Abstract

The aim of present study is prediction of blast-induced flyrock distance in opencast limestone mines using artificial intelligence techniques such as artificial neural network (ANN) and adaptive neuro fuzzy inference system (ANFIS). Blast design and geotechnical variables such as linear charge concentration, burden, stemming length, specific charge, unconfined compressive strength, and rock quality designation have been selected as independent variables and flyrock distance has been used as dependent variable. Blasts required for the study purpose have been conducted in four limestone mines in India. Out of one hundred and twenty-five (125) blasts, dataset of one hundred blasts have been used for training, testing and validation of the ANN and ANFIS based prediction model. Twenty-five (25) data have been used for evaluation of the trained ANN and ANFIS models. In order to know the relationship among the independent and dependent variables, multi-variable regression analysis (MVRA) has also been performed. The performance indices such as root mean square error (RMSE), mean absolute error (MAE) and coefficient of determination (R2) have been evaluated for ANN, ANFIS and MVRA. RMSE as well as MAE have been found lower and R2 has been found higher in case of ANFIS in comparison of ANN and MVRA. ANFIS has been found a superior predictive technique in comparison to ANN and MVRA. Sensitivity analysis has also been performed using ANFIS to assess the impact of independent variables on flyrock distance.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In surface mining, rock blasting results the fragmentation of overburden and exposure of ore benches (Bajpayee et al. 2004). In blasting, whenever an explosive charge detonates, massive amount of energy releases in the form of gas, heat, pressure and stress waves. This explosive energy doesn’t fully convert into mechanical energy to break the rock mass. Only a fraction of 20–30 % of this explosive energy is used for the desired rock breakage and the rest of it goes waste in untoward generation of ground vibration, flyrock, noise and air blast (Wiss and Linehan 1978; Hagan 1979; Singh et al. 1994; Bhandari 1997; Bajpayee et al. 2004; Raina et al. 2011; Trivedi et al. 2014). It has also been considered that flyrock is generated as explosive energy takes the least resistance path to travel (Little and Blair 2009; Trivedi et al. 2014). These unplanned blasting events cause threat to the safety of people and constructions of surrounding villages (Persson et al. 1984; Raina et al. 2011).

Major reasons which generate flyrock are insufficient burden, over charging of the blast holes, inadequate stemming, anomaly in geology of the rock structure, inaccuracy in design of blasthole pattern, faulty drilling, backbreak, and carelessness (Persson et al. 1984; Fletcher and D’Andrea 1986; Workman and Calder 1994; Adhikari 1999; Rehak et al. 2001). As per Bajpayee et al. (2000, 2004) imbalance in the geo-mechanical strength of the surrounding rockmass also leads explosive energy to the path of least resistance, which propels the flyrock beyond the protected blast area. Richards and Moore (2004) have identified cratering, rifling and face burst as the basic mechanisms of its occurrence in bench blasting. This unwanted propelling of fragments is one of the major causes of fatal accidents in Indian open cast mines (Rehak et al. 2001; Bajpayee et al. 2004). As per Verakis and Lobb (2003), flyrock and lack of blast area security accounted for 68 % of the injuries in the opencast mines. According to Kecojevic and Radomsky (2005) inappropriate blasting shelter, failure to evacuate blast area from human and inadequate guarding of the access roads has caused 45.64 % of the fatal and non-fatal accidents in surface coal mining in last 3 decades. Focusing on Indian opencast mines, Figs. 1 and 2 clearly illustrate the number of accidents and deaths that had taken place in Indian mines. As shown in Fig. 3, these cumulative accidents have been classified further into cause wise scenarios. As elucidated in Fig. 3, different reasons of accidents in mines are flyrock projectiles, misfires, blown out shots, delayed ignitions etc. Among these accidents, flyrock holds 31.29 % share of deaths and injuries in Indian mines during 2008–2013 (CSIR-CIMFR 2014).

