Abstract

The competence of novel fungal consortium, consisting of Nigrospora sp. LDF00204 (accession no. KP732542) and Curvularia lunata LDF21 (accession no. KU664593), was investigated for the treatment of pulp and paper mill effluent. Fungal consortium exhibited enhanced biomass production under optimized medium conditions, i.e., glucose as carbon (C), sodium nitrate as nitrogen (N), C/N 1.5:0.5, pH 5, temperature 30 °C, and agitation 140 rpm, and significantly reduced biochemical oxygen demand (85.6%), chemical oxygen demand (80%), color (82.3%), and lignin concentration (76.1%) under catalytic enzyme activity; however, unutilized ligninolytic enzymes, such as laccase (Lac), manganese peroxidase (MnP), and lignin peroxidase (LiP), were observed to be 13.5, 11.4, and 9.4 U/ml after the third cycle of effluent treatment in repeated batch process. Scanning electron microscopy (SEM) of fungal consortium revealed their compatibility through intermingled hyphae and spores, while the FTIR spectra confirmed the alteration of functional groups ensuring structural changes during the effluent treatment. Gas chromatography/mass spectroscopy (GC-MS) analysis showed the reduction of complex compounds and development of numerous low-molecular-weight metabolites, such as 1-3-dimethyl benzene, 2-chloro-3-methyl butane, pentadecanoic acid, and 1-2-benzene dicarboxylic acid, during the treatment, demonstrating the massive potential of the novel fungal consortium to degrade recalcitrant industrial pollutants.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The pulp and paper industries are extremely exhaustive in terms of water, raw materials, energy, and chemicals, thus enlisted among the 17 highly polluting industries categorized by the Central Pollution Control Board. Out of 759 paper mills in India, 30 are wood-based large-scale, 150 are Agra-based medium-scale, and 579 are recycled fiber-based medium- and small-scale mills, producing 3.40, 2.42, and 5.10 Mtpa paper, respectively. Paper production initiates with the pulping of raw material followed by pulp bleaching. The pulping process results in dissolved forms of lignin and other wood components called black liquor (Paliwal et al. 2012), whereas bleaching produces the monoaromatic compounds (chlorophenols, catechols, and guaiacols) and high-molecular-weight compounds (chloro-lignins) (Schnell et al. 2000). Besides, bleached effluent restrains chemical oxygen demand (COD), biochemical oxygen demand (BOD), chlorinated resin acids, phenols, dioxins, and color (Malaviya and Rathore 2007). Large-scale mills have chemical recovery operations, which involve chemical recovery from the spent cooking liquor and energy recovery from black liquor leading to less generation of water and air pollutants. However, small-scale mills often lack such installations due to their unavoidable operational costs; as a result, unrecovered effluent amplifies the pollutant toxicity which needs to be removed employing a cost-effective technique, prior to discharge.

There are many physicochemical processes, such as ion exchange, resin separation, reverse osmosis, and advanced oxidation processes, involved in the treatment of paper mill effluent; however, biological methods using fungi, bacteria, and actinomycetes are comparatively preferable, cost-effective, and environmentally friendly processes (Pant and Adholeya 2007). To curtail the toxicity of the effluent, fungi have several advantages over bacteria. The extracellular fungal enzymes, i.e., lignin and manganese peroxidases (LiP, MnP) and laccases (Lac), attack a wide range of complex compounds and nullify substrate diffusion limitation, as compared to bacteria (Gianfreda and Rao 2004; Kamitsuji et al. 2005). The majority of basidiomycetous fungi, such as Pleurotusostreatus, Phanerochaete chrysosporium, Lentinus edodes, and Trametes versicolor, have been studied for this purpose (Wu et al. 2005; Selvam et al. 2002; Santos and Linard 2004), whereas fewer reports are available for the degradation of paper mill effluent by other groups of fungi. Production of lignin-degrading enzymes by ascomycetous fungi such as, Magnaporthe grisea (Iyer and Chattoo 2003), Mauginella sp. (Palonen et al. 2003), Paraconiothyrium variabile (Gao et al. 2011), and Monocillium indicum (Thakker et al. 1992) have been studied, which demonstrate their potential to degrade lignin and colored compounds, but less information is available about the potential of ascomycetous fungi for the detoxification and degradation of pulp and paper mill effluent.

Microbial growth and enzyme production in the culture medium are affected by many environmental and nutritional factors, i.e., temperature, pH, aeration, C, and N (Wu et al. 2005). Increased supply of readily metabolizable carbon sources stimulates ligninolytic system in fungi and catalyzes the lignin degradation process (Hammerli et al. 1986), whereas increased nitrogen concentration inhibits fungal growth and lignin degradation (Garg and Modi 1999). Hence, the optimum C/N ratio is more promising for lignin degradation and color removal than the sole carbon and nitrogen sources. Therefore, it is essential to optimize these process parameters to achieve utmost output in less time at a large scale. Process optimization for effluent treatment has been studied using individual microbe and consortia (Malaviya and Rathore 2001; Singhal and Thakur 2009; Chandra et al. 2011; Yadav and Chandra 2015). Contrary to the observation that fungi do not proliferate under extreme environmental conditions, viz, high alkaline pH and low oxygen in submerged conditions (Chandra et al. 2007), many researchers reported that the fungal consortium approach enhanced the synergistic action of enzymes leading to maximum degradation of the effluent (Wu et al. 2005; Malaviya and Rathore 2007; Arantes and Milagres 2007). It is noteworthy that merely optimized conditions are not satisfactory for prolonged degradation of effluent and require prior investigation on the fungal growth rate, enzyme production, and simultaneous effluent treatment in repeated batch treatment.

The present study was carried out to assess the potential of novel ascomycetous fungal consortium (Nigrospora sp. and Curvularia lunata) in a repeated batch process under optimized conditions for treatment of pulp and paper mill effluent. The enzymatic potential of the fungal consortium was also investigated during the treatment to enable its profitable application at the industrial scale. Further, functional characterization of transforming compounds was analyzed by FTIR and degraded metabolites were studied using GC-MS.

