Abstract

Investigations on the mechanical behavior of compacted gravel lateritic soils have been the subject of several studies. Used as road materials, soils tests were mainly performed using standard tests. Static loads as unconfined compression test (UCT) remain the only engineering approach used. Alternative testing techniques can be chosen as supplementary tests for characterizing pavement materials. These researches were conducted so as to determine the response of these particular and problematic soils in its compacted form with road traffic loads. This paper presents the results of research conducted to investigate the effect of the soil compacity on the resilient modulus of lateritic soils. The influence of the percentage of cement added so as to stabilize each sample at the optimum modified proctor (OPM) State was also determined. Soil big specimens of around 180 mm diameter (with length to diameter aspect ratio of 2:1) were prepared according to the standard procedure described by AASHTO T 307 and then were subjected to repeated load triaxial tests. The models used, analyzed and developed in this paper are mainly the Andrei and the Uzan–Witczak universal model. Test results showed that the specimen compacity has no significant influence on the resilient modulus of the investigated gravel lateritic soils. Soil specimens with variation of the percentage of cement added exhibited the highest resilient modulus values while the specimens with variation of the compacity exhibited the lowest values. The resilient modulus variation seems to be independent of the level of stress.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Previous studies (Fall 1993; Fall and Tisot 1994, 1995, 1996; Fall et al. 2002a, b) underlined the importance to have adequate characteristics for an optimal design of road structures in tropical African regions. Researches in Senegal during the last 20 years permits to pronounce now amply on the geotechnical reasons of the premature ruin of road structures designed with tropical lateritic soils. The main problem of the weak life span of the road structures is due to an under-estimated engineering design caused by the use of inappropriate characteristics with no controls in the numerical codes of road design. In situ investigations done since then with complementary experimental works, permits to have reliable engineering information on local subgrades, the most common gravel lateritic materials, road making aggregates and finally the laterite-cement (lateritic soils stabilized with 1–3% of cement). This last material was the subject of particular attention, due to its specificity and especially to the fact that all bases or sub-bases layers in the African Western Countries is prepared with. Finally, a fine analysis of the interrelationships between these features, their strength parameters and their modulus of elasticity permits to have now tools of choice to do reasonable road design. The issue is therefore to define new norms/standards and specifications in road geotechnique.

In Senegal, as in a lot of developing countries, road construction is done without norms and standards. Road design had never been based on realistic knowledge or objectives information of local materials characteristics, the gravel lateritic soil notably. Indeed, the very scattered values of the elastic parameters of the materials, among others the dynamic modulus in technical reports can constitute a factor to convince of it. Besides, most base layers treated by cement undergo intense deformation or arrive at a premature failure. It probably leads us to think about the methods of design utilized. Is it that the empirical design methods, as, among others, the method of the BCEOM-CEBTP (1984) mostly used or the CBR methods, are the most suitable for gravel lateritic soils design of the bases pavements treated by cement? Is it necessary to incriminate the in situ setting of the laterite-cement? Do these methods say rational otherwise of road design that adopt analytic techniques and use numerical codes of calculation, are very sensitive to the value of the input parameters (Fall et al. 2002a, b)? If the so-called rational methods are adopted, what justifies that for laterites of CBR lower to 80% and stabilized with cement added at 2.5 or 3%, the very scattered values of elastic modulus ranging from 15,000 to 23,000 bars (and even sometimes 50,000 bars). It can be said therefore that in Senegal, regarding road studies, there are no serious specifications. In this paper, we’ll present investigations on monotonic (unconfined compression tests (UCT)) and cyclic loads (resilient modulus tests) of lateritic soils from Senegal and the results obtained are very different to those obtained since then in the mechanic characteristics of these soils.

2 Topics

The soil and aggregate layers forming the foundation of pavements or highway pavements are subjected to repeated traffic loading. Under individual cycles of loading, the layers behave essentially elastically, while plastic deformation accumulates with repeated cycles. Design of pavements requires a significant amount of input data such as traffic loading characteristics, properties of materials (base, subbase, and subgrade soil), environmental conditions and construction procedures. Properties of base materials are often evaluated by laboratory tests such as California bearing ratio (CBR), which do not represent the nature of repeated dynamic traffic load on subgrade soil. Recognizing this deficiency, the AASHTO guide for design of pavement structures (1986 and 1993) and the 2002 AASHTO guide for the design of new and rehabilitated pavement structures incorporated the resilient modulus for characterizing subgrade soils in flexible pavement design.

Resilient modulus is usually determined by repeated load triaxial tests with constant confining pressure, σ3, and with the deviator stress cycled between the hydrostatic state and some positive deviator stress (σ1–σ3). Resilient modulus (M R) as defined is equivalent to resilient Young’s modulus (E R). Resilient modulus of subgrade soils can be determined by laboratory testing such as the repeated load triaxial test. The AASHTO T 307 (determining the resilient modulus of soils and aggregate materials) is the current standard procedure designated by AASHTO for determining the resilient modulus of subgrade soils using the repeated load triaxial test. According to this standard procedure, the specimen size (diameter and length) depends upon the soil type as classified from particle size analysis and consistency limits. In addition, for type 2 materials (fine-grained soils), compacted specimens should be prepared in a mold that will produce a specimen of minimum diameter equals to five times the maximum particle size with an aspect ratio of length to diameter of not less than 2:1.

