Abstract

Mealworms from three different regions: Guangzhou, Tai’an and Shenzhen, were fed with three commonly used microplastics of polystyrene (PS), polyvinyl chloride (PVC) and low-density polyethylene (LDPE) for 1 month under favorable conditions, respectively. The survival rate and average weight of mealworms, the mass loss of microplastics and the production of frass were recorded every 4 days. Samples collected were characterized by X-ray diffraction, fourier transform infrared spectroscopy, thermogravimetric analyzer and gel permeation chromatography. The results showed that mealworms from Tai’an and Shenzhen could effectively metabolize the whole microplastics tested, while those from Guangzhou could only metabolize PS and LDPE. Besides, LDPE could be degraded by mealworms from Tai’an and Shenzhen, while those from Guangzhou showed no such capability, indicating that mealworms from different regions present different metabolism effects. Furthermore, PS and LDPE are more likely to be metabolized compared with PVC.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Microplastics are defined as plastic particles smaller than 5 mm in diameter. They can be divided into primary microplastics and secondary microplastics according to sources. The former are manufactured as tiny particles for particular industrial and domestic use, while the latter originated from fragmentation of larger plastic items (Browne et al. 2007). With ubiquitous distribution, high persistence in the environment and deleterious impact on biota, microplastics are emerging contaminants arising intimate concern worldwide, especially their sources, fates and risks in marine and freshwater systems (Browne et al. 2011; Eriksen et al. 2013; Van Cauwenberghe et al. 2013; Free et al. 2014; Ivar and Costa 2014; Auta et al. 2017; Martin and Scott 2017).

Microplastics ingested by aquatic organisms can retain for a long time, adversely affect their survival rate, lead to morphological and histopathological changes and cause reproductive and genetic toxicities (Anthony et al. 2013; Sussarellu et al. 2016; Leung and Chan 2017; Reichert et al. 2017; Ziajahromi et al. 2017). They also pose an immense threat to ecosystem through bioaccumulation and biomagnification along food chain (Lwanga et al. 2017). Besides, microplastics serve as a vector for pollutants from water column and sediment such as metal ions, hydrophobic contaminants and bacteria, forming an ecocorona (Dokyung et al. 2017; Syberg et al. 2017), which then transport and disperse throughout water bodies including rivers, lakes, coastal areas and oceans, from the Antarctic to the Arctic (Bergmann et al. 2017; Isobe et al. 2017; Waller et al. 2017). In this process, the density, surface charge of particles, bioavailability and toxicity of the compound contaminants may be altered in the presence of ultraviolet radiation and aquatic organisms (Galloway et al. 2017).

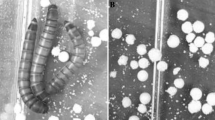

Mealworms are the larval stage of Tenebrio molitor Linnaeus. It is a holometabolic insect which belongs to Coleoptera Tenebrionidae and goes through with four life stages: egg, larva, pupa and adult. The survival capacity of mealworms is influenced by temperature, relative humidity, period of exposure and density (Manojlovic 1988; Punzo and Mutchmor 1980; Pielou and Gunn 1940; Morales-Ramos and Rojas 2015). Wheat, corn and soybean are three commonly used food to rear mealworms. Consumption of microplastics by mealworms was first reported by Chong-Guan Chen in 2003, who found that mealworms could eat extruded polystyrene (XPS). Yang et al. (2015a, b) noted that styrofoam could be degraded and mineralized by mealworms and isolated the bacterial strains from their guts. Yang et al. (2018) further investigated how temperature, polystyrene waste type and nutrition affected survival of the larvae and PS biodegradation rate. Zhang et al. (2017) reported degradation of polyethylene film by mealworms. Chen et al. (2017) analyzed the gut microbiota of polystyrene-eating mealworms by high-throughput sequencing and revealed three most dominant bacterial genera were Alcaligenes, Brevundimona and Myroides. All these studies indicated that styrofoam and polyethylene film could be degraded by mealworms, offering a new remedial option for the disturbing global plastic pollution.