Materials and methods

Chemicals and wastewater sample collection

Birchwood xylan, 2,2-azino-di-(3-ethylbenzothialozin-6-sulfonic acid) (ABTS), guaiacol, veratrayl alcohol, 2,6-di-methoxyphenol, and azure-B were procured from Sigma-Aldrich (St. Louis, MO, USA). All reagents were of analytical grade, purchased from Hi-Media (Mumbai, India). The effluent sample was collected in a sterilized plastic container from Century pulp and paper mill, situated at Lalkuan, Uttarakhand (India), and stored at 4 °C until used for analysis.

Isolation, screening, and identification of potential fungal strains for lignocellulolytic enzyme activity

Contaminated soil sludge samples from the effluent discharge sites were used for the isolation of the prospective fungal strains using conventional dilution technique (Barnett and Hunter 1972). The isolated fungi were purified on potato dextrose agar (PDA) plates, incubated for 96 h at 30 °C, and further inoculated in the screening medium containing different substrates, viz, azure-B (0.002% w/v), α-naphthol (0.005% w/v), birchwood xylan (4% w/v), and carboxymethyl cellulose (CMC) (2% w/v), for peroxidase, laccase, xylanase, and cellulase activities, respectively (Pointing 1999). The potential lignocellulolytic fungi were primarily identified according to their macro and micro morphological features (Domsch et al. 1980). For molecular identification, fungal genomic DNA was separated using a genome DNA kit (QiagenInc, USA), and 18s ribosomal RNA (rRNA) gene amplification was done using universal primer ITS1 (5`-TCC GTA GGT GAA CCT GCG G-3`) and ITS4 (5`-TCC TCC GCT TAT TGA TAT GC-3`). Polymerase chain reactions (PCRs) were performed in an Eppendorf master thermocycler (ABI 3500XL Genetic Analyzer, USA) under the following conditions: initial denaturation at 96 °C for 5 min, followed by 40 cycles at 94 °C for 30 s, 58 °C for 30 s, and 72 °C for 30 s, and a final extension at 72 °C for 15 min. The sequence data analysis was performed at Chromous Biotech Pvt. Ltd. (Bangalore), and their alignment was performed using the CLUSTAL W program. The neighbor-joining (NJ) algorithm was applied for phylogenetic analysis and performed using MEGA 5 software (Tamura et al. 2011). For genus and species identification, the sequences were subjected to BLAST analysis using the database GenBank (http:/www.ncbi.nem.nih.gov/BLAST) and submitted to NCBI GenBank for the accession number.

Evaluation of fungal isolates’ compatibility

Based on the ligninolytic enzyme’s activity, the fungal isolates (LDF00204 and LDF21) were evaluated for their compatibility in a co-culture. To study the growth and interaction, mycelial discs of the fungi were inoculated in one petri dish, maintaining a 40-mm distance and incubated for 15 days at 30 °C. The interactions between the fungi were examined according to the method of Molla et al. (2001). Microscopic characterization of the consortium was examined by JSM-6610LV (JEOL, Japan) scanning electron microscope (SEM). A single fungal culture was taken as a control.

Physicochemical analysis of the effluent

The effluent sample was analyzed for physicochemical parameters, such as TDS (total dissolved solids), TSS (total suspended solids), BOD (3 days), COD, nitrate, sulfate, and phosphates per standard methods of the American Public Health Association (Greenberg et al. 1995, APHA 2005). pH was measured by a digital pH meter (Elico, India) and ions by the flame photometer (Systronics 128, ASE Ltd). Chloride content was measured using sodium chloride as a standard solution by UV-Vis spectrophotometer (VARIAN Bio). Lignin was measured according to the method of Pearl and Benson (1940), and absorbance (430 nm) values were transformed into lignin residue (ppm). Heavy metals, such as iron (Fe), zinc (Zn), calcium (Ca), and magnesium (Mg), were analyzed by atomic absorption spectrophotometer (Shimadzu AA6701F). The color units were estimated according to the method of Bajpai et al. (1993), and absorbance (465 nm) value was transformed into color units (Co-Pt).

where A 1 is the absorbance of 500 CU Co-Pt standard at 465 nm and A 2 is the absorbance of a sample at 465 nm.

Lignin and color removal (%) was calculated as follows:

where N 0 and N t are the values of lignin/ color, before and after treatment.

Optimization of process parameters for effluent degradation

The effluent treatment by the fungal consortium (LDF00204 and LDF21) was optimized using various environmental parameters. A batch study was carried out using 100-ml autoclaved samples in Erlenmeyer flasks (250 mL) supplemented with minimal salt media (MSM) and inoculated with fungal strains LDF00204 and LDF21 (1-g wet weight/fungus) for 168 h in a shaker. The varieties of carbon (wheat bran, glucose, and rice bran) and nitrogen (ammonium nitrate, urea, and sodium nitrate) sources at 0.2% w/v were added to select the best-suited sources of C and N to improve the process, and then the varied ratios of C/N were tested for optimum degradation. Other parameters, viz, temperature (25–40 °C), pH (3.0–9.0), and agitation speed (120–200 rpm), were also optimized. A pure effluent sample was taken for the treatment to determine fungal consortium efficacy to resist the effluent alkalinity and synchronized degradation. A control set was also maintained without fungal inoculation. Samples were taken out from the flasks after 168 h of incubation and analyzed for degradation of lignin and color. Fungal biomass was estimated using the dry weight method prescribed by Dimitrokallis et al. (2008). For this, 20 ml of sample was withdrawn from flasks and centrifuged for 20 min at 4000 rpm. Fungal decant was washed in de-ionized water and dried in an oven for 4–6 h at 80 °C, cooled to room temperature, and weighed until a constant dry weight.

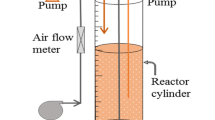

Biodegradation of effluent in repeated batch process

The biodegradation of pulp and paper mill effluent using free fungal consortium in a repeated batch culture was studied under optimized conditions to investigate its efficiency for long-term pollutant degradation. The initial inoculum of 5 g (wet weight/fungus) was inoculated in a 1-l Erlenmeyer flask, containing 500 ml of the autoclaved effluent and incubated at 30 °C for 168 h. After the completion of cycle 1, the initial sample was replaced by the freshly autoclaved sample. As such, three cycles of 7 days each were performed in continuity to investigate the change in pH, color, BOD, COD, lignin, and biomass of the effluent at regular time intervals (0, 24, 96, and 168 h). The experiments were carried out in triplicate along with a parallel set of uninoculated (control) to determine the effect of abiotic factors on the treatment of pulp and paper mill effluent.

