Abstract

Resilient modulus (Mr) of a soil is used as a basic input in the analysis of sub-grade and sub-base in the mechanistic empirical design approaches. The present work focuses on evolving a cost effective approach for the determination of resilient modulus in the laboratory based on tests performed using the CBR method, and the DCP. Lateritic sub-grades in India exhibit wide-ranging variations in strength and stiffness due to varying fines content, and other characteristics. Additionally, soils of lateritic origin with a higher proportion of fines, also called as lithomargic soils, pose difficulties to pavement engineers due to the poor supporting strength. In order to investigate the strength and stiffness of a wide variety of lateritic soils, it was proposed to perform tests on lateritic soils blended with lithomargic fines in this study. The study focuses on correlating the effect of grain-size, maximum dry-density (MDD), and optimum moisture content (OMC) on the resilient modulus (Mr) measured using the cyclic tri-axial test for various blends of lateritic soils. Tests were performed on soil samples compacted to MDD for molding water contents set to the OMC, dry-side of OMC, and the wet-side of OMC. The results indicated that an increase in the fines-content resulted in an increase in the OMC, and a decrease in the MDD and Mr values. Regressions were developed correlating the fines content to the resilient modulus. This study is expected to provide the necessary basis for estimating the strength of a wide variety of lateritic sub-grades based on the fines content.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Pavement sub-grades are subjected to repeated traffic loadings, and are expected to rebound elastically when subjected to wheel loads. However, when these sub-grades are repeatedly subjected to traffic loads, plastic deformations occur. Stiffer pavements are capable of withstanding more repetitions of traffic wheel loads. The long term performance of the pavement mainly depends on the strength and stiffness of soil under traffic loading. These stiffness values are used to set the critical limits for pavement performance during the design life (Van Gurp et al. 2000).

The resilient modulus (Mr) is a fundamental material property used in characterizing the stiffness of the sub-grades and it provides the basis for analyzing the soil strength under different conditions (AASHTO 1986). American Association of State Highway and Transportation Officials (AASHTO) formulated the guidelines for the analysis of pavement structures based on the resilient modulus for the Mechanistic-Empirical approach for design of pavement structures (AASHTO 1986; Monismith 1989). As the determination of resilient modulus in the laboratory is costly, time consuming, and cumbersome, a number of agencies have recommended the use of empirical models for the prediction of resilient modulus based on tests performed using the CBR method, and the DCP. Similar approaches for the determination of the resilient modulus are considered acceptable by AASHTO (1986), which will be of advantage to pavement engineers of various developing countries.

There are a number of methods to evaluate the sub-grade strength and stiffness. The most popular approaches include the use of the CBR tests, the plate bearing tests, the dynamic cone penetrometer (DCP), and the Geogauge. Additionally, the methods employed to determine the resilient modulus using the portable falling weight deflectometer, and the cyclic-triaxial tests also have gained popularity (Livneh and Goldberg 2001; Nazarian et al. 2002; Rahim and George 2002; Sawangsuriya et al. 2002; George et al. 2009).

The resilient modulus, a measure for soil stiffness, is influenced by a number of factors including the particle-size distribution, loading condition, type of soil, plasticity, soil-density, and the moisture content (Hicks and Monismith 1971; Burczyk et al. 1994; Li and Selig 1994; Al-Refeai and Al-Suhaibani 2002; George et al. 2009; Taheri and Tatsuoka 2012). Soil stiffness substantially depends on the inter-granular (effective) confining stress as well as on the applied deviatoric stress in a cyclic tri-axial test (Hardcastle 1992). A proper understanding of the various factors that influence strength and stiffness will provide the necessary basis for employing quality control measures in pavement construction.

The resilient modulus can also be obtained using correlations based on soil properties. Drumm et al. (1990), Farrar and Turner (1991), Von Quintus and Killingsworth (1998), Malla and Joshi (2008), George et al. (2009), and others performed studies on formulating regression expressions to determine the resilient modulus.

The present study is focused on the effect of soil parameters on the resilient modulus obtained using the cyclic tri-axial test on lateritic soils, lithomargic fines, and various blends of lateritic and lithomargic soils. Lateritic soils of peninsular India are characterized by the presence of lateritic and lithomargic soils that constitute 40% of the soil in this region (Rao 2008). In locations characterized by lateritic soils, it may be observed that the top portion of naturally occurring lateritic soils are stronger, when compared to the underlying lithomargic soil strata. This is due to the reason that lateritic soils are vesicular in nature, and finer particles of soil leach out to the bottom most layers when exposed to humid climatic conditions. M’Clelland (1841) provides detailed explanations on the origin and formation of lateritic and lithomargic soils.

