was set according to these aforesaid values. For every load interval, the resilient modulus is given by the average values found for two successive stages. The calculation algorithm is summarized in Fig. 8.

Algorithm of calculation used in Cast3M© (Samb 2014)

6 Analysis and Interpretation of the Results

6.1 Effect of the Variation of the Mesh and the Domain Boundary

Simulations were made to estimate the impact of the variation of the mesh and the domain boundary on the precision of the results. For that purpose, the size of the geometry in the transverse and longitudinal directions as well as the number of elements and the density of the mesh were made vary. Several dimensions of the domain were tested (Table 12). To choose an adequate mesh, the relative error obtained for every variation of dimension was calculated. This error is calculated as follows (Eq. 3):

Figures 9 and 10 show the evolution of the strains and the deflections according to the width and to the depth of the geometry. By choosing a tolerance of 5% of relative error on the result, the dimensions correspond to 20-times the loading radius in the transverse direction and to 140-times the loading radius in the longitudinal direction. These size also correspond to those of the models calculated by Kim (2007).

Effect of the variation of the width of the geometry: a deflection; b relative error (Samb 2014)

Effect of the variation of the depth of the geometry: a deflection; b relative error (Samb 2014)

6.2 Impact of Nonlinearity on the Axisymmetric Analysis

To study the impact of the nonlinearity for the axisymmetric model, the results of the 2D linear model and the 2D nonlinear model were compared under various angles: variation of the load, the depth and the width. At first, the results were compared for several values of the tire pressure (Figs. 11a, b, 12a, b). These observations show that the values of stresses, deflections and strains are much higher for the linear model than for the nonlinear model. Furthermore, the slope of the line of the critical response parameters is higher for the linear model.

Comparison of the values of strain and of deflection (in absolute value) for the linear and nonlinear models: a deflection; b strain (Samb 2014)

Comparison of the values of stress for the linear and the nonlinear models: a radial stress; b vertical stress (Samb 2014)

On the other hand, the evolution of the values of stresses and strains according to the depth, under the load point, was studied for both models. Figure 13a–d show that the stresses are higher for the linear model at the level of the asphalt layer and of the base layer. This trend is reversed from approximately 3/4 of the depth of the subbase. And, the stresses become higher for the nonlinear model at the level of the subgrade. Besides, we can notice that, at the level of the strains (Fig. 14a–d), the values at the surface of the road are higher for the nonlinear model. But this trend is reversed at the level of the asphalt layer, which makes the strains higher for the linear model as well as at the level of the base layer than for the subbase. However, curves join at the level of the subgrade layer to give appreciably equal strains. This result is very important because it shows that in some conditions, the same values can be considered for the vertical strain at the level of the subgrade which is, at the same time, the parameter prevailing in road design. The results generally show that the values of the critical response are much higher for the linear model than for the nonlinear model. A possible justification can be in the load type. Indeed, a static load which amounts to a punching is different from a cyclic load which lasts only a few seconds. Thus, the first load could be the most unfavorable. This point deserves however a particular reflection because of its importance for road design. Since these results were found for well determined model, load conditions and material properties, more thorough searches are necessary before reaching any conclusion.

Vertical stress according to the depth: a asphalt layer; b base layer; c subbase; d subgrade layer (Samb 2014)

Vertical strain according to the depth: a asphalt layer; b base layer; c subbase; d subgrade layer (Samb 2014)

Besides, it was possible to see the evolution of the resilient modulus under the load point, according to the depth of the base layer and the subbase (Fig. 15a, b). Observations show a much higher modulus for the subbase than for the base layer and which increases with the depth. These results seem at first sight contradictory because the base layer is supposed to be stiffer than the subbase. However, they are justified by the fact that, at the level of the cyclic tests, it had been noticed within the framework of the tested materials, that the addition of cement did not increase necessarily the stiffness of the material. In the case of the gravels of Ngoundiane, the untreated material gave much higher resilient modulus values than the material treated with cement. Yet, the choices which were made on the modeled layer concerned a lateritic base layer with 2% cement and a subbase with untreated gravels. This can justify the obtained results. Furthermore, the cyclic tests had also shown that the resilient modulus decreased with the increase of the deviatoric stress. This can be the cause of the increase in the modulus with the depth given that the stresses decrease at the same time. With regard to these results, it seems essential to study more closely the effect of the percentage of cement.