Number of fatal and serious accidents due to blasting in Indian mines (CSIR-CIMFR 2014)

Number of deaths and injuries due to blasting in Indian mines (CSIR-CIMFR 2014)

Cause wise deaths and injuries due to blasting from 2008 to 2013 in surface mines in India (CSIR-CIMFR 2014)

To solve this threatening problem of flyrock several empirical models have been proposed in the past by Lundborg (1974), Roth (1979), Workman and Calder (1994) and Richards and Moore (2004) but their biggest shortcoming is that they don’t include all variables that might affect the flyrock launch velocity or throw. That’s why these models have not been proved reliable enough to completely eliminate this problem from the opencast mines.

Now talking about more sophisticated and advanced artificial intelligence (AI) tools like fuzzy logic, developed by Zadeh (1965), exhibit its’ importance while making decisions with uncertainty that elucidate human reasoning and insight in developing mathematical schema. Due to its stochastic characteristic it has got wide application in information technology, decision making, data analysis and prediction models generation based on previous trend (Nauck and Kruse 1999; Pena-Reyes and Siper 1999). Adaptive neuro fuzzy inference system (ANFIS) is a sugeno fuzzy model framed in adaptive systems to ease learning and adaptation (Iphar et al. 2008). It can also be looked as assimilation of neural network and fuzzy logic for better and relevant output. It is a fuzzy technique that uses a given input–output dataset that creates membership functions and describes system behaviour. This method is also popular for natural grouping of given dataset while dealing large number of dataset for concise representation (Bezdek 1974; Dunn 1974; Bezdek et al. 1987). For example in subtractive clustering method, the dataset containing large numbers of data can be classified in clusters and respective centres using one pass algorithm (Chiu 1994).

From the past decades till now, AI techniques have been successfully applied in solving complex mining problems. Mostafa (2011) predicted ground and air vibrations using fuzzy logic. Monjezi et al. (2010a, b) and Esmaeili et al. (2014) predicted back break in open pit blasting using fuzzy set theory. Azimi et al. (2010) predicted blastability of rock masses using fuzzy sets. Alipour and Ashtiani (2011) predicted maximum charge per delay in surface mining using fuzzy modeling. This technique has also been widely applied in predicting uniaxial compressive strength and the modulus of elasticity (Grima and Babuska 1999; Gokceoglu and Zorlu 2004; Sobhani et al. 2010; Yesiloglu-Gultekin et al. 2012; Singh et al. 2013), performance prediction of a rock-cutting trencher (Den Hartog et al. 1997), performance of tunnel boring machine (Acaroglu et al. 2008), evaluating shear strength of the soil samples (Chuang 1995), roof categories in longwall mining (Jiang et al. 1997). Cabalar et al. (2012) have also discussed some geotechnical applications of ANFIS technique. Another AI technique i.e. artificial neural network (ANN) has also been used in predicting flyrock distance (Monjezi et al. 2010a, b; Trivedi et al. 2014). It has been implemented successfully in prediction of blasting problems (Khandelwal and Monjezi 2013; Remennikov and Mendis 2006; Singh and Singh 2005; Tawadrous and Katsabanis 2005; Trivedi et al. 2014).

In present paper, attempts have been made to predict the blast-induced flyrock distance using advanced AI techniques i.e. ANFIS and ANN. Blast design and geotechnical variables such as linear charge concentration, burden, stemming length, specific charge, unconfined compressive strength (UCS) and rock quality designation (RQD) have been selected as independent variables and flyrock distance as dependent variable. Out of one hundred and twenty-five (125) blasts, dataset of one hundred blasts have been used for training, testing and validation of the ANN and ANFIS models while dataset of twenty-five (25) blasts have been used for model evaluation. Multi-variable regression analysis (MVRA) has also been performed to know the relationship among the independent and dependent variables. The accuracy of these models have been compared quantitatively based on performance indices such as root mean square error (RMSE), mean absolute error (MAE) and coefficient of determination (R2). Sensitivity analysis has also been performed using ANFIS method to assess the impact of each of the independent variables on flyrock distance.

2 Materials and Methods

2.1 Field Study at Opencast Limestone Mines

Blasting sites location have been comprehensively described in Table 1. As shown in Fig. 4, mine-1 is located at Kymore village, district Katni, Madhya Pradesh, mine-2 is near to the Beawar district Ajmer, Rajasthan, mine 3 is located near to the Shanbhupura village, district Chittorgarh, Rajasthan and mine 4 is located at the Mohapura Jodhapura near Kotputli Town, district Jaipur, Rajasthan.

