Abstract

In this study, soil washing is applied for the remediation of heavy-metal (Pb, Cu and Zn) contaminated paddy soil located near an abandoned mine area. FeCl3 washing solutions were used in bench-scale soil washing experiments at concentrations in the range of 0.1 to 1 M. The strong acid, HCl was also used in this study for comparison. The washing process was performed at room temperature, mixing at 200 RPM for 1 h and a liquid to solid ratio of 2. A sequential extraction technique was performed to evaluate the chemical fractions of Pb in the soils. The soil washing effectiveness was evaluated and compared against regulations applicable to residential districts (Korean warning standards). The soil washing results showed that the heavy metal concentrations were reduced with increasing concentrations of FeCl3. Moreover, the lowest heavy metal concentrations were obtained with a 1 M FeCl3 washing solution. In the case of Pb removal, a 0.3 M FeCl3 washing solution was required to comply with the Korean warning standard of 200 mg/kg. The lowest Pb concentration of 117 mg/kg was obtained with 1 M FeCl3. Similar washing results were also obtained with HCl. The initial total concentrations for Cu and Zn were below the Korean warning standards of 150 and 300 mg/kg, respectively. Consequently, the reduction in Cu and Zn from the contaminated paddy soil using FeCl3 washing solutions was rather limited. The sequential extraction results showed that the exchangeable and weak acid-soluble fractions of Pb were significantly reduced upon FeCl3 washing.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Heavy metal contamination in paddy soil located near abandoned mine sites is a serious problem in the Republic of Korea. It is estimated that approximately 1300 out of 2600 abandoned mines in Korea are implicated in environmental issues associated with heavy metal releases (Mine Reclamation Corp. 2014). Among the various applicable remediation technologies for heavy metal removal (phytoremediation, stabilization/solidification, electrokinetics, soil washing, etc.) the soil washing process is a workable remediation alternative, capable of effectively treating heavy metal soil contamination (Vangronsveld and Cunningham 1998; Calmano et al. 2001). The efficacy of heavy metal remedial schemes in the Republic of Korea is assessed using an aqua regia extraction test (MOE 2010).

Heavy metals and various other inorganic contaminants held onto soil particles by adsorptive, precipitative or other bonding can be effectively removed by soil washing using appropriate extraction agents. Heavy metal removal rates and decontamination efficiencies depend on various factors including the type of washing solutions, the nature of the targeted contaminant(s), the extraction solution properties (bonding/chelating strength), and quality characteristics of the treated soil. In turn, these factors control the choice and concentration of the washing solution (Mulligan et al. 2001). In the past, strong acidic washing solutions (HCl, HNO3, H2SO4, etc.) have been used to improve the extraction effectiveness. For example, HCl (10:1, liquid-to-solids ratio) has been reported to remove Zn from a contaminated soil at a 67% Zn removal efficiency in a washing scrubber (Ko et al. 2005). Even though strong acid washing solutions produce effective metal removal results in soil washing applications, researchers are in pursuit of weak acids that provide promising results and at the same time safeguard the soil fabric often destructed by strong acid addition. Moreover, low pH values should be avoided in field soil washing applications to protect personnel exposure and corrosion of soil washing equipment. The use of FeCl3 has been reported for the effective removal of Cd from contaminated paddy soils (Makino et al. 2008). Moreover, FeCl3 is beneficial for the protection of clay minerals since proton release is governed by the hydroxide equilibria (Makino et al. 2008). In contrast, excess amounts of HCl may lead to the complete dissolution of clay minerals in soil. The same authors also report that in pot experiments FeCl3 soil washing exhibited no adverse effects on rice yields. Thus, to address heavy metal (Pb, Cu, and Zn) contamination of paddy soil, FeCl3 was selected as a washing solution in this study. Since heavy metal removal applications using FeCl3 in the literature are scarce, an investigation on the effectiveness of this extraction agent is warranted.

