Abstract

Automated Storage and Retrieval System (AS/RS) is driven by multiple motors for loading and unloading the items (z-axis) onto the fork or stacker, then moving the items horizontally (x-axis) and vertically (y-axis) at a time. Thus, it is practical to determine the speed configuration for each movement. To be responsive, it is reasonable to set the speed as fast as possible. However, high speed leads to high energy consumption which is undesirable in the context of green warehousing. Given that the speed changes dynamically, it is important to have an advanced optimization model for balancing both objectives and providing accurate estimation. This study proposed metamodel-based simulation–optimization (MSO) allowing to jointly optimize four speed-related variables namely horizontal speed (x), vertical speed (y), fork or depth speed (z), and acceleration/deceleration under the dynamicity of AS/RS. A case study was given in a warehouse comprising five cranes and ten racks. Using Desirability Function Analysis, the optimal speed configuration is obtained efficiently for minimizing travel time and energy consumption of AS/RS. The result also shows that row-based storage provides better responsiveness and energy efficiency than random-based storage. Further, rack design also indicates a significant impact on the AS/RS speed configuration.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The use of Automated Storage and Retrieval System (AS/RS) in modern and smart warehouses holds a vital role in better use of space, accuracy, and efficient picking and replenishment processes [1]. Besides the operational advantages, AS/RS also offers safety such as resistance to earthquakes, avoidance of product damage, and enhanced occupational health of laborers [2]. Thus, AS/RS has gained popularity, especially in the current growth of e-commerce and the need for urban logistics [3]. Global e-commerce also has shifted customer behavior where responsiveness is a key for business competition [4]. In the context of AS/RS, it has a direct relation with travel time. At the same time, the need for green warehouses is also necessary right now due to global warming [5], whereas, AS/RS consumes a lot of energy to move and load heavy items [6]. Thus, AS/RS should be designed as responsive as possible towards energy efficiency which strongly affects operational cost and emission.

The trade-off between responsiveness and energy efficiency becomes clearer in AS/RS where speed configuration plays a key role function. AS/RS speed drives the overall movement velocity in AS/RS including vertical movement, horizontal movement, loading, and unloading, where the speed changes dynamically due to acceleration and deceleration. The speed needs to be set as fast as possible for being responsive, but high speed leads to high energy consumption. Due to the variety of movements, this leads to multi-speed configuration problem which is quite complex amidst trade-off objectives. Further, due to the complexity of AS/RS operation and dynamic nature of warehouse environment, optimizing the multi-speed AS/RS can be complicated [7].

Most prior researches assumed AS/RS to move at constant speeds, neglecting the acceleration and deceleration in reality [8]. It is in line with the approach used namely analytical model for AS/RS [9] where the linearity plays an important property. However, the acceleration and deceleration significantly influence AS/RS performance [10], whereas, neglecting practical application of AS/RS due to simplifications and assumptions can result to bias and inaccurate representation of real-world AS/RS operations [11]. Furthermore, most previous studies in AS/RS considered only speed for horizontal (x) and vertical (y) directions [8, 9] without considering depth (z) direction that is done by fork of AS/RS which can influence the loading/unloading process. In fact, each direction can have different motors resulting in different speed configuration leading to significantly different overall performance. Thus, there is a need of optimization framework for multi-speed configuration by balancing the energy efficiency and responsiveness of AS/RS.

This study aims to develop a near optimal and practical multi-speed configuration model for green AS/RS, enhancing accuracy and alignment with real-world AS/RS operations. A Metamodel-based Simulation–Optimization (MSO) framework is proposed and built through the factorial design experiments as a decision-making tool. Compared to general simulation–optimization method such as Simheuristics, MSO emphasizes on computational efficiency of global optimization process due to metamodel built while still considering the dynamicity, complexity, and uncertainty captured from simulation experiments. Further, the conflicting objectives are unified through composite Desirability Function Analysis (DFA) enabling to solve the trade-off. To the best of our knowledge, there is no previous study investigating the influence of AS/RS multi-speed configuration on responsiveness and energy consumption. The proposed optimization framework and the experimental results are expected to provide useful method and practical information for researchers and practitioners. This issue is particularly relevant since speed configuration has taken place at the strategic level of any material handling systems, specifically with the effort to maintain customer satisfaction towards green warehousing.

The remainder of this study is organized as follows. In Section 2, the literature review regarding the AS/RS speed, including their modeling techniques, is reviewed to generate the state of the art of this study. In Section 3, the proposed methodology to optimize for multi-speed AS/RS is explained in detail. In Section 4, the process of AS/RS simulation modeling is outlined allowing for experimenting different speed of AS/RS. In Section 5, MSO with DFA was performed under specific case study. Finally, conclusion and future directions are given in Section 6.