Discussing about the similarity between chosen case study sites, all 4 mines are limestone mines where mining is being done by fully mechanized methods. The working pit has been developed with benches of 9.0–10 m height. Haul roads have been developed to approach the working faces. Shovel-dumper combination is the main workhorse of limestone production in the mines. The limestone is transported to in-pit crushers where it is crushed up to (−) 90 mm size.

2.2 Methodology Used in Data Generation

The problem of blast-induced flyrock is prominent at case study sites as these mines are surrounded by the villages and their mine management is quite pro-active in controlling blasting operations with due care and safety. Below Table 2 is showing all those parameters that have been collected from the field during blasting with their standard symbols and units.

Rock samples of every blasting operation, collected from the mines and further tested in CSIR-CIMFR Dhanbad, have been used to estimate the blast design variables like linear charge concentration, burden, spacing, stemming, average depth of blast holes, blasthole diameter, charge per hole, specific charge and flyrock distance from the blasting face. But due to the floating nature of these variable values, mean value has been considered appropriate for the analysis. Geotechnical variables such as volumetric joint count, joint spacing, dip and strike of major joint set and joint condition have been generated at face before blasting operation took place. Whereas variable like RQD has been estimated using volumetric joint count (Jv) method (Raina et al. 2011) and UCS through testing of 1 inch cube rock sample in the laboratory of CSIR-CIMFR, Dhanbad, India. Discussing about estimation of flyrock distance, only the fragments having size more than 10 cm have been selected to identify the maximum throw of blast-induced flyrock. For this purpose, hand-held global positioning system (GPS) was used in order to precisely measure the distance of flyrock.

Rest of the parameters like flyrock launch velocity and launch angle have been calculated by analyzing the videos of blasting events using ‘ProAnalyst 1.5.6.7’ software of XCITEX, USA as shown in Fig. 5. High resolution video camera of 24 g frames per second has been used to take the videos from safe distance. For performing this analysis, the calibration of the instrument was made using three red flags separated horizontally and vertically to known distance. For the verification of calibrated instrument, other known variables like bench height, cut length were also being calculated and compared. Hence, calculated mean value of all blast design and geotechnical variables through above mentioned methods have been shown in Table 3.

2.3 ANN Approach to Predict Blast-Induced Flyrock

Back propagation neural network (BPNN) method has been attempted to predict the blast induced flyrock distance in ANN technique. It primarily constitutes three layers i.e. independent layer, hidden layer and dependent layer. In this technique, neurons are the basic processing unit that actually computes the results by connecting the different layers of data with appropriate weights (w) and biases (b). Output of neurons in independent layer serve as input for hidden layer and output of hidden layer serve as an input for output layer that finally gives desired output. That’s why the process of computing output is a linear process discretize into two steps. In present case, 125 data has been classified such that 100 data have been used to train, test and validate the BPNN model and separate 25 data have been used for evaluation of flyrock distance. Out of 100 data used for developing a robust ANN structure, proportion of training, testing and validating data is taken as 80, 10 and 10 % respectively. During training of model, means generating the BPNN model using training data, first neural network is established and then during continuous training of the BPNN model, results are attuned according to any change detected in the model.

To attain the best possible ANN predictive model iterations have been made based on different values of number of hidden layers, number of neurons and transfer function, as shown in Table 4. According to Table 4, BPNN model with log sigmoid transfer function, 2 hidden layers and 10 neurons in each hidden layer has been identified as the best possible predictive combination with least RMSE and MAE value and better R2. The model structure of the best possible predictive model has been shown in Fig. 6 which reflects the way through which input and output data are connected through hidden layers. Figure 6 describes the mechanism of calculating output values based on independent variables that have different weights and biases, being determined by neurons in hidden layers. Figure 7 stands for trend of RMSE value of training, testing and validation data with respect to each other for number of iterations. In this figure, the small circle signifies that particular iteration where the difference in the output of training and validation data was minimum. Figure 8 is highlighting the regression analysis of 80 training, 10 testing and 10 validation data whose respective values are clearly been highlighted in the figure itself. It is being assumed that better the regression more is the accuracy of the predictive model.

