Abstract

The paper focuses on the methods commonly used for measuring and quantifying the joint roughness in the current rock mass characterization practice. Among the different parameters traditionally employed to express roughness, major relevance seems to be gained by the “Joint Roughness factor” (jR) applied in the Palmström’s rock mass characterization index system, having this factor also been integrated in some quantitative methods recently proposed for estimating the geological strength index of a rock mass. Therefore, a new quantitative approach for a more objective estimation of this factor has been fine-tuned and is presented in the paper. The new method has been specifically designed to assist engineering geologists in gaining consistent values of jR on the base of conventional routine field measurements. It can suitably integrate and support the traditional semi-qualitative Palmström’s classification of joint roughness, mostly related to more subjective descriptions, to estimate the most representative values of jR to be considered for rock mass characterization. In its original definition, the factor jR is evaluated for two-dimensional joint profiles by the product of a small-scale roughness factor (the joint smoothness or unevenness factor, js) with a large-scale roughness factor (the joint waviness factor, jw). In order to reduce the subjectivity on the estimate of these partial factors, a simple analytic equation relating them with some parameters traditionally used to quantify 2D joint roughness is here proposed, providing a continuous gradation among the different ratings of the jR scale and also facilitating the implementation of the factor in probabilistic approaches for managing its inherent uncertainty and variability. The presented method applies best for characterizing hard rock masses well-exposed after blasting (e.g., in dam foundation or quarry slopes) or favourably outcropping on natural rocky slopes, where joint surfaces can generally be easily attained and analysed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the last decades, a general trend towards the development of more sophisticated modelling and numerical design tools in rock engineering, was rapidly delineated.

Nevertheless, the refinement of these tools has, in general, not been followed by a parallel enhancement of the quality and objectivity of the required input data, that are still often derived from qualitative and subjective descriptions of the rock mass properties based upon field observations.

The physical characteristics of the natural discontinuities are particularly exemplificative of this subject because, despite playing a very important role in estimating the hydro-mechanical properties of a jointed rock mass, their assessment is mostly founded on approaches based on descriptive terms and classification procedures, whose reliability is strictly dependent on the sound experience and ability of the engineering geologists directly involved in field surveys.

Among these characteristics, the roughness of joint walls, particularly when clean and unfilled, has long been recognized to have a very significant impact on the mechanical and hydraulic behaviour of a discontinuous rock mass.

The term “roughness” is generally used to describe the geometry of a joint surface and is traditionally defined as a measure of the inherent “unevenness” and “waviness” of a discontinuity relative to its mean plane (Brady and Brown 1985).

Joint roughness is thus recognized to consist of two distinct components: one that may be referred to a random small-scale component, defined “unevenness”, and the other to a large-scale component in terms of “waviness” or curvature from planarity (ISRM 1978).

At small-scale, the unevenness is thought to influence the shear strength of the discontinuity, while at large-scale, the waviness affects both the direction in which shearing occurs and the dilation of the discontinuity surface during relative motion, assuming that the rock asperities do not fail (Poropat 2009).

The importance of joint roughness in rock mass characterization was clear since long time and all the traditional rock mass classification systems (e.g., RMR, Q, Laubsher’s MRMR, RMi) included almost a rank referred to this feature.

Actually, the Jr factor defined by Barton et al. (1974) for application in the Q-system and the similar “Joint Roughness factor” (jR) introduced by Palmström to calculate the Rock Mass characterization index (RMi) (Palmström 1995a, b, 1996), are the parameters most widely used in the current practice for quantifying the joint roughness for rock mass characterization/classification purpose.

Particularly the Palmström’s jR factor, having also been recently integrated in some quantitative methods for estimating the geological strength index (GSI) (e.g., Cai et al. 2004; Russo 2009), has currently gained a relevant interest in practical rock engineering.

Similarly to the approach firstly proposed by Sonmez and Ulusay (1999), these quantitative methods mainly use the block size (i.e. unitary volume of rock blocks or joint spacing) and the roughness and alteration conditions of the joint walls, globally expressed by a “joint condition factor” jC, as the main input parameters for the determination of the GSI.

At this scope, the factor jC is quantified dividing the mentioned jR, which is calculated as the product of jw and js (where jw is a large-scale waviness factor and js a small-scale smoothness factor), with a “joint alteration factor”. All these factors are intended to be estimated through the original chart and tables proposed by Palmström (1995a).

It has to be noted that in the method of Cai et al. (2004), the Palmström’s “joint size factor”, representing the influence of size and termination of joints, has been ignored, while it has been taken into account in the method of Russo (2009).

The factor jR theoretically spans from 0.6 for planar and slickensided joints to a maximum of 9 for very rough and large-scale interlocked joints and it is though to cover, in some way, also the influence of rock mass interlockness (Russo 2009).

Despite the mainly “qualitative” character traditionally accredited to jR, its accurate quantification seems desirable especially when functional to the use of this factor as numerical input parameter in one of the mentioned quantitative methods for assessing rock mass quality.

This primarily in order to avoid further scattering of values that could result, in addition to the often relevant natural variability of joint roughness, from inaccuracy, errors or inexperience in field data surveys.

In this light, an attempt to standardize and make the quantification of jR as much objective as possible appears of interest for practitioners and it has inspired the major intention of the present work.

2 The Joint Roughness Factors Applied in the Q and RMi Systems

Barton et al. (1974), in developing their well-known Q-system for the engineering classification of rock masses, included a Joint Roughness number (Jr) among the six basic parameters selected for describing the quality of the rock mass.

They related Jr to both the small and the intermediate (large) scale roughness of 2D joint profiles and suggested to quantify this factor through the conventional ratings summarized in the Table 1.

Barton (1987) also tried to link the ratings of Jr to the values of the joint roughness coefficient (JRC) defined in the Barton–Bandis shear strength criterion for unfilled rock joints (Barton 1973), finally proposing, for different sizes of in situ joint samples, the relationships shown in Fig. 1/left.