Also, it is experienced that the cut and fill activities in road construction works in lateritic terrains tend to expose the under laying silty soils (or lithomargic soils) that are weaker. Thus, pavement engineers in the peninsular region of India often experience difficulties in estimating the strength of lateritic and lithomargic soils that occur in varying proportions. In the present study, in order to investigate the strength and stiffness of a wide variety of lateritic and lithomargic soils, it was proposed to perform tests on pure lateritic soils, lithomargic soils, and various blends of lateritic and lithomargic soils of the nearby region.

The study focuses on correlating the effect of grain-size, maximum dry-density (MDD), and optimum moisture content (OMC) on the resilient modulus (Mr) measured using the cyclic tri-axial test for various blends of lateritic soils. Tests were performed on soil samples compacted to MDD for molding water contents set to the optimum moisture content (OMC), dry-side of OMC, and wet-side of OMC. The results indicated that an increase in the fines-content resulted in an increase in the OMC, and a decrease in the MDD and Mr values. Regressions were developed correlating the fines content to the resilient modulus. The study also includes the effect of deviator stress and confining stress on various lateritic blends. This study is expected to provide the necessary basis for estimating the strength of a wide variety of lateritic sub-grades based on the fines content.

2 Problem Definition and Scope

It may be observed that characteristics of lateritic rocks, lateritic aggregates, and lateritic soils are different. Lateritic rocks rich in iron and aluminum are rarely seen in India although it exists in many parts of Nigeria, and Ethiopia. Lateritic rocks are harder, and possess darker shades of color due to the immense presence of iron oxides that occur due to exposure to humid climatic conditions and sunlight. However, lateritic aggregates and lateritic soils are not so hard as these do not possess very high percentages of iron oxides. Akpokpodje and Hudec (1992) provide details on a wide variety of lateritic rocks obtained from ten different cities of Nigeria with specific gravities varying from 2.95 to 3.47, while Madu (1980) discusses details on lateritic rocks and aggregates with specific gravities varying from 2.6 to 2.9. Muthusamy et al. (2015) report a specific gravity of 2.54 for lateritic aggregates with 7.18% iron oxides for lateritic aggregates of Malaysia, while Raju and Ramakrishna (2006) report specific gravities ranging from 2.7 to 3.0 for lateritic aggregates in coastal Karnataka, India. George et al. (2009) also performed studies on lateritic soils in the coastal regions of Karnataka, India, and confirm that the specific gravities of lateritic soils vary between 2.6 and 2.7.

The present study is conducted on soil that is found to occur most commonly in the coastal regions of the District of Dakshina Kannada. Similar soil characteristics can be observed in the peninsular regions of Southern India including Malabar. The soils in this region are predominantly lateritic in nature, with intrusions of lithomargic soil (fine grained silty soil). It may be observed that although soils of lateritic nature are sufficiently strong enough to be used as sub-base courses, lithomargic soil intrusions are very weak especially when exposed to moist conditions. Also, since lateritic and lithomargic soils occur in the same locality, these are mostly seen to be intermixed with each other due to cut and fill, and site-leveling activities that take place on highway construction sites. Due to this reason, it was proposed to perform studies on various blends of lateritic and lithomargic soils. It may also be observed that the strength of these soils are easily affected by changes in moisture content, and the proportion of fines as observed by Kim and Kim (2006) and George et al. (2009).

This study includes tests on various blends of lateritic and lithomargic soils compacted to MDD for molding water contents set to the optimum moisture content (designated as Wopt), dry-side of optimum moisture content (designated as Wopt − 3%), and wet-side of optimum moisture content (designated as Wopt + 3%).

As part of this study, standard tests including grain-size analysis, and tests for Atterberg’s limits were performed in the initial stages. This was followed by investigations on the resilient modulus using the cyclic tri-axial test equipment on un-soaked remolded lateritic soil samples, in addition to tests on lateritic soil blended with various percentages of lithomargic soil (or fine grained silty soil) for soil specimens compacted to the three moisture contents as mentioned above.

Correlations were developed using the statistical package for social sciences (SPSS) quantifying the influence of the percentage of fines, gravel, sand, MDD and OMC, on the values of resilient modulus obtained from the tests using the cyclic tri-axial experiment for various soil blends.

3 Experimental Program

The following are the important steps in the methodology adopted for this study:

-

Preparation of five soil blends with varying percentages of lateritic and lithomargic soil fractions and performing of tests for Atterberg’s limits, particle size-distribution, soil classification and modified proctor compaction test for the five soil blends.

-

Determination of the resilient modulus (Mr) using the cyclic tri-axial test equipment for the five soil blends.

-

Development of regression models for quantifying the effect of changes in the proportion of fines, gravel and sand on the resilient modulus (Mr) in addition to the effect of MDD and OMC for various soil blends.

