Abstract

Periods of fire resistance are pervasive in the field of fire engineering. They are the basis of prescriptive structural fire guidance and also the end result of some quantitative analyses. Time equivalence methods are one such calculation approach that is used to define periods of fire resistance. However, these calculations often do not inherently consider the fundamental design challenges. These challenges are the fire safety goals and the constraints of the building and the physical world. The appropriate balance of these challenges is a solution. This paper further defines these concepts and gives examples of their application in the context of time equivalence analysis. It is found that the existing time equivalence methods do not adequately consider the challenges. An alternative framework, adopting a risk based approach, enables appropriate consideration of the goals and constraints to obtain a solution for structural fire resistance. This approach is sufficiently flexible that its component pieces can be improved and updated as new engineering techniques become available.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The idea of a “period of fire resistance” for elements of structure is pervasive in the field of fire engineering. It has become a universal method of specifying a structural system to achieve a required level of fire protection, whether the requirements come from a prescriptive code or a quantitative analysis. The design methods, however complex, are communicated in terms of periods of fire resistance against a standard fire [1]. This has the advantage of providing a common language in which designers, contractors, and regulators can speak. However, it can also be a hindrance to addressing the fundamental design challenges, as the conversation becomes one about fire resistance periods rather than about the actual goals and constraints that need to be considered to understand how a building is likely to behave during a fire.

One methodology used to determine the period of loadbearing fire resistance for building design is the time equivalence method. There are a number of formulations of this method. One common feature of all formulations of the time equivalence method is that they require the user to define various inputs. The inputs are related to physical constraints of the building (such as ceiling height or floor area) and to the usage of the building (such as fuel load). The time equivalence method requires the user (the engineer) to select the input values for each of the key parameters.

The time equivalence concept originated with Ingberg [2]. He aimed to correlate fuel load with an ‘equivalent’ duration of exposure to the standard fire, which had been first adopted a decade earlier. He conducted a series of tests to better understand this relationship and generate data for the comparison. Originally, Ingberg populated his test compartments with discarded furniture and paper records. He recognized that by selecting a particular amount of combustible material, and using this as a benchmark for defining “light office” classification, he was effectively taking an average, i.e. he understood that some offices in the real world would have more combustibles, and some less. Whether inadvertent or not, this resulted in the definition of a performance expectation, namely that the compartment should withstand burnout for an average fuel load (of the typical cellulosic-based office furnishings of the period).

This paper describes the fundamental design challenges that face all engineers and shows how these can be answered in the context of time equivalence, rather than relying on the existing methods, which often do not explicitly consider the goals and constraints.

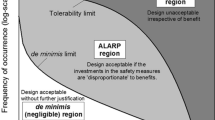

2 The Challenges of Design

For any design challenge, there will be goals and constraints. Goals are defined by the stakeholders; constraints are defined by the world in which we live. For example, a goal could be, an open atrium, a specific price, or to create an iconic building; as a minimum, the level of life safety expected by local regulations would be the goal. A constraint could be limits on budget and time, gravity and material properties. It is the role of the engineer to reconcile these competing demands in an effort to determine an optimum solution.

To summarise, in executing our role as engineers, we have to address three fundamental challenges. These are:

-

What are our goals?

-

What are the constraints?

-

What solution is an optimum balance between these?

It is the word “design” that links these items together, and as each challenge influences the other, none can exist in isolation. The process of design itself is combining these together to deliver an optimum solution. The process of attempting to solve these challenges leads us to ask a further three questions:

-

How are the goals expressed?

-

How are the constraints expressed?

-

How is the solution implemented?

These three questions are addressed by applying engineering skill and knowledge.

In addition to the hard constraints on design, there are also soft (or intellectual) barriers to our ability to determine an optimum solution. These are:

-

The competence of individuals;

-

The freedom of the engineer to practice in a given regulatory environment; and

-

The limits of our collective knowledge (including inherent uncertainty).

Figure 1 shows the design challenges, the key questions and the soft limitations that prohibit our ability to derive (or even conceive of) the optimum solution.