As known, the JRC coefficient represents a dimensionless scale of roughness originally developed for 10 cm long joint profiles and ranging from 0 for very smooth joints to a maximum value of 20 for very rough joints.

Barton proposed to estimate JRC either by back-analyzing shear tests or through the results of tilt and pull tests or, as a further alternative, by a simple visual comparison of the analysed joint profile with ten standard profiles taken as reference (Barton and Choubey 1977).

Nevertheless, as pointed out for example by Maerz et al. (1990), JRC is not a measure of the joint profile geometry but, more properly, is an empirical parameter specifically functional to the Barton–Bandis shear strength criterion for rock joints.

Despite all, JRC is still the most commonly used parameter for quantifying joint roughness. A general correlation between JRC and the maximum profile amplitude (amax), measured with respect to a straight edge of length (L), was firstly suggested by Barton (1982) on the base of earlier experimental studies of Bandis (1980); (Fig. 1/right). In particular, Barton found for the JRC a close correlation with the ratio (amax/L) and proposed the following approximate relationships:

Successively, Milne et al. (1991, 1992) introduced the concept that the Jr of the Q-system can be obtained by combining two partial ratings, respectively referred to a small-scale roughness factor (Jr/r) and to a large-scale (“intermediate scale”) roughness factor (Jr/w) and found, basing on data collected from surveys in some Canadian mines, a more rigorous approach for evaluating Jr through the JRC coefficient.

At this scope, the authors estimated JRC from the Barton–Bandis’s Chart by measuring in the field the maximum asperity amplitude of joint profiles with lengths of 10 cm and 1 m, respectively for small and large-scale roughness assessment (Fig. 2), and related the obtained JRC to the Barton’s roughness categories independently assessed by visual classification of joint profiles.

Small and large-scale roughness ratings proposed for calculating Jr in function of JRC (after Milne et al. 1991)

They finally found, for the partial factors (Jr/r) and (Jr/w), the ratings displayed in Fig. 2 in function of the coefficient JRC and proposed to calculate Jr by multiplying (Jr/r) with (Jr/w).

Some years later, a conceptually similar joint roughness factor, called jR, was also proposed by Palmström (1995a, 1995b) to calculate his RMi.

The numerical ratings defined by Palmström for jR are listed in Table 2, where some differences with the previously described Barton’s Jr factor can be appreciated (theoretical range of jR = 0.6–9 instead of Jr = 0.5–4).

In accordance with Milne et al. (1991), Palmström defined jR simply as the product of a small-scale smoothness factor (js) and a large-scale waviness factor (jw):

and proposed to estimate such partial factors through the descriptive terms and ratings shown in Table 3.

As evident from the table, the ratings assigned to js and jw gradually increase with the roughness of joints, reaching the highest values for “very rough” and “stepped-interlocked” joint types, respectively.

Similarly to Barton, Palmström proposed a link between the smoothness and waviness categories and the values of the JRC coefficient making use of the Palmström’s Chart (Fig. 3), where JRC is estimated through the “undulation factor” (u = a max /L) assuming the following approximate relationship:

where amax is the maximum profile amplitude measured over a joint sample length of L.

Palmström’s Chart relating the terms of the jR classification to the JRC coefficient estimated through the maximum asperity amplitude for different profile lengths (after Palmström 1995a)

It should be noted that, according to Table 3 and Fig. 3, Palmström has foreseen a unique rating of jw = 1.5 for joints with JRC variable in the very wide interval 1.5–15.

3 Assessment of Joint Roughness in the Common Field Practice

A huge number of field survey techniques to estimate joint roughness have been developed over the years, involving the use of either manual, mechanical or more sophisticated optical equipments.

In particular, the great diffusion of optical instruments has highly encouraged, especially in the last years, the development of new methods for joint roughness assessment based upon an accurate survey, in the field, of the 3D surface topography of joints. At the same time, new geometrical parameters able to describe the anisotropy and the spatial variability of roughness, started to be proposed in literature.

Nevertheless, such advanced methods are not yet widely applied in the common practice and the most usual approach in joint roughness quantification still remained the estimation of the coefficient JRC of 2D joint profiles.

Therefore, a quantity of different analytical methods have been developed, in the time, to more objectively assess the value of JRC, mainly involving correlations with statistical, empirical and fractal parameters.

In the following sub-sections, a brief excursus on the techniques currently adopted for joint roughness estimation, fitting best the practical imprinting of the present work, is presented.

The described methods are specifically based on 2D joint profiles analysis that, despite some known conceptual limitations and shortcomings (Tatone and Grasselli 2010), still represents, as mentioned early, the most widely diffused approach in joint roughness assessment.

A detailed review of these methods is, indeed, beyond the scope of the present study. Major sources on this subject are given in the reference list reported at the end of the paper.

3.1 Small-Scale Roughness Assessment

The most common method used for estimating the small-scale joint roughness consists in recording manually, directly on joint surface outcrops or borehole cores, the traces of linear profiles with a basic size of few centimetres.

At this scope, a simple profile gauge or a steel stylus comb 10 cm long is habitually used in the field (Barton and Choubey 1977; Stimpson 1982; Milne et al. 1991, 1992; Fig. 4/left).

This very simple manual method implies the direct contact of the operator with the joint surface and can cheaply provide a large amount of repeatable measures of joint traces ready to be digitized and subsequently analysed on desk.

The joint trace recorded can be compared with the standards roughness profiles defined by Barton and Choubey (1977);(Fig. 4/right) to estimate the corresponding small-scale joint roughness coefficient (JRC0).

Indeed, more sophisticated mechanical, electrical and photogrammetric equipments, suitable for a more accurate joint trace recording in the field, were described in the literature during the last decades.

Among these, the mechanical profilograph developed by Du et al. (2009); (Fig. 5/left) or the shadow profilometer originally fine-tuned by Maerz et al. (1990); (Fig. 5/right), that utilizes a light source at 45° angle to the discontinuity wall to obtain a profile of the surface, are, among many others, some examples of techniques whose use has, despite their relative simplicity, remained quite unusual in routine joint mapping.