From an engineering point of view, there is much to be desired about a mechanistic approach to pavement design. Recall that “mechanistic” means that the principles of engineering mechanics will apply, i.e., the design process will be rational (NCHRP 2004). Yoder and Witczak (1975) point out that for any pavement design procedure to be completely rational in nature: three elements must be fully considered. These are (1) the theory used to predict the assumed failure or distress parameter, (2) the evaluation of the materials properties applicable to the selected theory, and (3) the determination of the relationship between the magnitude of the parameter in question to the performance level desired (NCHRP 2004). While this Guide will consider all three elements only the first is discussed in this overview.

Generally for the general concept of a multi-layered elastic system, the analytical solution to the state of stress or strain makes several assumptions. Some of these are (1) the material properties of each layer are homogeneous; that is, the properties at each point are the same; (2) each layer has a finite thickness except for the lower layer, and all are infinite in the lateral directions. Other assumption are, (3) each layer is isotropic; that is, the property at a specific point is the same in every direction or orientation, (4) full friction is developed between layers at each interface. Finally, (5) surface shearing forces are not present at the surface, and (6) the stress solutions are characterized by two material properties for each layer. These properties are Poisson’s ratio, μ and the elastic modulus E.

Yoder and Witczak (1975) continue to show that at a given point within any layer, static equilibrium requires that nine stresses exist. These stresses are comprised of three normal stresses (σz, σr, σt) acting perpendicular to the element faces and six shearing stresses (τrt, τtr, τrz, τzr, τtz, τzt) acting parallel to the faces. Static equilibrium conditions also show that the shear stresses acting on intersecting faces are equal. Thus, τrz = τzr, τrt = τtr, and τtz = τzt. At each point in the system, there exists a certain orientation of the element such that the shear stresses acting on each face are zero. The normal stresses under this condition are defined as principal stresses and are denoted by σz (major stress), σr (intermediate), and σt (minor). The sum of the principal stresses at a point is defined as the bulk stress (θ). Considering this triaxial stress state of any element, the strains (for the vertical, radial, and tangential directions, respectively) may be determined from the following equations:

Building on these general equations, the type of theory used is generally distinguished by three properties of the material behavior response. They are the relationship between stress and strain (linear or nonlinear), the time dependency of strain under a constant stress level (viscous or non-viscous), and the degree to which the material can rebound or recover strain after stress removal (plastic or elastic). All three properties are to be addressed in the guide as appropriate to the various paving materials. Much of the “empirical” part of mechanistic-empirical relates to the characterization of materials or to various traffic, environmental or other inputs to the design process.

Generally, flexible and rigid pavements respond to loads in such different ways that there are fundamental differences in the analysis theories applied. Basically, rigid pavement slabs are cases where non-linearity of the stress–strain relationship is not an issue while discontinuities such as cracks and joints are of major importance. Essentially, the opposite is true with flexible pavements, i.e., non-linearity of the stress–strain relationship is a major issue while discontinuities are secondary or non-existent. Rehabilitated pavements, especially those with a combination of rigid and flexible layers, are an entirely different class and are to be handled separately in the Guide.

While the mechanistic approach to pavement design and analysis is much more rational than the empirical, it also is much more technically demanding. As mentioned earlier, mechanistic-empirical procedures were not practical until the advent of high-speed computers. The reason is the computational demands associated with the differential equations and finite element matrix solutions employed by the various analysis models. Such models will be incorporated in and described in detail in the Guide. As will be noted in the model descriptions, the choice of a model and how it is applied often will relate to the computational requirements and how much time is required to accomplish those computations.

3 Nonlinear Resilient Modulus Model

The resilient modulus, defined as the unloading modulus after many cycles of repeated loading, is used in pavement engineering as an appropriate measure of stiffness for the layers in a pavement structure. The sample is initially subjected to a hydrostatic confining pressure σc, which induces an initial strain εc (unmeasured in the test, but the same in all directions for isotropic material behavior). The axial stress is then cycled at a constant magnitude Δσ, which induces the cyclic resilient axial strain Δε. The resilient modulus M R is defined simply as the ratio of the cyclic axial stress to resilient axial strain:

The resilient modulus for most pavement materials is stress dependent. Many nonlinear models have been proposed over the years for incorporating the effects of stress level on the resilient modulus. A general form for these models can be expressed as (Andrei 1999):

in which

-

M R = resilient modulus

-

θ = bulk stress at the peak of the loading

-

=σx + σy + σz

-

=3σc + Δσ, for standard triaxial compression loading

-

τoct = octahedral shear stress at the peak of the loading

-

$$ = {\left\{ {\frac{1} {9}[(\sigma _{y} - \sigma _{y} )^{2} + (\sigma _{y} - \sigma _{z} )^{2} + (\sigma _{z} - \sigma _{x} )^{2} ] + \frac{2} {3}{\left[ {\tau ^{2}_{{xy}} + \tau ^{2}_{{yz}} + \tau ^{2}_{{zx}} } \right]}} \right\}}^{{1/2}} $$

-

$$ = \frac{{{\sqrt 2 }}} {3}\Delta \sigma $$

-

=Δσ for standard triaxial compression loading

-

P a = atmospheric pressure (normalizing factor)

-

k 1–k 7 = material parameters subject to the following constraints:

-

k 1 > 0; k 2 > 0; k 3 < 0; k 6 < 0; k 7 > 1

A simplified version of the Andrei equation with k 6 = 0 and k 7 = 1 has been adopted and gives the following equation:

The Andrei equation combines both the stiffening effect of bulk stress (the term under the k 2 exponent) and the softening effect of shear stress (the term under the k 3 exponent). Through appropriate choices of the material parameters k 1–k 7, one can recover the familiar two-parameter bulk stress model for granular materials and its companion two-parameter shear stress model for cohesive soils, the Uzan–Witczak universal model (Witczak and Uzan 1988), and the k 1–k 6 model from the Strategic Highway Research Program’s (SHRP) flexible pavement performance models (Lytton et al. 1993). The Andrei equation and its various specializations are convenient functional forms for fitting laboratory resilient modulus test data.