-

Conducting a study on the effect of confining pressure and deviator stress on various soil blends.

4 Preparation of Soil Samples, Material Properties and the Test Program

4.1 Preparation of Blended Soils

Engineers engaged in pavement construction in the districts of Dakshina Kannada and Udupi in Karnataka State, India, are required to build roads over lateritic soil sub-grades where frequent intrusions of weaker lithomargic soils are observed. Lateritic soils are moderately strong, while moisture-content and silty fines considerably reduce the strength and stiffness of these soils.

In the present investigation, pure lithomargic soil fractions were obtained from sites close to Kulai, near Mangalore, Karnataka, and lateritic soils were obtained from areas close to the existing National Highway near the National Institute of Technology Karnataka, Surathkal. The soil specimens comprising lateritic soils were designated as 100%L + 0%S, and those comprising pure lithomargic soils were designated as 0%L + 100%S.

In order to study the changes in strength and stiffness characteristics, the lateritic and lithomargic soil fractions were mixed in various proportions by the method of quartering. Blended soil specimens prepared with 75% lateritic soil and 25% lithomargic soil were designated as 75%L + 25%S, and soil specimens prepared with 25% lateritic soil and 75% lithomargic soil were designated as 25%L + 75%S. Additionally, blended soil specimens with 50% lateritic soil and 50% lithomargic soil were prepared and designated as 50%L + 50%S. Five types of blended lateritic soils with varying proportions of silty fines (or lithomargic soil) were thus prepared for this study. Figure 1 represents the soil profile of a typical highway construction site in the study area.

4.2 Material Properties

Standard tests for soil samples such as the tests for as specific gravity, liquid limit, plastic limit, shrinkage limit, grain-size distribution, and modified compaction were performed in accordance with the respective Indian Standard Specifications. It may be noted that the test procedures adopted in Indian Standard codes were derived based on ASTM and British standards. The results of these tests are provided in Table 1.

It may be noted that the USCS specifications for soil classification are synonymous to Indian specifications (2720 Part IV 1985) and IS: 1498 (1970). Also, tests using the hydrometer indicated that clay particles constituted 0.82, 3.6, 10.4, 17.9, and 30.1% for the five soil blends 100%L + 0%S, 75%L + 25%S 50%L + 50%S 25%L + 75%S 0%L + 100%S respectively.

4.3 Preparation of the Cylindrical Soil Specimens for Cyclic Tri-Axial Test

For each of the five bended soils, the optimal moisture content (OMC) was first determined using the modified Proctor tests performed as per IS: 2720 Part VIII (1983), where soil was compacted in 5 layers, with 25 blows using a rammer of 4.9 kg falling through a height of 450 mm. The density of the soil at OMC, and the maximum dry density (MDD) were determined using the modified Proctor test.

The cylindrical soil specimens to be tested using the cyclic tri-axial test equipment were then prepared according to AASHTO 37–99 by compacting the soil to MDD in steel moulds in order to obtain soil specimens of 50 mm diameter and 100 mm height for each of the soil blends as recommended by Ping and Ling (2007). See Fig. 2. Similar specimens were prepared for various blends of lateritic soils for compacting moisture contents of Wopt − 3%, Wopt and Wopt + 3%.

4.4 Experimental Setup for Tests Using the Cyclic Tri-axial Test Equipment

Investigations using the cyclic tri-axial test equipment for determining the resilient modulus for lateritic soil blends were performed at Siddaganga Institute of Technology, Tumkur. This equipment consists of a loading frame powered by either a pneumatic or electro-hydraulic loading system.

The apparatus consists of a load cell and two linearly variable differential transducers (LVDTs) for measuring the applied load and the deformation. The confining pressure (or cell-pressure) was applied through a compressor. The load-cell attachment was then placed over the prepared specimen.

The cylindrical soil specimen to be tested was placed over the base plate, and a cylindrical glass chamber (as used in tri-axial tests) was clamped over the cylindrical specimen. The load-cell attachment was then placed over it. The entire assembly was then mounted on the loading platform of the cyclic tri-axial testing machine. See Fig. 3. The hydraulic pump, the electronic control system, and the computer system with data logging capability attached to the machine, were then switched on. A software named Cyclic System Console V1.0.0 was used to perform the test in the dynamic test mode.

4.5 Cyclic Tri-Axial Tests on Lateritic Soil Blends

Cyclic tri-axial tests were conducted on the cylindrical soil specimen subjected to static confining pressure and a repeated axial cyclic stress of a fixed magnitude, load duration, and cycle duration for a certain number of cycles. Tests on the cyclic tri-axial test machine were performed at the confining pressure and deviator stress levels recommended by the AASHTO T-307-99. The tests were performed at deviator stresses of 13.8, 27.6, 41.4, 55.2, and 68.9 kPa for each of the confining stresses 41, 28, and 14 kPa for the determination of the resilient modulus for each blend. Moreover, based on studies performed at the University of Mississippi for the Minesotta Department of Transportation, George (2006) recommends that the resilient modulus determined at a deviator stress of 41 kPa and a confining pressure of 14 kPa, can be compared to the resilient modulus measured using the portable falling weight deflectometer (PFWD). This was taken into consideration while formulating the testing strategy.

