Abstract

Bench-scale soil washing experiments were conducted for simultaneous removal of heavy metals (Pb, Cu, Zn) and low-level petroleum hydrocarbon contaminants from soils. Various washing solutions including hydrochloric acid (HCl), nitric acid (HNO3), sulfuric acid (H2SO4), tartaric acid (C4H6O6) and ethylenediaminetetraacetic acid (C10H16N2O8, EDTA) were used. The concentration of the washing solutions ranged from 0.1 to 3M with a liquid-to-solid ratio of 10. The soil washing results showed that hydrochloric acid (HCl) was the best washing solution at 3M for heavy metal removal. Other washing solutions also showed a significant removal of heavy metals, except for sulfuric acid (H2SO4). Sulfuric acid (H2SO4) exhibited the worst performance among all washing solutions used with respect to Pb removal. 1M HCl and HNO3 were sufficient for effective Pb and Cu removal, and all of the tested washing solutions at a concentration of 0.1M produced results compliant with the Korean warning standard for Zn removal. In the case of total petroleum hydrocarbons (TPH), tartaric acid (C4H6O6) produced the highest removals at all concentration levels compared with other washing solutions. More specifically, TPH removal efficiencies exceeded 33 and 82 % at the lowest (0.1M) and highest (3M) tartaric acid (TA) concentrations, respectively. Overall, TA could be a viable washing solution for the removal of both heavy metals (Pb, Cu, Zn) and TPH from contaminated soils.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The railroad is considered an eco-friendly transportation system. However, for the past few decades, there have been many incidents of contamination at railway facility sites. Industrial and municipal solid wastes generated as a result of maintenance operations were dumped in underground railroad depot areas. The Yongsan railroad depot located in Seoul, the Republic of Korea, is one of the contaminated railway facility sites. This railroad depot was established in 1905 and operated until the 1980s (Baek et al. 2012). Heavy metals and petroleum are the main contaminants at the site. Currently, remedial action is taken to clean the soil at the site.

Depending on target contaminants and applicable environmental regulations, a variety of remediation methods are available in the literature. In the Republic of Korea, current soil environmental regulations are based on source rather than risk reduction (MOE 2010). Aqua regia extraction is used to evaluate the effectiveness of remedial processes for heavy metal-contaminated soils. Among various remediation technologies (phytoremediation, bioremediation, electro kinetics, stabilization/solidification, thermal desorption, land farming, soil vapor extraction, etc.), soil washing is a viable, most commonly employed technology for the removal of soil contaminants such as heavy metals and petroleum hydrocarbons. The effectiveness of the soil washing process depends on a multitude of factors including nature of the target contaminants, soil characteristics and bonding/chelating strength of the extraction solution. Thus, selection of the type of washing solution is of critical importance for the soil washing process (Mulligan et al. 2001).

An intensive study focused on a single type of contaminant (i.e., either heavy metal or organic contaminants). Moutsatsou et al. (2006) studied washing of a soil heavily contaminated by mining and metallurgical activities. They reported that hydrochloric acid showed a high extraction efficiency for heavy metals and metalloids (Pb, As, Cu, Zn, Mn and Fe). Ko et al. (2006) reported that similar extraction results were obtained for Zn and Ni (cationic) removal with HCl, H2SO4 and H3PO4. Also they reported that the As (anionic) extraction rate was higher for H2SO4 and H3PO4 as compared to HCl, due to competitive oxyanions (PO4 3− or SO4 2−). Moon et al. (2012) using various washing solutions reported that HCl was the best washing solution option for removal of Zn from contaminated soils.

Paterson et al. (1999) used five different surfactants (P103, P105, F108, Triton X 100 and Tween 20) in soil washing experiments, and these treatments were effective for the extraction of polycyclic aromatic hydrocarbons. Moreover, Madadian et al. (2014) tested two different surfactants (Triton X 100 and Brij 35) for the removal of polycyclic aromatic hydrocarbons in contaminated soil with effective soil washing results (the biggest removal of total PAH was 81.66 %).