The objective of this study was to assess the feasibility of FeCl3 as a washing solution for the removal of heavy metals (Pb, Cu and Zn) from contaminated paddy soil. Strong acidic washing solutions containing HCl were also used for comparison. The optimum washing conditions obtained from this study will be used for in-situ soil washing applications in the field. Determinations of the residual levels of the target metals (Pb, Cu, Zn) on paddy soils upon soil washing were used to assess the process effectiveness. The residual metal levels were compared to the applicable Korean warning standards for residential districts of 200 mg/kg (Pb), 150 mg/kg (Cu) and 300 mg/kg (Zn).

Experimental methodology

Contaminated paddy soil collection and pretreatment

The heavy metal contaminated paddy soil was obtained from a paddy field near a mine located in Gyeongju-si, Gyeongsangbuk-do Province, Republic of Korea (Fig. 1). Contaminated soil collection was performed at a depth of 0–30 cm from the surface of the paddy soil. Prior to soil washing treatments, the collected contaminated soil was treated by air-drying and screening through a #10 sieve (2 mm) to eliminate large particulate matter and improve particle size uniformity. A particle size analyzer (Sedigraph 5100, USA) was used for the classification of the contaminated soil. The total organic carbon (TOC) content was determined by the TOC-SSM-5000A (Shimadzu, Kyoto, Japan) analyzer. The bulk chemical analysis of the contaminated paddy soil was performed with X-ray fluorescence (XRF, ZSX100e, Rigaku, Japan).

Soil washing experimental conditions

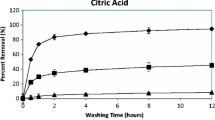

The soil washing experimental work was performed using an extraction solution to soil ratio of 2 to 1. This liquid to solid ratio was selected to simulate the in-situ soil washing process, similar to the study conducted by Makino et al. (2007). Specifically, 5 g of soil was mixed with 10 mL of FeCl3 (FeCl3·6H2O, Duksan, Republic of Korea) washing solution in a 125 mL conical flask. The concentration of the washing solutions ranged between 0.1-1 M. For comparison, the strong acidic washing solution containing HCl was also used at the same concentration levels. Sample suspensions were agitated at a shaking speed of 200 RPM for a duration of 1 h at 20 °C in an incubating shaker (LabTech, Daihan, Republic of Korea). Following the agitation process, the mixed sample was centrifuged at 3000 rpm for 25 min to separate the soil particles and liquid. After the washing process was completed, heavy metal concentrations in the soils were measured in accordance with KST Methods and the results were rivaled against the Korean regulatory warnings for residential areas (Pb = 200 mg/kg, Cu = 150 mg/kg, Zn = 300 mg/kg).

Chemical fraction analyses

In order to investigate the chemical fractions of Pb in the soil, the sequential extraction procedure (SEP) was used as developed by Tessier et al. (1979). Five fractions are identified by the SEP, namely: exchangeable, weak acid-soluble, reducible, oxidizable, and residual, commonly designated as F1-F5, respectively.

X-ray powder diffraction (XRPD) analyses

XRPD analyses were performed to obtain the mineralogical information of contaminated paddy soil. Prior to XRPD analyses, the samples were prepared according to the following experimental protocol: a) the samples were first air-dried for 24 h; b) subsequently, the samples were pulverized into a powder that cleared the U.S.-standard #200 sieve (0.075 mm). Collection of step-scanned X-ray diffraction patterns was performed using a PANalytical (X’Pert PRO MPD) X-ray diffractometer (XRD). The diffracted beam graphite-monochromator with Cu radiation was operated at 40 kV and 40 mA. The XRPD patterns were collected in the 2θ range of 5–65° using a step size of 0.02° and a count time of 3 s per step. The identification of the mineral compositions was accomplished using the software Jade v. 7.1 (MDI 2005) along with the PDF-2 reference database (International Center for Diffraction Data database, ICDD 2002).

Physicochemical analyses

The soil pH was determined using a L/S ratio of 5:1 based on the Korean Soil Environment Standard Test (KST for soil) (MOE 2010). The total heavy metal concentrations in the soil were determined by total sample digestion after sieving (#100 mesh) with aqua regia (3:1 HCl/HNO3 solution) (MOE 2010). The heavy metal concentrations in the soil after washing were determined by Inductively Coupled Plasma-Optical Emission Spectrometer (ICP-OES, Optima 7000DV) (PerkinElmer, CT, USA). All analytical tests were performed using duplicate samples and mean values were reported for single measurement errors within a 10% range. A quality assurance/quality control (QA/QC) protocol consisting of two different quality control standards and recovery spikes was used to safeguard equipment accuracy and performance.