2 Literature review

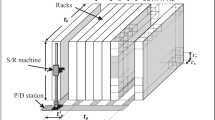

AS/RS offers flexibility in its operations with various complex decisions [7, 9]. Each decision is applied through computer-controlled programs in the Warehouse Management System (WMS) such that AS/RS can load, unload, and move both horizontally and vertically served by the S/R machine working in the middle of the racks [8]. Thus, speed determination in AS/RS plays an important role since it drives the overall movement velocity. AS/RS speed generally denotes the maximum speed of each movement, including vertical, horizontal, and loading/unloading, where the speed changes dynamically due to acceleration and deceleration. Furthermore, proper configuration of these parameters is crucial, particularly when prioritizing the consideration of AS/RS energy consumption [12] and responsiveness, e.g., travel time [13].

There are very limited studies investigating the speed configuration of AS/RS in the literature. While most previous studies assumed constant speed, the study by [14] proposed a travel-time model for AS/RS that took into account real-world speed profiles under random-based storage assignment. Continuing this research, a subsequent study proposed an analytical model by considering acceleration and deceleration with different speed profiles and command cycle type under class-based and full-turn-over-based storage focusing on travel time [10]. Another study proposed an AS/RS travel time model with random storage under different speeds with the focus on optimizing storage rack design [11]. Most other studies have focused on storage assignment [15], dwell-point positioning [16], physical design [17], and scheduling [18] with maximum speed given. This is reasonably clear if the research objective only studies the time-related performances such as travel time [19] and response time [20]. However, in the context of green-related performances, speed becomes an important decision factor consuming energy. Thus, speed configuration plays a key role in balancing energy and responsiveness of AS/RS.

In the context of AS/RS modeling, many previous studies developed a mathematical model to estimate the AS/RS travel time as performance evaluation [21, 22]. Regardless of inherent strict assumptions, analytical models allow for reaching travel time optimality [9]. However, the static and certain condition assumptions lead to impracticality of AS/RS real-world applications [9]. Thus, a simulation model has been applied to evaluate AS/RS performance with the flexibility performance measures under uncertainties [23, 24]. Despite the advantages of a simulation model, reaching optimality with a simulation-based experiment is a tedious task [25]. Therefore, a simulation–optimization (SO) has been proposed for efficient sampling schemes in optimizing a stochastic system via simulation with highly complex and non-linear characteristics [26]. Several studies have successfully used SO by integrating simulation with metaheuristics for AS/RS optimization such as Ant Colony Optimization (ACO) for request sequencing [27], Genetic Algorithm (GA) for storage assignment [15], and Whale Optimization Algorithm (WOA) for scheduling [18]. However, this approach can be computationally expensive when a direct simulation evaluation is used extensively especially if the search space is too large and the probability to stuck on local optimal is high.

Instead of using simulation with a direct evaluation extensively, a MSO methodology has been proposed [28]. In this context, a metamodel or a surrogate model is an abstraction form of the simulation model that has explicit form, deterministic output, and affordable computation to evaluate [29]. The metamodel is also transferable and understandable from a practical point of view when it is built through a regression model [30]. In AS/RS literature, there is one previous study that has used simulation metamodeling to measure the energy demand of AS/RS without performing optimization [17]. However, MSO has been successfully used in different material handling systems such as Automated Guided Vehicle (AGV) [31] and semiconductor manufacturing Automated Material Handling System (AMHS) [32].

Potrč et. al. [33] introduced simulation-based travel time models for AS/RS with a randomized storage assignment, considering single and multi-shuttle systems. This research implements “Strategy x” in establishing the relationship between average travel times and throughput capacity across various high storage racks and velocity profiles of the S/R machines. In 2014, Lerher et al. [34] introduced a mathematical model for energy efficiency of mini-load AS/RS under randomized storage assignment and adjacent I/O point. The model took into account factors such as total travel time, throughput capacity, engine power, energy consumption, and CO2 emissions. The decision factors in the model were the velocity profile including horizontal speed, vertical speeds, and acceleration/deceleration, the mass of AS/RS, and hoisted carriage. This research concluded that higher AS/RS velocity resulted in higher energy consumption and CO2 emissions.