Each sample in the repeated load test was subjected to a combination of three confining pressures (41.4, 27.6 and 13.8 kPa) and five deviator stresses (13.8, 27.6, 41.4, 55.2 and 68.9 kpa) for each of the confining pressures. Specimens for each combination of confining pressure and deviator stress were first subjected to a preconditioning load of 500 cycles within a total duration of about 90 min, and subsequently, a final load of 100 loading cycles was applied. The recoverable axial deformation of each of the specimen was measured for the 96th, 97th, 98th, 99th, and the 100th loading cycles in order to compute the resilient modulus.

The amplitudes and seating loads for various sequences of tests performed were set according to AASHTO T 307-99 (AASHTO 2003). The values of the resilient modulus for various soil blends were computed as the ratio of the deviatoric stress to the recoverable strain for the 96th, 97th, 98th, 99th and the 100th loading cycles (George and Kumar 2016). The average resilient modulus of the soil specimen was then determined and reported. Table 2 provides a summary of the values of the resilient modulus obtained based on the cyclic tri-axial tests.

5 Results and Discussion

It may be observed that the five soil blends designated as 100%L + 0%S, 75%L + 25%S, 50%L + 50%S, 25%L + 75%S, and 0%L + 100%S were created by addition of lithomargic silty fines (S) to lateritic soils (L). The fines content (referring to particles of size lesser than 75 micron) in the five blends vary from 14 to 86%. It may also be observed that an increase in the fines content is found to be associated with a decrease in the specific gravity from 2.58 to 2.37. However, since the Atterberg’s limits depend to a large extent on the presence of clays or soil fractions lesser than 2 microns, and since the proportion of soil fractions lesser than 2 microns (representing clay particles) has not changed significantly with the increase in the percentage of silty-fines, no significant change in the values of Atterberg’s limits were observed for various blends of soils.

5.1 Effect of Variations in Percentage of Fines on Resilient Modulus (M r) of Lateritic Soil Blends

Table 2 provides details on the values of resilient modulus (Mr) for various soil blends with fines content varying from 14 to 86% compacted to OMD for un-soaked soil conditions. The table also provides details for samples compacted to the dry-side of optimum (Wopt − 3%), and for samples compacted to the wet-side of optimum (Wopt + 3%).

Here, it can be seen that for various blends of lateritic soils tested at molding moisture content of Wopt − 3%, the values of Mr decreased from 283.81 to 65.45 MPa for un-soaked soil conditions. Similarly, for molding moisture content of Wopt, the values of Mr decreased from 298.75 to 68.89 MPa. Also, for molding moisture content Wopt + 3%, the values of Mr decreased from 268.88 to 44.0 MPa. Thus, it can be seen that the values of Mr decrease with increase in the fines content from 14 to 86% irrespective of the molding moisture contents. Also, the increase in the percentage of fines has resulted in a reduction in the soil stiffness as explained in the previous section.

However, it is observed that the values of Mr at OMC conditions (denoted by Wopt) are higher than that at the drier-side of optimum denoted as Wopt − 3% and that at the wetter-side of optimum denoted as Wopt + 3%. The soil strength determined at optimum moisture content (OMC) on un-drained soils using the tri-axial test equipment is higher due to the reason that in tri-axial tests, the soil strength is measured based on the combined effect of the deviator stress (or major principal stress), and the cell pressure (or minor principal stress), and the resistance offered by the effect of cohesion and the angle of internal friction of the soil sample. Similar observations were made by Kizza et al. (2014) on tri-axial tests for shear strength performed on un-drained soils.

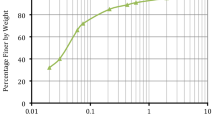

Regression equations were developed correlating the values of Mr for various lateritic soil blends to the values of the percentage of fines for samples compacted at moisture contents Wopt − 3%, Wopt and Wopt + 3% as shown in Table 3 using data compiled in Tables 1 and 2. The scatter plot for the same is provided in Fig. 4.

Thus, in the case of un-soaked soil samples, an increase in the proportion of fine silty soil fractions followed by a consequent decrease in the gravel content for the various soil blends, resulted in a decrease in the values of Mr with the scatter plot following linear trends.