Enzyme activity determination in repeated batch culture

Enzyme activities of the fungal consortium were determined on the treated liquid sample after completion of each effluent treatment cycle. Fungal mycelia were removed by centrifugation at 5000 g for 25 min, and the supernatant was taken for estimation of enzyme activity. Lac activity was determined using ABTS as the substrate, and its oxidation was measured spectrophotometrically at 420 nm (ε420 = 36,000/M/cm) at room temperature. LiP activity was determined by oxidation of veratrayl alcohol to veratraldehyde, and absorbance was measured at 310 nm (ε310 = 9300/M/cm), whereas MnP activity was measured at 270 nm by the formation of Mn+3-malonate complexes.

Functional group analysis of the effluent before and after treatment

The alteration in functional groups in untreated and treated samples during fungal degradation was investigated using FTIR (BRUKER ALPHA 200 model, USA). The effluent samples extracted with ethyl acetate were loaded on the analyzer, and the percentage of transmission was compared with 3500 to 1000/cm wave number region with 16 scan speeds. Baseline correction was done for the spectra, which further studied for changes in the chemical structure of the effluent.

GC-MS analysis of degraded metabolites

Characterization of the metabolites after treatment was analyzed using GC-MS (Perkin Elmer, UK). Twenty milliliters of the sample (untreated and treated) was centrifuged at 10,000 rpm for 15 min, and the supernatant was acidified (pH 2.0) using 1 N HCl and extracted thrice using 20 ml of ethyl acetate for utmost extraction of aromatic compounds from the effluent. The organic layer obtained was separated out, dewatered with anhydrous sodium sulfate (Na2SO4) and vacuum-dried. The dried deposits were derivatized with trimethylsilyl (TMS) (Lundquist and Kirk 1971). Derivatization method includes the addition of 100 μl dioxane and 10 μl pyridine in samples, followed by silylation with 50 μl trimethyl silyl (BSTFA (N, Obistrimethylsilyl)), trifluoroacetamide, and TMCS (trimethylchlorosilane) in the ratio of 99:1. The mixture was heated at 60 °C until residue dissolved completely by gently shaking. Samples were then filtered through 0.25-μm syringe filters before performing GC-MS. The compounds present in untreated and treated samples were identified by comparison of the retention time (RT) of mass spectra with reliable compounds available at NIST-08 database libraries.

Statistical analysis

The experimental data were processed for analysis of variance (ANOVA) using the SPSS software, and the statistical significance of the difference of the treatments was expressed at p < 0.05.

Results and discussion

Isolation, screening, and in-vitro lignocellulolytic activity of fungal strains

A total of eight fungal strains were isolated from pulp and paper mill soil sludge. Microbes flourishing on toxic recalcitrant pollutants-containing sites possibly build up the potential to degrade these compounds. Out of eight fungal strains, the two strains LDF00204 and LDF21 were capable of producing all the lignocellulolytic enzymes (peroxidase (LiP, MnP), laccase, cellulase, and xylanase) using in vitro plate assay method. The fungal enzymatic reactions with a diverse chromogenic substrate exhibited decolorized zone. Both fungal strains produced a violet color zone after the first day of incubation, indicating the presence of the laccase enzyme, whereas the disappearance of the blue color of Azure-B dye confirmed the presence of peroxidase enzyme (Supplementary data). These two major enzymes catalyze the oxidation of lignin units by one-electron transfer resulting in bond cleavage and have also been reported in Nigrospora sp. and Curvularia sp. for the degradation of azo dyes and lignocellulosic waste, respectively, by many workers (Ilyas and Rehman 2013; Neoh et al. 2015).

Fungal isolate LDF21 exhibited xylanase and cellulose activities by producing a yellow color zone and a hydrolysis zone in CMC agar media, respectively (Supplementary data), whereas it was absent in the fungal strain LDF00204, which may be due to genetic variation among fungi and uptake of the substrate. Xylanase, a hydrolytic enzyme, degrades the carbohydrate portion of lignocellulose, whereas the synergistic action of cellulase enzyme helps in the degradation of cellulose to glucose. The presence of these enzymes in the fungal strain LDF21 is well in line with an earlier investigation (Neoh et al. 2015). On the contrary, no activity was observed in control plates as these were devoid of respective substrate. Hence, the screening of fungi having lignocellulolytic potential is a significant step for swift removal of a multitude of pollutants including lignin and its co-compounds.

Identification of the potential fungal strains

Based on cultural characteristics and spore orientation, the fungal strains LDF00204 and LDF21 were identified as Nigrospora sp. and Curvularia sp., tentatively. To confirm the fungal strain (LDF00204 and LDF21) identification, the internal transcribed spacer region of both fungi was amplified and 18s rRNA gene sequences of fungal strains were compared with the available gene sequences of other organisms in GenBank at NCBI database at www.ncbi.nlm.nih.gov/BLAST. The constructed phylogram showed the nearest homology of the selected fungi LDF00204 and LDF21 with Nigrospora sp. and Curvularia lunata (Fig. 1a, b) therefore designated as Nigrospora sp. LDF00204 (accession no. KP732542) and Curvularia lunata LDF21 (accession no. KU664593). However, this is the first information evaluating the potential of Nigrospora sp. and Curvularia lunata in a mixed culture for the detoxification and treatment of pulp and paper mill’s effluent.