Finally, the related works are summarized and compared with this study according to some protocols such as the AS/RS performance, multi-speed variables considered, the approaches used, and the settings of Input/Output (I/O) point and storage assignment. The related works are summarized as presented in Table 1. In essence, most of previous studies have considered a variety of speeds in AS/RS, but they set them as fixed values, instead of investigating the multi-speed configuration as the decision point. Thus, there is no clear information for logistics or warehouse managers on optimally setting the AS/RS speed for each movement. Apart from that, only a few studies consider the green aspect in AS/RS. In this study, energy consumption is considered one of the objectives towards sustainability. Further, the trade-off between energy and responsiveness is also studied. In terms of approach, some studies have utilized SO in AS/RS applications, but this study enhances the use of SO by utilizing metamodel with DFA such that efficiency and optimality can be reached amidst the trade-off performances.

3 Methodology

This study consists of three main stages as an effort to fully optimize the multi-speed configuration of AS/RS as presented in Fig. 1. The detailed explanation is described point-by-point as follows.

3.1 Simulation modeling and performance formulation stage

First, the real system of AS/RS should be modeled via computer simulation model. Using discrete-event simulation, the complexity, dynamicity, and uncertainty of AS/RS can be considered which can lead to accuracy and practicality of the model. Then, simulation model passes the verification and α validation processes, ensuring that the simulation model represents the real system without error recognized. The credible simulation model was then used for experiment. Given that AS/RS can move in different axes, i.e. horizontal (x), vertical (y), and depth by fork (z), each axis is driven by different motors. Thus, it is important to determine the maximum speed for each. Further, each speed changes dynamically based on acceleration and deceleration variable. Thus, in this study, the four factors representing AS/RS multi-speed configuration are considered namely acceleration and deceleration which are seen as the same factor, horizontal speed for horizontal movement, vertical speed for vertical movement, and fork speed for loading and unloading movements, as shown in Fig. 2.

This stage also includes to formulate mathematical models for measuring two conflicting objectives namely travel time per unit (\(TT\)) and total energy consumption (EC). The expected TT can be measured through Eq. 1, where \({T}_{TL}\) is the time for traveling loaded, \({T}_{TE}\) is the time for traveling empty, \({T}_{L}\) is the loading time, \({T}_{U}\) is the unloading time, and \(N\) represents the total throughput or requests fulfilled, both storage and retrieval tasks.

For expected EC, it is measured based on force and work principles. A recent study [35] provides detail explanation where each AS/RS movement has specific energy consumption. However, it still lacks on considering comprehensive mass of AS/RS where only masses of shuttle and item are considered. In fact, different AS/RS movement will lift different part of AS/RS which can lead to different mass as presented in Fig. 3 comprising crane for horizontal movement, shuttle for vertical movement, fork for loading and unloading, and item loaded by fork. This study improves the previous energy consumption formulation by providing a more accurate calculation. Table 2 shows the nomenclature for EC formulation, and Eq. 2 provides a formula for calculating EC in kilojoules (kJ). It includes five components related to AS/RS movement: horizontal movement energy \({(E}_{MH})\), vertical upward movement energy \({(E}_{MVU})\), vertical downward movement energy \({(E}_{MVD})\), loading energy with items \({(E}_{L})\), and unloading energy without items \({(E}_{U})\), presented in Eqs. 3–7, respectively. When AS/RS moves horizontally, it lifts all masses of AS/RS. When AS/RS moves vertically only, it lifts all masses except for crane. When AS/RS loads or unloads, it lifts only fork and item loaded. Additionally, it is crucial to look whether each movement reaches maximum velocity or not. If the maximum velocity (\({V}_{top}={V}_{max}\)) is reached, energy is needed for acceleration, steady state, and deceleration. Otherwise, steady-state energy is not considered. All equations are finally embedded in the simulation program.

3.2 Metamodeling stage

Given the set of the inputs of decision factors and the set of outputs of objective functions or performance measures from previous simulation-based experiment, regression-based metamodel is then developed with second-degree polynomial and two-interaction term for each performance measure (\({y}_{o}\)) considered. The generic form is shown in Eq. 8 where \({\beta }_{0}\) is a constant term, \({\beta }_{i}\) is the main effect of factor i, \({\beta }_{ij}\) is the interaction effect of factor i and j, \({\beta }_{{i}^{2}}\) is the quadratic effect of factor i, and k is number of factors considered. This metamodel is significantly more efficient for optimization purpose without requiring expensive simulation evaluation, allowing to explore the global optimization for multiple decision factors. Further, the white-box form allows for transparency and flexibility. The metamodel accuracy is assessed through statistical test, i.e., analysis of variance (ANOVA) to see the significancy of main and interaction effects among all factors. Thus, the insignificant variables can be taken out from the metamodel. Finally, legitimize the developed metamodel against simulation result via β validation which measures the mean absolute percentage error (MAPE) as presented in Eq. 9 where \({y}_{S}\) is the yield of simulation, \({y}_{M}\) is the yield of metamodel, and n is the number of data being compared.