5.2 Correlations Between Gravel (%) and M r for Various Soil Blends

Based on a summary of the details on the values of the resilient modulus of soil (Mr), for various blends of lateritic soil samples (100%L + 0%S, 75%L + 25%S, 50%L + 50%S, 25%L + 75%S, and 0%L + 100%S) and for various molding moisture contents Wopt − 3%, Wopt and Wopt + 3% as shown in Table 2 for un-soaked soil samples, regression equations were developed correlating the values of Mr to the percentage of gravel as shown in Table 4. The scatter plot for the same is provided in Fig. 5.

In the above mentioned figure, it can be seen that in the case of un-soaked soil samples, an increase in the proportion of gravel particles followed by a consequent decrease in the fines content for the various soil blends, resulted in an increase in the values of Mr with the scatter plot following linear trends.

5.3 Correlations Between Sand (%) and M r for Various Soil Blends

Based on a summary of the details on the values of the resilient modulus of soil (Mr), for various blends of lateritic soil samples (100%L + 0%S, 75%L + 25%S, 50%L + 50%S, 25%L + 75%S, and 0%L + 100%S) and for various molding moisture contents Wopt − 3%, Wopt, and Wopt+ 3% as shown in Table 2 for un-soaked soil samples, regression equations were developed correlating the values of Mr to the percentage of sand as shown in Table 5. The scatter plot for the same is provided in Fig. 6.

Thus, it is observed that in the case of un-soaked soil samples, an increase in the proportion of sand particles was followed by a consequent decrease in the fines content for the various soil blends, which resulted in an increase in the values of Mr with the scatter plot following linear trends.

5.4 Correlations Between MDD and M r for Various Soil Blends

Based on a summary of the details on values of the resilient modulus of soil (Mr), at un-soaked soil conditions (Mr) for various blends of lateritic soil samples (100%L + 0%S, 75%L + 25%S, 50%L + 50%S, 25%L + 75%S, and 0%L + 100%S) and for various molding moisture contents Wopt − 3%, Wopt, and Wopt + 3% as shown in Table 2, regression equations were developed correlating the values of Mr to the values of MDD as shown in Table 6. The scatter plot for the same is provided in Fig. 7.

Here, it can be seen that in the case of un-soaked soil samples, an increase in the proportion of fine silty soil particles was followed by a consequent decrease in the gravel and sand content for the various soil blends, which resulted in an increase in the voids-ratio, and a decrease in the values of MDD with the scatter plot following linear trends. This observation conforms to studies made by Hicks and Monismith (1971), and Omotosho (2004).

5.5 Correlations Between OMC (%) and M r for Various Soil Blends

Based on a summary of the details on values of the resilient modulus of soil (Mr), for various blends of lateritic soil samples (100%L + 0%S, 75%L + 25%S, 50%L + 50%S, 25%L + 75%S, and 0%L + 100%S) and for various molding water contents Wopt − 3%, Wopt, and Wopt + 3% as shown in Table 2, regression equations were developed correlating the values of Mr, to the values of OMC as shown in Table 7. The scatter plot for the same is provided in Fig. 8.

In the above mentioned figure, it can be observed that in the case of un-soaked soil samples, an increase in the OMC for the blends 100%L + 0%S, 75%L + 25%S, 50%L + 50%S, 25%L + 75%S and 0%L + 100%S, is followed by a consequent decrease in the MDD that resulted in a decrease in the values of Mr with the scatter plot following linear trends. This conforms to studies made by Hicks and Monismith (1971), Omotosho (2004) and George et al. (2009).

5.6 Development of Multi-linear Regressions to Predict the Resilient Modulus

Based on the information compiled vide Tables 1 and 2 for the results of the tests conducted using the cyclic tri-axial test setup on un-soaked soil samples, it is possible to develop multi-linear regression models relating the Atterbergs’s limits, grain-size, maximum dry density (MDD), and the optimum moisture (OMC) to the resilient modulus (Mr). The list of regression models developed is provided in Table 8. The details regarding the R2 value, the adjusted R2 value, the F-test values, the t test values, and the levels of significance are also provided in the table.

5.7 Effect of Deviator Stress on Resilient Modulus for Various Soil Blends

Based on the results of the cyclic tri-axial tests on lateritic and lithomargic soil blends as obtained in Table 2, it can be seen that for lateritic soil blends compacted to MDD at OMC, and subjected to a confining pressure of 13.8 kPa, and a deviator stress of 41.4 kPa, the resilient modulus was observed to be about 298.75, and 285.55 MPa for lateritic blends 100%L + 0%S, and 75%L + 25%S, while the resilient modulus was about 149.56 MPa, and 68.90 MPa for lithomargic blends 25%L + 75%S, and 0%L + 100%S. This indicates that as the percentage of fine silty soil fractions increases, and as the sand content decreases, the resilient modulus decreases.