Compatibility evaluation of fungal stain consortium

Fungi interact with each other in many different ways, i.e., mutual/partial intermingling and invasion and inhibition (Stahl and Christensen 1992). In the present study, the interaction pattern of the two fungal strains LDF00204 and LDF21 was observed during co-incubation in PDA media. The result showed that both fungal isolates grew enormously with hyphal proliferation. The expanded mycelia growth confirmed mutual intermingling between the isolates (Supplementary data) which was categorized based on earlier reported studies (Stahl and Christensen 1992; Molla et al. 2001). The microscopic study of actual interactions between fungi was done by using SEM which revealed the presence of hyphae and spores of co-cultured fungi, confirming their mutual growth in vitro (Fig. 2a, b). The foremost benefit of using compatible fungal culture is to quicken the degradation process by their synergistic action. The accelerated bioconversion of domestic waste, sewage sludge, and industrial waste using co-cultured fungi has been studied by many workers (Molla et al. 2001; Mohammad et al. 2011). Considering the in vitro compatible relation, the fungal consortium was studied for the degradation of pulp and paper mill effluent.

Physicochemical characteristics of the pulp mill effluent

The physicochemical characteristics of pulp and paper mill effluent are given in Table 1. All the values were found beyond the Central Pollution Control Board (CPCB) guidelines. The effluent contained highly alkaline pH (9.8), COD (6735 mg/l), and lignin (1863 mg/l). The use of sodium hydroxide and sodium sulfite in the pulping process to dissolve lignin and hemicelluloses contributes to the excess pH and sulfate levels, whereas the release of lignin and its derivatives after bleaching process elevates the COD level of the effluent (Singhal et al. 2005). Furthermore, chloride content generated from the bleaching process had the concentration 285 mg/l. Lignin and its chlorinated derivatives impart color to the effluent. In the present study, the color concentration was 7253 mg/l, which inhibits the photosynthetic activity of aquatic bodies and causes toxicity of the food chain. The high BOD calculated was 2934 mg/l which indicates polluted wastewater which severely affects the survival of aquatic organisms. Total solids (TDS and TSS) contain a mixture of inorganic salts, organic molecules, and other dissolved materials, causing toxicity through the increase in salinity and change in ion composition (USEPA 1986). In the present study, TDS and TSS values were measured as 1753 and 632 mg/l, respectively, which poses threats to aquatic communities and causes chronic effects. Heavy metals, such as Fe (0.15 mg/l), Zn (0.11 mg/l), Ca (237 mg/l), and Mg (142 mg/l), were also observed in trace amounts. The presence of heavy metals in the effluent has been investigated by many workers (Hakeem and Bhatnagar 2010). These pollutants contribute to the toxicity of the effluent and affect humans as well as aquatic animals. Therefore, the detoxification and degradation of these pollutants were further performed using fungal consortium.

Effect of optimized process parameters on effluent treatment by fungal consortium

Different carbon (glucose, wheat bran, and rice bran) and nitrogen (ammonium nitrate, urea, and sodium nitrate) supplements were scrutinized for optimizing the process of pulp and paper mill effluent treatment by fungal consortium. Glucose was observed as a process-initiating carbon source among all the sources used which resulted in a maximum reduction in color units up to 2273.8 Co-Pt (68.65%) and lignin up to 778.4 mg/l (58.75%) and 4.21 g/l of biomass production after 168 h of the incubation period (Fig. 3a). Wheat bran and rice bran showed slow degradation comparatively. No degradation was observed in the control set with no fungal biomass. The requirement of carbon sources varies from organism to organism. Many research studies have reported the effect of different carbon sources on the color and lignin degradation of pulp and paper mill effluent (Da Re and Papinutti 2011). Among nitrogen sources, efficient degradation resulted from sodium nitrate, with 1972.8 Co-Pt (72.33%) reduction in color units and 681.9 mg/l (63.4%) reduction in lignin along with biomass production of 4.07 g/l (Fig. 3a). Low amount of nitrogen stimulates the production of ligninolytic enzymes and quickens lignin degradation, whereas reduced substrate degradation and restrained fungal growth have been reported when excess nitrogen was added (Mantovani et al. 2007). Optimization of other parameters like temperature, pH, C and N ratio, and agitation speed was also observed simultaneously. To assess the optimum values, different combinations of C and N (1:1, 0.5:1.5, and 1.5:0.5) were selected, and different temperatures (25, 30, 35, and 40 °C), pH (3, 5, 7, and 9), and agitation speeds (120, 140, 160, 180, and 200 rpm) were observed for effective degradation of effluent. Maximum degradation was observed using the C/N ratio 1.5:0.5. The color was reduced 73.1% (1951.1 Co-Pt) and lignin up to 65.23% (648.4 mg/l), whereas fungal biomass increased up to 5.54 g/l after 168 h of incubation period (Fig. 3b). A positive correlation was observed between biomass and color (r = 0.91) and biomass and lignin degradation (r = 0.90). Modi et al. (1998) observed that the balanced amount of C and N plays an important role in biomass production and concurrent degradation, whereas Jadhav et al. (2008) investigated the positive impact of high levels of C on decolorization. On the contrary, decolorization of the Kraft mill effluent by Trametes versicolor has occurred in less N or N-deficient conditions (Bajpai et al. 1993).

Temperature regulates microbial growth in many processes. In this study, utmost removal of color at 1784.3 Co-Pt (75.4%) and lignin degradation at 629.7 mg/l (66.2%) were observed at 30 °C, while biomass production was at 5.19 g/l. An increase in temperature resulted in slower growth and less removal of pollutants (Fig. 3c). Maximum reduction in color (75.7%) and lignin (67.1%) was observed during the experiment at pH 5 (Fig. 3c). Earlier findings showed the parallel trend of reduction in color and lignin by fungi (Malaviya and Rathore 2007; Kaushik and Thakur 2009). The most appropriate agitation speed was 140 rpm for the highest removal of color and lignin, 77.3 and 69.2% (Fig. 3d), respectively. Lignin degradation is an oxidative process; therefore, aeration speeds up the process as a function of oxygen concentration (Kirk et al. 1976). Several studies have reported the enhanced decolorization and delignification of black liquor in shaking conditions (Mishra and Thakur 2010; Chandra et al. 2011). Statistical analysis displayed a positive correlation between fungal biomass, color, and lignin degradation and was significant at p < 0.05. The control sets showed no changes in the effluent parameters.

