Abstract

This paper describes a study on tropical peat soil stabilization to improve its physical properties by using different stabilizing agents. The samples were collected from six different locations of Sarawak, Malaysia, to evaluate their physical or index properties. Out of them, sample having the highest percentage of organic content has been selected for stabilization purposes. In this study, ordinary portland cement (OPC), quick lime (QL), and class F fly ash (FA) were used as stabilizer. The amount of OPC, QL, and FA added to the peat soil sample, as percentage of dry soil mass, were in the range of 5–20%; 5–20% and 2–8%, respectively for the curing periods of 7, 14, and 28 days. The Unconfined Compressive Strength (UCS) test was carried out on treated/stabilized samples with the above mentioned percentages of the stabilizer and the result shows that the UCS value increases significantly with the increase of all stabilizing agent used and also with curing periods. However, in case of FA and QL, the UCS value increases up to 15 and 6%, respectively with a curing period of 28 days but decreases rather steady beyond this percentage. Some UCS tests have been conducted with a mixture of FA and QL to study the combined effect of the stabilizer. In addition, Scanning Electron Microscope (SEM) study was carried out on original peat soil and FA, as well as some treated samples in order to study their microstructures.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Peat soil has been identified as one of the major groups of soil found in Malaysia, which covers approximately 3.0 million hectares or 8% of the total land area. Out of that, Sarawak has the largest peat land area in Malaysia which is about 16,500 km2 or 13% of the state, of which about 90% of the peat is more than 1 m in depth (Mutalib et al. 1991).

Peat or highly organic soil is a major problem in the infrastructure development of the coastal areas of Sarawak. Peat soil is generally considered as problematic soil in any construction project, because of its high compressibility and very low shear strength (Huat 2004). With the rapid industrialization and population growth, it has become necessary to construct infrastructures facilities on peat-land. The common construction practice is the replacement of peat soil by suitable fill material, but if the peat depth is more, it may not be an economical choice.

Previous case histories revealed that several construction methods such as displacement, replacement, stage loading and surface reinforcement, pile supported embankment, light weight fill raft, deep in situ chemical stabilization and thermal precompression method are available to improve soft or peat soil (Edil 2003). Out of several alternatives, one of the promising method of construction on the peat soil is to stabilize the peat soil itself by using suitable stabilizer which can eliminate the need for expensive borrow materials and expedite construction.

Several researchers have studied the stabilization of clay, soft soil and mineral soil by using cement, fly ash, and lime. Only few studies (Hebib and Farrell 2003; Huat et al. 2005; Wong et al. 2008) discussed the stabilization of highly organic soil or peat. Also, very little data are available from East Malaysia especially in Sarawak (Huat 2004; Kolay and Suraya 2007; Kolay et al. 2011). Hence, the present study concentrates on the stabilization of peat soil samples collected especially from Matang, Sarawak, Malaysia, with different types of stabilizers or admixtures i.e., ordinary portland cement, fly ash, quick lime and combination of quick lime and fly ash. Finding the most suitable stabilizer and optimum mixing quantity for stabilizing the local tropical peat soil are final outcomes of the study.

2 Test Materials

2.1 Peat Soil

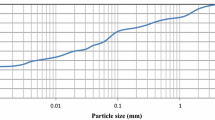

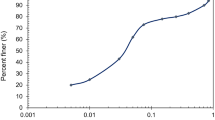

Peat soil samples were collected from six different locations (e.g., L1 to L6) of Sarawak particularly from Matang area (from 0.40 to 0.80 m depth) designated as M1 to M6, respectively. First the peat soil was sundried, grinded and passed through 1.18 mm sieve, then collected and used for different physical and engineering properties test.

2.2 Stabilizer

In this study, commercially available ordinary portland cement (OPC) and analytical grade quick lime (QL) (CaO, calcium oxide) have been used. The fly ash (FA) sample has been collected from Sejingkat thermal power plant, Kuching, Malaysia, for the stabilization purposes. The FA sample used in this study falls in the category of class F as per ASTM C 618 (1994).

3 Physical Properties

The natural moisture content of peat soil sample has been determined as per BS 1377 (1990) Part 2. The degree of decomposition has been determined by using the Von Post system (Von Post 1922). The Loss on Ignition (LOI) has been determined as a percentage of oven-dried mass as per ASTM D 2974 (2000). Organic content (H) is calculated as per the equation proposed by Skempton and Petley (1970).

The specific gravity (Gs) of the highly organic or peat soil is determined based on the procedure stated in BS 1377 (1990) Part 2. The fiber content is determined as per ASTM D 1997 (1996) standard. In this study, cone penetrometer method has been used to determine the liquid limit of peat soil sample and the liquid limit test has been conducted as per guidelines based on BS 1377 (1990) Part 2. The pH test has been conducted as per the procedure mentioned in BS (1990).