A graphical representation of the variation in resilient modulus with respect to deviator stresses is shown in Fig. 9 for blend 100%L + 0%S for purely lateritic soils. The variations between the resilient modulus and the deviator loads indicate that lateritic soil blends develop high resilient modulus when subjected to increasing deviator stress. The above observation tallies with conclusions made by Boateng-Poku and Drumm (1989) where it is seen that the resilient modulus of coarse grained soils increased with increasing deviator stresses, and confining stresses which is considered to occur because of the strain hardening effect that takes place due to the reorientation of soil grains into a denser state (Mehran et al. 2014). A similar trend is obtained in the case of lateritic blend of 75%L + 25%S as shown in Fig. 10.

Also, in the case of coarse-grained soils such as 100%L + 0%S, the resilient modulus is found to increase with the confining pressure as observed by Rada and Witczak (1981) or the bulk stress (that includes the deviator stress as well as the confining stress) as observed by AASHTO T-274-82 (AASHTO 1986).

Figure 13 provides a graphical representation of the variation in the resilient modulus with respect to deviator stresses for blend 0%L + 100%S for purely lithomargic soils. The variations between the resilient modulus and the deviator loads indicate that lithomargic soils are not capable of resisting increasing deviator loads.

The above observation tallies with conclusions made by Boateng-Poku and Drumm (1989) where it is seen that the resilient modulus of fine-grained cohesive soils decreased with increasing deviator stresses, which is considered to occur because of the stress softening behavior or strain softening (Mehran et al. 2014). A similar trend is obtained in the case of lithomargic blends of 50%L + 50%S, and 25%L + 75%S as in Figs. 11 and 12.

In the case of lateritic soil sample denoted as 100%L + 0%S, it can be seen vide Fig. 9 that for a confining pressure of 13.8 kPa, as the deviator stress increases the values of resilient modulus also increases. A similar trend is observed in the case of tests performed at confining pressures of 27.6 kPa, and 41.4 kPa, for the above mentioned soil blend. A similar trend can be seen in the case of soil blends 75%L + 25%S, 50%L + 50%S, 25%L + 75%S, and 0%L + 100%S, as in Figs. 10, 11, 12 and 13. In all these cases, it can be seen that soils tested at higher confining stresses show higher resilient modulus values. Similar observations were made by Seed et al. (1962), Thompson and Robnett (1976), and Pezo and Hudson (1994).

It may be seen that in the soil blends investigated, clay particles constituted 17.9, and 30.1% for the lithomargic soil blends 25%L + 75%S, and 0%L + 100%S respectively. Also, the fines content for these blends were 69 and 86% respectively as mentioned in Table 1. Thus, lithomargic soils possess lower clay content, and higher silt content. These lithomargic soil blends are found to possess lower resilient modulus values of 149.56 and 68.9 MPa respectively when compared to lateritic soil blends possessing lesser fines content. Similar observations were made by Thompson and Robnett (1976) and Lekarp et al. (2000) and Tang et al. (2016).

5.8 Conclusions

The above work focused on the study of the effect of soil parameters on resilient modulus values obtained using the cyclic-triaxial test on lateritic soils blended with lithomargic fines for the region of Dakshina Kannada. The investigations include tests on various blends of lateritic and lithomargic soils compacted to MDD for molding water contents set to the optimum moisture content, dry-side of optimum moisture content, and wet-side of optimum moisture content. The effect of various factors such as, the percentage of fines, gravel and sand, the MDD, and OMC on the resilient modulus (Mr) was observed, and correlations were developed. The following conclusions can be drawn based in this study:

-

In the investigations on the index properties of blended laterite soils, it was observed that an increase in the effective percentage of fines from 14 to 86% resulted in a corresponding increase in the OMC due to the increase in the total surface-area of the soil particles. This has consequently resulted in a reduction in the MDD, and the average specific gravity of the soil particles. However, no notable changes in the Atterberg’s limits were observed, since the Atterberg’s limits depend to a large extent on the presence of clays or soil fractions lesser than 2 microns, which have not changed significantly with the increase in the percentage of silty-fines.

-

In the cyclic tri-axial tests conducted on un-soaked blended laterite soil samples moulded at MDD, it was observed that the Mr values determined, showed a maximum value of resilient modulus at the optimum moisture content (Wopt), when compared to samples compacted at the dry-side of optimum due to the combined effect of the deviator stress (or major principal stress), and the cell pressure (or minor principal stress), and the resistance offered by the effect of cohesion and the angle of internal friction of the soil sample.

-

The regressions developed for Mr Vs Fines possessed a relatively good correlation indicating that the increase in the proportion of silty fines (Fines) resulted in a reduction in the resilient modulus (Mr) measured using the tri-axial test equipment. It may also be observed that an increase in the fines content was accompanied by an increase in the OMC due to the increase in the surface area of soil particles as observed in Table 2.