Only limited studies are available regarding simultaneous removal of metal and organic contaminants. Zhang et al. (2007) used ethylenediaminetetraacetic acid (EDTA)- and sodium dodecyl sulfate (SDS)-enhanced washing for Pb and marine diesel fuel-contaminated soil. They reported that multistage washing with a solution of low-concentration EDTA and SDS may be recommended when the concurrent serious heavy metal and MDF contamination is present. Moreover, as for the optimal washing sequence, EDTA soil washing followed by SDS addition achieved the highest Pb removal efficiency, while SDS soil washing followed by EDTA addition achieved the highest MDF removal efficiency (Zhang et al. 2007). Khodadoust et al. (2005) evaluated different extraction agents for the removal of phenanthrene and heavy metal (Pb and Zn) from a contaminated soil. They reported that the sequential use of 0.2M EDTA followed by 5 % Tween 80 or 5 % Tween 80 followed by 1M citric acid was found to be effective for the removal of both heavy metals and phenanthrene. Reddy et al. (2011) assessed the in situ (soil flushing) simultaneous removal of heavy metals and PAHs using 0.2M EDTA solution enhanced with either a surfactant (5 % Igepal CA-720) or cyclodextrin (10 % hydroxypropyl-β-cyclodextrin or HPCD). This study concluded that none of the attempted combinations were capable of removing all metals and PAHs simultaneously and suggested sequential flushing schemes.

In this study, various washing solutions such as hydrochloric acid (HCl), nitric acid (HNO3), sulfuric acid (H2SO4), tartaric acid (C4H6O6) and ethylenediaminetetraacetic acid (EDTA) are used to remove heavy metal (Pb, Cu and Zn) and low-level petroleum contaminants in soil. The use of these washing solutions has been demonstrated for heavy metal removal from contaminated soil but it has not been applied to petroleum-contaminated soil and is considered less effective compared with surfactants. Therefore, it is worth investigating the effectiveness of simultaneous TPH and heavy metal removal from contaminated soil using the aforementioned washing solutions. The effectiveness of the washing process was evaluated by measuring the residual heavy metals (Pb, Cu and Zn) and TPH concentrations after the washing process. The residual Pb, Cu, Zn and TPH concentrations were compared to the Korean warning standard of 200, 150, 300 and 500 mg/kg for residential area (area 1), respectively. The purpose of this study was to evaluate the treatment performance of various soil washing solutions for the simultaneous removal of heavy metals and petroleum from contaminated soils.

Experimental methodology

Contaminated soil

The heavy metal- and petroleum-contaminated site is located at the Yongsan railroad depot in Seoul, Republic of Korea. The total area of contamination is approximately 692,973 m2. Specifically, the amount of heavy metal contamination is estimated to be 134,861 m2, while petroleum contamination is estimated to be 148,223 m2. The area of simultaneous heavy metal- and petroleum-contaminated soil is estimated to be 21,163 m2. A soil sample of approximately 10 kg of both heavy metal- and petroleum-contaminated soil was collected from the site at a depth of 0–30 cm from the soil surface. The soil was then air-dried and passed through a #10 mesh (2 mm) to remove the large particles such as cobbles and gravel.

Soil washing process

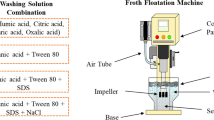

Reagent grade hydrochloric acid (HCl), nitric acid (HNO3), sulfuric acid (H2SO4, SA), tartaric acid (C4H6O6, TA) and ethylenediaminetetraacetic acid (C10H16N2O8, EDTA) were used as extraction agents. These washing solutions are widely used for the removal of heavy metals. Moreover, these washing solutions were also evaluated for the removal of incidental, low-level (TPH concentration less than 500 mg/kg) petroleum hydrocarbon contamination since no studies have been reported which indicate that they are not effective. The concentration of the washing solutions was varied from 0.1 to 3M. The washing process was performed with 5 g of soil mixed with 50 mL of washing solution in a 125-mL plastic bottle. The suspensions were then shaken at 200 RPM for 1 h at 20 °C in a shaking incubator (LabTech, Daihan, Republic of Korea). Following the shaking process, the suspended solids were separated by filtration with a 0.45-µm micropore filter and air-dried. After the washing process, the Pb, Cu, Zn and TPH concentrations in the soil were measured based on the Korean standard test methods and compared to the Korean warning standards for a residential area (MOE 2010).