The same concerns some advanced optical instruments (e.g., Fig. 6) whose utilization is, as well, not currently diffused in the common survey practice (e.g., Kulatilake et al. 1995; Milne et al. 2009, amongst others).

Portable laser profilometer developed by Milne et al. (2009)

As already mentioned, the profile trace recorded through one of the above described methods can be visually compared with the typical standard profiles of Barton and Choubey (1977) to estimate the JRC0 (Fig. 4/right).

However, it is generalized opinion that this classical procedure is too subjective and can provide controversial and biased or sometime unreliable results (Maerz et al. 1990; Hsiung et al. 1993; Beer et al. 2002; Leal-Gomes and Dinis-da-Gama 2007; Tatone and Grasselli 2010). So, its use appears not fully appropriate for the subject of the present study.

In order to overcome this drawback, many researchers investigated, over the years, more rigorous methods to assess the value of JRC0 and developed a number of correlations between this coefficient and some empirical (e.g., Maerz et al. 1990; Yu and Vayssade 1991), statistical (e.g., Tse and Cruden 1979; Reeves 1985; Yang et al. 2001; Kim and Lee 2009) and fractal parameters (e.g., Turk et al. 1987; Carr and Warriner 1989; Lee et al. 1990; Xie and Pariseau 1992; Wakabayashi and Fukushige 1995; Jang et al. 2006; Kim and Lee 2009 amongst others), all derivable from a geometrical analysis of the joint profile trace.

These methods, although certainly more complex and time-consuming than the simple visual comparison represent, as of today, the most reliable quantitative approaches to estimate JRC0.

Tatone and Grasselli (2010) have recently presented a further innovative empirical method to quantify the small-scale roughness of 2D joint profiles based on the analysis of digitized profile traces. The method has been developed basing on the 3D methodology firstly introduced by Grasselli et al. (2002), Grasselli and Egger (2003) and Grasselli (2006) and is essentially founded on the evaluation of the relative proportion, compared with the total length of the analysed 2D profile, of the steeper inclined line segments forming the profile and dipping opposite to the direction selected for the analysis (in case of profiles forward or reverse).

The 2D roughness metric used in this method is calculated from the shape of the cumulative distribution of the fractions of the total profile length more steeply inclined than progressively greater angular threshold values (Tatone and Grasselli 2010).

On the base of this geometric parameter, a new empirical equation to estimate JRC0 was derived by the authors, bringing an advanced quantification of the small-scale roughness coefficient that can capture its dependency from the analysis direction. In this way, a JRC coefficient able to incorporate the roughness anisotropy and more closely related to the shear strength behaviour of joints is obtained.

Due to these unquestionable merits, the use of this method for estimating joint unevenness appears recommendable.

3.2 Large-Scale Roughness Assessment

The application of the methods described in the previous sub-section to longer joint profiles generally results much more laborious in the field, mainly because further complicated and cumbersome equipments, besides very favourable joint surfaces exposures, are requested.

The most practical method commonly suggested for recording large-scale joint profile traces consists in placing a long straight edge, or a base line tape, on the surface of the joint and measuring, at frequent regular intervals, the distances from the surface and the base line (ISRM 1978; Fig. 7/left). Experiences on large-scale joint profiling also report the use of a small base-length mechanical profilometer continuously moved on the joint surface along the sampled profile (e.g., Cravero et al. 1995).

However, these approaches are, in general, very time consuming and consequently seldom applied for quantifying joint waviness in the practice, unless for some specific studies regarding mainly rock slopes stability.

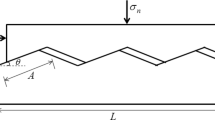

A simplified and faster alternative technique, consisting in measuring the maximum surface offset from a straight edge of length (L) placed on the exposed joint plane (Fig. 7/right), was, therefore, suggested by several authors since long time (e.g., Robertson 1970; Bandis 1980; Barton 1982; Milne et al. 1991, 1992; Palmström 1995a).

For joint waviness assessment the use of a straight edge with a standard length of about 0.9–1 m has been traditionally suggested (Piteau 1970; Milne et al. 1991, 1992; Palmström 1997), although this is not a general rule.

This very straightforward method, theoretically applicable also to short profiles, has practically become today the most used, if not the unique, practical field measurement carried out for joint waviness quantification, as able to provide, very quickly and easily, a great number of measurements directly exploitable to estimate the large-scale JRC coefficient (JRCn) by means of Barton’s or Palmström’s Charts.

Others techniques for recording of large-scale joint traces were, indeed, described in literature, including either the use of equipments requiring the direct contact with the rock surface, as for example long mechanical or electrical stylus profilographs (e.g., Fecker and Rangers 1971; Brown and Scholz 1985; Power et al. 1987; Ferrero and Giani 1990; Milne et al. 1991; Schmittbuhl et al. 1993; Du et al. 2009, amongst others) or more sophisticated devices not requiring the contact with the rock, like several photogrammetric methods (e.g., Wickens and Barton 1971; ISRM 1978; Lee and Ahn 2004; Renard et al. 2006; Sagy et al. 2007; Haneberg 2007; Baker et al. 2008; Poropat 2008).

More recently, in situ surveys of the 3D joint surface topography by means of image processing, interferometry and other advanced optical techniques, is emerged as very attractive also for joint roughness assessment (e.g., Lanaro 2000; Feng et al. 2003; Fardin et al. 2004; Rahman et al. 2006; Sagy et al. 2007; Tatone and Grasselli 2009); (Fig. 8).

3D stereo-topometric optical scanner utilized for the joint surface topography survey in the field (after Tatone and Grasselli 2009)

However, despite the great potentiality of these innovative techniques in offering the possibility of quickly and accurately collecting roughness data also in not directly accessible sites, their actual use is still mostly restricted to research purposes and, mainly because of the need of sophisticated equipments and specific know-how, no wide diffusion in the common practice has been reached yet.

