Abstract

In conventional automated storage and retrieval systems (AS/RS), storage and retrieval (S/R) machine travels simultaneously in the horizontal and vertical directions. However, S/R machine cannot support overly heavy loads, such as sea containers, so a new AS/RS, called split-platform AS/RS (SP-AS/RS), was introduced and studied in recent years. The SP-AS/RS employs vertical and horizontal platforms, which move independently, and are capable of handling heavy loads. The vertical platform which represents an elevator (or lift) with the elevator’s lifting table carries the load up and down among different tiers and the horizontal platform which represents the shuttle carrier or the shuttle vehicle can access all cells of the tier in which it belongs to. Single command cycle (SC) and dual command cycle (DC) are two main operating modes in AS/RSs. However, travel time models in all previous articles related to the SP-AS/RS are only for the SC. In this study, we first present a continuous travel time model for the DC in the SP-AS/RS under input and output (I/O) dwell point policy and validate its accuracy by computer simulations. Our model and simulation results both show that the square-in-time rack incurs the smallest expected travel time. After comparing with the existing model for the SC, we find that the DC is better than the SC in terms of the expected travel time.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Since its introduction in 1950s, automated storage and retrieval system (AS/RS) has been one of the major tools for inventory control and warehouse material handling. Widely used in automated production environments and distribution centres, AS/RS plays an important role in modern factories for work-in-process storage and has greatly improved the performance of the inventory control, and the utilization rates of time, space and equipment (Hur et al. 2004; Manzini et al. 2006; Van den Berg and Gademann 1999). There exist many literature papers that focus on issues and approaches related to improve the efficiency of AS/RS (Baker and Canessa 2009; De Koster and Le-DucT 2007; Gu et al. 2007; Rouwenhorst et al. 2000; Van den Berg 1999).

Briefly, a conventional AS/RS performs a storage operation as follows. Firstly, the incoming items are sorted and combined into loads. Secondly, the loads are routed through weighing station in order to ensure that they do not violate the load weight limit. Thirdly, the loads are transported to the input and output (I/O) station and the contents of the loads are memorized in the central computer. Fourthly, this computer assigns the load a cell in the rack, and records the location information in its memory. Finally, the load is moved from the I/O station to its assigned cell by the storage and retrieval (S/R) machine. The retrieval operation is relatively simpler. Upon receiving a retrieval request for a load, the computer searches its memory for its storage cell and dispatches the S/R machine to pick up the load. Then, the S/R machine transports the load from its storage cell to the I/O station (Linn and Wysk 1987).

Based on the rack structure, the product handling and picking methods, S/R machine capabilities and the interaction way with the workers, we can find a large number of system configurations for the AS/RS. The most basic version of an AS/RS has one S/R machine in each aisle, which cannot leave its designated aisle (aisle-captive) and can transport only one unit-load at a time (single shuttle).

The conventional AS/RS usually uses S/R machine to move the loads. Each S/R machine has a vertical drive, a horizontal drive and one or two shuttle drives. The vertical drive moves the load up-and-down, while the horizontal drive moves the load forth-and-back along the aisle. And the shuttle drives transfer the loads between the S/R machine’s carriages and the cells in the AS/RS rack. Although the vertical and horizontal drives are able to simultaneously move for greater efficiency, they cannot handle overly heavy loads. Therefore, to apply AS/RSs to handle sea containers, a new type of AS/RS, called the split-platform AS/RS (SP-AS/RS), was introduced by Hu et al. (2005). Then several literatures came to study the system. But only the single command cycle (SC) was considered. To our knowledge, we are the first paper that comes to focus on the dual command cycle (DC) and establish the foundation for future research of DC for the SP-AS/RS. The mechanism and operations of the SP-AS/RS will be described in detail in Sect. 2.

In the AS/RS, there are two main operating modes, namely SC and DC. The SC performs either a storage operation or a retrieval operation. Figure 1 shows that the time for completing an SC consists of two parts: one is the time from the I/O station to the cell and the other is the time from the cell to the I/O station. Differently, the DC consecutively performs a storage operation and a retrieval operation. From Fig. 2, we can see that the DC time includes three parts: the storage time from the I/O station to the storage cell, between-time from the storage cell to the retrieval cell, and the retrieval time from the retrieval cell to the I/O station. Intuitively, compared to the SC, the DC can perform two operations at the cost of only the between-time. As a result, we conjecture that the use of the DC may decrease the total travel time and improve the performance of the SP-AS/RS. In the previous articles related to the SP-AS/RS, the authors all focused on studying the travel time model for the SC. So in this study, we first attempt to investigate the impact of the DC on the average travel time in the SP-AS/RS.