Physicochemical analyses

The contaminated soil was characterized using a particle size analyzer (PSA) in accordance with the United States Department of Agriculture (USDA). The soil pH was measured in accordance with the Korean standard test (KST) method (MOE 2010). The bulk chemistry of the contaminated soil was measured using X-ray fluorescence (XRF, ZSX100e, Rigaku, Japan). The total Pb, Cu and Zn concentrations in the contaminated soil were obtained by total digestion using a 3:1 HCl/HNO3 solution (MOE 2010). Specifically, a soil sample of 0.3 g was mixed with aqua regia [0.7 mL of HNO3 (65 %, Merck) and 2.1 mL of HCl (37 %, J. T. Baker)]. The mixture was then heated to 70 °C for 2 h and diluted with 7.2 mL of distilled water (MOE 2010). The extracted solution was then filtered through a 0.45-μm micropore filter. The soluble Pb, Cu and Zn concentrations were analyzed using an inductively coupled plasma-optical emission spectrometer (ICP-OES, Optima 7000DV) with a detection limit of 0.03 mg/L (PerkinElmer, CT, USA).

The TPH concentration in the contaminated soil was determined in accordance with the KST method (MOE 2010): 10 g of soil was mixed with anhydrous sodium sulfate in a beaker and 100 mL of dichloromethane was added to the mixed material. The soil was then ultrasonically extracted twice for 3 min each time. The extract was then filtered using 5B filter paper, and the extractant was concentrated using a rotary evaporator until 2 mL of solution was obtained. The TPH concentration in the final solution was analyzed using gas chromatography fitted with a flame ionization detector (HP-6890, Agilent Tech., USA).

Sample analyses were conducted in duplicate or triplicate, and the average values were reported. The average values were reported only if the individual measurements were within an error range of 10 %. For QA/QC purposes, two quality control standards and matrix spikes were used to validate the accuracy and performance of the equipment.

X-ray diffraction (XRD) analysis

In order to obtain the mineralogical information for the contaminated soil, XRD analysis was performed. The sample was air-dried and hand-pulverized to pass through a #200 sieve. A step-scanned XRD pattern was collected using a PANalytical XRD instrument (X’Pert PRO MPD). The XRD analysis was conducted at 40 kV and 30 mA using a diffracted beam graphite monochromator with Cu radiation. The XRD pattern was collected in the 2θ range of 5°–65° with a step size of 0.02° and a count time of 3 s per step. The Jade software version 7.1 (MDI 2005) and the powder diffraction file (PDF)-2 reference database from the International Center for Diffraction Database (ICDD) (ICDD 2002) were used in order to qualify the XRD pattern.

Results and discussion

Characterization of contaminated soil

The physicochemical properties of the contaminated soil are presented in Table 1. Specifically, the soil pH was determined to be 6.62, and the contaminated soil was classified as loamy sand (Table 1). The soil was composed of 86.4 % sand, 5.6 % silt and 7.9 % clay. The organic matter content was determined to be 0.48 %, and the CEC value was measured at 11.7 cmol+/kg. The total Pb, Cu, Zn and TPH concentrations in the soil were approximately 842, 438, 375 and 200 mg/kg, respectively. The mineralogical information obtained from XRD analysis is presented in Table 1. Quartz (SiO2, PDF# 46-1045), calcite (CaCO3, PDF# 05-0586), albite [(Na, Ca)Al(Si, Al)3O8, PDF# 41-1480], microcline (KAlSi3O8, PDF# 19-0932) and muscovite-1M [KAl2Si3AlO10(OH)2, PDF# 07-0025] were the main phases identified in the contaminated soil. The bulk chemistry of contaminated soil is provided in Table 2.

Soil washing

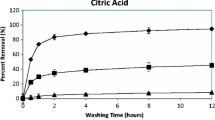

The soil washing results are presented in Figs. 1, 2, 3 and 4. The soil washing results using DI water were reported for benchmarking against the performance of the various washing solutions attempted in this study. Soil washing using DI water can expose the metal fraction that is weakly bound to the soil particles or sorbed on the outer surfaces of soil particles (Mann 1999). The maximum removal of heavy metals from contaminated soil using DI water was 3.2 % for Pb, and the TPH extraction rate was less than 2.5 %. The removal effectiveness of heavy metals and TPH depends on how strongly the contaminants are bound to the soil particles. Heavy metals are associated with the following fractions: ion exchangeable, adsorbed, precipitated, organically bound or trapped in an insoluble form in the soil matrix (Mann 1999). Moutsatsou et al. (2006) reported that the soil solubility in DI water was below 50 mg/kg and below 1 % for all tested metals because the bulk of the metals were very tightly bound to the soil particles.