Moreover, they generally request very good exposure conditions (large joint surface outcrops) that seldom can be found on natural rocky outcrops or on underground excavation faces.

4 Proposal of a New Practical Approach to More Objectively Estimate the Joint Roughness Factor jR

As seen in previous sections, Palmström (1995a) already suggested the use of the JRC coefficient estimated through the maximum profile amplitude to evaluate the joint smoothness and waviness factors, js and jw, whereby the jR can be calculated.

Developing further this basic concept, a simple analytic equation linking js and jw to some roughness parameters easily measurable or directly derivable from traditional field measurements on joint profiles, is here proposed to analytically estimate jR.

The equation finally fine-tuned presents the general form

where JRC0 is the small-scale (decimetre) roughness coefficient and WSF represents a “Waviness Shape Factor” purposely defined to numerically express the large-scale shape of a joint profile.

A detailed description of the two terms of the equation is the main topic of the following sub-sections.

It has to be outlined that all parameters included in Eq. 1 are specifically referred to 2D linear joint profiles.

In many cases, profiles oriented along the dip direction of joint planes are investigated to assess roughness (Piteau 1970; ISRM 1978), by postulating this direction roughly coincident with the most probable direction of potential sliding along joints.

However, it is well-known that roughness of natural rock joint planes is often anisotropic as its value can vary with the orientation of the linear profile sampled on the joint surface. In addition, roughness can also display distinct values along a single joint profile in function of the considered direction of analysis (forward or reverse) (Grasselli et al. 2002; Grasselli and Egger 2003; Tatone and Grasselli 2010).

Consequently, a more rigorous approach to characterize joint roughness should theoretically include the analysis of several profiles oriented in different directions on each joint surface. Nevertheless, this procedure is obviously very time-consuming and thus more often inapplicable in real joint mapping. Systematic measurements along profiles aligned in the direction of maximum and minimum roughness, if clearly recognizable in the field, or oriented along dip and strike directions of joints can then be suggested as a more practical and faster approach to establish upper and lower bound values of joint roughness.

As general concern, it should also be pointed out that various joints in a location may have different roughness and, when more joint sets are present, there is the problem to establish a value for roughness representative of all sets in the rock mass.

Many practical approaches are currently used at this scope, involving either the use of an average value or of the minimum value, other than a “weighted average” value (e.g., Palmström 1995a; Brown and Marley 2008).

Others authors simply suggest the use of the value typical of the main/dominating joint set or that of the least favourable one for stability both from the point of view of orientation and shear resistance (e.g., Barton et al. 1974).

Although a discussion on these items is outside the main scope of the present work, it can be stated that the mentioned appoaches are all valid and experience indicates that usually the choice between an “objective” and more demanding survey of joint properties or of a faster and selective but generally more “subjective” one, mainly depends on the time and budget available and must suit the importance of the works in design.

In this context, an effective practical method should allow to collect as much information as possible from the analysis of some representative joint surfaces of a given rock mass or, as often is the case in the real practice, of the few surfaces available.

The proposed quantitative approach can, hence, be justified also in this concept.

4.1 Estimation of the Smoothness Factor js

The first term (in square brackets) of the Eq. 1 provides an estimation of the wall “smoothness factor” js as a function of the small-scale roughness coefficient JRC0 through the simple relation \(\left[ {j_{s} = 0.12 \times JRC_{0} + 0.6} \right]\)

In practice, a direct linear correlation between js and JRC0 is assumed, respecting the conventional range of js and the following basic constraints:

-

js = 0.6 for JRC0 = 0

-

js = 3.0 for JRC0 = 20

The comparison between js values obtained through the proposed relationship and corresponding Palmström’s ratings, evaluated in function of JRC0, is shown in Fig. 9.

Comparison between the js factors estimated through the first term of Eq. 1 (dashed line) and the traditional Palmström’s ratings (continuous line)

As can be noted, the new equation defines a linear envelope (dashed line) that roughly interpolate the step-shaped trend depicted by the original ratings (continuous line) and provides a continuous and constant-rate variation of js in response to any changes of the coefficient JRC0.

It should also be observed how the adopted relation, due to its linear form, may tend to a more conservative estimate of js especially for the lower range of the coefficient JRC0. Furthermore, it forces the values of JRC0 indicatively lower than 3 to be associated to “polished” and “slickensided” joints types of Palmström’s classification, approximation reasonably acceptable considering that the residual roughness of joints previously affected by shearing processes may be close to zero (e.g., Cai and Kaiser 2007).

4.2 Estimation of the Waviness Factor jw

The second term of Eq. 1 allows an estimation of the joint “waviness factor” jw assuming a direct correlation with a purposely defined “Waviness Shape Factor” WSF \(\left[ {j_{w} = 0.05 \times W_{SF} + 1} \right]\). WSF mainly depends on two basic parameters recognized to adequately describe a joint profile geometry (see e.g., Leal-Gomes and Dinis-da-Gama 2007 and references therein; Hong et al. 2008): the maximum profile amplitude (amax) and the angle of slope (i°-angle) of large-scale asperities (first-order asperities sensu Patton 1966).

In the proposed approach both these large-scale geometric parameters of joints are intended to be measured placing a straight edge of length L on the discontinuity surface, aligned along the selected profile of analysis.

The “Waviness Shape Factor” can be defined as

where:

-

AP is a dimensionless “amplitude” parameter related to the maximum asperities height (amax) measured with respect to a straight edge of length (L) representative of the in situ joint size. Milne et al. (1991) and Palmström (1995a) proposed the use of this simple expression to roughly estimate the JRC coefficient for joint profiles of metric size;

-

[1/cos(i°)] is a “textural” parameter representing the secant function of the inclination angle of the profile asperities (waviness angle i°) dipping opposite to the selected analysis direction (Fig. 10/left). The angle i° can be defined as the apparent acute angle between the asperity side facing the selected analysis direction and a reference line materialized on the joint surface by the straight edge (Fig. 10/right). For the mathematical validity of the Eq. 2, the i°-angle must be lower than 90°.