Variation of resilient modulus according to the depth (Samb 2014)

6.3 Impact of the Variation of the Percentage of Cement at the Level of the Base Layer

The results of the simulations made on a standard lateritic layer composed of gravels treated with 2% cement for the base layer and untreated gravels for the subbase, showed that the resilient modulus of the base layer can be lower than that of the subbase, according to trial results. Indeed, according to the lateritic gravels tested, the results of the cyclic tests showed that the resilient modulus was not necessarily sensitive to the addition of cement, and that, for some gravels as those from Ngoundiane and Pâ Lo, the resilient modulus of the untreated laterite could be greater than that of the laterite improved with cement. This made the comparison difficult since this difference of stiffness depends to a large extent on the tested material. The variation of critical response parameters according to the addition of cement have been studied. The stiffness of the base layer is make to vary by using successively the untreated gravels and those treated with 3% of cement and by maintaining the parameters of the subbase. These results will then be compared with those of the standard layer already tested with gravels improved with 2% of cement. It is necessary to bear in mind that, in the case of the gravels of Ngoundiane, the cyclic tests had shown that the resilient modulus was higher respectively for the untreated specimen, than for the specimen treated with 2% and lastly for the one with 3% of cement. Figure 16a, b give the values of deflections and strains for various types of materials for the base layer. We can notice that deflections and strains are higher, respectively for the material improved with 3% of cement, than with 2% of cement, and for the untreated material.

Variation of the deflection and the strain according to the percentage of cement (Samb 2014)

7 Conclusion

The objective of this work was to determine the critical response of lateritic roads under traffic loading. It was possible to obtain several results from the modeling with Cast3M©. The study of the variation of the mesh allowed us to choose the geometrical dimensions of the models which are of 20-times the loading radius in the transverse direction and of 140-times the loading radius in the longitudinal direction. Besides, several trends were observed:

-

The study of the evolution of the stresses and strains values according to depth, under the point of load, showed that in a general way, the values of the critical response are much more raised for the linear model than for the nonlinear model. A possible justification could be in the static type of loading which could be more unfavorable than the cyclic loading which lasts only some seconds and allows the material to find quickly its balance after load;

-

The study of the evolution of the resilient modulus according to the depth reveals a much more raised modulus for the subbase than for the base layer and which increases with the depth. It is so to pay attention on the choice of the Uzan parameters which depend on the considered material.

-

The results of the cyclic tests had shown that within the framework of the tested materials, the addition of cement did not necessarily increase the stiffness of the material.

-

The study of the variation of the parameters of critical response according to the addition of cement confirm that in the case of the gravels of Ngoundiane, the resilient modulus decreases with the percentage of cement and varies conversely with the deflection and the strain.

-

The results of the cyclic tests had shown that within the framework of the tested materials, the addition of cement did not necessarily increase the stiffness of the material.

These first results require however some reflection and a certain level of attention, because of the importance of the result. Indeed, the main conclusions that we can get from these observations is the fact that the predictions of the linear model seem to be towards the safety. Which could mean that the road degradation could not be the effect of the non-consideration of the nonlinear behavior of the lateritic gravels. However, it is important to bear in mind that this modeling was made with precise input data which may vary according to the type of lateritic gravels used. Besides, gravel lateritic soils are not easy to study because of their complexity. The results may vary considerably from a material to another one. Thus, later studies must be conducted to confirm these results. It is necessary to note however that the effect of a single wheel was tested. To know the total deflections and strains, it is necessary to take into account the twinning of the wheels.

References

Andrei D (1999) Development of a Harmonized test protocol for the resilient modulus of unbound materials used in pavement design. MS thesis, University of Maryland-College Park

Ba M (2012) Comportement mécanique sous sollicitations cycliques de granulats quartzitiques de Bakel - Comparaison avec des matériaux de référence du Sénégal et d’Amérique (USA). Thèse de doctorat Géotechnique routière, UCAD, Faculté des Sciences et Techniques

BCEOM-CEBTP (1971) Manuel pour le renforcement des chaussées revêtues en Afrique tropicale et à Madagascar

BCEOM-CEBTP (1972) Manuel sur les routes dans les zones tropicales et désertiques

BCEOM-CEBTP (1984) Guide Pratique de dimensionnement dans les pays tropicaux. Ministère Français de la Coopération, p 155

BCEOM-CEBTP (1991) Les routes dans les zones tropicales et désertiques, Tome II. Etudes techniques et constructions

Brown SF, Pell PS (1967) An experimental investigation of the stresses, strains and deflections in a layered pavement structure subjected to dynamic loads. In: Proceeding of the 2nd international conference of structure design of asphalt pavements, pp 487–504

Chen DH, Zaman M, Laguros J, Soltani A (1995) Assessment of computer programs for analysis of flexible pavement structure. Transp Res Rec 1482:123–133

DAMA (1991) Pavement structural analysis using muli-layered elastic theory. Asphalt Institute, DAMA (CP-1/1991 Revision), Lexington

Dehlen GL (1969) The effect of nonlinear material response on the behaviour of pavements subjected to traffic loads. Ph.D. thesis, University of California, Berkeley, Berkeley