The dwell point in an AS/RS is the position where the idle S/R machine stays. A suitable dwell point policy can improve the system performance. The most popular dwell point policies in literature include the I/O dwell point policy, the stay dwell point policy and the return to middle dwell point policy (Bozer and White 1984; Egbelu and Wu 1993; Linn and Wysk 1987; Peters et al. 1996). Hu et al. (2005) presented a reliable travel time model under the stay dwell point policy for the SP-AS/RS. Subsequently, Vasili et al. (2006) extended the study of Hu et al. (2005) by considering the return to middle and return to start dwell point policies. In this paper, we only consider the I/O dwell point policy in the SP-AS/RS.

Simulation is a methodological approach that is widely applied in various research fields (Bekker 2013; Smew et al. 2013). In our paper, we use simulation to validate the accuracy of our proposed model.

The contributions of our paper are fourfold. Firstly, we present a closed-form model for the travel time of the DC in the SP-AS/RS with the I/O dwell point policy. Secondly, we validate the accuracy of this model by computer simulations. Thirdly, we show that the DC outperforms the SC, significantly improving system performance in terms of the expected travel time. The comparison results reveal that our model results improve on the results of Vasili et al. (2006) by around 27 % on average. Finally, our model tells us that the most effective rack configuration for our SP-AS/RS is square-in-time.

The remainder of this paper is structured as follows. Section 2 describes the mechanism and operations of the SP-AS/RS in detail. Section 3 reviews the existing literature on warehouse design and control. Section 4 derives the travel time model for the DC in the SP-AS/RS, which is subsequently validated by computer simulations and compared with the model of Vasili et al. (2006) in Sect. 5. Finally, conclusions and further study are given in Sect. 6.

2 The split-platform AS/RS

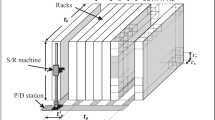

Figure 3 gives a schematic view of an SP-AS/RS, which includes one vertical platform (VP) for each rack and one horizontal platform (HP) for each vertical level. The vertical levels, called tiers, are numbered by integers from 1 onwards and the columns, called bays, are numbered by integers from 0 onwards. The VP vertically links the different tiers of the rack, and the HP accesses individual cells on the tier in which it belongs to. The operations of the VP and the HPs are performed independently. By using VP and HPs, the SP-AS/RS is able to handle heavier loads at a higher speed, compared with the conventional AS/RS. High lifting capacity enables the SP-AS/RS to deal with all types and sizes of sea containers that pass through the container terminals (Hu et al. 2005).

The structure of an SP-AS/RS (Hu et al. 2005)

Combined with Fig. 3, the operations in the DC in the SP-AS/RS with the I/O dwell point policy can be described as follows. A DC performs a storage operation and a retrieval operation in turn. When executing the storage operation, the I/O station first transfers the load to the VP, which carries the load to the designated tier. Then, the load is transferred from the VP to the HP, which carries it to its destination cell. Immediately after finishing the storage operation, the HP of a certain tier picks up a load and then travels to bay 0. Meanwhile, the VP moves to that tier to receive the load. Finally, the VP carries the load to the I/O station. Following the I/O dwell point policy, after completing a DC, the VP stays at the I/O station and all HPs move to bay 0.

3 Existing research on warehouse design and control

In the last several decades, researchers have delved into many issues and approaches on warehouse design and control (Baker and Canessa 2009; De Koster and Le-DucT 2007; Gu et al. 2007; Lerher et al. 2014; Rouwenhorst et al. 2000; Van den Berg 1999). These papers focus only on a fraction of the AS/RS issues, including system configuration, travel time estimation, storage policy, dwell point strategy, request sequencing and batching. To get a broad overview of issues in AS/RSs, we refer the reader to Roodbergen and Vis (2009), which is the first survey paper on the AS/RSs in literature to the best of our knowledge.