Fig. 10 Left: Definition of the waviness i°-angle related to the analysis direction (from Patton 1966, modified); Right: Example of waviness i°-angles evaluation with reference to the two possible analysis directions along a joint profile (forward and reverse)

In general, WSF increases as the maximum profile amplitude (amax) and the waviness angle (i°) get higher.

As shown, the i°-angle has been included in Eq. 2 through the value of its secant function [1/cos(i°)] in order to emphases the contribution of “stepped” and “interlocked” asperities, generally characterized by high i°-angles (see e.g., Hack 1996; Murata and Saito 2003), in increasing WSF.

The term [1/cos(i°)], in fact, results practically negligible (close to 1) for i°-angles lower than about 30°, usually typical of joints from “planar” to “roughly undulated” (see also Hack 1996), but become significantly higher when the angle increases over about 60°, as generally usual for “stepped” joints.

With regard to the joint length to be considered for assessing waviness in rock mass characterization, Palmström (1995a, 2001) recommends the use of a straight edge of the same size as joints, provided that this is practically possible, or, anyway, of the longest possible one. Moreover, a decimetre to metre “intermediate scale” related to the natural in situ block size is usually considered in the Q-system for assessing the factor Jr.

As a general guidance, the use of a straight edge around one metre long seems, indeed, appropriate for most common practical applications. According to Hack (1996), the i°-angle should then be evaluated for asperities characterized by a distance between the maximum peaks (i.e. asperity wavelength) indicatively greater than 20 cm.

It is important to observe that being the i°-angle measured referring to a defined analysis direction of a joint profile (Fig. 10/right), the possible anisotropy of waviness can be taken into account in the estimation of jw. This could be relevant mainly for “stepped” joint profiles, whose waviness anisotropy could be accentuated in relation to the orientation of the risers of steps with respect to the considered analysis direction.

To simplify the field assessment of the waviness angle i°, the following Table 4 can be advantageously used for selecting a value of the parameter [1/cos(i°)] of Eq. 2 sufficiently approximate for practical purposes.

The Fig. 11 displays a comparison between the values of the factor jw obtained strictly applying the second term of the Eq. 1 and the ratings provided by original Palmström’s classification.

Comparison between jw factors assessed from Eq. 1 (dashed line) and traditional Palmström’s ratings (continuous line with classification terms superimposed)

As shown in the graph, jw is constrained in the interval from 1 to 3, consistently with the original Palmström’s ratings range, while the amplitude parameter AP (fairly comparable to JRCn) is represented in the conventional range from 0 to 20.

Higher values of AP are, indeed, admitted and not unusual in real cases.

As it can be seen from Fig. 11, the jw factor calculated with the new equation results directly correlated with both the maximum profile amplitude (amax) and the slope angle i° of large-scale asperities.

In particular, for relatively low i°-angles (i° ≅ 0°–30°) and AP variable in the common range 0–20, the new equation provides linear envelopes fairly averaging the ratings of jw traditionally assigned to “planar” and “roughly undulated” joints, ranging between 1 and 2 in function of AP.

The maximum values of jw conventionally attributed to “stepped” and “interlocked” joints (jw = 2.5–3) are then gradually reached for greater waviness angles or larger values of the parameter AP. In particular, the highest values of jw could be achieved, for example, for joints characterized by a relatively low amplitude parameter AP and a very high (>70°) i°-angle (e.g., as may be the case of “stepped” joints). The same values could be theoretically obtained also for very strongly undulated joints with high AP (>20) and relatively lower i°-angles.

In such cases, the values of jw resulting from the new equation can even fall over the conventional range fixed by original Palmström’s classification and the maximum theoretical value of three must, thus, be assumed.

5 Example of Application

In order to compare jR values obtained by applying the new analytical method with those derived from the traditional Palmström’s Chart, field joint surveys were conducted in the Northern Apennine Chain (Northern Italy) on well-exposed jointed rock masses.

In particular, two distinct rock types, widespread outcropping in the study area, such as massive serpentinites of Cretaceous age and a tertiary sedimentary formation of thick-bedded marly-limestones and marls, were involved.

A total of about 300 measurements of smoothness and waviness were carried out in the field on carefully selected 2D joint profiles by means of traditional survey techniques described in previous sections.

In detail, a stylus profilometer 10 cm long, with metal pins of about 0,8 mm dia., was used to record the small-scale joint profile traces, whereas the large-scale joint waviness was investigated by measuring, directly in the field, the maximum profile amplitude with a steel straight edge one meter long (L = 1 m).

At the same time, measurements of the waviness i°-angle were accurately executed on every joint profiles making use of a hand protractor and a short steel rule.

On each joint surface, the measures of roughness parameters were conventionally conducted along both the down-dip and the up-dip directions.

The methodology of Tatone and Grasselli (2010) was adopted to estimate the small-scale roughness coefficient JRC0 from the analysis of joint traces recorded along both directions. At this scope, the 10 cm traces obtained from field profiling were digitized by a CAD software with a sampling interval of 1 mm and coordinates of the points defining the profiles exported as an ASCII file and subsequently analysed with a predisposed MS Excel worksheet.

For each joint trace recorded, the undulation ratio a/L has been evaluated, as well.

The measure of the large-scale i°-angles followed the same directional criterion adopted for small-scale smoothness, so implying the collection of two sets of measures for each joint profile (i.e. along down-dip and up-dip directions, respectively).

Generally, tested joints were mostly unfilled, with rock walls unweathered or slightly weathered and with trace lengths usually in the range 1–10 m.

The classification of the surveyed discontinuities on the base of traditional categories, assessed from Palmström’s Chart for smoothness and waviness, is depicted in the Fig. 12, separately for the two rock types.