This approach allows engineers to focus clearly on the questions for which they should be seeking answers. There is often a fixation on detail and on the particular engineering tools or approaches that are being used. This detail is necessary as without it, the limits on our knowledge would be such that it would be impossible to complete many engineering tasks which we now take for granted. However, often the fundamental questions become obscured by the focus on detail. Defining the design questions as above, ensures that engineers remain cognisant that the questions they are seeking to answer are independent of any particular solution or engineering approach.

This approach permits the constant re-examination of the available technical methods and therefore assists in the identification of areas where improvements may be made. Clarity regarding the aspect of each of the questions above allows ready identification of the shortcomings in the way that they are currently answered. There are multiple ways in which this may occur. For example:

-

The correct goals or constraints may not be identified. In this case, irrespective of the effectiveness of our engineering tools the solution obtained is unlikely to optimally balance the true goals and constraints.

-

Alternatively, the methods used to express the goals and constraints may be inappropriate.

These shortcomings are likely to stem from one of the three barriers to design identified above. If the limiting barrier can be identified this is the first step to addressing the problem and creating a better solution.

It is inevitable that as the method for answering one of the questions improves, the answers to the other questions will begin to appear crude. This is particularly importance for aspects that have significant impact on the overall result. If one part of an answer is too crude, it will render the refinement and complexity of any other methods largely irrelevant. It is necessary, therefore, that we strive for a consistent level of crudeness [3] in the answer to each of these questions. Rather than devoting our resource and attention to making incremental improvements in one area, we should focus on trying to improve the areas where our collective knowledge, ability or freedom to engineer is comparatively limited—and where this limitation is has a significant impact on our ability to adequately derive an optimum solution.

A further benefit of considering the design questions as illustrated in Figure 1 is that it encourages consideration of goals beyond those immediately associated with fire safety. Taken to its logical conclusion (by simultaneously considering all the goals associated with a building), this approach requires the integration of the fire safety engineer into the overall design process [4], and also the integration of the design process across a project’s life cycle. This facilitates the engagement of the fire engineering within in the delivery of sustainable design. For example, once the goals and constraints of a project are accurately articulated, the long term costs and benefits associated with different fire protection solutions become apparent. In addition, the relative benefit of fire protection when balanced against other building systems may also be evaluated.

3 How Does this Relate to Time Equivalence?

The concept and history of time equivalence provides a long standing example for understanding how the three challenges of design have been answered since the inception of the standard fire curve, which was first adopted in 1918 [5].

The concept of time equivalence was (and is) an attempt to bring rationality and usefulness [6] to this arbitrary [7] and frequently unreliable [8] testing procedure. Simply put, it is a method of specifying a solution. A number of individuals in the field of fire safety engineering have variously turned their attention to developing methods to derive time equivalence after Ingberg first pioneered the idea [9–11]. Although these approaches each have different inputs and various levels of refinement, they share one universal feature. Fundamentally, they provide a formula that attempts to correlate a uniform compartment temperature evolution with a duration of exposure to a standard furnace test. Each identifies the physical constraints imposed by compartments and occupancies, and represents these as input parameters which may then be used to derive a period of fire resistance.

This approach to determining the input values for an engineering tool is a proxy method of stating the goals for a design. In one of its most recent manifestations, a time equivalence approach is provided in the Eurocode [12]. This particular approach modifies the result of the time equivalence analysis by a risk factor based on the height and the occupancy of the building. This risk factor is a further way of introducing some kind of goal into the design process. It also links the different parts so closely together, that it is difficult (or impossible) to reconsider one aspect of the process without revisiting the whole. As such, the goals, constraints and solutions are combined in such a manner that prevents detailed consideration of each part of the process as described above. In other words, using time equivalence enables an engineer to produce a solution (specifying a level of fire resistance) without directly considering the goals (how robust should the structure be?) or constraints (is a uniform fire in this space likely?) of the given building.