The AS/RS travel time models are based on either the discrete rack or continuous rack. In the discrete travel time models, we treat the AS/RS rack face as a discrete set of locations. The discrete rack can be normalized to a continuous pick face. In practice, we find that there is no significant difference between the obtained results of the continuous and discrete racks (Sari et al. 2005). The discrete representation of the rack was studied by many researchers (Ashayeri et al. 2001; Egbelu 1991; Sari et al. 2005; Thonemann and Brandeau 1998). Since the study of Hausman et al. (1976), many papers also pay close attention to the continuous representation of the rack. The relevant literature can be classified into two main groups according to the shape of the AS/RS, namely square-in-time and rectangular-in-time. In a square-in-time AS/RS, the horizontal maximum travel time is equal to the vertical maximum travel time (Valili et al. 2006). Any rack that is not square-in-time belongs to the rectangular-in-time group. Based on a continuous rack approximation approach, Bozer and White (1984) presented the expected travel times for both single and DCs in the AS/RS. They viewed the rack as a continuous rectangular pick face and analyzed alternative I/O stations and various dwell point policies.

Many researchers also paid attention to the travel time models and simulation analysis for AS/RS with various characteristics (Lerher et al. 2006, 2010a, b, 2011, 2015a, b). For example, Lerher et al. (2015) considered shuttle-based storage and retrieval systems, and proposed analytical travel time model to compute the travel time for the system. Lerher et al. (2010) proposed analytical travel time models for automated warehouses with aisle transferring S/R machine. They considered the operating characteristics of the S/R machine. Lerher et al. (2011) addressed a multi-shuttle AS/RS. They first proposed analytical and simulation models of this system, and then compared the performance of these models. Lerher et al. (2010) paid attention to a double-deep AS/RS in which the characteristics of the S/R is also considered.

Travel time in an AS/RS consists of S/R machine travel time and pick-up/deposit time. Since the pick-up/deposit time is generally constant and independent on the rack shape and travel velocity of the S/R machine, researchers often ignored it in analytical approaches. Doing this can simplify the model without affecting the performance analyses of the control policies (Bozer and White 1984; Hausman et al. 1976; Hu et al. 2005; Sari et al. 2005).

The selection of the dwell point policy in the AS/RS was widely discussed in literature (Van den Berg 1999). Graves et al. (1977) adopted the I/O station as the dwell-point of the S/R machine. In their work, they also raised many new research topics related to the design, planning and control of warehouse systems. Bozer and White (1984), Linn and Wysk (1987) and Regattieri et al. (2013) investigated various dwell point policies for the S/R machine, which are briefly re-described as follows:

-

1.

I/O dwell point policy: move to the input station after the completion of an SC storage operation; stay at the output station after the completion of either an SC retrieval operation or a DC.

-

2.

Stay dwell point policy: stay at the destination cell after the completion of an SC storage operation; stay at the output station after the completion of either an SC retrieval operation or a DC.

-

3.

Return to middle dwell point policy: move to the midpoint location of the rack after the completion of any type of cycle.

-

4.

Return to start dwell point policy: move to the input station after the completion of any type of cycle.

Egbelu (1991) presented a linear programming method to obtain the expected travel time of S/R machine. By computer simulations, Egbelu and Wu (1993) compared six dwell point policies under randomized and dedicated storage policies. They also compared the four rules presented by Bozer and White (1984) and the two formulations proposed by Egbelu (1991). Meller and Mungwattana (2005) dealt with the impact of several different dwell point policies on relative response time by the means of simulation.

In order to determine the optimal dwell point locations for the S/R machine, Peters et al. (1996) proposed analytical models with continuous rack approximation. They provided closed-form expressions for selecting the optimal dwell point location in an AS/RS. In addition, they made a few extensions of AS/RSs. For example, they considered a variety of configurations that includes multiple I/O stations. However, Peters et al. (1996) did not computationally verify the effectiveness of their dwell point policy. Chang and Egbelu (1997) presented formulations for pre-positioning S/R machine with the objective of minimizing the expected system response time. In the same year, Chang and Egbelu (1997) tried to minimize the maximum system response time for a multi-aisle AS/RS also by pre-positioning S/R machine. Van den Berg (2002) identified the optimal dwell point position that can minimize the expected travel time from the dwell point position to the position of the first operation after the idle period.

As a new AS/RS system, the SP-AS/RS was first studied by Hu et al. (2005). Not only did the authors introduce the mechanism and operations of this new system, but also proposed a travel time model for the SC. Following this pioneering work, several literature papers also addressed the SP-AS/RS. Vasili et al. (2006) compared different dwell point policies for the SP-AS/RS, such as return to middle, return to start and stay dwell point policies, and showed that the stay dwell point policy outperformed other policies. Then, Vasili et al. (2008) established a statistical cycle time model for the SC in the SP-AS/RS and validated the accuracy of their model by Monte Carlo simulation. At the same year, Hu et al. (2008) applied SP-AS/RS to a container yard. They used an integrated container simulation system to compare different allocation policies, and proved that the second-carrier-based policy can improve the terminal performance. More recently, Hu et al. (2010) proposed novel load shuffling algorithms for the SP-AS/RS to minimize the response time of retrieving a batch of loads.