4 Experimental Program and Results

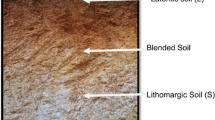

The soils considered in this study were collected from different locations within Senegal (West Africa). Standard laboratory tests were conducted to classify these soils and determine their properties. Laboratory testing consisted of particle size analysis (mechanical sieving and hydrometer analysis), specific gravity, consistency limits, and modified proctor compaction test. Moreover, the repeated load triaxial test was used to determine the resilient modulus of these soils.

4.1 Soil Properties

Laboratory tests were conducted on the investigated soils following the standard procedures of the American society for testing and materials (ASTM). The Modified Proctor compaction test was conducted using the AASHTO T 99 procedure. Table 1 present a summary of test results. Test results showed that the selected soils are classified mainly as A-26 materials according to AASHTO.

4.2 Unconfined Compression Test

Preparation and testing of soil specimens were conducted in accordance with AASHTO T 208-70. All soil samples were prepared under the optimum moisture content and maximum dry unit weight. This test had been done so as to have reliable correlation with the CBR values. It permits to have a comparison with the ancient correlations made in Senegal with an UCT test.

4.3 Repeated Load Triaxial Test

Preparation and testing of soil specimens were conducted in accordance with AASHTO T 307. The test sequence required for these kinds of soils is the one specified by the procedure AASHTOO T 292-97. All soil samples were prepared under the optimum moisture content and maximum dry unit weight.

5 Alternative Testing Techniques for Modulus

Stiffness measurements have gained increased appreciation in pavement engineering. Bender elements (BE) and soil stiffness gauge (SSG) have been adopted as they show potential and means of monitoring the stiffness and/or modulus of pavement materials. The typical range of strain amplitudes imposed by the bender elements and the SSG is compared with those incurred in the pavement base and subgrade layers to evaluate their suitability in the assessment of pavement layer stiffness and/or modulus (Fig. 1 and Table 2) (Sawangsuriya et al. 2003).

The strains induced in the pavement bases and subgrades that are subjected to the typical traffic loadings were compiled from other studies. In general, they can be classified into three main groups: (1) finite-element analysis, (2) large-scale model experiment, and (3) in situ test section. Table 2 presents the vertical strains in base, subbase, and subgrade layers summarized from various studies. The type of measurement and/or analysis, pavement structure, and loading characteristic employed in each study are also reported herein.

For pavement bases and subgrades, the stress–strain behavior of soil is highly nonlinear and soil modulus may decay with strain by orders of magnitude. A relationship between the small-strain (linear-elastic) modulus (strains less than 10−2%) and nonlinear behavior exhibited by soils at large strains (above 10−2%) must be established. The shear modulus of soil at various shear strain levels for different pavement layers and modulus tests is shown in Fig. 1. Generally, strains in base and subbase vary from 0.01% to 1%, whereas those in subgrade may vary from 0.003% to 0.6%. Therefore, the pavement base, subbase, and subgrade layers involve strains at higher levels, i.e., typical strain range of 10−2% to 1%, and soil exhibits nonlinear properties. Figure 1 also shows that the resilient modulus (M r) test operates within these strain range.

We present below some results derived from UCT known as part of the only means used in some tropical countries to evaluate the soil stiffness and also the results of bender elements tests so as to make a comparison of these results with models given by the resilient modulus tests.

5.1 Unconfined Compression Tests

As seen from the tables below (Table 3a–e), we can evaluate that these results are mainly different to those obtained since then in Senegal (Fall et al. 2002a, b) and from different African laboratories. The UC modulus (E s; s means static) is less than 300 MPa for the samples stabilized by cement. It was generally admitted that the static modulus used for road design purposes and for materials with nearly 2–3% of cement, that the soil rigidity exceeds 1,000 MPA. The general trend is often the same for all the samples, from 95% of compaction at the OPM to 100%, we can easily admit than the soil rigidity increase as attested by the Table 3a–e. And, also the modulus increase at the same manner from 1% to 3% of cement added in the soil samples. The soil rigidity seems to be more affected by the variation of the percentage of cement added so as to stabilize the soil samples tested.

As seen in the tables below, the soil compacity do not makes significant difference when the samples are tested at 100% of the maximum density, excepted to 90% and 95% of the compacity where the difference can be noticed from sample to sample in regard to the soil’s physical characteristics. Nevertheless, the state of reference remains the soil at 100% of compacity, which is the reference of soil settings in situ.

5.2 Bender Elements

An elastic wave propagation technique that utilizes two-layer piezoceramic bender elements as source and receiver provides a means of measuring the shear wave velocity and the corresponding small-strain shear modulus. The bender element test has become increasingly popular in a variety of geotechnical laboratory applications (Dyvik and Madshus 1985; Thomann and Hryciw 1990; Souto et al. 1994; Fam and Santamarina 1995; Zeng and Ni 1998; Fioravante and Capoferri 2001; Pennington et al. 2001; Mancuso et al. 2002). The transmitting bender element produces a shear wave (S-wave), which propagates through the soil when it is excited by an applied voltage signal. This S-wave impinges on the receiving bender element, causing it to bend, which in turn produces a very small voltage signal. Figure 2a illustrates typical input and output signals from the transmitting and receiving bender elements.