Most studies focused on the biodegradation of plastic products by mealworms, with little attention on microplastics to date. Considering the excessive amount of microplastics which enter water bodies and the great threat they pose to ecosystem, it is urgent to investigate the biodegradation of microplastics. Therefore, this study was aimed at identifying the feeding and metabolism effects of three common microplastics (polystyrene, low-density polyethylene and polyvinylchloride) by Tenebrio molitor L. It is hoped to provide references on biological treatment of microplastics as well as making full use of mealworms as a resource.

Materials and methods

Mealworms and test materials

Mealworms (growth age at approximately 3–4 instars) were purchased from insect breeding plants in Guangzhou (Guangdong), Tai’an (Shandong) and Shenzhen (Guangdong) in China.

Microplastics tested included polystyrene (PS), polyvinyl chloride (PVC) and low-density polyethylene (LDPE), which were obtained from Jinshuowang Plastic Materials Co., Ltd, Dongguan (Guangdong), China. The average particle size of each microplastic was 150 μm, and no catalysts or additives were added.

Methods

Microplastics feeding tests

The mealworms were incubated in polypropylene plastic containers (12.5 cm × 8 cm × 6 cm) in a chamber under controlled conditions [(25 ± 1) °C temperature, (65 ± 5)% humidity and 12:12-h (light/dark) photoperiod] for 1 month. An amount of 500 mealworms were selected at random as a group and were fed with 7.0 g microplastics, respectively, as a sole diet. Controls were fed with bran alone or kept in starvation. All tests were performed in triplicate. The survival rate and average weight of mealworms and mass loss of microplastics were measured every 4 days. Afterward, the mealworms were cleansed with a stream of compressed air, transferred to a clean box to collect frass (solid excreta) for further characterization and then returned to the original incubator. Frass collected was stored at − 80 °C.

Characterization of frass

XRD measurements were taken to determine the crystal structure on the Bruker D8 Advance diffractometer operated at 40 kV and 40 mA with Cu-Kα radiation (λ = 1.5406 A) and a diffracted beam monochromator, using a step scan mode with the step size of 0.075° (2θ) and scan rate of 1.2°/min (Moon and Jeon 2008; Wooseok 2017; Gong et al. 2004).

FTIR spectra of samples were measured by direct transmittance using the KBr pellet technique. All spectra were obtained using a PerkinElmer Spectrum 100 spectrometer with a spectral resolution of 4 cm−1 in the range 400–4000 cm−1 (Conti et al. 1988; Satchwill and Harrison 1986).

The thermochemical property of samples was analyzed using a thermogravimetric (TG) analyzer (TGA-50, Shimadzu, Japan). The frass collected and microplastics tested were analyzed at a heating rate of 10 °C/min from ambient temperature to 600 °C under high-purity nitrogen (99.999%) at a flow rate of 40 mL/min (Bae and Sik 2009; Nishizaki and Yoshida 1981; Parthasarathy et al. 2013).

Number-average molecular weight (Mn), weight-average molecular weight (Mw) and molecular weight distribution (MWD) were determined by gel permeation chromatography (GPC) (Roovers and Toporowski 1981; Boborodea et al. 2016). PS and PVC samples were extracted by dimethylformamide (DMF) and injected into a GPC operating at a DMF eluent flow rate of 1.0 mL/min and temperature of 35 °C (PL-GPC 220, Agilent, Japan). LDPE samples were extracted by 1,2,4-trichlorobenzene and injected into a GPC operating at a 1,2,4-trichlorobenzene eluent flow rate of 1.0 mL/min and temperature of 150 °C (PL-GPC 120, Agilent, Japan).

Results and discussion

The growth of mealworms

According to Duncan’s multiple range test, for mealworms from three regions, there was no significant difference between the survival rate of mealworms fed with PS, PVC and LDPE microplastics and bran as a sole diet (pGuangzhou = 0.066 > 0.05, pTai’an = 0.081 > 0.05, pShenzhen = 0.130 > 0.05), indicating that microplastics would not impose a negative effect on the survival capabilities of mealworms, which was consistent with Yang’s study.