Biodegradation efficiency of the fungal consortium in repeated batch culture

Optimized culture conditions (C/N ratio 1.5:0.5, temperature 30 °C, pH 5.0, and agitation rate 140 rpm) were applied to investigate the reduction in pH, BOD, COD, color, and lignin using fungal consortium in a repeated batch culture (Table 2). The efficiency of fungal consortium in three repeated batch cycles was observed based on pH reduction, biomass production, and removal of the pollutants after 168 h of incubation. Significant removal was observed in the second treatment cycle along with decreased pH (4.6) which showed efficient removal of color (82.3%), lignin (76.1%), BOD (85.6%), and COD (80%) (Table 2). Comparatively, slow removal rates were observed in the first treatment cycle (color 77.4%, lignin 69.8%, BOD 79.3%, and COD 74%) and the third treatment cycle (color 79.7%, lignin 71.2%, BOD 81.1%, and COD 77%), respectively. This may be due to the instability or shear of fungal mycelia under the long periods of shaking conditions in repeated batch process, as not all the mycelial fungi are capable of forming mycelial pellets in a shaking culture; some remain as amorphous vegetative mass (Clark 1962). Therefore, flow and cell density are two major factors which determine the efficiency of repeated batch process. In this study, a positive correlation was found between the color and COD (r = 0.99, p < 0.05), which confirms that color reduction increases as the COD decreases. The similar reduction in color and COD was observed by many other workers (Font et al. 2003; Wu et al. 2005). However, pH was found to decrease with the successive decrease in COD. A significant correlation (r = 0.97) between these two parameters was found significant at p < 0.05. The previous study reported that it is due to the release of chloride ions and hydrogen ions from chlorinated compounds which accompanied the decrease in pH (Yang and Lee 2007). The findings are well in line with the previous works of researchers (Agnihotri 2015). Reduction in other parameters, i.e., TDS, TSS, Na, K, heavy metals, nitrate, and sulfate, was also observed (data not shown). However, no changes were observed in control experiments.

On the other hand, biomass growth exhibited a continuous increase during the treatment. Biomass growth in the first treatment cycle was observed at 5.9 g/l. Thereafter, a significant increase in growth was observed for the second and third treatment cycles, at 8.2 and 9.15 g/l, respectively (Table 2). But no noticeable difference was observed in biomass production in the second and third treatment cycles. The significant growth could be associated with carbon and nitrogen sources present in the effluent sample which uphold primary metabolism of fungal culture. However, the consumption of energy sources and impeding oxygen transfer due to the excess mycelial proliferation could be correlated with the saturation of biomass.

Ligninolytic enzyme production in repeated batch process

Ligninolytic enzyme activity was observed in culture supernatant at different time intervals in repeated batch treatment (Fig. 4). In the present study, the maximum enzyme production, LiP 9.4 U/ml, Lac 13.5 U/ml, and MnP 11.4 U/ml, at 168 h was observed in the second treatment cycle, followed by the third treatment cycle, where LiP, Lac, and MnP productions were 6.81, 11.42, and 8.5 U/ml, respectively. Comparatively, the minimum enzyme activity of LiP (5.21 U/ml), MnP (7.81 U/ml), and Lac (9.8 U/ml) was recorded in the first treatment cycle. Enzyme activity is relatively proportional to the mycelial biomass. As reported earlier, fungi are the slow grower and ligninolytic enzymes are generally produced after 4 days of inoculation (Wu et al. 2002). In the first treatment cycle, slow biomass growth was observed (Table 2) which led to less enzyme production. Maximum enzyme activities in the second and third treatment cycles are well in line with earlier findings which reported that enzymes are generally produced during secondary metabolism of fungi (Gayazov and Rodakiewicz-Nowak 1996). Moreover, the production of enzyme varies with culture conditions, such as pH, temperature, and carbon and nitrogen sources. Carbon is generally required for growth, but excess carbon slows down the laccase production by repressing its induction (Eggert et al. 1996). Although, oxygen is obligatory for the production of ligninolytic enzymes, agitated cultures exert a shear stress on mycelia, affecting enzyme production in submerged cultures, which coincide with slow enzyme production in the third treatment cycle. In addition, ligninolytic enzymes are not constantly secreted throughout the second phase and are assimilated by extracellular proteases. The presence of all three major enzymes in the treated effluent attributed to the efficiency of fungal consortium. These enzymes play a concurrent task in the medium, attacking a wide range of pollutants through the different mechanisms, such as LiP and MnP degrading lignin, and phenolic and non-phenolic units by oxidative depolymerization due to high redox potential, whereas Lac uses molecular oxygen to oxidize aromatic compounds (Dashtban et al. 2010). LiP and MnP enzymes degrade lignin monomers and release phenols in the medium, which are simultaneously attacked by the laccase enzyme. The maximum amount of laccase enzyme was recorded in the supernatant which confirms the degradation of phenols. On the contrary, the control experiment showed no enzyme activity; hence, sterilized conditions were maintained.

Functional group characterization of degraded products

The treated effluent sample of the second treatment cycle was characterized by FTIR spectra after 168 h of incubation, which gives information about a change in functional groups and a significant difference between control and fungal consortium activities (Fig. 5a, b). The wide absorbance peak in the 3400 to 3300/cm region in the figure is attributed to O–H stretching, corresponding to the aliphatic molecules in lignin. In both samples, FTIR spectra showed a significant difference in the region 1700 to 1000/cm which is assigned to aromatic ring absorption of lignin. New peaks in the 1410 to 1310/cm region were observed in the treated effluent which represents O–H bending of phenol or a tertiary alcohol. On the other hand, increase in the intensity of absorption bands (1643, 1516, 1397, 1337, 1175, 1090/cm) was observed in the treated sample which represents enhanced degradation process. Pandey and Pitman (2003) also reported increased intensities of absorption bands resulting from lignin degradation process. The absorption at 1637 and 1643/cm indicate the aromatic skeleton vibrations, while the absorption at 1380 to 1320 cm are attributed to the bending vibration of C–H and C–O groups of the aromatic rings of polysaccharides. The assignments of infrared absorption bands of the samples are given in Table 3.