In general, the signals may be different from those in Fig. 2, possibly due to the stiffness of the soil, the boundary conditions, the test apparatus, the degree of fixity of the bender element into the platen or housing, and the size of the bender element and specimen (Sawangsuriya et al. 2003). By measuring the travel time of the S-wave and the tip-to-tip distance between transmitting and receiving bender elements, the S-wave velocity of the soil is obtained. The small-strain shear modulus (G) can be calculated according to elastic theory using the measured S-wave velocity (V S) and total density of the soil (ρ) with the relationship \( G = \rho v^{2}_{{\text{s}}} \) and \( G = E_{{\text{s}}} /(2(1 + \nu )) \) (with E s, the static modulus; ν, the Poisson’s ratio).

A bender element test was performed on a specimen nearly 100 mm in diameter and nearly 180 mm high subjected to a range of confining pressures. Figure 2b shows the plot of shear modulus obtained from the bender element (BE) tests as a function of the compacity. Results (Fig. 3, Table 4a, b) indicated good agreement with those suggested by the UCT results.

6 Determination of Resilient Modulus

The repeated load triaxial test consists of applying a cyclic deviator stress (σd) on a cylindrical sample under constant confining pressure (σ3) and measuring the recoverable axial strain (εr). The repeated axial load is applied in fixed 1 s cycles in which 0.1 s is the load duration (AASHTO Designation, T 292-97 2000). The specimen is first subjected to a minimum of 1,000 conditioning cycles to eliminate permanent deformation (Table 5).

Resilient modulus determined from the repeated load triaxial tests is defined as the ratio of the repeated axial deviator stress to the recoverable or resilient axial strain. Equation below shows the definition of the resilient modulus.

The results of repeated load triaxial test Senegalese soils are presented in Tables 6 and 7, respectively. The test results of all the lateritic soils samples are presented in graphical format. Figures 1–3 show the variation of the resilient modulus of the specimens with the deviator stress, the bulk modulus and the bulk stress at different confining pressures, compacities and the percentage of cement added. The different soils preparations were conducted so as to obtain different specimens varying from 100% of the optimum modified proctor (i.e., 100 OPM) to 95% OPM and 90% OPM. The percentages of cement vary also from 1%, 2% and 3%. These particular conditions of soil preparation are those accepted in the field, the most bases layers in tropical regions are stabilized from 1% to 2% so as to increase the soil modulus and prevent the base layer to be ruined by the water effect.

The results of repeated load triaxial test on lateritic soils Lat.1 to Lat.6 are presented in Figs. 4a, b–8a, b respectively. In regard of the large amount of data, we have chosen to present all of the figures so as to show the results and to interpret them all. Figures show the variation of the resilient modulus of Senegalese lateritic soils samples with the deviator stress or the bulk stress at different confining pressures, the sample’s size remain the same.

As presented in the figures, the resilient modulus of the lateritic soils vary with deviator stress from 300 to 1,800 kPa for the specimen stabilized with 1% of cement; from 500 to 2,500 kPa at 2% of cement and greater at 3% of cement. The samples varying with the compacity (none stabilized) described trends, which are located under those ones stabilized by cement added and the soil moduli are less. The variation shows an increasing trend in the resilient modulus with the increase in the sample state of compaction and also the percentage of cement added for the same deviator stress. This increase is significant. In addition, the variation is independent of the level of the deviator stress, at low or high stress levels the behavior is the same.

Examination of all test result presented in Tables 4 and 5 indicates that the specimens, which vary with the percentage of cement of the investigated soils exhibited the highest resilient modulus values compared to those varying with the compacity.

7 Regression Analysis of the Resilient Modulus Test Results

7.1 Introduction

In recent years engineers have devoted considerable effort to determining the nonlinear stress–strain characteristics of pavement material. During the past few decades several constitutive models have been developed and used by pavement design engineers. These developments have provided powerful tools for research and design engineers to conduct pavement analysis in a more realistic manner. However stress and deformation or deformation analysis cannot be useful unless a correct constitutive equation that describes the actual behavior of material has been in the analysis. Each times a load passes in a pavement structure, the pavement rebounds less than it was deflected under load. After repeated loading and unloading sequences, each layer accumulates only a small amount of permanent deformation, with recoverable or resilient deformation. To explain this behavior, researchers have used the concept of resilient modulus.

There are several models that were developed for the estimation of resilient modulus of subgrade soils and base/subbase materials.

Witczak and Uzan (1988) and Barksdale (1972) has shown that the resilient modulus of granular materials increase with increasing confining stress. The following bulk stress model is currently used by most pavement design engineers (Hicks and Monismith 1971; Shook et al. 1982):

in which

-

M R = resilient modulus

-

θ = bulk stress at the peak of the loading or first stress invariant

-

=σ1 + σ2 + σ3

-

=3σc + Δσ, for standard triaxial compression loading

-

k 1, k 2 = material and physical property parameters

-

P a = atmospheric pressure, expressed in the same unit as M R and θ, used to make the constants independent of the units used

The main disadvantage of this model is that it does not adequately model the effect of deviator stress. May and Witczak (1981) suggested the following equation to describe the resilient modulus of granular materials:

where K 1 is a function of pavement structure, test load, and developed shear strain, and k 1, k 2 are constants.