2.4 ANFIS Approach to Predict Blast-Induced Flyrock

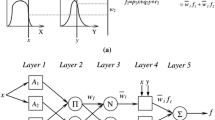

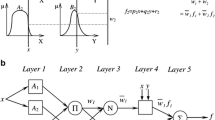

ANFIS maps independent and associated variables through membership function to generate required output through output membership functions as shown in the Fig. 9. Figure 9 is demonstrating the structure of the generated ANFIS model and the way in which input and output functions are linked through membership function layers. According to the structure, there are five layers in which computation of ANFIS model takes place i.e. input layer, input membership function layer, rule layer, output membership function layer and output layer. As elucidated in the Fig. 9, six input variables are used with nine rules to generate required ANFIS model.

Before performing the ANFIS operation on the dataset, 125 blasting data have been classified into training and checking dataset such that range of the input and output data in training dataset encompass the range of input and output data of checking dataset. This is performed because only then selected samples for checking purpose can represent complete population and generate generalized ANFIS flyrock model to predict the precise flyrock distance generated in the mines. After classifying the dataset into two classes named training and checking dataset in the above presented manner, model generation process began. In present case, 125 data are divided into 100 training and 25 checking data. Training dataset is used to generate the required ANFIS model while the checking dataset is used as an input to test the validity of the generated ANFIS model and to calculate the error in flyrock distance prediction.

As highlighted in Fig. 10 after loading training dataset, ANFIS model is generated using subtractive clustering method. While using this method, value of range of influence (ROI) and squash factor (SF) needs to be defined as these values affect the number of rules required for generating model and that ultimately affects the RMSE of the model. Number of iterations has been made in selecting the appropriate values of these variables to get the best possible predictive ANFIS model with least complicacy in terms of rules and RMSE value, as defined in Table 5. Table 5 is comprehensively highlighting the changes made in the value of ROI and SF to get the best possible model. The model so generated needs to be tuned further to reduce the error using hybrid algorithm. During tuning process, hybrid algorithm i.e. combination of least square and back propagation technique, tunes the ANFIS model in forward and backward pass by minimizing the errors involved in the calculation of weights of individual independent variables to get final output value. The graph drawn between the epochs and error in Fig. 10 also indicate the limit up to which tuning can be performed and that is defined by the overfitting property. Over-fitting is identified by the unusual increase in the error for continuous number of iterations.

The final stage of this model is its validation using checking dataset. In Fig. 11, the plot is depicting the graphical difference between the value of the flyrock distance generated by the ANFIS model and the actual value collected in the field. Red* stands for the ANFIS output of the model while blue + stands for the value of the flyrock distance observed in the mine and provided by the user to the model. The numerical value of the error is root mean square error (RMSE) i.e. 1.17 m that implies the degree of precision of the ANFIS flyrock model.

2.5 Prediction of Flyrock by Multiple Regression

The relation between the variables, independent or dependent, can be calculated by using multi variable regression analysis (MVRA), which performs least squares fit, to solve the data set. Regression matrix solves the simultaneous equations thus created. MVRA has been performed by the same dataset and the same independent variables which were used in ANN and ANFIS techniques. The equation for prediction of flyrock by MVRA is as follows

3 Results and Discussion

3.1 Performance of ANN and ANFIS

To compare the performance of this technique, Figs. 12, 13 and 14 have been used in which graphs are drawn between observed and predicted flyrock distance value by ANN, ANFIS and MVRA model respectively. Figure 15 is demonstrating the blast wise comparison in observed and predicted values. These models have also been compared quantitatively using performance indices like mean absolute error (MAE), root mean square error (RMSE) and coefficient of determination (R2) as summarized in Table 6. According to Table 6, high value of R2 reflects excellent correlation between observed and predicted values of flyrock distance by ANN and ANFIS model. High value of R2 i.e. 0.95 in case of ANN and 0.98 in case of ANFIS indicates that these predictive models can be successfully applied in solving complex flyrock distance problems of opencast mines. It is also evident from Table 6 that ANFIS is better than ANN and MVRA model as it has least value of errors namely RMSE and MAE. Thus on the basis of present analysis ANFIS seems to be a better predictive model in comparison of ANN and MVRA.