Results and discussion

Characterization of heavy metal contaminated paddy soil

The characteristics of the heavy metal contaminated paddy soil are provided in Table 1. The soil pH value was determined to be 4.76. The contaminated paddy soil with a textural composition consisting of 44.6% sand, 28.5% silt and 26.9% clay was characterized as loam (Table 1 and Fig. 1b). The organic content was measured at 5.97% and the total Pb, Cu, and Zn concentrations were measured at 251 mg/kg, 47.4 mg/kg and 111.6 mg/kg, respectively. XRPD analyses of the contaminated paddy soil showed that quartz, albite, muscovite, and illite were the main mineral phases. The bulk chemistry of heavy metal contaminated paddy soil is provided in Table 2.

Soil washing results

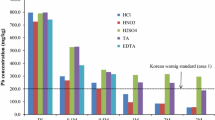

The soil washing results from the contaminated paddy soil using FeCl3 and HCl solutions are presented in Figs. 2–4. Control samples were treated using DI water for benchmarking and comparison with FeCl3 and HCl washing solutions.

Based on the reported results, soil washing with DI water is not effective in removing heavy metals (Fig. 1). The limited extraction capability of DI water indicates that heavy metals are not present in soluble forms. This finding is consistent with the reported literature. In fact, inorganic contaminants exhibit a strong bonding affinity for mineral surfaces or become integrated into the recalcitrant mineral lattice (Ko et al. 2005). Evidently, DI water is not a practical extraction solution for mobilizing heavy metals from the mineral phase.

The total Cu and Zn levels in the control samples were below the Korean warning standards of 150 mg/kg and 300 mg/kg, respectively. Therefore, Cu and Zn are not considered as target contaminants, but the washing results are presented to understand extraction behavior. According to the washing results, the Cu and Zn concentrations soil decreased as the extractant (FeCl3 and HCl) levels increased. However, the extraction of Cu and Zn was very limited. Even under the low pH conditions (0.3 at 1 M) encountered when applying HCl to the contaminated paddy soil, the extraction levels of Cu and Zn were not significant. This may be due to the types of Cu and Zn compounds that exist in the soil samples. Insoluble Cu and Zn [e.g., sphalerite (ZnS), Cu6Al2O8CO3·12H2O (Qiao et al. 2007)] precipitates may be possible mineral forms in the contaminated paddy soil. Therefore, the use of HCl is not recommended because similar washing results can be obtained using FeCl3. The use of HCl can cause damage to the soil fabric and issues regarding worker safety and corrosion of soil washing equipment arise as a result of the very low pH conditions associated with HCl.

In the case of Pb extraction, the total Pb concentration in the control sample was approximately 264 mg/kg which exceeds the Korean warning standard of 200 mg/kg. Therefore, Pb is considered a target contaminant and remediation of the contaminated paddy soil is deemed necessary. The soil washing results show that the Pb soil concentrations decreased with increasing concentrations of FeCl3 and HCl. Specifically, the lowest Pb concentrations of 112 mg/kg and 117 mg/kg (approximately 55% and 53% removal) were obtained with 1 M FeCl3 and HCl, respectively. Moreover, 0.3 M FeCl3 and HCl were required to comply with the Korean warning standard of 200 mg/kg. This indicates that similar washing results were attained using FeCl3 and HCl for the removal of Pb from the contaminated paddy soil. Therefore, use of FeCl3 over HCl may be reasonably recommended for effectively removing heavy metals from contaminated soils and avoiding the very low pH conditions associated with the use of HCl.