4 Travel time model for the DC in the SP-AS/RS

We formulate the travel time model for the DC as a continuous one, which can considerably reduce the difficulty of the subsequent analyses. Figure 4 outlines the deriving process of the expected travel time.

Organization of Sect. 4

4.1 Assumptions and notations

The following assumptions are used throughout this paper:

-

1.

Unit loads are considered;

-

2.

Randomized storage is used, which means that any point within the pick face is equally likely to be selected for storage or retrieval;

-

3.

The rack is considered to be a continuous rectangular pick face;

-

4.

The numbers of storage operations and retrieval operations are equal.

-

5.

Specifications of the rack and the platforms are known. The platforms travel at a constant speed;

-

6.

There is no prior information of the subsequent jobs, and thus there are no concurrent VP and HP movements for different operations. During a DC transaction, the operations enter into the system in turn. When the DC starts, we only know the information of the storage operation and that the next operation is a retrieval operation. That is, the detailed information on the retrieval operation is not known until it enters into the system.

-

7.

I/O dwell point policy is adopted, i.e., the VP moves to tier 1 and the HP returns to bay 0 after the completion of a DC.

We will use the following notations to build the model: L, the length of the rack; H, the height of the rack; n, the number of tiers of the rack; α, the probability that the storage operation is situated at the same tier as the retrieval operation is; β, the probability that the storage and the retrieval operation lie in different tiers; v h , the speed of the HP; v v , the speed of the VP; t 0, the time needed to transfer a load between VP and HP, or between HP and a cell; c 0, the time needed to transfer a load between VP and HP, or between HP and a cell after normalizing the rectangular pick face; t 1, the time needed to transfer a load between the I/O station and the VP; c 1, the time needed to transfer a load between the I/O station and the VP after normalizing the rectangular pick face; t h , the travel time required for the HP to go to the farthest bay from bay 0; t v , the travel time required for the VP to go to the highest tier from tier 1; b, the shape factor; t, the DC time; t s , the time spent on the storage operation; t r , the time spent on the retrieval operation.

It is easy to get t h = L/v h and t v = H/v v . We define the shape factor as b = t v /t h , which reflects the shape of a rack in the form of time ratio. With all the above notations, the rack can be normalized as a rectangular pick face with length of 1 and height of b. At the same time, to normalize the transfer times, we define c 0 = t 0/t h and c 1 = t 1/t h . Under the conventional AS/RS mechanism, the symmetry of the vertical and horizontal movements requires 0 ≤ b ≤ 1. Whereas, in the SP-AS/RS, we allow b to be any positive value.

4.2 Overall analysis

In a DC, we let (x 1, y 1) and (x 2, y 2) be the storage and retrieval cells, respectively, where x and y denote the identification numbers of bay and tier. All these coordinates’ values are in terms of time. Under the randomized storage policy, the probability distribution function and probability density function of y i (i = 1, 2) are as follows (Hu et al. 2005):

Thus, we have

Similarly, the probability distribution function and the probability density function of x i (i = 1, 2) are (Hu et al. 2005):

Hence, we have

The formula of the expected travel time for a DC is

where t denotes the DC time, t s is the time spent on the storage operation, and t r is the time spent on the retrieval operation. Thus, E(t) denotes the expected travel time for the DC, which is the sum of the expected times of the storage operation and the retrieval operation. In the following context, we derive the closed-forms for E(t s ), E(t r ) and E(t).