4 Revisiting Time Equivalence

The remainder of this paper will outline an approach recently developed by the authors to assess the time equivalence period for a range of different buildings. The methods for identifying goals and constraints and finding the solution will be described.

4.1 Goals

In design, there are two approaches to defining fire safety goals:

-

benchmarking of existing codes and standards that are known to deliver an acceptable level of performance; and

-

defining as, an absolute, the performance that a building is expected to deliver.

In many countries, the legislative framework provides a functional requirement that construction is required to satisfy. In the United Kingdom (England and Wales) the Building Regulations [13] state that in relation to structural fire design “the building shall be designed and constructed so that, in the event of fire, its stability will be maintained for a reasonable period”. The absolute performance in relation to any of the goals or constraints is not stated either within the regulations or the accompanying guidance documents [14]. The guidance documents provide fire resistance periods for various occupancies and, based on the continued use of these documents and the lack of substantial revisions to their recommendations, there is a perception that these values deliver an acceptable level of fire safety performance.

Absolute definition of structural fire safety goals offers significant advantages for all stakeholders. It permits a true cost/benefit analysis to be conducted and, therefore, allows the simultaneous optimisation of all the parameters of which the designer has an understanding [4]. Although many of the tools for absolute structural fire design already exist (e.g. the risk based approaches described in [15]), the methods associated with comparative design are significantly better developed and have other particular advantages as described below.

The method for defining structural fire engineering goals described by the authors below uses the benchmarking technique as this has already been adopted in BS 9999:2008 [16]. This approach to defining the required performance was based on maintaining a constant level of risk across all building stock, irrespective of its occupancy or height and is benchmarked against the guidance documents for England and Wales.

4.1.1 A Risk Based Approach

In the England and Wales, the guidance of Approved Document B is generic for all common types of building. A more refined risk based approach was developed by Kirby et al. [17] and used many thousands of different building arrangements, fuel loads, and ventilation conditions to find the most appropriate fire resistance period for several building types.

Kirby’s approach adopts a number of assumptions regarding the frequency of fire occurrence and consequence of failure. These are as follows:

-

Frequency. It was assumed that the frequency of fire occurrence was primarily influenced by the size of a building. Building height was therefore adopted as the measure of frequency. Although this is a crude assumption (for example, it does not account for floorplate area) it is accords with existing frameworks which define fire resistance periods based on building height [17].

-

Consequence of failure. It was assumed that the consequence was due to damage that would occur if the time equivalent period of the structure was exceeded. Although Kirby acknowledged that the consequence was likely to be influenced by the mode of failure, a binary approach to failure was adopted and it was assumed that consequence was directly proportional to height [17].

These assumptions led to the following equation where: R is the risk index for the building; P occ () is the frequency of fire occurrence; P fail () is the probability of failure; and C is the consequence of failure.

By making the substitutions described above, this can be expressed as follows where h is the building height, and r is the required reliability to prevent failure:

To ensure the proposed approach would deliver an acceptable level of risk, the above equation was calibrated against the existing guidance documentation. Since the proposed application for this methodology was within England and Wales, the guidance of Approved Document B [14] was used to calibrate the acceptable risk. This exercise found that at 18 m height, the required reliability should be 80% to accord with the existing guidance. This results in the following definition of allowable risk:

This value of risk is jurisdiction specific. However, the same methodology and calibration could be applied in other jurisdictions to permit an equivalent definition of acceptable risk.

When tabulated, these equations lead to the level of reliability presented in Table 1, column 2. However, this methodology does not account for the presence of sprinklers. Sprinklers can be represented either explicitly (by accounting for their likely success in supressing or controlling a fire); or implicitly by modifying the resultant fire severity using a sprinkler factor.

The authors have adopted an explicit approach because:

-

It allows the expected reliability of a sprinkler system to be directly incorporated into the analysis.

-

It prevents the artificial reduction in resultant fire severity that can occur from using a sprinkler factor applied to the fuel load.