-

The regressions developed for Mr Vs OMC too displayed a reasonably good correlation which showed that the increase in OMC (due to the increase in fines) resulted in a reduction in the resilient modulus (Mr) measured using the cyclic tri-axial test equipment.

-

On analysing the effect of deviator stress on the resilient modulus for lateritic soils classified as coarse-grained soils, it can be seen that such soil blends develop high resilient modulus when subjected to increasing deviator loads as observed by Boateng-Poku and Drumm (1989), and as explained by Mehran et al. (2014).

-

In the case of coarse-grained soils, it is also seen that the resilient modulus increases with the confining stress, or even the bulk stress. This tallies with observations made by Rada and Witczak (1981) and AASHTO T-274-82 (AASHTO 1986).

-

In the case of lithomargic soils classified as fine-grained soils, it can be seen that these soil blends care not capable of resisting deviator loads. Similar observations were made by Boateng-Poku and Drumm (1989). This is said to occur due to the stress softening behavior or strain softening (Mehran et al. 2014).

The regressions developed in the above sections assist in quantifying the effect of various soil parameters such as fines, gravels, sand, MDD, and OMC on the resilient modulus. In the analyses using simple regressions and multi-linear regression models, the values of the coefficients of the independent variables of the regressions developed indicate the degree of influence of the corresponding independent variables. The regressions developed are expected to be of use to practicing engineers in estimating the values of the resilient modulus for lateritic soils for the design of pavement sub-grades and embankments.

References

AASHTO (1986) Standard method for testing resilient modulus. AASTHO T 274-82 AASHTO, Washington

AASHTO (2003) Standard method of test for determining the resilient modulus of soils and aggregate materials. In: AASHTO T 307-99, American Association of State Highway and Transportation Officials (AASHTO), Washington

Akpokpodje EG, Hudec P (1992) Properties of concretionary laterite gravel concrete. Bull Int Assoc of Eng Geol 4:45–50

Al-Refeai TO, Al-Suhaibani AS (2002) Factors affecting resilient behavior of subgrade soils in Saudi Arabia. J King Saud Univ Eng Sci 2(14):165–182 (A.H. 1422/2002)

Boateng-Poku Y, Drumm EC (1989) Hyperbolic model for the resilient modulus response of fine-grained subgrade soil. In: Resilient moduli of soils. ASCE Geotechnical Special Publication No. 24, pp 1–14

Burczyk JM, Ksaibati K, Anderson-Sprecher R (1994) Factors influencing determination of a sub-grade resilient modulus value transportation research record 1462. TRB, National Research Council, Washington, pp 72–79

Drumm EC, Boateng-Poku Y, Pierce TJ (1990) Estimation of subgrade resilient modulus from standard tests. J Geotech Eng 1165:774–789

Farrar MJ, Turner JP (1991) Resilient modulus of Wyoming subgrade soils. Mountain plains consortium rep. no. 91-1. University of Wyoming, Laramie

George KP (2006) Portable FWD (PRIMA 100) for in-situ subgrade evaluation. Department of Civil Engineering, in cooperation with Mississippi Department of Transportation (MDOT), and the U.S. Department of Transportation, Federal Highway Administration (FHWA), Mississippi

George V, Kumar A (2016) Studies on resilient modulus using cyclic tri-axial test and correlations to PFWD, DCP, and CBR. Int J Pavement Eng. https://doi.org/10.1080/10298436.2016.1230428

George V, Rao CN, Shivashankar R (2009) PFWD, DCP and CBR correlations for evaluation of lateritic subgrades. Int J Pavement Eng 10(3):189–199

Hardcastle JH (1992) Subgrade resilient modulus for idaho pavements. Final report of ITD research project RP 110-D, agreement no. 89-47, Department of Civil Engineering, University of Idaho, Moscow, p 252

Hicks RG, Monismith CL (1971) Factors influencing the resilient properties of granular materials, transportation research record 345, transportation research board. National Research Council, Washington, pp 15–31

IS: 1498 (1970) Indian standard classification and identification of soils for general engineering purposes. Bureau of Indian Standards, New Delhi, pp 23–40

IS: 2720 Part IV (1985) Indian standard methods of test of soil for grain size analysis. Bureau of Indian standards, New Delhi, pp 73–91

IS: 2720 Part VIII (1983) Indian standard methods of test for soils: Part 8: determination of water content—dry density relation using heavy compaction. Bureau of Indian Standards, New Delhi

Kim D, Kim RJ (2006) Resilient behavior of compacted subgrade soils under the repeated tri-axial test. Sci Dir Constr Build Mater 21(7):1470–1479