Heavy metal removal by acid washing has been postulated to proceed according to the following scheme. First, desorption of heavy metals takes place via ionic replacement of metals by H+. Subsequently metal dissolution phenomena lead to heavy metal release to the solution bulk. Finally, as a result of dissolution, other soil mineral constituents (e.g., as iron/manganese oxides) bond with the released heavy metals (Dermont et al. 2010). Pb removal by FeCl3 washing solutions could be explained based on the aforementioned mechanisms. Specifically, as FeCl3 washing solutions are applied to the contaminated paddy soil, precipitation of ferric hydroxide leads to significant decreases in the extraction pH due to the proton release (Makino et al. 2008; Yoo et al. 2016). The extraction pH is strongly linked to the Pb extraction efficiency. Yoo et al. (2016) have indicated that FeCl3 can remove Pb from the contaminated soil due to its low pKa and the chlorides can form Pb-Cl complexes that can enhance the extraction of Pb. The same authors have also reported that 10 and 25 mM of FeCl3 exhibit comparable Pb removal efficiency to HCl solutions of 50 and 100 mM because of the equilibrium solution pH. Furthermore, Si release from the clay structure was less using FeCl3 rather than with HCl, signifying that FeCl3 was less damaging to the clay structure (Makino 2014). Therefore, FeCl3 as a washing chemical is superior to HCl as it is capable of comparable Pb removal efficiencies from the contaminated paddy soil without damaging the soil structure.

During the soil washing process, the pH value of the washing solution with 0.3 M FeCl3 was approximately 2. This pH value is acceptable for field application. Since this soil washing experiment was designed for in-situ soil washing applications, pH is a very important operational parameter when considering the soil washing equipment. pH values lower than 2 are dangerous for personnel and corrosive to the soil washing equipment. Moreover, when this washing method is applied to the heavy metal contaminated field soil, this method could be valuable for clay preservation. Even though the cost of using the FeCl3 solution is higher (approximately 1.5 time more expensive than HCl), this method could be utilized for farmland. From an ecological perspective, significant loss of organic matter, low soil pH, and consequent implications on soil fertility, problems commonly associated with the use of strong acid washing solutions, are alleviated by using FeCl3 solutions. Thus, use of FeCl3 washing solutions, although costlier, is more favorable than a strong acid addition. Nevertheless, subsequent measures (e.g., lime or amendment addition) to improve the quality of the washed soils prior to crop planting may need to be considered.

Chemical fraction results

The chemical Pb fraction results of the control and the washed soil with 0.3 M FeCl3 analyzed by SEP are presented in Fig. 5. The washed soil with 0.3 M FeCl3 was selected because this treated soil passed the Korean warning standard of 200 mg/kg. Evidently, Pb extraction using FeCl3 caused significant shifts in the composition of the various chemical fractions before and after the soil washing process. The significant reduction in the exchangeable fraction (F1) indicates that the re-adsorption of washed out Pb from other fractions is very limited. Similar results for Pb extraction using FeCl3 were obtained for the Wu-Ri site soil which is the same soil texture (loam) (Cheng et al. 2013). The alleviating effect on re-adsorption of Pb in the F1 fraction is strongly associated with the characteristics of the soil (Cheng et al. 2013). Therefore, the Pb extraction with 0.3 M FeCl3 is most probably associated with the significant reduction in the exchangeable (F1) and weak acid-soluble (F2) fractions.

Conclusions

Soil washing experimental work was performed to study the removal of heavy metals from contaminated paddy soil using a FeCl3 solution. The FeCl3 concentration ranged from 0.1 to 1 M and the washing process was conducted with an extraction solution to soil ratio of 2. Mixing was performed at 200 RPM for 1 h. For comparison, HCl was also used for the soil washing process under the same conditions. The results of the soil washing experiments indicated that the heavy metal removal rate increased with increasing FeCl3 and HCl concentrations. In the case of Pb extraction, FeCl3 and HCl washing solutions concentration greater than 0.3 M were required for compliance with the Korean warning regulation of 200 mg/kg for residential districts. The removal of Cu and Zn was limited possibly due to the presence of sparingly soluble Cu and Zn compounds. The sequential extraction results showed that significant Pb removal was strongly associated with the exchangeable and weak acid-soluble fractions of Pb. Overall, since removal of heavy metal contamination from paddy soils using FeCl3 washing solution showed similar results with HCl at comparable concentrations, FeCl3 was recommended as a washing solution over HCl.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Ball, D. F. (1964). Loss-on-ignition as an estimate of organic matter and organic carbon in non-calcareous soil. Journal of Soil Science, 15, 84–92.