3.2 Sensitivity Analysis in ANFIS

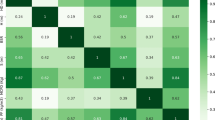

Sensitivity analysis is used to identify the impact of an individual independent variable on flyrock distance keeping all other independent variables constant. In present study it is performed for independent variables namely linear charge concentration, burden, stemming length, specific charge, UCS, RQD using ANFIS-Edit tool box of Matlab software. As blasting data are collected for two different blasthole diameters i.e. 115 and 165 mm, separate sensitivity analysis has been made for two different blasthole diameters. The results of sensitivity analysis of independent variables are depicted in Figs. 16, 17, 18, 19, 20 and 21 and enlisted in Table 7.

While performing sensitivity analysis of an independent variable, all other independent variables are set at its mean values as specified in Table 3. Value of the gradient of the graph drawn between independent variable and observed flyrock distance has been taken as the evaluating parameter to determine the impact of unit change in independent variable on flyrock distance value keeping all other constant for two different blasthole diameters. According to the obtained results, linear charge concentration and specific charge show positive correlation with the flyrock distance for both blasthole diameter cases while variables like burden, stemming, UCS and RQD have negative correlation with the flyrock distance. Table 7 summarizes the degree of change in flyrock distance with unit change in value of independent variable. For example, for 115 mm blasthole diameter if linear charge concentration is changed by 0.1 kg/m then the flyrock distance shall change by 1.54 m in same manner.

4 Conclusion

With the performed study, ANFIS has been found as a superior predictive tool in comparison to ANN and MVRA in case of complex flyrock distance prediction problems of opencast mines. Values of RMSE and MAE are lowest in case of ANFIS in comparison to ANN and MVRA and excellent correlation has also been noted between observed and predicted values by ANN and ANFIS model. Thus, ANFIS model can successfully eliminate the complexity in designing safety zone for flyrock hazards in opencast mines. Results of the sensitivity analysis are also significant as they not only identify the potential parameters that affect flyrock generation but also give quantitative idea about the degree of impact of individual independent variables on the flyrock distance. It will also help in making change in the values of these variables while using this predictive model so that flyrock distance can be controlled effectively.

References

Acaroglu O, Ozdemir L, Asbury B (2008) A fuzzy logic model to predict specific energy requirement for TBM performance prediction. Tunn Undergr Space Technol 23:600–608. doi:10.1016/j.tust.2007.11.003

Adhikari GR (1999) Studies on flyrock at limestone quarries. Rock Mech Rock Eng 32(4):291–301

Alipour A, Ashtiani M (2011) Fuzzy modeling approaches for the prediction of maximum charge per delay in surface mining. Int J Rock Mech Min Sci 48:306–310. doi:10.1016/j.ijrmms.2010.11.010

Azimi Y, Osanloo M, Aakbarpour M, Bazzazi AA (2010) Prediction of the blastability designation of rock masses using fuzzy sets. Int J Rock Mech Min Sci 47:1126–1140. doi:10.1016/j.ijrmms.2010.06.016

Bajpayee TS, Rehak TR, Mowrey GL, Ingram DK (2000) A summary of fatal accidents due to flyrock and lack of blast area security in surface mining, 1989–1999. In: Proceedings of 28th annual conference on explosives and blasting technique. International Society of Explosives Engineers, 10–13 Feb 2000, NIOSH, Las Vegas, Nevada, pp 105–188

Bajpayee TS, Rehak TR, Mowrey GL, Ingram DK (2004) Blasting injuries in surface mining with emphasis on flyrock and blast area security. J Saf Res 35:47–57. doi:10.1016/j.jsr.2003.07.003

Bezdek J (1974) Cluster validity with fuzzy sets. J Cybern 3(3):58–71. doi:10.1080/01969727308546047

Bezdek J, Hathaway R, Sabin M, Tucker W (1987) Convergence theory for fuzzy c-means: counterexamples and repairs. IEEE Trans Syst Man Cybern 17:873–877

Bhandari S (1997) Engineering rock blasting operations. Balkema, Rotterdam

CSIR-CIMFR (2014) Prediction and control of flyrock hazards due to blasting in opencast mines using artificial neural network. Interim report, Grant in Aid Project (GAP/87/EMG/DST/2010-11) Central Institute of Mining and Fuel Research, Dhanbad, India