3.3 Metamodel-based simulation–optimization stage

The valid metamodel is then used to perform optimization by first unifying all conflicting objectives into single objective via desirability function analysis (DFA). DFA aims to find the best solution by maximizing desirability score (D) [36]. In order to calculate D, each \({y}_{o}\) is first transformed into individual desirability function \({(d}_{o}\left({y}_{o}\right))\). For minimization objective, Eq. 10 is used as a transformer where \({T}_{o}\) is a small enough value for the objective o, \({s}_{o}\) is a weight, and \({U}_{o}\) is the desired upper value. This transformation implies that if \({y}_{o}\) is entirely undesirable, then \({d}_{o}\left({y}_{o}\right)=0\). Otherwise, \({d}_{o}\left({y}_{o}\right)=1\) representing the perfect value. Finally, unification for each \({d}_{o}\left({y}_{o}\right)\) is done by the geometric mean represented in Eq. 11 where l is the number of objectives which can be optimized as a maximization problem.

4 Simulation-based experiment and discussion

4.1 Case description and experimental design

The warehouse system given by [35] is adopted as a case study. There are five aisles in the warehouse, each controlled by one unit-load AS/RS. Each aisle is located in the middle of two racks. Thus, it contains ten single-deep racks, each with 40 columns and six layers, totaling 240 cells per rack. Each AS/RS is dedicated to handle two racks. Entering products are delivered to the warehouse via conveyor. AS/RS can move vertically and horizontally simultaneously, following a Chebyshev distance. Only one unit load or pallet can be transported at a time for retrieval or storage or single batching. There are 20 different product types considered, with turnover rates uniformly distributed and each product having different weights. Each rack stores two different product types, one light and one heavy. There is no weight constraint in the racks, only a slot space constraint. For AS/RS setting, a hybrid cycle is used. Request Sequencing follows First Come First Serve (FCFS) rule. Dwell Point Positioning is based on the last-visited. Input and Output configuration is opposite or two-side docking.

Design of Experiment (DoE) was shown in Table 3. It can be seen that all four factors related to speed variables are in the form of continuous values which the ranges are different depending on the speed type. Practically speaking, horizontal speed can reach higher maximum speed among others, followed by vertical, and fork speeds, while acceleration and deceleration are generally set the same. In addition to multi-speed variables, storage assignment is also included to learn the impact of different storage methods. Using full factorial design principle, there will be 108 scenarios.

4.2 Simulation model construction

Since the focus of this study is for configuring AS/RS multi-speed, the logical process of how AS/RS configure different speed is shown in Figure 4. It can be seen that when request is arrived, either storage or retrieval, it is important to assess the distance measuring different positions of AS/RS and the request location whether it differs horizontally only, vertically only, or both. This is particularly relevant because AS/RS’s moves are driven by different motors and AS/RS can move horizontally and vertically at a time following Chebyshev metric. After it has been determined, AS/RS starts to move in empty loaded. If the distance is quite far, AS/RS performs acceleration first until it reaches maximum velocity, then moving in steady-state speed, and finally deceleration until it stop. If the distance is close, AS/RS performs acceleration first; before it reaches maximum speed, deceleration is performed directly. Then, the loading process is performed where the speed depends on fork speed. Afterwards, similar idea is used to deliver request to the desired location with additional mass due to item loaded. Finally, the unloading process is done. This logical process is embedded in simulation software.

In this study, FlexSim as discrete-event simulation software is used. The simulation model is built under two different setting namely random-based storage and row-based class assignment as shown in Fig. 5, respectively. It can be noticed that the item placement is totally different. Any request whether storage (supply) or retrieval (demand) is generated randomly under normal distribution with mean 19 and standard deviation 4 in second unit, representing the real situation where both variables are uncertain. For initialization phase, it is programmed so that the states are in a steady-state condition, instead of performing warming up for efficiency purpose. It can be done by directly generating products, tasks, and AS/RS locations in the warehouse randomly under specific policy used. To maintain the availability of products in warehouse, capacity maintenance rule is applied instead of adopting certain inventory control which can avoid stockout and overstock in the warehouse, leading to unbiased assessment [35]. For transparency purpose, the programming showing how AS/RS is configured in terms of multi-speed is presented in Fig. 6. It can be seen that all speed-related variables are stored in Global Table first which link with simulation experiment control. These variables are updated whenever AS/RS is reset by using “setProperty” function. The corresponding variable is also used in energy consumption formulation which is embedded in Process Flow, corresponding to AS/RS movement. In Fig. 6, it shows for measuring energy consumption in vertical movement which only considers the masses of item, fork, and shuttle.