Uzan (1985) has demonstrated that the first equation expressed for granular material cannot adequately describe the nonlinear behavior of granular soils. In 1988, he suggested the equation below to describe the nonlinear behavior founded in repeated triaxial load tests, which was obtained from empirical observations. This model includes the influence of deviator stress on resilient modulus.

where σd is the deviator stress (σ1–σ3) and k 1, k 2, and k 3 are material constants.

A new “harmonized” resilient modulus test protocol is being developed through the NCHRP project 1-28A (NCHRP 2000) for implementation at the AASHTO 2002 pavement design guide. The new protocol uses the universal nonlinear model that is applicable for all types of subgrade soils and also for granular materials. The model is given by (NCHRP Project 1-37A 2002):

where M r is the resilient modulus, σd is the deviator stress, σb is the bulk stress (=σ1 + σ2 + σ3), τoct is the octahedral shear stress, P a is the atmospheric pressure (used to normalize M r units), and k 1, k 2 and k 3 are material constants. This model is really close to the Andrei model (Andrei 1999) which makes differences from the use of the bulk stress compare to the model of the NCHRP Project using the deviator stress. The Andrei model is:

7.2 Results

In this paper, the Uzan–Witczak universal model (Witczak and Uzan 1988), the Andrei model, the k–Θ model (\( M_{{\text{R}}} = k_{3} \theta ^{{k_{4} }} \)) and the power model (\( M_{{\text{R}}} = k_{1} \sigma ^{{k_{2} }}_{{\text{d}}} \)) have been intensively use so as to find the best suitable model which can represent the relationship between resilient modulus and stress levels of lateritic soils used in this study. In order to achieve this, a linear regression analysis was conducted to evaluate the material constants k 1, k 2 and k 3.

Results of the statistical analysis are summarized in Table 6 (k–Θ model and the power model) and Table 7 (Uzan–Witczak model, Andrei model). The Uzan–Witczak universal nonlinear model and the Andrei model are preferred and presented so as to characterize the resilient modulus of the investigated soils. The predicted resilient moduli obtained from the power and k–Θ model gave a poor correlation to actual resilient moduli (Fig. 9a–e). The statistics given in Tables 6 and 7 provide evidence of better predictability in describing behavior of lateritic soils using the universal and the Andrei models than the power model. The k–Θ model gives good correlation but the fact that it’s limited by only one variable (the bulk modulus). In this study, the two models as Andrei and Universal gave similar statistics and the choice had been make to evaluate the soil parameters with the Andrei parameters. The Andrei model is therefore more suitable to represent the relationship between resilient modulus and stress levels of granular lateritic soils.

(a) Actual resilient moduli versus predicted resilient moduli for Lat.1. (b) Actual resilient moduli versus predicted resilient moduli for Lat.3. (c) Actual resilient moduli versus predicted resilient moduli for Lat.4. (d) Actual resilient moduli versus predicted resilient moduli for Lat.5. (e) Actual resilient moduli versus predicted resilient moduli for Lat.6

Using the Andrei model, inspection of Table 7 indicates that the values of the material constants (k 1, k 2, and k 3) for the investigated soils vary significantly with samples state (from difference with the percentage of cement added) and not significantly when it is question of the state of compaction (from 90% of OPM to 100%). For example, when it is question of the percentage of cement added so as to stabilized the lateritic soil, the variation is very significant; so we get the following trend, with 1% of cement added, k 1 vary from 191 to 49 MPa, with 2% of cement 268 to 35.4 MPa and at least with 3% of cement, it increase from 347 to 35.4 MPa (Fig. 10a). k 1 vary from 258 to 103 MPa for soil samples at 100% OPM, 148–76.4 MPa at 95% and 135–102 MPa at 90% OPM (Fig. 10b).

(a) Variation of the material parameter k 1 with the percentage of cement added in the soil specimen. (b) Variation of the material parameter k 1 with the percentage of cement added in the soil specimen. (c) Variation of the material parameter k 2 with the percentage of cement added in the soil specimen. (d) Variation of the material parameter k 2 with the percentage of cement added in the soil specimen. (e) Variation of the material parameter k 3 with the percentage of cement added in the soil specimen. (f) Variation of the material parameter k 3 with the percentage of cement added in the soil specimen

The values of k 1 seem to be the most important material parameter and their variations have significant importance for the soil behavior estimation.

k 2 and k 3 change slowly in regard of with the variation of the compacity and significantly with the percentage of cement (Fig. 10c–e). For k 2, the variation is significant in regard of the percentage of cement added. At 1%, the mean is equal to −0.04 and k 2 vary from 0.060 to −0.100, at % from 0.080 to −0.110 and at 3%, from 0.020 to −0.100. k 3 seems to be less variable than the other sample’s parameters. And from 1% to 3% of cement added, the variation is between 0.500 and 0.900, the minimum and the maximum is generally for 1% between 0.770 and 0.510, at 2% between 0.870 and 0.470 and at 3% between 0.810 and 0.470.

The trend of variation (of k 1 and k 2) seems to be less affected when it is question of the soil compacity and from 95% OPM to 100% OPM, k 2 is between −0.110 and 0 and k 2 from 0.510 to 0.760. At 90% OPM, the variation of k 2 and k 3 are more significant.

We can conclude right now that the most sensitive parameter, which can really change the soil’s material parameter remains the percentage of cement which changes directly the soil rigidity. If we point out the soil compacity state, we can imagine than the AASHTO test procedure which began with 1,000 cycles of precondition cycling bring to the different soil at state which is somewhat nearly to the OPM. It that which gave not significant difference of the soil parameters when we point out the state of compacity.