Furthermore, this approach allows the variability in reliability of sprinkler systems to be captured thereby incentivising the provision of an effective sprinkler system—and allowing the benefits associated with a more reliable sprinkler system to be realised elsewhere within the package of fire safety measures provided within a building.

The contribution of the sprinklers to the structural reliability can be expressed as follows, where r T is the aggregate reliability of the structure, r sp is the sprinkler reliability and r st is the reliability of the structure in the event of sprinkler failure.

This can be rearranged to obtain a figure for required structural reliability as follows.

This leads to the calculation of required structural reliability as shown in Table 1.

The approach is consistent with the principles in many jurisdictions that the structural reliability (or fire resistance) may be lower if sprinklers are provided. It is also notable that this approach implies that, if sprinklers are provided, structural fire protection may be omitted. Although this may be appropriate for some low-rise structures, for taller buildings it is unlikely that omitting structural fire protection would be acceptable as, in the event that sprinklers did not succeed in supressing the fire, failure of the structure would be inevitable and rapid. Unless the evacuation strategy for the building can support sufficiently rapid egress—fire protection should not be omitted.

4.2 Constraints

There are three types of fire that could occur on the floors of a typical office building:

A smouldering fire. These will not be considered further due to the relatively low temperatures associated with a smouldering fire, and the localised nature of the burning.

A uniform fire. Uniform fires are more likely to occur when they are in relatively small enclosures, allowing significant radiative feedback to occur between the surrounding compartment and the fuel sources. These are the type of fires that have traditionally been used in structural fire analysis (they are often referred to as post-flashover fires), and are often extrapolated for design to compartments much larger than the experiments on which temperature correlations are based.

A travelling fire. Travelling fires have been observed to occur where there are relatively large compartments/floors. Travelling fires burn non-uniformly, gradually consuming the fuel over a large area. They can burn for a long duration. A design methodology for travelling fires has recently been developed and addresses many of the shortcomings of the traditional post-flashover methods, as applied to large compartments [18].

The authors have adopted an approach whereby travelling fires are utilised in spaces greater than 100 m2, and compartment fires are expected to occur in spaces less than 100 m2. This assumption is necessary, as, to date, there has been little research determining when a compartment becomes “large” in the context of the difference between uniform and travelling fires. Using the two types of fires has allowed the authors to more directly consider the geometrical constraints in the building.

4.3 Solution

The end solution must be expressed in such a way that it can be specified and built. The common language in fire engineering is of periods of fire resistance. For any building, therefore, there are two aspects to the solution—the fire resistance period (time equivalence period) and the arrangement of the protection.

The optimum product from the goal and constraints is where the two balance. The fire resistance period which, at the design percentile, does not allow a notional structural section to exceed its limiting temperature is the optimum fire resistance period.

The approach by which the fire events are represented in the present method is informed by the manner in which the goal and constraints are expressed. The goal is expressed as reliability; as such, it is a natural progression to execute a probabilistic analysis. This is further supported by the uncertainty of many of the constraints as described above. Unlike in a deterministic approach, many thousands of design fire scenarios can be analysed as part of a Monte Carlo assessment.

Selection of the inputs for the Monte Carlo analysis that adequately represent the range of fire scenarios that may occur is therefore fundamental. The input parameters vary based on the methods used to represent the fires. The approaches described above (the parametric fire method and the travelling fire method) require several different inputs including fuel load, compartment dimensions, and ventilation conditions.

The severity of each fire can be assessed using a lumped mass heat transfer calculation for a protected section. The fire resistance of the section may be varied iteratively until the temperature in the steel was equal (at the target reliability) to the limiting temperature of the section. The resulting cumulative frequency curve from this approach is illustrated indicatively in Figure 2.

It should be noted that the output from this analysis also provides the starting-point for a more in-depth structural analysis to determine the second part of the solution (the optimum structural and protection arrangement).The design fires that induce the limiting temperature within the structure are, by definition, the reasonable worst case fire scenarios. A more detailed structural model such as those described by Flint [19] can then be used to test the structure against these scenarios to determine the optimum structural arrangements, the optimum location for the fire protection, and to ensure that the proposed design is able to resist the selected fires.