Identification of metabolites through GC-MS

The control and treated samples of the second treatment cycle of repeated batch process showed higher degradation of pollutants and were examined by GC-MS to uncover the degradation prototype in the effluent. The metabolic products and total ion chromatograph (TIC) of the treated samples at diverse time intervals (0, 96, and 168) are shown in Fig. 6a–c, respectively. The GC-MS study exhibited the reduction of peaks in the control sample and the generation of new peaks in the fungal treated sample processed after 96 and 168 h of treatment (Fig. 6b, c) which indicates generation of new metabolites. Table 4 shows the identified compounds from the available standards in the NIST-08 library. Major peaks detected in the control samples (Fig. 6a) at different RTs were 1-methyl-4-(1-methylethenyl)-cyclohexene (RT 9.46), 3,7-dimethyl-1,6-octadien-3-ol (RT 10.91), (−)-β-caryophyllene (RT 16.05), dodecanoic acid (RT 17.72), 4-hexen-2-one,5-phenyl (RT 18.00), diisobutyl phthalate (RT 21.18), pentadecanoic acid (RT 22.07), butyl phthalyl butyl glycolate (RT 22.15), benzene-1,2-dicarboxylic acid (RT 26.88), octyl phthalate (RT 27.44), and butyl-octyl-diphenylamine (28.09). The compounds at RTs 9.46, 10.91, and 21.18 were terpenes, which are generally produced from pulp and paper mill during the cooking of softwood chips (Grant and Grant 1987), mono-terpenoids, terpene alcohol (found in higher plants), and low-molecular-weight derivatives of lignin (Chandra et al. 2011), respectively. As illustrated by Fig. 6b, the TIC of the treated sample (96 h) with fungal consortium showed a huge increase in the peaks (58 peaks) as compared to the control sample (17 peaks), which signifies the release of a large amount of low-molecular-weight compounds from the wastewater sample as a consequence of fungal degradation. Furthermore, the detected peaks such as nonadecane (RT 20.34), hexadecanoic acid (RT 22.06), and phthalic acid (RT 27.25) were degraded after 168 h of incubation and some new peaks emerged, specifying breakdown or mineralization of low-molecular-weight compounds (Fig. 6c). The low molecular weight alkane compounds such as 1-3-dimethyl benzene (RT 6.24), 2-chloro-3-methyl butane (RT 9.46), heptadecane (RT 19.24), phytane (RT 20.45), and eicosane (RT 22.38), tetracontane (RT 28.45) and acidic compounds such as acetic acid (RT 8.18), pentadecanoic acid (RT 22.06), and 1-2-benzene dicarboxylic acid (RT - 27.25) were identified in the treated effluent sample (Table 4) which can be assigned to degraded lignin and phenolic compounds as reported earlier (Raj et al. 2007). The transformation of high-molecular-weight compounds to low-molecular-weight compounds and the presence of acidic compounds after microbial transformation of paper mill effluent were also investigated by many researchers (Chandra et al. 2011; Paliwal et al. 2015). The pulp and paper mill effluent contained high-molecular-weight aromatic compounds, resin acids, terpenoids, and some endocrine-disrupting compounds (Khan and Hall 2003; Blount et al. 2000). However, diisobutyl phthalate was not able to degrade by fungi, which determines its recalcitrant nature, and was earlier reported as a low-molecular-weight derivative of lignin (Chandra et al. 2011). Phthalate derivatives are teratogenic compounds and major contaminants of industrial pollutants (Blount et al. 2000).

Conclusion

This study clearly depicted the efficiency of contaminated sludge-dwelling ascomycetes fungi and their capability to degrade toxic compounds of pulp and paper mill effluent which pose threats to an aquatic environment. Under optimized process parameters, the fungal consortium showed an array of potential by producing desirable enzymes that catalyzed the degradation process for an extended duration in repeated batch process. SEM analysis confirmed the stable association of both fungi in a consortium. Further, GC-MS analysis showed the utilization of organic pollutants as energy sources during the effluent biodegradation process by the fungal consortium. This study further opens new facets, utilizing these fungi immobilized on a stable matrix as a biofilm carrier to restrain shear stress and to use in a continuous batch process for large-scale detoxification of the industrial effluent.

Abbreviations

- LDF:

-

Lignin-degrading fungi

- Mtpa:

-

Million tonnes per annum

- Co-Pt:

-

Cobalt–platinum

- C/N:

-

Carbon/nitrogen

- w/v :

-

Weight by volume

- g/l:

-

Gram per liter

- U/ml:

-

Unit per milliliter

References

Agnihotri, S. (2015). Use of fungal culture in free and in immobilized form to decolorize biomethanated distillery effluent. International Journal of Current Microbiology and Applied Science, 4(5), 586–595.

American Public Health Association, American Water Works Association, Water Environment Federation (APHA-AWWA-WEF). (2005). Standard methods for the examination of water and wastewater (21st ed.). Washington, DC: American Public Health Association.

Arantes, V., & Milagres, A. M. F. (2007). The synergistic action of ligninolytic enzymes (MnP and laccase) and Fe3+ reducing activity from white-rot fungi for degradation of azure B. Enzyme and Microbial Technology, 42(1), 17–22.

Bajpai, P., Mehna, A., & Bajpai, P. K. (1993). Decolorization of Kraft bleach plant effluent with the white rot fungus Trametes versicolor. Process Biochemistry, 28(6), 377–384.

Barnett, H. L., & Hunter, B. B. (1972). Illustrated Genera of Imperfect Fungi. Minneapolis: Burgess Publishing Company.

Blount, B. C., Milgram, K. E., Silva, M. J., Malek, N. A., Reidy, J. A., & Needham, L. L. (2000). Quantitative detection of eight phthalate metabolites in human urine using HPLC-APCIMS/MS. Analytical Chemistry, 72(17), 4127–4134.

Chandra, R., Raj, A., Purohit, H. J., & Kapley, A. (2007). Characterisation and optimisation of three potential aerobic bacterial strains for kraft lignin degradation from pulp paper waste. Chemosphere, 67(4), 839–846.

Chandra, R., Abhishek, A., & Sankhwar, M. (2011). Bacterial decolorization and detoxification of black liquor from rayon grade pulp manufacturing paper industry and detection of their metabolic products. Bioresource Technology, 102(11), 6429–6436.