In the case of Pb removal, soil washing using HCl and HNO3 showed a significant reduction in Pb removal from contaminated soil (Fig. 1). Both of these washing solutions were capable of producing soil washing results consistently below the Pb Korean warning standard (200 mg/kg) for a residential area at washing solution concentrations greater than 1M. HNO3 yielded higher Pb removals compared with the HCl at low concentration ranges (0.1–1M). However, a similar Pb removal was obtained using HCl and HNO3 at high concentrations (>2M). At the highest concentration level (3M), both of the above washing solutions generated Pb removals higher than 93 %. These results compare favorably to those by Moutsatsou et al. (2006) who reported 79 % and 44 % Pb extraction using 3M HCl and 6M HNO3 solutions, respectively. Pb extraction with HCl and HNO3 was much better than the extraction results for TA and EDTA. Pb extraction with EDTA up to 0.5M was better than TA, but it was limited due to the solubility of EDTA for the given soil pH. This explains the absence of EDTA data for concentrations greater than 0.5M in Fig. 1. At low concentrations, none of the TA and EDTA washing solutions produced results compliant with the Pb Korean warning standard (200 mg/kg) for a residential area. However, at 3M washing solution concentration, TA produced a Pb removal greater than 77 % and was compliant with the Korean warning standard for Pb. Soil washing using H2SO4 was not as effective in removing Pb from contaminated soil compared with the other mineral acid solutions tested. H2SO4 was the worst case washing solution in this study, and Pb concentrations were virtually unchanged for washing solution concentrations greater than 1M H2SO4. This may be attributed to the formation of PbSO4 in contaminated soil which can be precipitated as an insoluble salt (Ksp PbSO4 = 1.82 × 10−8) (Moutsatsou et al. 2006). Additionally, the use of H2SO4 failed to meet the Korean warning standard at all attempted washing solution concentrations (0.1–3M). Based on all results from the tested washing solutions, except those for H2SO4 at levels greater than 1M, it is safe to conclude that Pb removal efficiency increases with increasing washing solution concentrations following a law of diminishing incremental efficiencies. Therefore, the selection of the optimal washing solution concentration must be arrived at by taking into account not only performance but also cost and regulatory considerations.

In the case of Cu removal, the most effective washing solution was HCl that produced sub-regulatory levels of Cu (<150 mg/kg) at all attempted washing solution concentrations (0.1–3M). The least effective washing solution was TA (Fig. 2) which failed to generate sub-regulatory levels for Cu at all attempted washing solution concentrations (0.1–3M). Cu removal of approximately 91 % was obtained with the 3M HCl solution. This removal efficiency compares favorably to that reported by Moutsatsou et al. (2006) where only 51 % of the Cu was mobilized with 3M HCl due to the precipitation of CuCl2. CuCl2 solubility limitations did not emerge in the present study as the concentration levels of the washing solution and Cu are well below the CuCl2 solubility product (\( K_{{{\text{sp}}\,{\text{CuCl}}_{2} }} = 579 \)) and is evidenced by the high Cu removal efficiency attained with the HCl washing solution. However, it should be noted that a reducing environment, where CuCl exists, may lead to precipitation since the solubility product of this compound is approximately eight orders of magnitude smaller than that of CuCl2 (\( K_{{{\text{sp}}\,{\text{CuCl}}}} = 1.2 \times 10^{ - 6} \)). The minimum washing solution concentration for attaining sub-regulatory Cu levels (based on the Korean warning standard of 150 mg/kg for residential areas) was 0.1M for HCl, 1M for HNO3 and 2M for H2SO4. The highest attained Cu removal efficiencies were: 91 % for HCl, 80 % for H2SO4, 79 % for HNO3, 55 % for TA and 49 % for EDTA. The highest Cu removal efficiencies were observed at the highest attempted washing solution concentration (3M) except for EDTA (0.5M) which was limited by solubility. Based on all results from the tested washing solutions, it can be safely stated that Cu removal efficiency increases with increasing washing solution concentrations following a law of diminishing incremental efficiencies. Therefore, the selection of the optimal washing solution concentration must be arrived at by taking into account not only performance but also cost and regulatory considerations.