4 Engineering Properties

4.1 Standard Proctor Test

Standard Proctor test has been conducted as per BS 1377 (1990): Part 4 to determine the maximum dry density (MDD) (γd) and the optimum moisture content (OMC) of the peat soil sample.

4.2 Unconfined Compressive Strength (UCS) Test

To determine the strength gain by the peat soil with different types of stabilizer, UCS test has been conducted according to the guidelines provided by ASTM D 2166 (2000). The size of the mold used in this study was 38 mm in diameter and 76 mm in height. The percentage of FA, OPC and QL is 5–20%; 5–20% and 2–8%, respectively and were mixed with original peat soil to check the strength gain. Few UCS tests have been conducted with a mixture of FA and QL with different combinations (i.e., 10, 15 and 20% FA + 2, 4, 6 and 8% QL) to study the combined effect of the stabilizer. The specimens were cured for 7, 14, and 28 days under water and then tested.

5 Microstructural Analysis

5.1 Scanning Electron Microscope (SEM)

The SEM micrographs of original peat soil and fly ash sample, as well as some treated peat soil samples have been conducted to study the morphology of the samples. The SEM test was conducted by using the instrument JEOL, Japan, with model no. JSM-6701F. The micrographs were taken at a magnification of 1000 for original peat, fly ash and treated peat soil samples.

6 Results and Discussion

6.1 Physical Properties

The results of different physical properties of peat soil samples are presented in Table 1. From Table 1, it has been observed that the sample M1 falls in the category with degree of humification H1 to H3 (Fibric), M2 to M5 falls in the category with degree of humification H4 to H6 (Hemic), and sample M6 can be categorized as H7 to H10 (Sarpic); according to the Von Post scale. If the percentage of organic content in soil is more than 75%, then the soil can be categorized as peat as per ASTM D 2607 (1990). In this study, sample M4 and M6 has organic content less than 75%, which can be categorized as highly organic soil and remaining samples has organic content more than 75% hence can be categorized as peat. The result shows that sample M1 has the highest fiber content and the sample M6 has the lowest fiber content.

The specific gravity value for the sample M6 is the highest; this may be attributed to the fact that the sample M6 has lower fiber content as compared to the other samples.

The liquid limit value for the sample M1 is the highest, because it contains more fiber, which results in high water absorption capacity as compared to the other samples. All samples collected from Matang, Sarawak, are non-plastic. The result also shows that sample M2 has the lowest pH value, hence it is more acidic due to higher organic content, and sample M6 has the highest pH value.

6.2 Engineering Properties

Out of six samples, one sample (i.e., M2) has been selected for the stabilization purposes as it has the highest percentage of organic content. Also engineering properties test has been conducted only for this sample.

6.2.1 Standard Proctor Test

Standard Proctor test was carried out for peat soil sample (M2) to determine the compaction characteristics. From the compaction test results it has been found that sample M2 have Maximum Dry Density (MDD) and Optimum Moisture Content (OMC) of 7.06 kN/m3 and 62%, respectively.

6.2.2 Unconfined Compressive Strength (UCS) Test

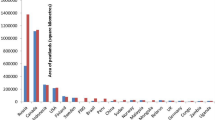

UCS test has been conducted for original peat soil sample (M2) compacted at its MDD and OMC. It has been found that for the original peat soil the UCS value was 14.23 kPa. The sample M2 mixed with different percentage of admixtures, compacted at MDD and OMC of the original peat soil, and the results have been presented in Figs. 1, 2, 3, 4, 5, and 6. It can be noticed that considerably higher compressive strength has been obtained with different percentages of OPC as compared to QL and FA.

From Fig. 1 it can be observed that, in general the UCS value increases with the increase of percentage of OPC content added to the original peat soil sample. Also, the strength increases with the curing period for all percentages of OPC added and the increase in strength is much more predominant with higher percentage (i.e., 20%) of OPC added.

Figure 2 shows that the UCS value increases with the increase of QL percentage added to the original peat soil sample and also increases with curing period. It increases up to addition of 6% QL, with a curing period of 28 days but decreases rather steady beyond this percentage. The same trend has been observed in case of FA (Fig. 3) added to the original peat soil sample in which the result increases up to addition of 15% FA. This may be attributed to the fact that FA reacts with peat soil molecules after long curing period. Figures 4 and 5 shows that the UCS value increases with the combination of QL and FA stabilized samples, and also with a curing period of 28 days but decreases rather parallel after addition of 15% FA plus 6% QL as shown in Fig. 6.