The average weight of mealworms fed with bran increased, while the microplastics feeding and starving groups witnessed a decrease after incubation for 1 month (Table 1). This implied that mealworms taken microplastics as a sole diet could not obtain enough energy for biomass growth. The result was in line with previous studies (Bhone et al. 2012; Yang et al. 2015a; Zhang et al. 2017).

Microplastics-eating behavior

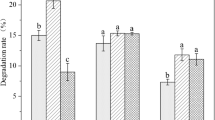

Mealworms from three regions all ingested microplastics as food. The mass loss of PS microplastics caused by mealworms from Guangzhou, Tai’an and Shenzhen was 57.5, 34.4 and 51.4%, respectively (Fig. 1). After incubation for 1 month, the mass of PVC microplastics reduced by mealworms from Guangzhou, Tai’an and Shenzhen was 48.4, 34.0 and 57.0%, respectively. The mass loss of LDPE microplastics caused by mealworms from those three regions was 36.9, 22.0 and 29.7%, respectively.

Characterization of frass and microplastics

X-ray diffraction analysis

There was only one dispersion peak shown at 20° in PS microplastic, while for frass collected from mealworms from three regions, more than two dispersion peaks were obtained and peak strength was weaker. In other words, XRD spectra showed a difference of crystalline structure between raw material and frass produced by mealworms from three regions (Fig. 2).

The XRD spectrum of frass collected from mealworms from Guangzhou fed with PVC was the same as that of PVC microplastic, indicating no crystalline structure change, while for mealworms from Tai’an and Shenzhen, a new diffraction peak appeared at 27° and the position of dispersion peaks differed from PVC, which indicated different crystalline structures between them, and there were fine grains in the metabolites.

There was a sharp diffraction peak at 20° and several dispersion peaks at 35°–45° in LDPE microplastic. The XRD spectra of frass produced by mealworms from three regions fed with LDPE were quite different. The diffraction peak at 20° widened in the frass collected from mealworms from Guangzhou, indicating a decrease in crystallinity (Slichter and Mandell 1958). For frass collected from mealworms from Tai’an and Shenzhen, there were only two dispersion peaks shown at 20° and 27°, and the results implied that crystalline polymer LDPE was transformed to amorphous polymer after metabolized by mealworms from those two regions.

As indicated by XRD spectra, crystalline structure of PS and LDPE changed after metabolized by mealworms from all three regions. However, the crystalline structure of PVC could only be changed by mealworms from Tai’an and Shenzhen.

Fourier transform infrared spectroscopy analysis

As given in Table 2, the benzene ring CH stretching vibration, benzene ring vibration, benzene ring CH plane and non-plane variable angle vibration disappeared in frass collected from mealworms from three regions fed with PS, implying the damage of benzene ring. Moreover, C=O and C–O stretching vibration bands were added in the frass, which illustrated the appearance of carbonyl group.

Compared with PVC microplastic, a new band at 3500 cm−1 assigned to O–H stretching vibration and another at 1650 cm−1 assigned to O–H plane variable angle vibration were clearly shown in the frass collected from mealworms from Guangzhou fed with PVC. They were typical FTIR bands of water, which was probably formed during the metabolic process. Apart from these, no more functional groups were observed in the frass, which proved no structure change caused by mealworms from Guangzhou, while for frass collected from mealworms from Tai’an and Shenzhen, two new bands analyzed as C=O and C–O stretching vibration were added, demonstrating the existence of carbonyl group.

For frass collected from mealworms from Guangzhou, CH2 shear vibration and CH2 plane swing vibration disappeared, as an evidence of molecular structure change. For frass collected from mealworms from Tai’an and Shenzhen, C=O and C–O stretching vibration bands were added, indicating that hydrocarbon chain was oxidized and carbonyl group appeared in the frass.