As shown in the figure, the discontinuities of serpentinites are mainly classified from “slightly rough” to “moderately rough” and from “slightly to moderately undulated” to “strongly undulated”. Those in marls preferentially fall inside the “slightly rough” smoothness class and in the “slightly to moderately undulated” and “strongly undulated” waviness categories.

The comparison between the jR factors estimated through the new quantitative method and by the traditional Palmström’s Chart is graphically displayed in Fig. 13. Results, expressed in terms of main statistical indices [min, max, mean and coefficient of variation (COV)], are summarized in the subsequent Table 5.

By analyzing the results, it can be stated that the use of the two approaches has given rather comparable values of the factor jR in terms of mean values and ranges of variability, although a general tendency of the new equation to provide slightly conservative estimates can be noticed for the discontinuities analysed.

This seems more evident for marls, dominantly characterized by slightly rough joints, for which a reduction of about 26 % of the mean value of jR referred to the whole data set has been obtained with the new method, compared to the traditional ranking approach.

For serpentinites, the mean reduction of jR has resulted in the order of only 4 %.

The correlation coefficient, r-Pearson, between the two sets of jR values used for comparison results of 0.81.

From Table 6 it can also be appreciated the sensitivity of the new jR to variation of the analysis direction of joint profiles. In practice, with the new method, two different values of jR have been obtained for each joint profile in function of the direction along which the measures of smoothness and waviness were performed, whereas a unique jR value is derived from the traditional classification approach.

The ratio between the maximum and minimum values of jR calculated with the new method results, on average, of 1.11 for serpentinites and 1.16 for marls. For both rock types, the higher values have been obtained from measures along the up dip direction.

It can also be noted from Table 6 as the mean values and variability ranges of jR, calculated with the new relationship for the up-dip direction of joints, result quite more comparable with those obtained using the traditional Palmström’s ratings. Conversely, the values derived from analysis performed along the down-dip direction are, in general, notably lower.

This aspect appears of some relevance in rock mass characterization, since the most reliable assessment of lower and upper bound values of jR should be a primary goal of the geomechanical investigation and, therefore, should properly account for the possible anisotropy of roughness.

A rough correlation between jR values assessed with the two methods has been obtained by linear regression analysis of the entire data set currently available (N. 296 data) and is displayed in Fig. 14.

As can be seen in the figure, the found correlation seems to confirm the average tendency of the new method to give, for tested joints, slightly conservative estimates of the jR factor compared to the traditional classification.

It can also be observed as jR values calculated with the new equation can present a quite large variability at some constant ratings of Palmström’s classification. This apparent scatter may mainly be related to the different approach followed by the new analytical method to estimate js and jw factors, essentially based on approximate interpolations of Palmström’s discrete ratings with continuous linear functions (see Figs. 9, 11), as well as to its aforementioned capability to provide, unlike the traditional one, two different values of jR for each single joint profile, in function of the analysis direction.

As shown in Fig. 15, the factor jR calculated with the new equation can be modelled, for the use in probabilistic analyses, as a statistically continuous variable generally following a lognormal distribution.

6 Conclusive Remarks

The various methods commonly used for measuring and quantifying the joint roughness in the current rock mass characterization practice have been illustrated in the paper.

Moreover, a new quantitative method to more objectively estimate the jR factor applied in the Palmström’s RMi characterization system has been presented, attempting to provide a standardized and simple rational approach for field acquisition and elaboration of joint roughness data, functional to the estimation of jR from 2D profiles analysis.

The new method can efficiently integrate and support the traditional more subjective classification of joint roughness based on Palmström’s Chart, to improve the reliability of the jR estimation in rock mass characterization studies.

An example of application on natural rocky discontinuities has revealed a general consistency between jR values obtained with the new analytical method and those independently derived from the traditional ranking approach. Results of application have also put in evidence the high potentiality of the proposed quantitative method to discriminate jR in function of any possible variation of joint profiles geometry, as well as its ability to account for the roughness anisotropy.

This last aspect seems not to have been taken into great consideration in the previous methods for assessing jR from analysis of 2D joint profiles and could, hence, be considered a potential strong point of the new approach, allowing to better investigate the possible variability of jR in a given rock mass.

Efforts are, of course, needed in future to test the new method on varying joint and rock types and further investigate the linear form of the mathematical relationships currently adopted to calculate js and jw factors.

References

Baker BR, Gessner K, Holden E-J, Squelch AP (2008) Automatic detection of anisotropic features on rock surfaces. Geosphere 4(2):418–428

Bandis S (1980) Experimental studies of scale effects on shear strength and deformation of rock joints. Ph.D. Thesis, University of Leeds, Department of Earth Sciences

Barton N (1973) Review of a new shear-strength criterion for rock joints. Eng Geol 7(4):287–332

Barton N (1982) Modelling rock joint behaviour from in situ block tests: implications for nuclear waste repository design. Office of Nuclear Waste Isolation, Columbus, OH, p 96, ONWI-308

Barton N (1987) Predicting the behaviour of underground openings in rock. Manuel Rocha Memorial Lecture, Lisbon. Oslo: Norwegian Geotech. Inst

Barton N, Choubey V (1977) The shear strength of rock joints in theory and practice. Rock Mech 10:1–54

Barton N, Lien R, Lunde J (1974) Engineering classification of rock masses for the design of tunnel support. Rock Mech 6(4):189–236

Beer AJ, Stead D, Coggan JS (2002) Estimation of the joint roughness coefficient (JRC) by visual comparison. Rock Mech Rock Eng 35(1):65–74

Brady BHG, Brown ET (1985) Rock mechanics for underground mining. George Allen & Unwin, London, p 527

Brown ET, Marley M (2008) Estimating rock mass properties for stability analyses of new and existing dams. International Commission on Large Dams, 76th Annual Meeting, Sofia, Bulgaria, June 2–6, 2008—Symposium: Operation, rehabilitation and up-grading of dams

Brown SR, Scholz CH (1985) Broad bandwidth study of the topography of natural rock surfaces. J Geophys Res 90:12575–12582