6.2.3 Scanning Electron Microscope (SEM)

SEM’s of original peat soil and FA are shown in Figs. 7 and 8, respectively and stabilized peat soil (with 20% OPC, 20% FA, 6% QL, 20% FA and 6% QL) cured for 28 days are shown in Figs. 9, 10, 11, 12. Figure 7 shows that the untreated peat soil is composed of fibers which are woody and porous in nature and Fig. 9 shows that the original FA sample consists of predominantly spherical particles with some irregular particles. But the stabilized peat soil (i.e., Figs. 9, 10, 11, 12) shows significant changes as new mineralogical phases are observed when cured under water with different stabilizers. Also SEM micrographs for stabilized peat samples show that the particles are closely packed and strongly bonded. When mineral soil stabilized with OPC or other chemical admixtures; niddle like structures or very closely packed bonds are generally observed. But in case of highly organic soil or peat, which is acidic in nature, very closely packed bonds are usually not witnessed; which leads to lower UCS value upon stabilization.

7 Conclusions

The present study investigates the effect of different types of stabilizer on peat soil samples from Matang, Sarawak, Malaysia. From the laboratory tests results, the following conclusions can be drawn:

-

i.

UCS test result for stabilized peat soil sample increases with the increase percentage of OPC (i.e., 5, 10, 15 and 20%) added to the original peat soil sample.

-

ii.

The UCS values for peat soil samples increases with 2, 4, and 6% of QL but decreases rather steady beyond 6% of QL added.

-

iii.

The result of UCS test also show that the strength of peat soil sample increases with 5, 10, 15% of FA but decreases rather steady when 20% of FA was used.

-

iv.

The result of UCS test increases with curing period (i.e., 7, 14 and 28 days) for all types of stabilizer used.

-

v.

UCS value for combined QL and FA shows better results in comparison with the individual use of QL and FA.

-

vi.

In the present study, OPC is the most suitable stabilizer. But approximately 80% of the UCS value with 20% OPC can be achieved with the combination of 6% QL and 15% FA.

From the result it can be concluded that addition of chemical admixture, i.e., OPC, QL and FA can improve the physical properties of tropical peat soils.

References

ASTM C 618 (1994) Specification for coal fly ash and raw or calcined natural pozzolan for use as a mineral admixture in Portland cement concrete. Annual book of ASTM standards, vol 04.02. ASTM, Philadelphia, pp 296–298

ASTM D 1997 (1996) Standard test method for laboratory determination of the fiber content of peat samples by dry mass, annual book of ASTM standards. ASTM, Philadelphia

ASTM D 2166 (2000) Standard test method for unconfined compressive strength of cohesive soil. Annual book of ASTM standards. ASTM, Philadelphia

ASTM D 2607 (1990) Classification of peats, mosses, humus, and related products. Annual book of ASTM standards. ASTM, Philadelphia

ASTM D 2974 (2000) Standard test method for moisture, ash, and organic matter of peat and other organic soils. Book of ASTM standards. ASTM, Philadelphia

BS 1377 (1990) Methods of test for soils for civil engineering purposes, Part 1–4. British Standards Institution, London, UK

Edil TB (2003) Recent advancements in geotechnical characterization and construction over peat and organic soil. In: Huat et al. (ed) Proceeding of 2nd international conference on advances in soft soil engineering and technology. Putrajaya, Malaysia, pp 3–35

Hebib S, Farrell RE (2003) Some experiences on the stabilization of Irish peats. Can Geotech J 40:107–120

Huat BBK (2004) Organic and peat soils engineering. University Putra Malaysia, pp 5–11

Huat BBK, Shukri MS, Mohamed TA (2005) Effect of chemical admixtures on the engineering properties of tropical peat soils. Am J Appl Sci 2(7):1113–1120

Kolay PK, Suraya NBR (2007) Stabilization of organic soil by different types of stabilizer. International conference on civil engineering in the new millennium: opportunities and challenges (CENeM). BESU, Shibpur

Kolay PK, Aminur MR, Taib SNL (2011) Effect of alkali on tropical peat stabilized with different stabilizers. Int J Geotech Eng 5(2):189–197

Mutalib AA, Lim JS, Wong MH, Koonvai L (1991) Characterization, distribution and utilization of peat in Malaysia, tropical peat. In: Proceeding of the international symposium on tropical peatland, Kuching, Sarawak, Malaysia, pp 7–16

Skempton AW, Petley DJ (1970) Ignition loss and other properties of peats and clays from Avonmouth, King’s Lynn and Cranberry Moss. Geotechniques 20(4):343–356

Von Post L (1922) Sveriges Geologiska Undersøknings Torvinventering Och Nogra Av Dess Hittils Vunna Resultat (SGU peat inventory and some preliminary results) Svenska Mosskulturføreningens Tidsskrift, Jønkøping, Sweden 36

Wong LS, Roslan H, Faisal HA (2008) Engineering behaviour of stabilized peat soil. Eur J Sci Res 21(4):581–591

Acknowledgments

The author would like to acknowledge the MOSTI for financial support (Grant no. 03-01-09-SF0032).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kolay, P.K., Aminur, M.R., Taib, S.N.L. et al. Stabilization of Tropical Peat Soil from Sarawak with Different Stabilizing Agents. Geotech Geol Eng 29, 1135–1141 (2011). https://doi.org/10.1007/s10706-011-9441-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-011-9441-x