Clark, D. S. (1962). Submerged citric acid fermentation of ferrocyanide treated beet molasses: Morphology of pellets of Aspergillus niger. Canadian Journal of Microbiology, 8(1), 133–136.

Da Re, V., & Papinutti, L. (2011). Black liquor decolorization by selected white-rot fungi. Applied Biochemistry and Biotechnology, 165(2), 406–415.

Dashtban, M., Schraft, H., Syed, T. A., & Qin, W. (2010). Fungal biodegradation and enzymatic modification of lignin. International Journal of Biochemistry and Molecular Biology, 1(1), 36–50.

Dimitrokallis, V., Meimaroglou, D. M., & Markaki, P. (2008). Study of the Ochratoxin A effect on Aspergillus parasiticus growth and aflatoxin B1 production. Food and Chemical Toxicology, 46(7), 2435–2439.

Domsch, K. H., Gams, W., & Anderson, T. H. (1980). Compendium of soil fungi. Pp 865. London: Academic Press (London) Ltd.

Eggert, C., Temp, U., Dean, J. F. D., & Eriksson, K. E. L. (1996). A fungal metabolite mediates degradation of nonphenolic lignin structures and synthetic lignin by laccase. FEBS Letters, 391(1–2), 144–148.

Font, X., Caminal, G., Gabarrell, X., Romero, S., & Vicent, M. T. (2003). Black liquor detoxification by laccase of Trametes versicolor pellets. Journal of Chemical Technology and Biotechnology, 78(5), 548–554.

Gao, H., Wang, Y., Zhang, W., Wang, W., & Mu, Z. (2011). Isolation, identification and application in lignin degradation of an ascomycete GHJ-4. African Journal of Biotechnology, 10(20), 4166–4174.

Garg, S. K., & Modi, D. R. (1999). Decolorization of pulp–paper mill effluents by white-rot fungi. CRC Critical Reviews in Biotechnology, 19(2), 85–112.

Gayazov, R., & Rodakiewicz-Nowak, J. (1996). Semi-continuous production of laccase by Phlebia radiata in different culture media. Folia Microbiologica, 41(6), 480–484.

Gianfreda, L., & Rao, M. A. (2004). Potential of extra cellular enzymes in remediation of polluted soils: A review. Enzyme and Microbial Technology, 35(4), 339–354.

Grant, R. L., & Grant, A. C. (1987). Grant & Hackh’s chemical dictionary. New York: McGrawHill.

Greenberg, A. E., Connors, J. J., Jenkins, D., & Franson, M. A. (1995). Standard methods for the examination of water and wastewater (15th ed.). Washington, DC: American Public Health Association.

Hakeem, A. S., & Bhatnagar, S. (2010). Heavy metal reduction of pulp and paper mill effluent by indigenous microbes. Asian Journal of Experimental Biology Science, 1(1), 201–203.

Hammerli, S. D., Leisola, M. S. A., & Feichter, A. (1986). Polymerization of lignins by ligninases from Phanerochaete chrysosporium. FEMS Microbiology Letters, 35(1), 33–36.

Ilyas, S., & Rehman, A. (2013). Decolorization and detoxification of Synozol red HF-6BN azo dye by Aspergillus niger and Nigrospora sp. Iranian Journal of Environmental Health Science & Engineering, 10(1), 12.

Iyer, G., & Chattoo, B. B. (2003). Purification and characterization of laccase from the rice blast fungus, Magnaporthe grisea. FEMS Microbiology Letters, 227(1), 121–126.

Jadhav, S. U., Jadhav, M. U., Kagalkar, A. N., & Govindwar, S. P. (2008). Decolorization of Brilliant Blue G dye mediated by degradation of the microbial consortium of Galactomyces geotrichum and Bacillus sp. Journal of Chinese Institute of Chemical Engineers, 39(6), 563–570.

Kamitsuji, H. Y., Watanabe, T., & Kuwahara, M. (2005). Mn2+ is dispensable for the production of active MnP2 by Pleurotus ostreatus. Biochemical and Biophysical Research Comm unications, 327(3), 871–876.

Kaushik, G., & Thakur, I. S. (2009). Isolation of fungi and optimization of process parameters for decolorization of distillery mill effluent. World Journal of Microbiology and Biotechnology. https://doi.org/10.1007/s11274-009-9970-0.

Khan, Z. M., & Hall, E. R. (2003). Occurrence and removal of plant sterols in pulp paper mill effluents. Journal of Environmental Engineering and Science, 2(1), 17–26.

Kirk, T. K., Connors, W. J., & Zeikus, J. G. (1976). Requirement for a growth substrate during lignin decomposition by two wood-rotting fungi. Applied and Environmental Microbiology, 32(1), 192–194.

Lundquist, K., & Kirk, T. K. (1971). Acid degradation of lignin. IV. Analysis of lignin acidolysis products by gas chromatography, using trimethylsilyl derivatives. Acta Chemica Scandinavica, 25(3), 889–894.

Malaviya, P., & Rathore, V. S. (2001). A correlation study on some physico chemical quality parameters of pulp and paper mill effluents. Pollution Research, 20(3), 465–470.

Malaviya, P., & Rathore, V. S. (2007). Bioremediation of pulp and paper mill effluent by a novel fungal consortium isolated from polluted soil. Bioresource Technology, 98(18), 647–3651.

Mantovani, T. R. D., Linde, G. A., & Colauto, N. B. (2007). Effect of the addition of nitrogen sources to cassava fiber and carbon-to-nitrogen ratios on Agaricus brasiliensis growth. Canadian Journal of Microbiology, 53(1), 139–143.

Mishra, M., & Thakur, I. S. (2010). Isolation and characterization of alkalotolerant bacteria and optimization of process parameters for decolorization and detoxification of pulp and paper mill effluent by Taguchi approach. Biodegradation, 21(6), 967–978.

Modi, D. R., Chandra, H., & Garg, S. K. (1998). Decolorization of bagasse based paper mill effluent by white-rot fungus, Trametes versicolor. Bioresource Technology, 66(1), 79–81.