Thermogravimetric analysis

For PS microplastics, the pyrolysis completed in only one stage and the maximum decomposition rate occurred at 388 °C with a weight loss of 68.01% (Fig. 3). In contrast, frass collected from mealworms from Guangzhou fed with PS showed three weight loss stages, and the maximum decomposition rate of each stage appeared at 85, 276 and 427 °C with a weight loss of 10.76, 24.66 and 60.30%, respectively. The thermal degradation of polystyrene was a free radical reaction initiated from chain end scission (Carniti et al. 1989; McNeill et al. 1990), and the pyrolysis process of polystyrene with different molecular weights differs. So it could be inferred there is a chemical composition change between PS microplastics and frass collected from mealworms from Guangzhou. The same situation happened in the frass from another two regions. Frass collected from mealworms from Tai’an fed with PS contained three weight loss stages, and the maximum decomposition rate of each stage appeared at 61, 269 and 403 °C with a weight loss of 4.30, 18.48 and 57.96%, respectively. The decomposition of frass collected from mealworms from Shenzhen fed with PS also included three weight loss stages, and the maximum decomposition rate of each stage occurred at 52, 308 and 390 °C with a weight loss of 2.51, 30.46 and 59.55%, respectively .

The decomposition of PVC microplastics included two stages, namely dechlorination and chain scission period (Chang and Salovey 1974). The maximum decomposition rate of the first stage occurred in 258 °C with a weight loss of 26.75%, and the maximum decomposition rate of the second stage occurred in 432 °C with a weight loss of 82.44%. The decomposition of frass collected from mealworms from Guangzhou can be divided into two parts: the maximum decomposition rate reached at 245 and 417 °C and the corresponding weight losses were 26.81 and 70.27%, which was almost the same as raw material, indicating no chemical composition change occurred. Frass collected from mealworms from Tai’an fed with PVC showed three weight loss stages, and the maximum decomposition rate of each stage appeared at 66, 275 and 431 °C with a weight loss of 3.74, 24.88 and 58.81%, respectively. The decomposition of frass collected from mealworms from Shenzhen fed with PVC also included three weight loss stages, and the maximum decomposition rate of each stage occurred at 94, 242 and 415 °C with a weight loss of 4.15, 25.59 and 66.49%, respectively. In a word, there were chemical composition changes between PVC microplastic and frass collected from mealworms from Tai’an and Shenzhen.

For LDPE microplastics, the pyrolysis completed in one stage and the maximum decomposition rate occurred at 441 °C with a weight loss of 66.32%. It is a chain scission process, and the main products were alkenes such as ethane, ethene, propane, propene, butane and butane (Williams and Williams 1999). Frass collected from mealworms from Guangzhou showed three weight loss stages, and the maximum decomposition rate of each stage appeared at 100, 312 and 437 °C with a weight loss of 4.24, 17.58 and 71.82%, respectively. Frass collected from mealworms from Tai’an showed three weight loss stages, and the maximum decomposition rate of each stage appeared at 70, 338 and 433 °C with a weight loss of 5.22, 27.86 and 48.97%, respectively. Frass collected from mealworms from Shenzhen showed three weight loss stages, and the maximum decomposition rate of each stage appeared at 61, 281 and 422 °C with a weight loss of 3.81, 28.36 and 65.58%, respectively. The results indicated that mealworms from three regions could metabolize LDPE microplastic and changed its chemical composition.

Gel permeation chromatography analysis

The Mn and Mw values of frass produced by mealworms from Guangzhou fed with PS were significantly different from PS microplastics (pMn = 5.41E−8 < 0.05, pMw = 3.94E−9 < 0.05). The Mn value of frass increased by 117.45%, Mw decreased by 47.10% and the molecular weight distribution narrowed, indicating depolymerization and degradation of polymers (Phua et al. 1987). The Mn value of frass collected from mealworms from Tai’an fed with PS was significantly different from PS microplastics (pMn = 1.14E−4 < 0.05), while the Mw value showed no significant difference (p = 0.300 > 0.05). The Mn value of frass increased by 117.41% and the molecular weight distribution narrowed, probably due to the cross-linking reaction of low molecular fraction of the polymer (Sakai et al. 2002). The Mn and Mw values of frass produced by mealworms from Shenzhen fed with PS differed from the raw material (pMn = 1.45E−4 < 0.05, pMw = 0.031 < 0.05). The Mn and Mw values of frass increased by 184.55 and 18.19%, respectively, and the molecular weight distribution narrowed. This could be attributed to the preferential assimilation of the low molecular weight fraction of PS by the microorganism (Jeon and Kim 2013).