In the case of Zn removal, the highest removal of Zn (89 %) was obtained with 3M HCl and the worst Zn removal efficiency (59 %) was attained with 3M TA washing solution (Fig. 3). A previous study also showed that the best Zn removal was obtained from HCl extraction (Moon et al. 2012). At low concentrations (0.1–1M), the HNO3 washing solution performed better than H2SO4, but this trend was reversed at high washing solution concentrations (2–3M). Similar results have been reported by Moutsatsou et al. (2006) where Zn mobilization was highest (97 %) with 6M HCl and 6M H2SO4 (78 %) showed a better mobilization rate compared with 6M HNO3 (45 %). It is worth noting that all washing solutions produced sub-regulatory levels of Zn at all washing solution concentrations attempted. Evidently, washing solution concentrations as low as 0.1M were sufficient to treat effectively relatively low Zn soil contamination (375 mg/kg) and produce results compliant with the Korean warning standard of 300 m/kg for a residential area. This indicates that, for the given soil, initial metal contamination levels and test conditions, Zn was more readily removable than Pb and Cu.

In the case of TPH removal, the Korean warning standard for TPH for a residential area is 500 mg/kg. Therefore, technically the soil studied here is not considered TPH-contaminated soil and requires no remedial action. However, in view of the fact that no relevant literature was available, it was worth investigating the washing results using the same solutions studied for heavy metal removal. TPH removal for the three mineral acids at the highest concentration level (3M) was limited, namely 45 % for H2SO4, 36 % for HCl and 30 % for HNO3. On the other hand, the two organic acids EDTA and TA performed comparatively better than their mineral counterparts with EDTA achieving a 39 % at 0.5M and TA attaining the highest removal of all (82 %) at the 3M concentration level. Choi (2005) reported that TPH removal by an organic acid was not caused by a reduction in surface tension because TPH is a hydrophobic organic compound. The surface tension of strong acids and organic acids was measured using a ITOH interfacial tensiometer (ITOH, Japan) and ranged from 71 to 74 mN/m at 16.9 °C which was not significantly different from the surface tension of DI water at 73.1 mN/m. Choi (2005) reported that the attraction between the organic acids and TPH molecules increases the solubility of TPH and may be the main mechanism for TPH removal. Moreover, evidence indicating the interaction of tartaric acid with nonpolar organic compounds is reported in the literature (Upadhyay and Keshav 2012) where extraction of tartaric acid from an aquatic phase was performed successfully using a variety of nonpolar solvents. This study suggests that the driving forces behind the successful extraction of tartaric acid from an aquatic phase into a variety of organic nonpolar solvents are the solvation of ionic species and the neutralization of their charge by ion pairing. In other words, dissociated molecules of the organic acid are neutralized and solvated by the formation of hydrogen bonds to the nonpolar solvent possibly still carrying a few molecules of hydration water, thus reducing the hydrophobicity of the nonpolar solvent. Nevertheless, it appears that organic acids, under certain conditions, may produce sizeable removal of TPH during soil washing operations. However, the mechanism of organic acid–hydrocarbon interaction, the effect of initial TPH concentration, the type of organic acid and soil characteristics are some issues that cannot be answered by the present study. Hopefully, this work will generate genuine interest and motivation for further research efforts that will shed light and resolve these issues.

Conclusions

A soil containing heavy metals (Pb, Cu and Zn) and low-level petroleum hydrocarbons was washed with hydrochloric acid (HCl), nitric acid (HNO3), sulfuric acid (H2SO4), tartaric acid (C4H6O6) and ethylenediaminetetraacetic acid (C10H16N2O8, EDTA). The washing solution concentrations ranged from 0.1 to 3M with a liquid-to-solid ratio of 10. The washing solutions were applied to the contaminated soil in order to examine the removal of Pb, Cu, Zn and TPH. The soil washing results showed that hydrochloric acid was the best washing solution for heavy metal removal while tartaric acid was the best washing solution for TPH removal. In the absence of precipitation reactions, the metal removal efficiency increased with increasing washing solution concentrations in the range of 0.1–3M following a law of diminishing incremental efficiencies. Based on the results of this study, the H2SO4 washing solution exhibited the worst Pb removal performance due to PbSO4 precipitation and failed to meet the Korean warning standard. 1M HCl and HNO3 were sufficient for effective Pb and Cu removal and compliance with the Korean warning standard while washing solutions with concentrations of 0.1M were necessary for Zn removal. Overall, for the consideration of simultaneous heavy metal (Pb, Cu and Zn) and TPH removal, tartaric acid could be a viable washing solution but further research is needed to resolve a number of unsettled issues. Strong acids failed to provide effective TPH removal. In order to apply specific washing solutions to the contaminated soil, the soil type, type of contaminant, soil mineralogy and concentration, etc. should carefully be considered to obtain effective washing results.