Mohammad, N., Alam, M. Z., Kabashi, N. A., & Adebayo, O. S. (2011). Development of compatible fungal mixed culture for composting process of oil palm industrial waste. African Journal of Biotechnology, 10(81), 18657–18665.

Molla, A. H., Fakhrul-Razi, A., Abd-Aziz, S., Hanafi, M. M., & Alam, M. Z. (2001). In vitro compatibility evaluationof fungal mixed culture for bioconversion of domestic wastewater sludge. World Journal of Microbiology and Biotechnology, 17(9), 849–856.

Neoh, C. H., Lam, C. Y., Yahya, A., Ware, I., & Ibrahim, Z. (2015). Utilization of agro-industrial residues from palm oil industry for production of lignocellulolytic enzymes by Curvularia clavata. Waste and Biomass Valorization, 6(3), 385–390.

Paliwal, R., Rawat, A. P., Rawat, M., & Rai, J. P. N. (2012). Bioligninolysis: recent updates for biotechnological solution. Applied Biochemistry and Biotechnology, 167(7), 1865–1889.

Paliwal, R., Uniyal, S., & Rai, J. P. N. (2015). Evaluating the potential of immobilized bacterial consortium for black liquor biodegradation. Environment Science and Pollution Research, 22(9), 6842–6853.

Palonen, H., Saloheimo, M., Viikari, L., & Kruus, K. (2003). Purification, characterization and sequence analysis of a laccase from the ascomycete Mauginiella sp. Enzyme and Microbial Technology, 33(6), 854–862.

Pandey, K. K., & Pitman, A. J. (2003). FTIR studies of the changes in wood chemistry following decay by brown rot and white-rot fungi. International Biodeterioration and Biodegradation, 52(3), 151–160.

Pant, D., & Adholeya, A. (2007). Enhanced production of ligninolytic enzymes and decolorization of molasses distillery wastewater by fungi under solid state fermentation. Biodegradation, 18(5), 647–659.

Pearl, I. A., & Benson, H. K. (1940). The determination of lignin in sulphite pulping liquor. Paper Trade Journal, 111, 35–36.

Pointing, S. B. (1999). Qualitative methods for the determination of lignocellulolytic enzyme production by tropical fungi. Fungal Diversity, 2, 17–33.

Raj, A., Reddy, M. M. K., & Chandra, R. (2007). Decolourisation and treatment of pulp and paper mill effluent by lignin-degrading Bacillus sp. Journal of Chemical Technology and Biotechnology, 82(4), 399–406.

Santos, V. L., & Linard, V. R. (2004). Biodegradation of phenol by a filamentous fungi isolated from industrial effluents-identification and degradation potential. Process Biochemistry, 39(8), 1001–1006.

Schnell, A., Steel, P., Melcer, H., Hodson, P. V., & Carey, J. H. (2000). Enhanced biological treatment of bleached kraft mill effluents—I. Removal of chlorinated organic compounds and toxicity. Water Research, 34(2), 493–500.

Selvam, K., Swaminathan, K., Song, M. H., & Chae, K. S. (2002). Biological treatment of a pulp and paper industry effluent by Fomes lividus and Trametes versicolor. World Journal of Microbiology and Biotechnology, 18(6), 523–526.

Singhal, A., & Thakur, I. S. (2009). Decolourization and detoxification of pulp and paper mill effluent by Cryptococcus sp. Biochemical Engineering Journal, 46(1), 21–27.

Singhal, V., Kumar, A., & Rai, J. P. N. (2005). Bioremediation of pulp and paper mill effluent with Phanerochaete chrysosporium. Journal of Environment Biology, 26(3), 525–259.

Stahl, P. D., & Christensen, M. (1992). In vitro mycelial interactions among members of a soil microfungal community. Soil Biology and Biochemistry, 24(4), 309–316.

Tamura, K., Peterson, D., Peterson, N., Stecher, G., Nei, M., & Kumar, S. (2011). MEGA5: molecular evolutionary genetics analysis using maximum likelihood, evolutionary distance, and maximum parsimony methods. Molecular Biology and Evolution, 28(10), 2731–2739.

Thakker, G. D., Evans, C. S., & Rao, K. K. (1992). Purification and characterization of laccase from Monocillium indicum Saxena. Applied Microbiology and Biotechnology, 37(3), 321–323.

United States Environmental Protection Agency, Office of Water (1986). Quality criteria for water (gold book). EPA 440/5-86-001. Washington D.C.

Wu, J., Xiao, Y. Z., & Wang, Y. P. (2002). Treatment of pulp mill wastewaters by white-rot fungi. Journal of Biology, 19, 17–19.

Wu, J., Xiao, Y. Z., & Yu, H. Q. (2005). Degradation of lignin in pulp mill wastewaters by white-rot fungi on biofilm. Bioresource Technology, 96(12), 1357–1363.

Yadav, S., & Chandra, R. (2015). Syntrophic co-culture of Bacillus subtilis and Klebsiella pneumonia for degradation of kraft lignin discharged from rayon grade pulp industry. Journal of Environmental Science, 33, 229–238.

Yang, C. F., & Lee, C. M. (2007). Biodegradation and dechlorination of pentachlorophenol with a pentachlorophenol degrading bacterium Sphingomonas chlorophenolica. Journal of Environmental Engineering and Management, 17(3), 157–161.

Acknowledgements

One of the authors (DR) is thankful to Dr. Ajay Kumar and Dr. Ruchita Pal (AIRF, Jawaharlal Nehru University, New Delhi) for their assistance with the GC-MS and SEM analyses. Laboratory facilities received from Govind Ballabh Pant University of Agriculture and Technology, Pantnagar, is gratefully acknowledged. The authors declare that they have no conflict of interest.

Funding

One of the authors (DR) is thankful to the Department of Science & Technology (DST), Ministry of Science & Technology for providing financial assistance (grant no. IF120513).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

ESM 1

(DOCX 661 kb)

Rights and permissions

About this article

Cite this article

Rajwar, D., Paliwal, R. & Rai, J.P.N. Biodegradation of pulp and paper mill effluent by co-culturing ascomycetous fungi in repeated batch process. Environ Monit Assess 189, 482 (2017). https://doi.org/10.1007/s10661-017-6198-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10661-017-6198-6