After developing the simulation model, validation and verification were conducted to ensure its accuracy in representing the real system without any programming errors. Verification involved a structured walk-through-based debugging process. For validation, two techniques were used. Firstly, animation was employed to visually inspect the operational behavior in the model step-by-step [37]. Secondly, extreme conditions were tested to observe the model’s behavior and output under extreme inputs [38]. The study compared system utilization by varying the number of requests under normal and extreme conditions, expecting that AS/RS states would be extremely higher with extremely higher number of requests. Verification confirmed the absence of errors or exceptions in the simulation program. Validation through animation confirmed that the AS/RS moved logically based on predetermined logic and entity flow was tracked accurately. The model also performed as expected under extreme conditions. Therefore, the simulation model was considered verified and validated.

4.3 Metamodel-based optimization results and discussion

Since we cope with stochastic simulation in order to consider request arrival uncertainties, each scenario is evaluated under ten independent replications and average value will be taken as expected objectives. The warehouse is simulated for eight operating hours. These output data will be used to create the meta-model. Common Random Number (CRN) principle is applied for reducing variance between scenario. All parameters needed are summarized in Table 4 where some values are adopted from the literature [35] and some are from the observation. For convenient purpose, the experimental result is classified into two groups based on the storage assignment used.

4.3.1 Random-based storage

The second-order regression-based metamodels are first developed for both objectives in random-based storage setting and later for row-based storage. The metamodels for energy consumption (EC) and travel time (TT) are shown in Eqs. 12 and 13, respectively, where HS represents horizontal speed, VS represents vertical speed, FS represents fork (depth) speed, and AD represents acceleration and deceleration. The feature selection has been done through backward stepwise selection with minimum α = 0.05 while always maintaining the basic single variables for assessing their impacts. These white-box models have good performance indicated by high Predicted R2 namely 99.46% for EC and 99.92% for TT. The β validation is done by calculating MAPE on 15 unseen data that are randomly selected. The obtained MAPE is 4.5% for EC and 3.1% for TT. The model is considered to be accurate once the MAPE is less than 5% [39]. Thus, the metamodels are considered to be valid. The analysis of variance (ANOVA) showing the significancy of each variable is presented in Appendix Table 5.

Based on the metamodel built, the response surface can be plotted and visualized in Fig. 7a, b for energy consumption and travel time, respectively. It can be seen that the non-linear relationship appears for both objectives. The positive trend is given by the energy consumption which is clearly caused by the faster motors move leading to the higher energy consumption, whereas, the negative trend is given by travel time. This validates that a very fast AS/RS speed indeed results in the shorter travel time, but it comes with high energy consumption. The interesting result is shown by the impact of horizontal speed to travel time. Within around 1 to 3 m/s horizontal speed can reduce travel time but starting from 3 to 4 m/s, travel time starts to increase. This is caused by the fact that the travel time is impacted by the combination among all speed variables, not only horizontal speed. When horizontal speed is set high, AS/RS may reach the desired horizontal position faster, but AS/RS may not reach the desired vertical position yet. Further, multi-speed configuration also affects another important decision factors namely request sequencing since the different speed may lead to the different request availability that can affect overall performances. This implies that it is important to optimize AS/RS multi-speed with other factors concurrently.

Using Minitab software, DFA is performed, and the optimal configuration of AS/RS multi-speed is shown in Fig. 8. It can be seen that the composite desirability can be obtained by 70.7% score where the optimal solution for a random-based storage involves implementing horizontal speed as 2.5455 m/s, vertical speed as 1 m/s, fork speed as 1.8889 m/s, and acceleration/deceleration as 0.5 m/s2. This results in 31.03 s TT and 1.015E + 05 kilo Joule EC. Figure 8 also indicates that horizontal speed seems to be the most significant factors compared other speed variables. This is particularly relevant because in this study, the rack shape or design is long horizontally but short vertically. Thus, it can be concluded that the rack shape has a strong correlation with the AS/RS multi-speed configuration.

4.3.2 Row-based storage

The metamodel is now developed for row-based storage setting. The metamodels of energy consumption and travel time are shown in Eqs. 14 and 15, respectively. These metamodels have good performance indicated by high predicted R2 namely 99.77% for EC and 99.94% for TT, while the β validation shows that the MAPE scores obtained are 4.92% for EC and 3.81% for TT. Thus, the metamodels are considered to be valid. The ANOVA result is shown in Appendix Table 6.