Cabalar AF, Cevik A, Gokceoglu C (2012) Some applications of adaptive neuro-fuzzy inference system (ANFIS) in geotechnical engineering. Comput Geotech 40:14–33. doi:10.1016/j.compgeo.2011.09.008

Chiu S (1994) Fuzzy model identification based on cluster estimation. J Intell Fuzzy Syst 2(3):827–841

Chuang PH (1995) Use of fuzzy sets for evaluating shear strength of soils. Comput Geotech 17:425–446. doi:10.1016/0266-352X(95)94914-C

Den Hartog MH, Babuska R, Deketh HJR, Grima MA, Verhoef PNW, Verbruggen HB (1997) Knowledge-based fuzzy model for performance prediction of a rock-cutting trencher. Int J Approx Reason 16(1):43–66. doi:10.1016/S0888-613X(96)00118-1

Dunn J (1974) A fuzzy relative of the isodata process and its use in detecting compact well separated cluster. J Cybern 3(3):32–57. doi:10.1080/01969727308546046

Esmaeili M, Osanloo M, Rashidinejad F, Bazzazi AA, Tazi M (2014) Multiple regression, ANN and ANFIS models for prediction of backbreak in the open pit blasting. Eng Comput 30:549–558. doi:10.1007/s00366-012-0298-2

Fletcher LR, D’Andrea DV (1986) Control of flyrock in blasting. In: Proceedings of the 12th conference on explosives & Blasting Tech Atlanta, Georgia, 2/9-14/86

Gokceoglu C, Zorlu K (2004) Fuzzy model to predict the uniaxial compressive strength and the modulus of elasticity of a problematic rock. Eng Appl Artif Intell 17:61–72. doi:10.1016/j.engappai.2003.11.006

Grima M, Babuska R (1999) Fuzzy model for the prediction of unconfined compressive strength of rock samples. Int J Rock Mech Min Sci 36:339–349. doi:10.1016/S0148-9062(99)00007-8

Hagan TN (1979) Rock breakage by explosives. Acta Astronaut 6(3–4):329–340. doi: 10.1016/0094-5765(79)90102-4

Iphar M, Yavuz M, Ak H (2008) Prediction of ground vibrations resulting from the blasting operations in an open-pit mine by adaptive neuro-fuzzy inference system. Environ Geol 56:97–107. doi:10.1007/s00254-007-1143-6

Jiang YM, Park DW, Deb D, Sanford R (1997) Application of fuzzy set theory in the evaluation of roof categories in longwall mining. Min Eng 49(3):53–57

Kecojevic V, Radomsky M (2005) Flyrock phenomena and area security in blasting-related accidents. Saf Sci 43:739–750. doi:10.1016/j.ssci.2005.07.006

Khandelwal M, Monjezi M (2013) Prediction of flyrock in open pit blasting operation using machine learning method. Int J Min Sci Technol 23(3):313–316. doi:10.1016/j.jrmge.2014.07.003

Little TN, Blair DP (2009) Mechanistic Monte Carlo models for analysis of flyrock risk. In: Proceedings of the 9th international symposium on rock fragmentation by blasting, Granada, Spain, pp 641–647

Lundborg N (1974) The hazards of fly rock in rock blasting. Swedish Detonic Research Foundation, Report DS 13, Stockholm

Monjezi M, Bahrami A, Yazdian V (2010a) A simultaneous prediction of fragmentation and flyrock in blasting operation using artificial neural networks. Int J Rock Mech Min Sci 47:476–480

Monjezi M, Rezaei M, Yazdian A (2010b) Prediction of backbreak in open-pit blasting using fuzzy set theory. Expert Syst Appl 37:2637–2643. doi:10.1016/j.eswa.2009.08.014

Mostafa MT (2011) Performance of fuzzy logic and artificial neural network in prediction of ground and air vibrations. Int J Rock Mech Min Sci 48:845–851. doi:10.1016/j.ijrmms.2011.04.016

Nauck D, Kruse R (1999) Obtaining interpretable fuzzy classification rules from medical data. Artif Intell Med 16:149–169. doi:10.1016/S0933-3657(98)00070-0