5 Example

To illustrate the approach described above, an example analysis was conducted. The key information for a notional building are provided in Table 2.

5.1 Goal

Following the risk based approach described in Sect. 4.1.1, a 50 m tall office building with sprinklers that were assumed to be 75% reliable would require the structural fire protection to deliver a structure that would resist 90% of the fires that could occur within the building (that were not manually or sprinkler supressed). The target reliability for the structure was, therefore, 90%.

5.2 Constraints

The possible fires that could occur within this space were characterised using various possible input parameters including the following.

-

Fuel load. The usage for this building was office and therefore the fuel load distribution for office buildings provided in EN 1991-1-2 [20] was adopted.

-

Compartment area. The maximum compartment area was the maximum floor area. There were also likely to be a range of smaller rooms—and potentially partitioning of the office in the future. Therefore a distribution of compartment areas was used that encompassed the smallest and largest compartments. A number of sensitivity studies were conducted and it was found that larger compartment areas resulted in more severe fire conditions. The distribution of compartments was biased to increase the likelihood of a fire occurring in a large compartment.

-

Ventilation. Ventilation is a key input parameter for the parametric fire method, and is highly variable both due to the possible arrangement of rooms and uncertainty regarding glazing breakage. A range of possible values were adopted between a single door/window opening, and full height glazing around three of the four sides of a compartment.

The resulting cumulative frequency for each of these distributions is shown in Figure 3.

5.3 Solution

The selected distributions were used to generate a range of possible design fires. The resulting temperature time distributions were then analysed using a lumped mass heat transfer calculation as described in Buchanan [21]. An iterative process was required to determine the optimum fire resistance period; a series of trial fire resistance periods were applied to a notional steel section until the assumed limiting temperature of 550°C was not exceeded at the 90th percentile (as illustrated in Figure 4a).

It was found that 88 min fire protection was required to prevent the steel from exceeding its limiting temperature. This value, therefore, represents the optimum fire resistance period for the elements of structure within the building. The resulting temperature time distribution for the 88 min protected section when exposed to a range of the fire scenarios are illustrated in Figure 4b.

As noted in Sect. 4.3, the fires which induce the limiting temperature correspond to the design fires which the structure would be expected to resist. In the event that a more detailed structural fire assessment (such as that described by Flint [19]) was conducted, these fires may be used to test the structure. Several of these fires are highlighted in Figure 4b.

The resulting standard of fire protection for the elements of structure in this building was therefore specified as 90 min (loadbearing capacity, integrity, insulation as appropriate).

6 A Consistant Level of Crudeness

The limitations and simplifications of each of the methods described above are multiple and widespread. Nevertheless, the components that were assembled to answer the design challenges are based on the available engineering knowledge. As each of the questions has been identified separately, it is possible to understand more precisely where our fundamental knowledge is most deficient.

Over the course of developing this approach the authors have made the following observations regarding the available knowledge and our application of it:

-

Knowledge of the fundamental goals is limited. There are comparative approaches that are available, but these do not allow effective integration of structural fire engineering into the design optimisation process as, necessarily, these approaches are self-contained (within the discipline) and self-referencing (to levels of safety previously judged to be acceptable).

-

Knowledge of fire dynamics and the constraints that govern the fires that could occur in a building less limited. There is a relative plethora of research on fire behaviour and the recent research on large building fires allows a significantly more robust approach to design fire selection, but there remains significant uncertainty about the size of fires that may occur in large buildings.

-

There is a significant body of knowledge on the behaviour and response of structures subject to thermal attack—particularly for steel and composite structures.

Based on the above, and on the concept of consistent levels of crudeness, the gaps in research are primarily in the relative crudeness of the identified goals in comparison to our knowledge of structural behaviour. In addition, the overlap between each of the areas of knowledge is key to understanding their interaction, and developing the optimum solution.