The surface plots are also visualized in Fig. 9a, b for EC and TT, respectively. Overall, the surface plot in row-based storage delivers similar information as shown in the random-based storage. The interesting difference is shown in the range of objectives instead of the impact of each speed variable. The row-based storage provides significantly lower EC and TT compared to the random-based storage on average. This is reasonable because in row-based storage, the heavier items are allowed to be stored in the lower row while the lighter items are stored in the higher row leading to the lower EC. Further, random-based storage provides more back-and-forth movement due to random selection leading to higher TT than row-based storage. This indicates that dedicating storage in rows is better than random, especially when the different item masses are considered.

DFA is then performed to optimize AS/RS multi-speed as shown in Fig. 10. The composite desirability can be obtained by 70.05% score where the optimal solution for a row-based storage involves implementing horizontal speed as 2.4848 m/s, vertical speed as 1 m/s, fork speed as 1.8485 m/s, and acceleration/deceleration as 0.5 m/s2. This optimal configuration is different from random-based storage only in horizontal speed and fork speed, while others remain the same namely setting the VS and AD at the lowest level. In addition, TT and EC obtained are 30.07 s and 8.954E + 04 kilo Joule, respectively. Since both objectives are better than random-based storage, it can be concluded that row-based storage leads to better responsiveness and energy efficiency than random-based storage. However, once the rack design and other AS/RS control policies change, the optimal speed configuration may be significantly different as well.

5 Conclusion

In this study, the multi-speed configuration problem of Automated Storage and Retrieval System (AS/RS) is addressed. Given that AS/RS can move under different axes, this problem consists of multiple variables namely horizontal speed (x), vertical speed (y), fork or depth speed (z), and acceleration/deceleration of AS/RS that needs to be set up concurrently. Since the speed changes dynamically, it is important to provide a model that can cope with dynamicity for providing practical and accurate estimation. A metamodel-based simulation–optimization (MSO) framework is proposed which can be used to optimize conflicting objectives namely energy consumption and responsiveness of AS/RS. The trade-off between both objectives is addressed via Desirability Function Analysis (DFA). While higher energy efficiency affects the lower cost and greener operation, the higher responsiveness affects customer satisfaction and overall efficiency. Based on the experiment, the proposed MSO is capable in optimizing multi-speed configuration of AS/RS efficiently under dynamic uncertainty and conflicting objectives. Thus, this study provides a practical optimization model to improve AS/RS multi-speed configuration prior implementation amidst trade-off condition. While efficient in reducing computational costs and time by approximating complex simulations, the proposed MSO may suffer from the drawback of model accuracy and generalizability such as not capturing all intricate dynamics of the actual simulation, leading to suboptimal or misleading results, thus, ensuring the metamodel accuracy is crucial. Future research can implement multi-speed configuration optimization for different automated material handling systems such as Autonomous Vehicle Storage and Retrieval Systems (AVS/RS), Shuttle Based Storage and Retrieval System (SBS/RS), or improved version of AS/RS such as dual-stacker AS/RS that can have different speed for each stacker [40]. Another optimization technique or machine learning-based metamodel may also improve effectivity and efficiency of the algorithm used in this study. For enhancing metamodel accuracy, advanced techniques like adaptive sampling and incorporating uncertainty quantification such as conformal prediction may better capture variability and improve robustness of optimization results.

Data availability

The detailed data are available from the corresponding author upon request. The AS/RS simulation model animation can be seen in the following link: https://www.youtube.com/watch?v=sLyrkdFwulw.

References

Edouard A, Sallez Y, Fortineau V, Lamouri S, Berger A (2022) Automated storage and retrieval systems: an attractive solution for an urban warehouse’s sustainable development. Sustainability 14(15):9518. https://doi.org/10.3390/su14159518

Fenercioğlu A, Soyaslan M, Kozkurt C (2011) Automatic storage and retrieval system (AS/RS) based on Cartesian robot for liquid food industry. In: 12th International Workshop on Research and Education in Mechatronics, pp 283–287

Settey T, Gnap J, Beňová D, Pavličko M, Blažeková O (2021) The growth of e-commerce due to COVID-19 and the need for urban logistics centers using electric vehicles: bratislava case study. Sustainability 13(10):5357. https://doi.org/10.3390/su13105357

Gupta S, Kushwaha PS, Badhera U, Chatterjee P, Gonzalez EDRS (2023) Identification of benefits, challenges, and pathways in E-commerce industries: an integrated two-phase decision-making model. Sustain Oper Comput 4:200–218. https://doi.org/10.1016/j.susoc.2023.08.005