Cai M, Kaiser PK (2007) Obtaining modelling parameters for engineering design by rock mass characterization. In: Ribeiro e Sousa, Olalla & Grossmann (eds) 11th Congress of the International Society for Rock Mechanics. Taylor & Francis Group, London, p 381–384

Cai M, Kaiser PK, Uno H, Tasaka Y, Minami M (2004) Estimation of rock mass deformation modulus and strength of jointed hard rock masses using the GSI system. Int J Rock Mech Min Sci 41:3–19

Carr JR, Warriner JB (1989) Relationship between the fractal dimension and joint roughness coefficient. Bull Assoc Eng Geol 26(2):253–263

Cravero M, Iabichino G, Piovano V (1995) Analysis of large joint profiles related to rock slope instabilities. 8th ISRM 25/09/1995, Tokio, Japan, AA Balkema, Rotterdam

Du S, Hu Y, Hu X (2009) Measurement of joint roughness coefficient by using profilograph and roughness ruler. J Earth Sci 20(5):890–896

Fardin N, Feng Q, Stephansson O (2004) Application of a new in situ 3D laser scanner to study the scale effect on the rock joint surface roughness. Int J Rock Mech Min Sci 41(2):329–335

Fecker E, Rangers N (1971) Measurement of large scale roughness of rock planes by means of profilograph and geological compass. Rock Fracture, In: Proceedigs of International Symposium on Rock Mechanism, Nancy, Paper, p 1–18

Feng Q, Fardin N, Jing L, Stephansson O (2003) A new method for in situ non-contact roughness measurement of large rock fracture surfaces. Rock Mech Rock Eng 36(1):3–25

Ferrero AM, Giani GP (1990) Geostatistical description of the joint surface roughness. 31th U.S. Symposium on Rock Mechanics (USRMS), A. A. Balkema, Rotterdam

Grasselli G (2006) Manuel Rocha medal recipient shear strength of rock joints based on quantified surface description. Rock Mech Rock Eng 39(4):295–314

Grasselli G, Egger P (2003) Constitutive law for the shear strength of rock joints based on three-dimensional surface parameters. Int J Rock Mech Min Sci 40:25–40

Grasselli G, Wirth J, Egger P (2002) Quantitative three-dimensional description of a rough surface and parameter evolution with shearing. Int J Rock Mech Min Sci 39:789–800

Hack R (1996) Slope stability probability classification SSPC. ITC publication n. 43, Technical University Delft & Twente University—International Institute for Aerospace Survey and Earth Sciences (ITC Enschede), Netherlands. p 258. http://www.itc.nl/library/papers_1996/general/hack_slo.pdf

Haneberg WC (2007) Directional roughness profiles from three-dimensional photogrammetric or laser scanner point clouds. In: E. Eberhardt, D. Stead, and T. Morrison, (eds) Rock mechanics: meeting society’s challenges and demands: Proceedings, 1st Canada-U.S. Rock Mechanics Symposium, Vancouver, May 27–31, p 101–106

Hong ES, Lee JS, Lee IM (2008) Underestimation of roughness in rough rock joints. Int J Numer Anal Methods Geomech 32(11):1385–1403

Hsiung SH, Ghosh A, Ahola MP, Chowdhury AH (1993) Assessment of conventional methodologies for joint roughness coefficient determination. Int J Rock Mech Min Sci Geomech Abstr 30(7):825–829

I.S.R.M.—Commission on standardization of laboratory and field test (1978) Suggested method for the quantitative description of discontinuities in rock masses. Int J Rock Mech Min Sci Geomech Abstr 15:319–368

Jang BA, Jang HS, Park H-J (2006) A new method for determination of joint roughness coefficient. In: Proceedings of IAEG2006: engineering geology for tomorrow’s cities, Nottingham, UK, 6–10 September 2006: Paper 95, London, UK: The Geological Society of London, p 9

Kim D-Y, Lee H-S (2009) Quantification of rock joint roughness and development of analyzing system. In P. H. S. W. Kulatilake (Ed.), Proceedings of the International Conference on Rock Joints and Jointed Rock Masses Tucson, AZ, 7–8 January 2009: Paper 1019, p 8

Kulatilake P, Shou G, Huang TH, Morgan RM (1995) New peak shear-strength criteria for anisotropic rock joints. Int J Rock Mech Min Sci Geomech Abstr 32(7):673–697

Lanaro F (2000) A random field model for surface roughness and aperture of rock fractures. Int J Rock Mech Min Sci 37:195–210

Leal-Gomes MJA, Dinis-da-Gama C (2007) New insights on the geomechanical concept of joint roughness. In: Ribeiro and Sousa, Olalla and Grossmann (eds) 11th congress of the international society for rock mechanics

Lee HS, Ahn KW (2004) A prototype of digital photogrammetric algorithm for estimating roughness of rock surface. Geosci J 8(3):333–341

Lee YH, Carr JR, Barr DJ, Haas CJ (1990) The fractal dimension as a measure of the roughness of rock discontinuity profiles. Int J Rock Mech Min Sci Geomech Abstr 27(6):453–464

Maerz NH, Franklin JA, Bennet CP (1990) Joint roughness measurement using shadow profilometry. Int J Rock Mech Min Sci Geomech Abstr 27(5):329–343

Milne D (1988) Suggestions for standardisation of rock mass classification. MSc dissertation, Imperial College, University of London, p 123

Milne D, Germain P, Grant D, Noble P (1991) Systematic rock mass characterization for underground mine design. International Congress on Rock Mechanics, A. A. Balkema, Aachen, Germany

Milne D, Germain P, Potvin Y (1992) Measurement of rock mass properties for mine design. In: Hudson JA (ed) Proceedings of the ISRM symposium on rock characterization: Eurock ‘92, Chester, England, 1992. Thomas Telford, London, pp 245–250

Milne D, Hawkes C, Hamilton P (2009) A new tool for the field characterization of joint surfaces. In: Toronto, Diederichs M, Grasselli G (eds) RockEng09: proceedings of the 3rd CANUS rock mechanics symposium