4.2.1 The calculation of E(t s )

The DC in the SP-AS/RS consists of a storage operation and a retrieval operation. To perform the storage operation, the I/O station first transfers the load to the VP. Next, the VP carries the load to its assigned tier and transfers it to the HP. The HP in the assigned tier sends the load to the destination cell and transfers the load to the cell. The formula for the time spent for the storage operation is

As the transfer time t 0 and t 1 are rather smaller compared with the time spent on platform movements, and also in order to simplify the following computation, we can set t 0 and t 1 to be 0. If the transfer times have to be considered, we can directly add them into the expected travel time at the last stage. As a result, we have c 0 = 0, c 1 = 0 and t s = x 1 + y 1. It can be easily derived that

4.2.2 The calculation of E(t r )

When performing the retrieval operation, there are two cases to be considered. In the first case, x 1 is situated at the same tier as x 2, namely y 1 = y 2. Firstly, the HP at tier y 1 moves from bay x 1 to bay x 2, and then the cell transfers the load to the HP. After that, this HP moves the picked load to bay 0 and transfers it to the VP. Finally, the VP moves the load to tier 1, and transfers it to the I/O station. For this case, the formula of the time spent on a retrieval operation is calculated by

Since c 0 = c 1 = 0, we have

And

Letting W = |x 1 − x 2|, we can obtain the probability distribution function and density function as follows:

From “Appendix”, we have

Therefore,

Hence,

Substituting Eqs. (6) into (5) yields,

In the other case, x 1 and x 2 are situated at different tiers, namely y 1 ≠ y 2. The relevant operations are sequentially performed in the following order: (1) the HP at tier y 2 moves to bay x 2 from bay 0; (2) the cell transfers the load to the HP; (3) the HP moves from x 2 to bay 0, and meanwhile the VP moves from y 1 to y 2; (4) the HP transfers the load to the VP; (5) the VP moves the load to and transfers it to the I/O station. For this case, the formula of the time spent on the retrieval operation is

Since c 0 = 0 and c 1 = 0, we get

And

After setting \(W = \hbox{max} \left( {\left| {y_{1} - y_{2} } \right|,2x_{2} } \right)\), because \(\left| {y_{1} - y_{2} } \right|\) and \(2x_{2}\) are independent, we can derive

From Appendix D of paper (Hu et al. 2005), we have

And it is easy to get

So we can have:

-

1.

when 0 ≤ b ≤ 2

$$F_{W} (z) = \left\{ {\begin{array}{*{20}l} { 0,} \hfill & {z \le 0} \hfill \\ {\frac{{z^{2} }}{b} - \frac{{z^{3} }}{{2b^{2} }},} \hfill & {0 \le z \le b} \hfill \\ {\frac{z}{2},} \hfill & {b \le z \le 2} \hfill \\ {1,} \hfill & {z \ge 2} \hfill \\ \end{array} } \right.\,{\text{and}}\,f_{W} (z) = \left\{ {\begin{array}{*{20}l} { 0,} \hfill & {z \le 0} \hfill \\ {\frac{2z}{b} - \frac{{3z^{2} }}{{2b^{2} }}} \hfill & {0 \le z \le b} \hfill \\ {\frac{1}{2},} \hfill & {b \le z \le 2} \hfill \\ {0,} \hfill & {z \ge 2} \hfill \\ \end{array} } \right.$$(9) -

2.

when b ≥ 2

$$F_{W} (z) = \left\{ {\begin{array}{*{20}l} { 0,} \hfill & {z \le 0} \hfill \\ {\frac{{z^{2} }}{b} - \frac{{z^{3} }}{{2b^{2} }},} \hfill & {0 \le z \le 2} \hfill \\ {\frac{2z}{b} - \frac{{z^{2} }}{{b^{2} }},} \hfill & {2 \le z \le b} \hfill \\ {1,} \hfill & {z \ge b} \hfill \\ \end{array} } \right.\,{\text{and}}\,f_{W} (z) = \left\{ {\begin{array}{*{20}l} { 0,} \hfill & {z \le 0} \hfill \\ {\frac{2z}{b} - \frac{{3z^{2} }}{{2b^{2} }}} \hfill & {0 \le z \le 2} \hfill \\ {\frac{2}{b} - \frac{2z}{{b^{2} }},} \hfill & {2 \le z \le b} \hfill \\ {0,} \hfill & {z \ge b} \hfill \\ \end{array} } \right.$$(10)

Based on Eqs. (9) and (10), we obtain

Substituting Eqs. (11) into (8) yields,

We assume that the probability that x 1 is situated at the same tier as x 2is α. So the probability that x 1 and x 2 lies in different tiers is β = 1-α. Now we can get

Substituting Eq. (7) and Eq. (12) into Eq. (13) yields,

4.3 The final formula for E(t)

Substituting Eq. (4) and Eq. (14) into Eq. (3) yields,

Under the randomized storage policy, if we assume that the rack has n tiers, then we have \(\alpha = \frac{1}{n}, \, and \, \beta = 1 - \alpha = \frac{n - 1}{n}.\) Thus, the expected travel time for a DC can be finalized as:

5 Validation of the travel time model

5.1 Configurations

To evaluate the effectiveness and accuracy of our continuous model, we compared its results with those from the computer simulations and those from the model by Vasili et al. (2006). The reason why we compare our results with the one of Vasili et al. (2006) is that our objective is to study the impact of DC on the performance of SP-AS/RS. And except for the command is different (ours is DC and the command of Vasili et al. (2006) is SC), the system and other assumptions of Vasili et al. (2006) is the same with our paper, such as SP-AS/RS, I/O dwell point policy and so on. So Vasili et al. (2006) is the most suitable literature to be compared with.

In our computer simulations, we used two sets of configurations introduced by Hu et al. (2005), which are repeated as follows.

Configuration 1:

-

(a)

in the rack the number of total storage cells is 288;

-

(b)

the height and width of each cell are both 4.5 m;

-

(c)

the speed of the VP is 1 m/s and the speed of the HPs is 2 m/s.

Configuration 2:

-

(a)

in the rack the number of total storage cells is 2592;

-

(b)

the height and the width of each cell are both 1.5 m;

-

(c)

the same as (c) in Configuration 1.

The total area of the rack used in these two configurations is the same, while the cell dimensions are different. It is easy to find that Configuration 2 contains more cells than Configuration 1.

We performed 100,000 random DC operations, each of which is a pair of a random storage operation and a random retrieval operation, using each of the two configurations in our simulations. The analysis results are reported in the following context. And the all results are measured in seconds.

5.2 Results analysis

5.2.1 The comparison between our model results and computer simulations

The formula used to calculate the gap between the results of our model and computer simulations is

We compared our model results with those of the computer simulations under configurations 1 and 2, and show the results in Tables 1 and 2.

From these two tables, we can first find that the maximum “Deviation (%)” is less than 0.84 % except when the number of tiers is 1, which reveals that our continuous model is quite accurate. When the number of tiers is 1, the assumption of the continuous pick face is not so reasonable. So in this case, the “Deviation (%)” is exceptionally larger.

Second, after comparing the results in Tables 1 and 2, we observe that with the same shape factor b, the value of “Deviation (%)” under Configuration 1 is larger than that under Configuration 2. This finding reflects the fact that as the number of cells in the rack increases, the discrete rack is closer to a continuous pick face and therefore the continuous model is more accurate. This also gives us a hint that when the area of the rack is fixed, our model is more accurate for the configuration with larger number of cells.

Finally, we can see that the travel time of a DC is a convex function of the shape factor b. When the shape factor b is less than 1 and increases, the travel time decreases. However, the expected travel time increases as the value of b when b ≥ 1. The travel time reaches its minimum when b = 1, where the smallest values of our model and the simulation under configuration 1 are 136.31 and 137.26, respectively. This verifies that the square-in-time rack is the most efficient design of the rack in terms of the expected travel time. From the practical perspective, it provides a theoretical basis for the design of rack, which is very important for warehouse designers.

5.2.2 The comparison between our model results and those of Vasili et al. (2006)

We present the comparison results of our model and the model by Vasili et al. (2006) in Tables 3 and 4. The formula used to calculate the “Deviation (%)” is

Since Vasili et al. (2006) considered the SC (manipulate one unit load) and our work considers the DC (manipulate two unit loads), to make it fair we halved our calculated expected travel time for comparison. So the results in Tables 3 and 4 present the average travel time for manipulating one unit load, which is the reciprocal of the throughput capacity (the number of unit loads per time unit) of the system.

In the model by Vasili et al. (2006), the travel time is also a convex function of the shape factor with the minimum value at b = 1. The reason why the optimal shape factor equals to 1 is that an operation contains the horizontal and vertical movements and only both of these two movements are finished, the operation is carried out. So we conjecture that the performance is optimal when the horizontal and vertical travel times keep balance.

Under Configuration 1, the smallest travel time of our model and the model of Vasili et al. (2006) are 68.16 and 85.50, respectively. In terms of the travel time, our model is more efficient than that of Vasili et al. (2006), with an improvement of over 20.29 %. Moreover, Tables 3 and 4 present that the average values of “Deviation (%)” under Configurations 1 and 2 are around 27.76 and 26.85 %, respectively. This also shows that the DC is better than the SC. We manipulate two unit loads per DC transaction while one load unit is dealt with in an SC transaction. That is to say, we manipulate one more unit load only at the cost of increasing the travel time between the storage location and the retrieval location, which is far less than the travel time needed by an SC transaction.