Bartolini M, Bottani E, Grosse EH (2019) Green warehousing: systematic literature review and bibliometric analysis. J Clean Prod 226:242–258. https://doi.org/10.1016/j.jclepro.2019.04.055

Meneghetti A, Dal Borgo E, Monti L (2015) Decision support optimisation models for design of sustainable automated warehouses. Int J Shipp Transp Logist 7(3):266–294. https://doi.org/10.1504/IJSTL.2015.069127

M H, A K, T A (2019) The automatic storage and retrieval system: an overview. Int J Comput Appl 177(16):36–43. https://doi.org/10.5120/ijca2019919603

Roodbergen KJ, Vis IFA (2009) A survey of literature on automated storage and retrieval systems. Eur J Oper Res 194(2):343–362. https://doi.org/10.1016/j.ejor.2008.01.038

Gagliardi JP, Renaud J, Ruiz A (2012) Models for automated storage and retrieval systems: a literature review. Int J Prod Res 50(24):7110–7125. https://doi.org/10.1080/00207543.2011.633234

Wen UP, Chang D, Chen S (2001) The impact of acceleration/deceleration on travel-time models in class-based automated S/R systems. IIE Transactions (Institute of Industrial Engineers) 33(7):599–608. https://doi.org/10.1080/07408170108936857

Yang P, Miao L, Xue Z, Qin L (2015) Optimal storage rack design for a multi-deep compact AS/RS considering the acceleration/deceleration of the storage and retrieval machine. Int J Prod Res 53(3):929–943. https://doi.org/10.1080/00207543.2014.942441

Meneghetti A, Monti L (2013) Sustainable storage assignment and dwell-point policies for automated storage and retrieval systems. Prod Plan Control 24(6):511–520. https://doi.org/10.1080/09537287.2011.637525

Yang P, Miao L, Qin L, Xue Z (2013) The impact on designing storage rack for a multi-deep compact AS/RS on the speed profile of the storage and retrieval machine. In Proc 2013 6th Int Conf Inf Manag Innov Manag Ind Eng ICIII 2013 209–212.https://doi.org/10.1109/ICIII.2013.6702911

Chang DT, Wen UP, Lin JT (1995) The impact of acceleration/deceleration on travel-time models for automated storage/retrieval systems. IIE Transactions (Institute of Industrial Engineers) 27(1):108–111. https://doi.org/10.1080/07408179508936723

Zhou G, Mao L (2010) Design and simulation of storage location optimization module in AS/RS based on FLEXSIM. Int J Intell Syst Appl 2(2):33–40. https://doi.org/10.5815/ijisa.2010.02.05

Egbelu PJ, Wu CT (1993) A comparison of dwell point rules in an automated storage/retrieval system. Int J Prod Res 31(11):2515–2530. https://doi.org/10.1080/00207549308956880

Ertl R, Günthner WA (2016) Meta-model for calculating the mean energy demand of automated storage and retrieval systems. Logist J 2:9–14. https://doi.org/10.2195/lj_NotRev_ertl_en_201602_01

Hsu HP, Wang CN, Dang TT (2022) Simulation-based optimization approaches for dealing with dual-command crane scheduling problem in unit-load double-deep AS/RS considering energy consumption. Mathematics 10(21). https://doi.org/10.3390/math10214018

Xu X, Gong Y (Yale), Fan X, Shen G, Zou B (2018) Travel-time model of dual-command cycles in a 3D compact AS/RS with lower mid-point I/O dwell point policy. Int J Prod Res 56(4):1620–1641. https://doi.org/10.1080/00207543.2017.1361049

Meller RD, Mungwattana A (2005) AS/RS dwell-point strategy selection at high system utilization: a simulation study to investigate the magnitude of the benefit. Int J Prod Res 43(24):5217–5227. https://doi.org/10.1080/00207540500215617

Hausman WH, Schwarz LB, Graves SC (1976) Optimal storage assignment in automatic warehousing systems. Manage Sci 22(6):629–638. https://doi.org/10.1287/mnsc.22.6.629

Graves SC, Hausman WH, Schwarz LB (1977) Storage-retrieval interleaving in automatic warehousing systems. Manage Sci 23(9):935–945. https://doi.org/10.1287/mnsc.23.9.935

Bozer YA, White JA (1994) Travel-time models for automated storage/retrieval systems. IIE Transactions (Institute of Industrial Engineers). https://doi.org/10.1080/07408178408975252

Zhang Z, Wang X, Yang S, Wu Y, Du J (2020) Simulation and Analysis of the complex dynamic behavior of supply chain inventory system from different decision perspectives. Complexity 2020:7393848. https://doi.org/10.1155/2020/7393848