Using the Uzan–Witczak universal nonlinear model, Inspection of Table 5 indicates that the values of the material constants (k 1, k 2, and k 3) for the investigated soils vary significantly with samples state (from difference with the percentage of cement added) and not significantly when it is question of the state of compaction (from 90% of OPM to 100%). For example, when it is question of the percentage of cement added so as to stabilized the lateritic soil, the variation is very significant; so we get the following trend, with 1% of cement added, k 1 vary from 191 to 49 MPa, with 2% of cement 268 to 35.4 MPa and at least with 3% of cement, it increase from 347 to 35.4 MPa (Fig. 11a). k 1 vary from 258 to 103 MPa for soil samples at 100% OPM, 148 to 76.4 MPa at 95% and 135 to 102 MPa at 90% OPM (Fig. 11b).

(a) Variation of the material parameter k 1 with the percentage of cement added in the soil specimen. (b) Variation of the material parameter k 1 with the percentage of cement added in the soil specimen. (c) Variation of the material parameter k 2 with the percentage of cement added in the soil specimen. (d) Variation of the material parameter k 2 with the percentage of cement added in the soil specimen. (e) Variation of the material parameter k 3 with the percentage of cement added in the soil specimen. (f) Variation of the material parameter k 3 with the percentage of cement added in the soil specimen

The values of k 1 seem to be the most important material parameter and their variations have significant importance for the soil behavior estimation.

k 2 and k 3 change slowly in regard of with the variation of the compacity and significantly with the percentage of cement (Fig. 11c–f). For k 2, the variation is significant in regard of the percentage of cement added. At 1%, the mean is equal to −0.676 and k 2 vary from 0.510 to 0.770, at 2% from 0.770 to 0.870 and at 3%, from 0.360 to 0.800. k 3 seems to be less variable than the other sample’s parameters, this was observed when it was question of the Andrei model. And from 1% to 3% of cement added, the variation of k 3 more significant and it is between −0.200 and 0.110 at 1%, at 2% between 0.140 and −0.030 and at 3% between 0.170 and −0.290.

The trend of variation (of k 1 and k 2) seems to be less affected when it is question of the soil compacity and from 90% OPM to 100% OPM, k 2 is between 0.510 and 0.750 and k 3 from −0.170 to 0.190.

We can conclude right now that the most sensitive parameter which can really change the soil’s material parameter remains the percentage of cement which changes directly the soil rigidity. If we point out the soil compacity state, we can imagine than the AASHTOO test procedure which began with 1,000 cycles of precondition cycling bring to the different soil at state which is somewhat nearly to the OPM. It that which gave not significant difference of the soil parameters when we point out the state of compacity.

8 Conclusion

Repeated load triaxial test was conducted on different soils collected from different sites within Senegal. In order to investigate the effect of samples compacity and the percentage of cement added on resilient modulus, soil specimens with diameters of nearly 100 mm were considered. Soil specimens were subjected to resilient modulus test in accordance with AASHTO T 307. Test results showed that the resilient modulus for gravel lateritic soils is significantly affected by the percentage of cement added of the soil specimen tested. Soil specimens with 3% of cement exhibited the highest resilient modulus values while the specimens with the variation of the compacities exhibited the lowest values. The resilient modulus variation with the percentage of cement was significant at low deviator stress levels and remains the same evolution with the increase of the deviator stress. Soil specimens with variation of the percentage of cement added exhibited the highest resilient modulus values while the specimens with variation of the compacity exhibited the lowest values. The resilient modulus variation seems to be independent of the level of stress. Results obtained in this research are no longer comparable to those obtained earlier for these kinds of materials, in Senegal. The correlation between Young modulus with the CBR values to obtain a resilient modulus gives high characteristics, which are no longer justified for road design purposes.

References

AASHTO (1986) Guide for Design of Pavement Structures. American Association of State Highway and Transportation Officials, Washington, DC

AASHTO (1993) Guide for Design of Pavement Structures. American Association of State Highway and Transportation Officials, Washington, DC

AASHTO T292-97 (2000) Test procedure for Resilient Modulus of Unbound Materials. American Association of State Highway and Transportation Officials, Washington, DC

AASHTO (2002) Guide for Design of Pavement Structures. American Association of State Highway and Transportation Officials, Washington, DC

AASHTO T 307 (2003) Determining the Resilient Modulus of Soils and Aggregate Materials. American Association of State Highway and Transportation Officials, Washington, DC

AASHTO T 99 (2001) Standard Method of Test for the Moisture-Density Relations of Soils. American Association of State Highway and Transportation Officials, Washington, DC

Andrei D (1999) Development of a Harmonized Test Protocol for the Resilient Modulus of Unbound Materials Used in Pavement Design, MS Thesis, University of Maryland—College Park

Barksdale RD (1972) Repeated load testing evaluation of base course materials, GHD research Project 7002, final report. FHWA, US Department of Transportation, 1972

BCEOM-CEBTP (1984) Manuel sur les routes dans les pays tropicaux et désertiques—Tome 1, 2 et 3. Ed. Min. Français Coop. Et Dév

Brown SF, Pappin JW (1981) Analysis of Pavements with Granular Bases, Transportation Research Record, Transportation Research Board, National Research Council, Washington, DC, pp 17–23

Chen HH, Marshek KM, Saraf CL (1986) Effects of truck tire contact pressure distribution on the design of flexible pavements: a three-dimensional finite element approach. Transport Res Rec 1095:72–78

Chen D-H, Zaman M, Laguros J, Soltani A (1995) Assessment of computer programs for analysis of flexible pavement structure. Transport Res Rec 1482:123–133