References

Baek S-J, Park I-S, Lim H-S, Park J-W (2012) Risk assessment of the Yongsan rail yard by using the RBCA tools and RISK5 Tools. In: Proceedings of Korean Geo-Environmental Society Conference, 75–78

Ball DF (1964) Loss-on-ignition as an estimate of organic matter and organic carbon in non-calcareous soil. J Soil Sci 15:84–92

Choi HJ (2005) Cleanup of soil contaminated with combined pollutants by soil washing. Ph.D. Dissertation, Korea University, p 156

FitzPatrick EA (1983) Soils: their formation, classification and distribution. Longman Sci Tech, London, p 353

ICDD (2002) Powder Diffraction File.PDF-2 Database Release. In: International Centre for Diffraction Data, Pennsylvania, USA

Khodadoust AP, Reddy KR, Maturi K (2005) Effect of different extraction agents on metal and organic contaminant removal from a field soil. J Hazard Mater B117:15–24

Ko IW, Lee CH, Lee KP, Lee SW, Kim KW (2006) Remediation of soil contaminated with arsenic, zinc, and nickel by pilot-scale soil washing. Environ Prog 25(1):39–48

Madadian E, Gitipour S, Amiri L, Alimohammadi M, Saatloo J (2014) The application of soil washing for treatment of polycyclic aromatic hydrocarbons contaminated soil: a case study in a petrochemical complex. Environ Prog Sustain Energy 33:107–113

Mann JM (1999) Full-scale and pilot-scale soil washing. J Hazard Mater 66:119–136

MDI (2005) Jade Version 7.1.Material’s Data Inc., California, USA

Ministry of Environment (MOE) (2010) The Korean Standard Test (KST) methods for soils. Korean Ministry of Environment, Gwachun, Kyunggi, p. 225 (in Korean)

Moon DH, Lee J-R, Wazne M, Park J-H (2012) Assessment of soil washing for Zn contaminated soils using various washing solutions. J Ind Eng Chem 18:822–825

Moutsatsou A, Gregou M, Matsas D, Protonotarios V (2006) Washing as a remediation technology applicable in soils heavily polluted by mining-metallurgical activities. Chemosphere 63:1632–1640

Mulligan CN, Yong RN, Gibbs BF (2001) Remediation technologies for metal-contaminated soils and groundwater: an evaluation. Eng Geol 60:193–207

Paterson IF, Chowdhry BZ, Leharne SA (1999) Polycyclic aromatic hydrocarbon extraction from a coal tar-contaminated soil using aqueous solutions of non-ionic surfactants. Chemosphere 38(13):3095–3107

Reddy KR, Al-Hamdan AZ, Ala P (2011) Enhanced soil flushing for simultaneous removal of PAHs and heavy metals from industrial contaminated soil. J Hazard Toxic Radioact Waste 15(3):166–174

Upadhyay B, Keshav A (2012) Modeling of recovery of tartaric acid using various solvents. In: Proceedings of International Conference on Chemical, Ecology and Environmental Sciences (ICEES’2012), March 17–18, Bangkok, 173–176

USEPA (1986) Cation-exchange capacity of soils (Sodium acetate), Test method 9081, Washington DC

Zhang W, Tsang DCW, Lo IMC (2007) Removal of Pb and MDF from contaminated soils by EDTA-and SDS-enhanced washing. Chemosphere 66:2025–2034

Acknowledgments

This study is supported by the Republic of Korea Ministry of Environment as “Green Remediation Research Center for Organic–Inorganic Combined Contamination (The GAIA Project-2012000550001)”. This study was also supported by the Republic of Korea Ministry of Environment as the GAIA (Geo-Advanced Innovative Action) Project (No. 2015000550003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moon, D.H., Park, JW., Koutsospyros, A. et al. Assessment of soil washing for simultaneous removal of heavy metals and low-level petroleum hydrocarbons using various washing solutions. Environ Earth Sci 75, 884 (2016). https://doi.org/10.1007/s12665-016-5690-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-016-5690-6