Murata S, Saito T (2003) A new evaluation method of JRC and its size effect, in: ISRM 2003, Technology roadmap for rock mechanics, South African Institute of Mining and Metallurgy, pp. 855–858

Palmström A (1995a) RMi—a rock mass characterization system for rock engineering purposes. PhD thesis, University of Oslo, Norway, p 400. http://www.rockmass.net

Palmström A (1995b) RMi—a system for characterizing rock mass strength for use in rock engineering. J Rock Mech Tunn Technol 1(2):69–108

Palmström A (1996) Characterizing rock masses by the RMi for use in practical rock engineering. Part 1: the development of the rock mass index (RMi). Tunn Undergr Space Tech 11:75–88

Palmström A (1997) Collection and use of geological data in rock engineering. Published in “ISRM News Journal”, 21–25

Palmström A (2001) Measurement and characterization of rock mass jointing. In: Sharma VM, Saxena KR (eds) In-situ characterization of rocks, A. A. Balkema publishers, p 49–97

Patton FD (1966) Multiple modes of shear failure in rock and related materials. Ph. D. Thesis, University of Illinois, p 282

Piteau DR (1970) Geological factors significant to the stability of slopes cut in rock. In: Proceedings of symposium on planning open pit mines, Johannesburg, South Africa, p 33–53

Poropat GV (2008) Remote characterization of surface roughness of rock discontinuities. In: Potvin Y, Carter A Dyskin J, Jeffery R (eds) Proceedings 1st southern hemisphere international rock mechanics symposium, Perth, Australia, p 447–458

Poropat GV (2009) Measurement of surface roughness of rock discontinuities. In: Diederichs M, Grasselli G (eds) RockEng09: Proceedings of the 3rd CANUS Rock Mechanics Symposium, Toronto

Power WL, Tullis TE, Brown SR, Boitnott GN, Scholz CH (1987) Roughness of natural fault surfaces. Geoph Res Lett 14(1):29–32

Rahman Z, Slob S, Hack R (2006) Deriving roughness characteristics of rock mass discontinuities from terrestrial laser scan data. IAEG2006 Paper number 437

Reeves MJ (1985) Rock surface roughness and frictional strength. Int J Rock Mech Min Sci Geomech Abstr 22:429–442

Renard FO, Voisin C, Marsan D, Schmittbuhl J (2006) High resolution 3D laser scanner measurements of a strike-slip fault quantify its morphological anisotropy at all scales. Geoph Res Lett 33:Lo4305

Robertson AM (1970) The interpretation of geological factors for use in slope theory. Proc.Symp. Planninmh Open Pit Mines, Johannesburg, South Africa, 55–71

Russo G (2009) A new rational method for calculating the GSI. Tunn Undergr Space Technol 24:103–111

Sagy A, Brodsky EE, Axen GJ (2007) Evolution of fault-surface roughness with slip. Geology 35(3):283–286

Schmittbuhl J, Gentier S, Roux S (1993) Field-measurements of the roughness of fault surfaces. Geoph Res Lett 20(8):639–641

Sonmez H, Ulusay R (1999) Modifications to the geological strength index (GSI) and their applicability to stability of slopes. Int J Rock Mech Min Sci 36:743–760

Stimpson B (1982) A rapid field method for recording joint roughness profiles. Int J Rock Mech Min Sci Geomech Abstr 19(6):345–346

Tatone BSA, Grasselli G (2009) Use of a stereo-topometric measurement system for the characterization of rock joint roughness in situ and in the laboratory. In: Diederichs M, Grasselli G (eds) RockEng09: Proceedings of the 3rd CANUS Rock Mechanics Symposium, Toronto

Tatone BSA, Grasselli G (2010) A new 2D discontinuity roughness parameter and its correlations with JRC. Int J Rock Mech Mining Sci. doi:10.1016/j.ijrmms.2010.06.006

Tse R, Cruden DM (1979) Estimating joint roughness coefficient. Int J Rock Mech Min Sci Geomech Abstr 16:303–307

Turk N, Grieg MJ, Dearman WR, Amin FF (1987) Characterization of rock joint surfaces by fractal dimension. In: Farmer IW, Daeman JJK, Desai CS, Glass CE, Neuman SP (eds) Proceedings of 28th US. Rock Mechanics Symposium, Tuscon, AZ, 29 June–1 July 1987. Rotterdam: A.A. Balkema, p 1223–1236

Wakabayashi N, Fukushige I (1995) Experimental study on the relation between fractal dimension and shear strength. In: Myer, Cook, Goodman & Tsang (eds) Fractured and jointed rock masses, Balkema, Rotterdam, p 125–131

Wickens EH, Barton N (1971) The application of photogrammetry to the stability of excavated rock slopes. Photogram Rec 7(37):46–54

Xie H, Pariseau WG (1992) Fractal estimation of joint roughness coefficients. In: Myer LR, Cook NGW, Goodman RE, Tsang CF (eds) Proceedings of the conference on fractured jointed rock masses, Lake Tahoe, CA, 3–5 June 1992. Rotterdam: Balkema; p 125–31

Yang ZY, Lo SC, Di CC (2001) Reassessing the joint roughness coefficient (JRC) estimation using Z2. Rock Mech Rock Eng 34(3):243–251

Yu XB, Vayssade B (1991) Joint profiles and their roughness parameters. Int J Rock Mech Min Sci Geomech Abstr 28(4):333–336

Acknowledgments

The author is grateful to Eng. G. Baldovin and Eng. E. Baldovin; Dr. D. Marenghi and Dr. F. Lusignani for their help in field data collection; Mrs. A. Stefli for her precious contribution.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Morelli, G.L. On Joint Roughness: Measurements and Use in Rock Mass Characterization. Geotech Geol Eng 32, 345–362 (2014). https://doi.org/10.1007/s10706-013-9718-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-013-9718-3