There were no significant differences between the Mn and Mw values of frass produced by mealworms from Guangzhou fed with PVC and PVC microplastics (pMn = 0.095 > 0.05, pMw = 0.217 > 0.05), implying there was no molecular weight change. The Mn and Mw values of frass produced by mealworms from Tai’an fed with PVC differed from PVC microplastics (pMn = 0.002 < 0.05, pMw = 0.003 < 0.05). The Mn and Mw values of frass increased by 93.34 and 15.12%, respectively, and the molecular weight distribution narrowed. This also happened to frass produced by mealworms from Shenzhen fed with PVC (pMn = 7.12E−7 < 0.05, pMw = 6.46E−5 < 0.05), Mn and Mw increased by 69.44 and 19.67%, respectively; the molecular weight distribution narrowed), an indication of preferential assimilation of the low molecular weight fraction of PVC.

No significant differences between the Mn and Mw values of frass produced by mealworms from Guangzhou fed with LDPE and LDPE microplastics were observed (pMn = 0.079 > 0.05, pMw = 0.579 > 0.05), implying there was no molecular weight change. The Mn and Mw values of frass produced by mealworms from Tai’an fed with LDPE differed dramatically from LDPE microplastics (pMn = 4.02E−5 < 0.05, pMw = 3.17E−6 < 0.05). The Mn and Mw values of frass decreased by 78.50 and 54.30%, respectively, with the widened molecular weight distribution. As for frass collected from mealworms from Shenzhen fed with LDPE, the Mn and Mw values differed significantly (pMn = 1.18E−6 < 0.05, pMw = 9.36E−9 < 0.05), Mn decreased by 77.28% and Mw decreased by 45.66%, with the widened molecular weight distribution. These results suggested that depolymerization of the long-chain structure of LDPE took place (Yang et al. 2015a).

As given in Table 3, the molecular weight of three microplastics changed after metabolized by mealworms from Tai’an and Shenzhen. Mealworms from Guangzhou could only degrade PS and did not affect the molecular weight of PVC and LDPE.

Taken into account the results of XRD, FTIR, TGA and GPC, we could infer that for PS and LDPE microplastics, the physical and chemical properties of frass were different from the raw material, which meant PS and LDPE microplastics could be metabolized by mealworms from three regions though the effects among them were different. Mealworms from Guangzhou could depolymerize the high molecular weight fraction of PS, destroy benzene ring and oxidize hydrocarbon chain. Mealworms from Tai’an could also destroy benzene ring and oxidize hydrocarbon chain; besides, cross-linking reaction of low molecular weight fraction of the polymer happened. Mealworms from Shenzhen were able to preferentially assimilate the low molecular weight fraction of PS. LDPE could be degraded by mealworms from Tai’an and Shenzhen through the oxidation of hydrocarbon chain, while those from Guangzhou showed no such capability. For PVC microplastic, frass collected from mealworms from Guangzhou was the same as the raw material in terms of physical and chemical properties, indicating that this mealworm showed no metabolism effect on PVC, while mealworms from Tai’an and Shenzhen could metabolize PVC. The possible mechanism was preferential assimilation of low molecular weight fraction of PVC, and there were crystalline materials in the frass.

Conclusion

Mealworms could ingest PS, PVC and LDPE microplastics as sole diets and survived for 1 month, though these microplastics did not provide enough energy for growth. The metabolism effects of mealworms from different regions on each microplastic tested varied, inferring different gut microbiota. Furthermore, it could be speculated that PVC was less likely to be digested by mealworms since it could only be metabolized by mealworms from Tai’an and Shenzhen, while PS and LDPE could be metabolized by mealworms from all three regions. This might be interpreted as a result of complicated molecular structure and elemental composition.

References

Anthony, M., Niven, S. J., Galloway, T. S., Rowland, S. J., Thompson, R. C., & Browne, M. A. (2013). Microplastic moves pollutants and additives to worms, reducing functions linked to health and biodiversity. Current Biology, 23(23), 2388–2392.