Pena-Reyes CA, Siper M (1999) A fuzzy-genetic approach to breast cancer diagnosis. Artif Intell Med 17:131–155. doi:10.1016/S0933-3657(99)00019-6

Persson P, Holmberg R, Lee J (1984) Rock blasting and explosives engineering. CRC Press, New York

Raina AK, Chakraborty AK, Choudhury PB, Siha A (2011) Flyrock danger zone demarcation in opencast mines: a risk based approach. Bull Eng Geol Environ 70:163–172. doi:10.1007/s10064-010-0298-7

Rehak TR, Bajpayee TS, Mowrey GL, Ingram DK (2001) Flyrock issues in blasting. In: Proceedings of the 27th annual conference on explosives and blasting technique. vol 1. International Society of Explosives Engineers, Cleveland, pp 165–175

Remennikov AM, Mendis PA (2006) Prediction of airblast loads in complex environments using artificial neural networks. WIT Trans Built Environ 87:269–278. doi:10.2495/978-1-84564-750-6/06

Richards AB, Moore AJ (2004) Flyrock control—by chance or design. In: Proceedings of 30th annual conference on explosives and blasting technique. International Society of Explosive Engineers

Roth JA (1979) A model for the determination of flyrock range as a function of shot condition. (Los Altos, CA: Management Science Associates. USBM contract J0387242)

Singh TN, Singh V (2005) An intelligent approach to predict and control ground vibration in mines. Geotech Geol Eng 23:249–262. doi:10.1007/s10706-004-7068-x

Singh DP, Singh TN, Goyal M (1994) Ground vibration due to blasting and its effect. In: Pradhan GK, Hota JK (eds) Enviromin. Bhubaneshwar, India, pp 287–293

Singh R, Vishal V, Singh T, Ranjith P (2013) A comparative study of generalized regression neural network approach and adaptive neuro-fuzzy inference systems for prediction of unconfined compressive strength of rocks. Neural Comput Appl 23(2):499–506. doi:10.1007/s00521-012-0944-z

Sobhani J, Najimi M, Pourkhorshidi AR, Parhizkar T (2010) Prediction of the compressive strength of noslump concrete: a comparative study of regression, neural network and ANFIS models. Constr Build Mater 24:709–718. doi:10.1016/j.conbuildmat.2009.10.037

Tawadrous AS, Katsabanis PD (2005) Prediction of surface blast patterns in limestone quarries using artificial neural networks. Int J Bl Fragm 10:233–242. doi:10.1080/13855140600979531

Trivedi R, Singh TN, Mudgal K (2014) Impact of geotechnical parameters on blast induced flyrocks using artificial neural network—a case study. In: Proceedings of 2nd international conference on advanced technology in exploration and exploitation of minerals, advance Minetech. Jodhpur, India, pp 128–134

Verakis HC, Lobb TE (2003) An analysis of blasting accidents in mining operations. In: Proceedings of the 29th annual conference on explosives and blasting technique, 2 Cleveland, OH: International Society of Explosives Engineers, pp 119–129

Wiss JF, Linehan PW (1978) Control of vibration and air noise from surface coal mines—III. USBM Report No: OFR 103 (3)—79

Workman JL, Calder PN (1994) Flyrock prediction and control in surface mine blasting. In: Proceedings of 20th annual conference on explosives and blasting technique, Austin, Texas, Cleveland, OH: International Society of Explosives Engineers, pp 59–74

Yesiloglu-Gultekin N, Sezer E, Gokceoglu C, Bayhan H (2012) An application of adaptive neuro fuzzy inference system for estimating the uniaxial compressive strength of certain granitic rocks from their mineral contents. Expert Syst Appl 40(3):921–928. doi:10.1016/j.eswa.2012.05.048

Zadeh LA (1965) Fuzzy sets. Inf Control 8(3):338–353. doi:10.1016/S0019-9958(65)90241-X

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Trivedi, R., Singh, T.N. & Gupta, N. Prediction of Blast-Induced Flyrock in Opencast Mines Using ANN and ANFIS. Geotech Geol Eng 33, 875–891 (2015). https://doi.org/10.1007/s10706-015-9869-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-015-9869-5