Dai S, Van Deusen D (1998) Field study of in situ subgrade soil response under flexible pavement. Transport Res Rec 1639:23–35

de Pont J, Thakur K, Pidwerbesky B, Steven B (2004) Validating a whole life pavement performance model. Transit New Zealand, CAPTIF Research Facility, 15

Dyvik R, Madshus C (1985) Lab measurements of Gmax using bender elements. Proceedings of the advances in the art of testing soil under cyclic conditions, ASCE, Detroit, MI, 186–196

Fall M (1993) Identification et caractéristiques mécaniques de graveleux latéritiques du Sénégal. Application au domaine routier. Thèse de Doctorat en Génie Civil & Minier à l’INPL-ENSG, p 273, et Annexes;Nancy (France)

Fall M, Tisot J-P (1994) Specifications for road design using statistical data. An example of laterite or gravel lateritic soils from Senegal. Publié par l’AIGI (Géologie de l’Ingénieur), Bull. AIGI N°50 (Paris 1994)

Fall M, Tisot J-P (1995) Comportement mécanique à l’appareil de cisaillement de Casagrande de trois graveleux latéritiques compactés provenant du Sénégal Occidental. Publié par l’AIGI (Géologie de l’Ingénieur), Bull. AIGI N°52 (Paris 1995)

Fall M, Tisot J-P (1996) Undrained behaviour of compacted gravel lateritic soils from the western part of Senegal under monotonic and cyclic triaxial loading. Eng Geol 47(1997):71–87

Fall M, Senghor B, Lakhoune A (2002a) Analyse de la pratique du dimensionnement rationnel des structures de chaussées au Sénégal. Influence des paramètres d’entrée dans les codes de calcul pour le renforcement des chaussées. Annales du Batiment et des Travaux Publics, N° 1/02 (1/9)

Fall M, Paye F, Mbodji A (2002b) Current knowledge and research results for the design of flexible pavements in Senegal, EJGE, 2002

Fam M, Santamarina JC (1995) Study of geoprocesses with complementary wave measurements in an oedometer. Geotech Testing J 18(3):307–314

Fioravante V, Capoferri R (2001) On the use of multi-directional piezoelectric transducers in triaxial testings. Geotech Testing J 24(3):243–255

Hardy MSA, Cebon D (1993) Response of continuous pavements to moving dynamic loads. J Eng Mech, ASCE 119(9):1762–1780

Helwany S, Dyer J, Leidy J (1998) Finite-element analyses of flexible pavements. J Transport Eng, ASCE 124(5):491–499

Hicks RG, Monismith CL (1971) Factors influencing the relient properties of granular materials. Highway research record 345, Highway Research Board, Washington, DC pp 15–31

Hjelmstad KD, Taciroglu E (in press) Analysis and implementation of resilient modulus models for granular soils, J Eng Mech, ASCE

Huang YH (2004) Pavement analysis and design. Pearson Prentice Hall, Upper Saddle River, NJ

Jardine RJ, Potts DM, Fourie AB, Burland JB (1986) Studies of the influence of non-linear stress–strain characteristics in soil-structure interaction. Geotechnique 36(3):377–396

Jardine RJ, Potts DM (1988) Hutton tension platform foundation: an approach to the prediction of pile behavior. Geotechnique 38(2):231–252

Kim D-S, Stokoe KH II (1992) Characterization of resilient modulus of compacted subgrade soils using resonant column and torsional shear tests. Transport Res Rec 1369:83–91

Kim D-S, Kweon G-C, Lee K-H (1997) Alternative method of determining resilient modulus of compacted subgrade soils using free-free resonant column test. Transport Res Rec 1577:62–69

Lytton RL, Uzan J, Fernando EG, Roque R, Hiltunen DR, Stoffels SM (1993) Development and validation of performance prediction models and specifications for asphalt binders and paving mixtures. Report No. SHRP-A-357, Transportation Research Board, National Research Council, Washington, DC

Mancuso C, Vassallo R, d’Onofrio A (2002) Small strain behavior of a silty sand in controlled-suction resonant column-torsional shear tests. Can Geotech J 39(1):22–31

Marsh JG, Jewell RJ (1994) Vertical pavement strain as means of weighing vehicles. J Transport Eng, ASCE 120(4):617–632

May RW, Witczak MW (1981) Effective granular modulus to model pavement responses. In: Transportation research record 810, TRB, National Research Concil, Washington, DC, pp 1–9

NCHRP (2000) Harmonized test methods for laboratory determination of resilient modulus for flexible pavement design, vol 1, Unbound Granular Material, NCHRP Project 1–28a Draft Report, p 198

NCHRP Project 1–37A (2002) Summary of the 2002 AASHTO guide for the design of new and rehabilitated pavement structures. NCHRP, Washington, DC

NCHRP (2004) NCHRP Project 1–37A Design guide, mechanistic-empirical design of new and rehabilitated pavement structures, http://www.trb.org/mepdg/. NCHRP, Washington, DC

Pennington DS, Nash DFT, Lings ML (2001) Horizontally mounted bender elements for measuring anisotropic shear moduli in triaxial clay specimens. Geotech Testing J 24(2):133–144

Pidwerbesky BD (1995) Strain response and performance of subgrades and flexible pavements under various loading conditions. Transport Res Rec 1482:87–93

Saleh MF, Steven B, Alabaster D (2003) Three-dimensional nonlinear finite element model for simulating pavement response: study at Canterbury accelerated pavement testing indoor facility, New Zealand. Transport Res Rec 1823:153–162