Kizza R, Leong EC, Rahardjo H (2014) Martic suction and strength of dynamically compacted soils. In: Khalili R, Khoshghaib A (eds) Unsaturated soils: research strength and applications. Taylor and Francis Group, London, pp 1323–1327

Lekarp F, Isacsson U, Dawson A (2000) State of the art. I: resilient response of unbound aggregates. J Transport Eng 126(1):66

Li D, Selig ET (1994) Resilient modulus for fine-grained subgrade soils. J Geotech Eng ASCE 120(6):939–957

Livneh M, Goldberg Y (2001) Use of falling-weight deflectometer and light drop weight for quality assessment during road formation and foundation construction. In: TRB 80th annual meeting, Washington, pp 69–77

M’Clelland J (1841) Calcutta journal of natural history, vol 1. W. Ridsdale, Bishop’s College Press, Calcutta, p 189

Madu RM (1980) The performance of laterite stones as concrete aggregates and road chipping. Mater Struct 13:6

Malla BR, Joshi S (2008) Subgrade resilient modulus prediction models for coarse and fine-grained soils based on long-term pavement performance data. Int J Pavement Eng 9:431–444

Mehran M, Navarro E, Abdallah I, Nazariann S (2014) Comparison of numerical and experimental responses of pavement systems using various resilient modulus models. Soils Found 54(1):36–44

Monismith CL (1989) MR testing-interpretation of laboratory results for design purposes. In: Workshop on resilient modulus testing, Oregon State University, Corvallis. http://books.google.co.in/books

Muthusamy K, Kamaruzaman NW, Ismail MA, Budiea AMA (2015) Durability performance of concrete containing laterite aggregates. KSCE J Civ Eng (0000) 00(0):1–8. www.springer.com/12205. https://doi.org/10.1007/s12205-015-0279-2

Nazarian S, Yuan D, Arellano M (2002) Quality management of base and subgrade materials with seismic methods. In: Proceedings of 81st annual meeting transportation board, Washington, pp 50–60

Omotosho O (2004) Influence of gravelly exclusion on compaction of lateritic soils. Geotech Geol Eng 22:351–359

Pezo R, Hudson WR (1994) Prediction models of resilient modulus for non granular materials. Geotech Test J GTJODJ 17(3):349–355

Ping WV, Ling CC (2007) Enhancement of resilient modulus data for the design of pavement structures in Florida. Final report BD-543-4, Florida A&M University, Florida State University, Tallhassee

Rada G, Witczak MW (1981) A comprehensive evaluation of laboratory resilient moduli results for granular soils. Transportation Research Record 810, TRB, Washington

Rahim AM, George KP (2002) Automated dynamic cone penetrometer for subgrade resilient modulus characterization. In: Proceedings of 81st annual meeting transportation board

Raju KN, Ramakrishna R (2006) Properties of laterite aggregate concrete. Mater Struct 5:307

Rao CN (2008) Studies on strength and stiffness characteristics for lateritic soil for pavement subgrades. Ph.D. thesis submitted to the Department of Civil Engineering National Institute of Technology, Karnataka, India

Sawangsuriya A, Edil T, Bosscher P (2002) Comparison of moduli obtained from the soil stiffness gauge with moduli from other tests, transportation research record 1755. National Research Council, Washington

Seed H, Chan C, Lee C (1962) Resilience characteristics of subgrade soils and their relation to fatigue in asphalt pavements. In: Proceedings of international conference on the structural design of asphalt pavements, University of Michigan, pp 611–636

Taheri A, Tatsuoka F (2012) Primary stress–strain relations inferred from multiple-step triaxial compression test results. Soils Found 52(4):748–766

Tang X, Stoffels SM, Palomino AM (2016) Mechanistic-empirical approach to characterizing permanent deformation of reinforced soft soil subgrade. Geotext Geomembr 44(2016):429–441

Thompson MR, Robnett QL (1976) Resilient properties of subgrade soils. In: Transportation engineering series no. 14. Illinois Cooperative Highway and Transportation Series No. 160, University of Illinois

Van Gurp CAPM, Groenendijk J, Beuving E (2000) Experience with various types of foundation tests. In: Proceedings of 5th international symposium unbound aggregates in roads (UBAR5). University of Nottingham, United Kingdom, pp 21–23

Von Quintus H, Killingsworth B (1998) Analysis relating to pavement material characterizations and their effects on pavement performance. Rep. No. FHWA-RD-97-085, FHWA, U.S. DOT, Washington

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, A., George, V. Effect of Soil Parameters on Resilient Modulus Using Cyclic Tri-Axial Tests on Lateritic Subgrade Soils from Dakshina Kannada, India. Geotech Geol Eng 36, 3987–4000 (2018). https://doi.org/10.1007/s10706-018-0550-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-018-0550-7