7 Conclusions

This paper has presented the three key challenges that engineers face on each project on which they work, namely defining the goal, defining the constraints, and defining a solution. Existing methods of time equivalence implicitly incorporate these factors and it is therefore difficult, or impossible, to explicitly analyse specific goals or constraints.

A method for defining the appropriate fire resistance for a building has also been presented which explicitly considers each design challenge as follows:

-

Goals. The goals were defined using a risk based approach that was benchmarked (for use in the UK) using the Approved Document B guidance. This provided a percentile target design reliability which was related to building height.

-

Constraints. These are expressed using two design fire methodologies (uniform and travelling fires) and wide range of inputs for the uncertain building features and usage. The variety of fires and uncertainty regarding input values is represented using a Monte Carlo analysis.

-

Solution. The end solution is the optimum balance of these two factors and is expressed as a time equivalence period. This approach can also be used to define the appropriate severity of design fires for further structural analysis.

References

ISO 834-1 Fire-Resistance Tests (1999) Elements of building construction—part 1 general requirements. International Organization for Standardization

Ingberg SH (1928) Tests of the severity of building fires. Natl Fire Prot Assoc Q 22:43–46

Buchanan A (2009) The challenges of predicting structural performance in fires. Fire Saf Sci 9:79–90. doi:10.3801/IAFSS.FSS.9-79

Law A, Bisby LA, Torero JL (2012) Structural fire engineering: who cares, and why bother? SFPE conference on performance-based codes and fire safety design methods

Babrauskas V, Williamson RB (1978) The historical basis of fire resistance testing—part I. Fire Technol 14:304–316. doi:http://dx.doi.org/10.1007/BF01983053

Law M (1971) Prediction of fire resistance. Symposium No. 5 Fire Research Station

Babrauskas V, Williamson RB (1978) The historical basis of fire resistance testing—part II. Fire Technol 14:304–316. doi:http://dx.doi.org/10.1007/BF01998390

Wickström U (1994) The plate thermometer—a simple instrument for reaching harmonized fire resistance tests. Fire Technol 30:195–208. doi:10.1007/bf01040002

Harmathy TZ, Mehaffey JR (1982) Normalized heat load: a key parameter in fire safety design. Fire Mater 6:27–31. doi:http://dx.doi.org/10.1002/fam.810060108

Law M (1971) A relationship between fire grading and building design and contents. Fire Research Note No. 877

Pettersson O, Magnuson SE, Thor J (1976) Fire engineering design of structures. Swedish Institute of Steel Construction

EN1991-1-2 (1999) Eurocode 1: actions of structures—part 1–2: general actions—actions on structures exposed to fire

(2010) Building Regulations (England and Wales) 2010

(2010) Approved document B—volume 2 buildings other than dwellinghouses. HM Government

Hasofer AM, Beck VR, Bennets ID (2007) Risk analysis in building fire safety engineering. Butterworth-Heinemann, Oxford

(2008) BS 9999 Code of practice for fire safety in the design, management and use of buildings. BSI

Kirby BR, Newman GM, Butterworth NA et al (2004) A new approach to specifying fire resistance periods. Struct Eng 84:34–37

Stern-Gottfried J, Rein G (2012) Travelling fires for structural design—part II: design methodology. Fire Saf J 54:96–112. doi:http://dx.doi.org/10.1016/j.firesaf.2012.06.011

Flint G, Lamont S, Lane B et al (2012) Recent lessons learned in structural fire engineering for composite steel structures. Fire Technol. doi:http://dx.doi.org/10.1007/s10694-012-0291-8

EN1992-1-2 (2004) Eurocode 2: design of concrete structures—part 1–2: general rules—structural fire design.

Buchanan AH (2006) Structural design for fire safety. Wiley, Chichester

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Law, A., Stern-Gottfried, J. & Butterworth, N. A Risk Based Framework for Time Equivalence and Fire Resistance. Fire Technol 51, 771–784 (2015). https://doi.org/10.1007/s10694-014-0410-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10694-014-0410-9