Sawangsuriya A, Edil TB, Bosscher PJ (2003) Relationship between soil stiffness gauge modulus and other test moduli for granular soils. Transport Res Rec 1849:3–10

Sawangsuriya A, Bosscher PJ, Edil TB (submitted) Application of the soil stiffness gauge in assessing small-strain stiffness of sand with different fabrics and densities. Geotech Testing J, ASTM

Sawangsuriya A, Biringen E, Fratta D, Bosscher PJ, Edil TB (2006) “Dimensionless limits for the collection and interpretation of wave propagation data in soils”. ASCE Geotechnical Special Publication (GSP): “Site and Geomaterial Characterization”. GeoShanghai Conference. Shanghai, China

Schwartz CW (2000) Effect of stress-dependent base layer on the superposition of two-dimensional flexible pavement solutions, proceedings, 2nd international conference on 3D finite elements for pavement analysis, design, and research, Charleston, WV, October, pp 329–354

Schwartz CW (2001) Implementation of a nonlinear resilient modulus constitutive model for unbound pavement materials, proceedings, 10th international conference on computer methods and advances in geomechanics, Tucson, AZ, January, pp 13851390

Seed HB, Idriss IM (1970) Soil moduli and damping factors for dynamic response analyses. Report EERC 70–10, Earthquake Engineering Research Center, University of California, Berkeley, CA

Shook JF, Finn FN, Witczak MW, Monismith CL (1982) Thickness design of asphalt pavement—the Asphalt Institute Methid. Presented at 5th international conference on the structural design of asphalt pavements, Delft, The Netherlands

Souto A, Hartikainen J, Özüdoğru K (1994) Measurement of dynamic parameters of road pavement materials by the bender element and resonant column tests. Geotechnique 44(3):519–526

Sun JI, Golesorkhi R, Seed HB (1988) Dynamic moduli and damping ratios for cohesive soils. Report EERC-88/15, Earthquake Engineering Research Center, University of California, Berkeley, CA

Tanyu BF, Kim WH, Edil TB, Benson CH (2003) Comparison of laboratory resilient modulus with back-calculated elastic moduli from large-scale model experiments and FWD tests on granular materials. Resilient Modulus Testing for Pavement Components, ASTM STP 1437, West Conshohocken, PA, pp 191–208

Tatsuoka F, Shibuya S (1991) Deformation characteristics of soils and rocks from field and laboratory tests. Proceedings of the 9th Asian regional conference on soil mech. and found. engrg., Bangkok, Thailand, vol 2. pp 101–170

Tatsuoka F, Siddiquee MS, Park CS, Sakamoto M, Abe F (1993) Modeling stress–strain relations of sand. Soils Found 33(2):60–81

Terzaghi K, Ralph BP (1948) Soil mechanics in engineering practice, Wiley, New York, The second edition by Ralph BP, 1967

Thomann TG, Hryciw RD (1990) Laboratory measurement of small strain shear modulus under Ko conditions. Geotech Testing J 13(2):97–105

Thompson MR (1990) NCHRP 1–26: Calibrated mechanistic structural analysis procedures for pavements. volume I—final report, prepared for the National Cooperative Highway Research Program, Transportation Research Board, National Research Council, Washington, DC, March

Thompson MR, Garg N (1999) Wheel load interaction: critical airport pavement responses, COE Report No. 7, Center of Excellence for Airport Pavement Research, Department of Civil Engineering, University of Illinois at Urbana-Champaign, July

Tutumluer E (1995) Predicting behavior of flexible pavements with granular bases, PhD dissertation, School of Civil and Environmental Engineering, Georgia Institute of Technology, Atlanta, GA

Tutumluer E, Little DN, Kim S-H (2003) Validated model for predicting field performance of aggregate base courses. Transp Res Rec 1837:41–49

Uzan J (1985) Characterization of granular material, transportation research record 1022, TRB, National Research Council, Washington, DC, pp 52–59

Uzan J (1991) SHRP Quarterly report: A-005 performance models and validation of test results. Quarter 2 of 4, of Year 2, Texas Transportation Institute, The Texas A&M University System, College Station, Texas, July 15

Vucetic M, Dobry R (1991) Effect of soil plasticity on cyclic response. J Geotech Eng, ASCE 117(1):89–107

Witczak MW, Uzan J (1988) The universal airport pavement design system. Report I of V: granular material characterization, Department of Civil Engineering, University of Maryland, College Park, MD

Yoder EJ, Witczak MW (1975) Principles of pavement design (2nd edn). Wiley, New York, NY

Zeng X, Ni B (1998) Application of bender elements in measuring Gmax of sand under Ko condition. Geotech Testing J 21(3):251–263

Acknowledgements

The research presented by this paper was financially supported by the University of Wisconsin-Madison Department of Civil and Environmental Engineering through a Fulbright grant of the United States Department of States. The authors would like to acknowledge the Geo-Engineering and Geological Engineering Program Research Team and the Fulbright Team in Washington DC for their guidance and valuable input in this research project. The “Entreprise Jean Lefebvre Senegal sa” is greatly acknowledged for supporting the high-price shipping of lateritic materials from Senegal to Madison at Wisconsin (United States).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fall, M., Sawangsuriya, A., Benson, C.H. et al. On the Investigations of Resilient Modulus of Residual Tropical Gravel Lateritic Soils from Senegal (West Africa). Geotech Geol Eng 26, 13–35 (2008). https://doi.org/10.1007/s10706-007-9144-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-007-9144-5