Fall M (1993) Identification et caractérisation mécanique de graveleux latéritiques du Sénégal: application au domaine routier. Thèse de doctorat INPL, ENSGN

Fall M, Senghor B, Lakhoune A (2002) Analyse de la pratique du dimensionnement rationnel des structures de chaussée au Sénégal. Influence des paramètres d’entrée dans les codes de calcul pour le renforcement des chaussées”, Annales du Bâtiment et des travaux publics, UCAD, FST, IST

Fall M, Sawangsuriya A, Benson CH, Edil TB, Bosscher PJ (2007) On the investigations of resilient modulus of residual tropical gravel lateritic soils from Senegal (West Africa). Geotech Geol Eng J 26(1):13

Harichandran RS, Yeh MS, Baladi GY (1989) MICH-PAVE User’s manual, final report, FHWA-MI-RD-89-023. Department of Civil and Environmental Engineering, Michigan State University, East Lansing

Hicks RG (1970) Factors influencing the resilient properties of granular materials. PhD thesis, University of California, Berkeley, Berkeley, Calif

Hicks RG, Monismith CL (1971) Factors influencing the resilient properties of granular materials. Highw Res Rec 345:15–31

Hopkins TC, Beckham TL, Sun C (2007) Resilient modulus of compacted crushed stone aggregate bases. Research report KTC-05-27/SPR-229-01-1F. Kentucky Transportation Center, College of Engineering, University of Kentucky, p 89

Huang YH (1993) Pavement analysis and design. Prentice-Hall Inc, Englewood Cliffs

ILLI-PAVE PC Version User’s Manual (1990) NCHRP Project 1-26. Transportation Facilities Group, University of Illinois, Urbana-Champaign

Kim M (2007) Three-dimensional finite element analysis of flexible pavements considering nonlinear pavement foundation behavior. Dissertation, University of Illinois

Lekarp F, Isacsson U, Dawson A (2000) State of the art. I: resilient response of unbound aggregates. J Transp Eng 126:66

Martinez J (1982) Contribution au dimensionnement des chaussées souples. Comportement des matériaux et méthodes de calcul”, Thèse de Doctorat d’Ingénieur INSA Rennes

Martinez J (1990) Contribution au dimensionnement rationnel des structures de chaussées souples et inverses - Comportement des graves non traitées et des sols supports. NCHRP (2004). Laboratory determination of resilient modulus for flexible pavement design National Cooperative Highway Research Program (NCHRP) Project 1-28A, Transportation Research Board of National Academies

NCHRP (2004) Laboratory determination of resilient modulus for flexible pavement design National Cooperative Highway Research Program (NCHRP) Project 1-28A. Transportation Research Board of National Academies

Samb F (2014) Modélisation par éléments finis des chaussées en graveleux latéritiques traités ou non et application au dimensionnement Mécanistique-Empirique. Thèse de doctorat, Géotechnique, ED2DS, Université de Thiès

Seed HB, Mitry FG, Monismith CL, Chan CK (1967) Prediction of flexible pavement deflections from laboratory repeated load tests. NCHRP report No. 35, National Cooperative Highway Research Program

Taciroglu E (1998) Constitutive modeling of the resilient response of granular solids. Thesis, University of Illinois at Urbana - Champaign Urbana, Illinois

Ullidtz P (1998) Modeling flexible pavement response and performance. Polyteknisk Forlag, Denmark

Uzan J (1985) Characterization of granular material. Transp Res Rec 1022, Transportation Research Board, Washington, D.C., pp 52–59

Witczak MW, Uzan J (1988) The universal airport pavement design system. Report I of IV: granular material characterization. University of Maryland, College Park, Md

Yoder EJ, Witczak MW (1975) Principles of pavement design, 2nd edn. Wiley, New York

Zaghoul S, White T (1993) Use of a three-dimensional dynamic finite element program for analysis of flexible pavements. Transp Res Rec 1388, Transportation Research Board, National Research Council, Washington, DC, pp 60–69

Acknowledgements

We want to thank Professor Meissa Fall as he co-directed this research and was the main correspondent for me for the scientific aspects of the thesis. We don’t have words to name his important contributions to this work. We also want to thank Samsidine Niang and Amadou Niane who made the identification tests and the realization of the test specimens for all the mechanical tests and Moussa Samb who helped us for performing the Finite Element Modelling with Cast3M©.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Samb, F., Berthaud, Y., Ba, M. et al. Nonlinear Mechanical Behavior Analysis of Flexible Lateritic Pavements of Senegal (West Africa) by FEM for M.-E. Pavement Design. Geotech Geol Eng 36, 2939–2956 (2018). https://doi.org/10.1007/s10706-018-0514-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-018-0514-y