Calmano, W., Mangold, S., Stichnothe, H., & Tho Ming, J. (2001). Clean-up and assessment of metal contaminated soils. In R. Stegmann, G. Brunner, W. Calmano, & G. Matz (Eds.), Treatment of Contaminated Soil (pp. 471–490). Berlin, Germany: Springer.

Cheng, S.-F., Tu, Y.-T., Huang, C.-Y., Chen, J.-R., & La, C.-Y. (2013). Characteristics and removal efficiency of washing with different reagent for soil contaminated by leads of various sources. Advanced Materials Research, 671–674, 2613–2616.

Dermont, G., Bergeron, M., Richer-Laflèche, M., & Mercier, G. (2010). Remediation of metal-contaminated urban soil using flotation technique. Science of Total Environment, 408, 1199–1211.

FitzPatrick, E. A. (1983). Soils: their formation, classification and distribution (p. 353). London: Longman Science & Technical.

ICDD (2002) Powder diffraction file.PDF-2 database release, International Centre for Diffraction Data, Newtown Square, Pennsylvania, USA.

Ko, I., Chang, Y.-Y., Lee, C.-H., & Kim, K.-W. (2005). Assessment of pilot-scale acid washing of soil contaminated with As, Zn and Ni using the BCR three-step sequential extraction. Journal of Hazardous Materials, A127, 1–13.

Makin, T. (2014) Heavy metal contamination in Japan. International Forum on Soil and Groundwater, The K Hotel, Seoul Republic of Korea.

Makino, T., Takano, H., Kamiya, T., Itou, T., Sekiya, N., Inahara, M., & Sakurai, Y. (2008). Restoration of cadmium-contaminated paddy soils by washing with ferric chloride: Cd extraction mechanism and bench-scale verification. Chemosphere, 70, 1035–1043.

MDI (2005) Jade Version 7.1. Material’s Data Inc., Livermore, California, USA

Mine Reclamation Corp. (2014) 2013 Yearbook of MIRECO Statistics. p. 242 (in Korean)

MOE (2010) The Korean Standard Test (KST) Methods for Soils. Korean Ministry of Environment, Gwachun, Kyunggi, pp. 225 (in Korean).

Mulligan, C. N., Yong, R. N., & Gibbs, B. F. (2001). Remediation technologies for metal-contaminated soils and groundwater: an evaluation. Engineering Geology, 60, 193–207.

Qiao, X. C., Poon, C. S., & Cheeseman, C. R. (2007). Investigation into the stabilization/solidification performance of Portland cement through cement clinker phases. Journal of Hazardous Materials, B139, 238–243.

Tessier, A., Campbell, P. G. C., & Bisson, M. (1979). Sequential extraction procedure for speciation of particulate trace metals. Analytical Chemistry, 51, 844–851.

Vangronsveld, J., & Cunningham, S. D. (1998). Introduction to the concepts. In J. Vangronsveld & S. D. Cunningham (Eds.), Metal-Contaminated Soils (pp. 1–15). Berlin, Germany: Springer.

Yoo, J.-C., Shin, Y.-J., Kim, E.-J., Yang, J.-S., & Baek, K. (2016). Extraction mechanism of lead from shooting range soil by ferric salts. Process Safety and Environmental Protection, 103, 174–182.

Funding

This study was supported by the Mine Reclamation Corporation, Republic of Korea (No. 20150733708–00).

Author information

Authors and Affiliations

Contributions

Deok Hyun Moon: Conceptualization, data collection, data management and statistical analyses, writing–original draft, writing–review and editing. Yoon-Young Chang: Conceptualization, funding acquisition, supervision, writing–review and editing. Minho Lee: Data collection. Agamemnon Koutsospyros: writing–review and editing. Il-Ha Koh: Conceptualization, writing–review and editing. Won Hyun Ji: supervision, writing–review and editing. Jeong-Hun Park: writing–review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

Not applicable.

Animal research

Not applicable.

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Moon, D.H., Chang, YY., Lee, M. et al. Assessment of soil washing for heavy metal contaminated paddy soil using FeCl3 washing solutions. Environ Geochem Health 43, 3343–3350 (2021). https://doi.org/10.1007/s10653-021-00815-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10653-021-00815-3