6 Conclusions

In this paper, we analyze the expected travel time of the DC in the SP-AS/RS with the I/O dwell point policy. The use of SP-AS/RS can bring many advantages, such as the capability of handling very heavy loads and the high fault tolerance. We first present a continuous travel time model for the DC. Secondly, we validate the accuracy of our model by computer simulations. We find that the results of our model are quite close to those generated by computer simulations under each test rack configuration. Thirdly, we also find that the travel time of the DC reaches its minimum when the shape factor b of the rack is equal to 1. This verifies that the square-in-time rack leads to the smallest expected travel time in our SP-AS/RS. This result can provide a theoretical basis for the design of rack, which is very important for warehouse designers. Fourthly, when the area of the rack is fixed, our continuous model can more accurately represent the actual discrete rack under the configuration with larger number of cells than the one under the configuration with smaller number of cells. Finally, we show the superiority of our model by comparing it with the results of Vasili et al. (2006). In other words, our application of DC is better; it manipulates two unit loads per transaction while an SC transaction only deals with one unit load. Manipulating one more unit load only consumes the travel time between the storage location and the retrieval location, which is far less than the travel time needed by an individual SC transaction.

It is worth to note that our travel time analysis is for a scenario that is a lower bound of the performance of the DC. The results of the paper cannot be taken as the average performance of the DC. In the future research, we will focus on considering the best case performance of DC. Analyzing the impacts of different storage assignment policies and dwell point policies on the expected travel time of the DC in the SP-AS/RS is also a promising research direction.

References

Ashayeri J, Heuts RM, Beekhof M, Wilhelm MR (2001) On the determination of class-based storage assignments in an AS/RS having two I/O locations. Tilburg University, Tilburg

Baker P, Canessa M (2009) Warehouse design: a structured approach. Eur J Oper Res 193(2):425–436

Bekker J (2013) Multi-objective buffer space allocation with the cross-entropy method. Int J Simul Model 12(1):50–61

Bozer YA, White JA (1984) Travel-time models for automated storage/retrieval systems. IIE Trans 16(4):329–338

Chang SH, Egbelu PJ (1997a) Relative pre-positioning of storage/retrieval machines in automated storage/retrieval system to minimize expected system response time. IIE Trans 29(4):313–322

Chang SH, Egbelu PJ (1997b) Relative pre-positioning of storage/retrieval machines in automated storage/retrieval systems to minimize maximum system response time. IIE Trans 29(4):303–312

De Koster RBM, Le-DucT Roodbergen KJ (2007) Design and control of warehouse order picking: a literature review. Eur J Oper Res 182(2):481–501

Egbelu PJ (1991) Framework for dynamic positioning of storage/retrieval machines in an automated storage/retrieval system. Int J Prod Res 29(1):17–37

Egbelu PJ, Wu CT (1993) A comparison of dwell-point rules in an automated storage/retrieval system. Int J Prod Res 31(11):2515–2530

Graves SC, Hausman WH, Schwarz LB (1977) Storage-retrieval interleaving in automatic warehousing systems. Manage Sci 23(9):935–945

Gu J, Goetschalckx M, McGinnis LF (2007) Research on warehouse operation: a comprehensive review. Eur J Oper Res 177(1):1–21

Hausman WH, Schwarz LB, Graves SC (1976) Optimal storage assignment in automatic warehousing systems. Manage Sci 22(6):629–638

Hu YH, Huang SY, Chen C, Hsu WJ, Toh AC, Loh CK, Song T (2005) Travel time analysis of a new automated storage and retrieval system. Comput Oper Res 32(6):1515–1544

Hu YH, Zhu ZD, Hsu WJ (2008) AS/RS based yard and yard planning. J Zhejiang Univ Sci A 9(8):1083–1089

Hu YH, Zhu ZD, Hsu WJ (2010) Load shuffling algorithms for split-platform AS/RS. Robot Comput Integr Manuf 26(6):677–685

Hur S, Lee YH, Lim SY, Lee MH (2004) A performance estimation model for AS/RS by M/G/1queuing system. Comput Ind Eng 46(2):233–241

Lerher T, Sraml M, Kramberger J, Potrc I, Borovinsek M, Zmazek B (2006) Analytical travel time models for multi aisle automated storage and retrieval systems. Int J Adv Manuf Technol 30(3–4):340–356