Dengiz B, Bektas T, Ultanir AE (2006) Simulation optimization based DSS application: a diamond tool production line in industry. Simul Model Pract Theory 14(3):296–312. https://doi.org/10.1016/j.simpat.2005.07.001

Baghel M, Agrawal S, Silakari S (2012) Survey of metaheuristic algorithms for combinatorial optimization. Int J Comput Appl 58(19):21–31. https://doi.org/10.5120/9391-3813

Roozbeh Nia A, Haleh H, Saghaei A (2017) Dual command cycle dynamic sequencing method to consider GHG efficiency in unit-load multiple-rack automated storage and retrieval systems. Comput Ind Eng 111:89–108. https://doi.org/10.1016/j.cie.2017.07.007

Soares do Amaral JV, Montevechi JAB, de C. Miranda R, de S. Junior WT (2022) Metamodel-based simulation optimization: a systematic literature review. Simul Model Pract Theory 114:102403. https://doi.org/10.1016/j.simpat.2021.102403

Barton RR (2020) Tutorial: metamodeling for simulation. In: Proceedings - Winter Simulation Conference, pp 1102–1116. https://doi.org/10.1109/WSC48552.2020.9384059

Parnianifard A, Azfanizam AS, Ariffin MKA, Ismail MIS, Ale Ebrahim N (2019) Recent developments in metamodel based robust black-box simulation optimization: an overview. Decis Sci Lett 8(1):17–44. https://doi.org/10.5267/j.dsl.2018.5.004

Chen JC, Chen TL, Teng YC (2021) Meta-model based simulation optimization for automated guided vehicle system under different charging mechanisms. Simul Model Pract Theory 106:102208. https://doi.org/10.1016/j.simpat.2020.102208

Kuo Y, Yang T, Peters BA, Chang I (2007) Simulation metamodel development using uniform design and neural networks for automated material handling systems in semiconductor wafer fabrication. Simul Model Pract Theory 15(8):1002–1015. https://doi.org/10.1016/j.simpat.2007.05.006

Potrč I, Lerher T, Kramberger J, Šraml M (2004) Simulation model of multi-shuttle automated storage and retrieval systems. J Mater Process Technol 157:236–244. https://doi.org/10.1016/j.jmatprotec.2004.09.036

Lerher T, Edl M, Rosi B (2014) Energy efficiency model for the mini-load automated storage and retrieval systems. Int J Adv Manuf Technol 70(1–4):97–115. https://doi.org/10.1007/s00170-013-5253-x

Rizqi ZU, Chou SY, Khairunisa A (2024) Multi-objective simulation-optimization for integrated automated storage and retrieval systems planning considering energy consumption. Comput Ind Eng 189:109979. https://doi.org/10.1016/j.cie.2024.109979

Harrington EC (1965) The desirability function. Ind Qual Control 21(10):494–498

Beck A (2008) Simulation: the practice of model development and use. J Simul 2(1):67–67. https://doi.org/10.1057/palgrave.jos.4250031

Sargent RG (2010) Verification and validation of simulation models. In: Proceedings - Winter Simulation Conference, pp. 166–183. https://doi.org/10.1109/WSC.2010.5679166

Chen J, Chou SY, Yu THK, Rizqi ZU, Hang DT (2022) System dynamics analysis on the effectiveness of vaccination and social mobilization policies for COVID-19 in the United States. Plos One. https://doi.org/10.1371/journal.pone.0268443

Rizqi ZU, Chou S-Y, Choon SS (2023) Performance of dual stacker automated storage and retrieval system (AS/RS) with double-deep configuration. In: 2023 IEEE 5th Eurasia Conference IOT Communication and Engineering (ECICE). IEEE, pp 683–687. https://doi.org/10.1109/ECICE59523.2023.10383137

Acknowledgements

This work was supported in part by the Intelligent Manufacturing Innovation Center from the Featured Areas Research Center Program within the framework of the Higher Education Sprout Project by the Ministry of Education in Taiwan.

Author information

Authors and Affiliations

Contributions

Zakka Ugih Rizqi: conceptualization, methodology, software, investigation, writing—original draft, writing—review and editing, data curation, validation, visualization. Shuo-Yan Chou: resources, funding acquisition, supervision, formal analysis, project administration.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

Appendix 2

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rizqi, Z.U., Chou, SY. Multi-speed configuration of AS/RS amidst responsiveness and energy efficiency trade-off: metamodel-based simulation–optimization. Int J Adv Manuf Technol 134, 1711–1728 (2024). https://doi.org/10.1007/s00170-024-14206-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-14206-2