Lerher T, Potrc I, Sraml M, Tollazzi T (2010a) Travel time models for automated warehouses with aisle transferring storage and retrieval machine. Eur J Oper Res 205(3):571–583

Lerher T, Sraml M, Potrc I, Tollazzi T (2010b) Travel time models for double-deep automated storage and retrieval systems. Int J Prod Res 48(11):3151–3172

Lerher T, Sraml M, Potrc I (2011) Simulation analysis of mini-load multi-shuttle automated storage and retrieval systems. Int J Adv Manuf Technol 54(1–4):337–348

Lerher T, Edl M, Rosi B (2014) Energy efficiency model for the mini-load automated storage and retrieval systems. Int J Adv Manuf Technol 70(1–4):97–115

Lerher T, Ekren BY, Dukic G, Rosi B (2015a) Travel time model for shuttle-based storage and retrieval systems. Int J Adv Manuf Technol 78(9–12):1705–1725

Lerher T, Ekren YB, Sari Z, Rosi B (2015b) Simulation analysis of shuttle based storage and retrieval systems. Int J Simul Model 14(1):48–59

Linn RJ, Wysk RA (1987) An analysis of control strategies for an automated storage/retrieval system. INFOR 25(1):66–83

Manzini R, Gamberi M, Regattieri A (2006) Design and control of an AS/RS. Int J Adv Manuf Technol 28(7):766–774

Meller RD, Mungwattana A (2005) AS/RS dwell-point strategy selection at high system utilization: a simulation study to investigate the magnitude of the benefit. Int J Prod Res 43(24):5217–5227

Peters BA, Smith JS, Hale TS (1996) Closed form models for determining the optimal dwell point location in automated storage and retrieval systems. Int J Prod Res 34(6):1757–1772

Regattieri A, Santarelli G, Manzini R, Pareschi A (2013) The impact of dwell point policy in an automated storage/retrieval system. Int J Prod Res 51(14):4336–4348

Roodbergen KJ, Vis IFA (2009) A survey of literature on automated storage and retrieval systems. Eur J Oper Res 194(2):343–362

Rouwenhorst B, Reuter B, Stockrahm V, Van Houtum GJ, Mantel RJ, Zijm WHM (2000) Warehouse design and control: framework and literature review. Eur J Oper Res 122(3):515–533

Sari Z, Saygin C, Ghouali N (2005) Travel-time models for flow-rack automated storage and retrieval systems. Int J Adv Manuf Technol 25(9):979–987

Smew W, Young P, Geraghty J (2013) Supply chain analysis using simulation, Gaussian process modelling and optimisation. Int J Simul Model 12(3):178–189

Thonemann UW, Brandeau ML (1998) Optimal storage assignment policies for automated storage and retrieval systems with stochastic demands. Manage Sci 44(1):142–148

Valili MR, Tang SH, Homayouni SM, Ismail N (2006) Comparison of different dwell-point policies for split-platform automated storage and retrieval system. Int J Eng Technol 3(1):91–106

Van den Berg JP (1999) A literature survey on planning and control of warehousing systems. IIE Trans 31(8):751–762

Van den Berg JP (2002) Analytic expressions for the optimal dwell-point in an automated storage/retrieval system. Int J Prod Econ 76(1):13–25

Van den Berg JP, Gademann AJRM (1999) Optimal routing in an automated storage/retrieval system with dedicated storage. IIE Trans 31(5):407–415

Vasili MR, Tang SH, Homayouni SM, Ismail N (2008) A statistical model for expected cycle time of SP-AS/RS: an application of Monte Carlo simulation. Appl Artif Intell 22(7–8):824–840

Acknowledgments

This research was partially supported by the National Natural Science Foundation of China (Grant No. 71131004).

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Calculation of \(P\left( {\left| {x_{1} - x_{2} } \right| \le z} \right)\)

where Q z is the area bounded by the lines: \(u = t + z,\) \(u = t - z,\) \(0 \le u \le 1\) and \(0 \le t \le 1\).

Then, we have

As x 1 and x 2 are independent and have the same probability distribution function, it is easy to get

Thus, we have

Rights and permissions

About this article

Cite this article

Liu, T., Xu, X., Qin, H. et al. Travel time analysis of the dual command cycle in the split-platform AS/RS with I/O dwell point policy. Flex Serv Manuf J 28, 442–460 (2016). https://doi.org/10.1007/s10696-015-9221-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10696-015-9221-7