Auta, H. S., Emenike, C. U., & Fauziah, S. H. (2017). Distribution and importance of microplastics in the marine environment: A review of the sources, fate, effects, and potential solutions. Environment International, 102, 165–176.

Bae, D. C., & Sik, K. K. (2009). Thermal characteristics of polyvinylchloride in combustion reaction using TGA. Journal of Korea Safety Management & Science, 11(3), 217–226.

Bergmann, M., Lutz, B., Tekman, M. B., & Gutow, L. (2017). Citizen scientists reveal: Marine litter pollutes Arctic beaches and affects wild life. Marine Pollution Bulletin, 125(1–2), 535–540.

Bhone, M. K., Ravi, C., Meena, K. S., Chu, S. L., & Kishore, R. S. (2012). Biodegradation of low density polythene (LDPE) by Pseudomonas species. Indian Journal of Microbiology, 52(3), 411–419.

Boborodea, A., Mirabella, F., & O’Donohue, S. (2016). Characterization of low-density polyethylene in dibutoxymethane by high-temperature gel permeation chromatography with triple detection. Chromatographia, 79(15–16), 971–976.

Browne, M. A., Crump, P., Niven, S. J., Teuten, E., Tonkin, A., Galloway, T., et al. (2011). Accumulation of microplastic on shorelines woldwide: Sources and sinks. Environmental Science and Technology, 45(21), 9175–9179.

Browne, M. A., Galloway, T., & Thompson, R. (2007). Microplastic—An emerging contaminant of potential concern? Integrated Environmental Assessment and Management, 3(4), 559–561.

Carniti, P., Gervasini, A., Beltrame, P. L., & Audisio, G. (1989). Evidence of formation of radicals in the polystyrene thermodegradation. Journal of Polymer Science Part A: Polymer Chemistry, 27(11), 3865–3873.

Chang, E. P., & Salovey, R. (1974). Pyrolysis of poly(vinyl chloride). Journal of Polymer Science: Polymer Chemistry Edition, 12, 2927–2941.

Chen, G. Z., Zhang, B. L., Ji, M. M., Wu, X. G., Zhou, J. Y., Chen, J. N., et al. (2017). Gut microbiota of polystyrene-eating mealworms analyzed by high-throughput sequencing. Microbiology China, 44(9), 2011–2018.

Conti, G., Santoro, E., Resconi, L., & Zerbi, G. (1988). FTIR spectra and structure of new polystyrene—Syndiotactic polystyrene and poly-para-methyl-styrene. Microchimica Acta, 1(1–6), 297–300.

Dokyung, K., Yooeun, C., & Youn, J. (2017). Mixture toxicity of nickel and microplastics with different functional groups on Daphnia magna. Environmental Science and Technology, 51(21), 12852–12858.

Eriksen, M., Mason, S., Wilson, S., Box, C., Zellers, A., Edwards, W., et al. (2013). Microplastic pollution in the surface waters of the Laurentian Great Lakes. Marine Pollution Bulletin, 77(1–2), 177–182.

Free, C., Jensen, O., Mason, S., Eriksen, M., Williamson, N., & Boldgiv, B. (2014). High-levels of microplastic pollution in a large, remote, mountain lake. Marine Pollution Bulletin, 85(1), 156–163.

Galloway, T. S., Cole, M., & Lewis, C. (2017). Interactions of microplastic debris throughout the marine ecosystem. Nature Ecology & Evolution, 1(5), 116.

Gong, F. L., Zhao, C. G., Feng, M., Qin, H. L., & Yang, M. S. (2004). Synthesis and characterization of PVC/montmorillonite nanocomposite. Journal of Materials Science, 39(1), 293–294.

Isobe, A., Uchiyama-Matsumoto, K., Uchida, K., & Tokai, T. (2017). Microplastics in the Southern Ocean. Marine Pollution Bulletin, 114(1), 623–626.

Ivar, J. A., & Costa, M. F. (2014). The present and future of microplastic pollution in the marine environment. Environmental Pollution, 185, 352–364.

Jeon, H. J., & Kim, M. N. (2013). Isolation of a thermophilic bacterium capable of low-molecular-weight polyethylene degradation. Biodegradation, 24(1), 89–98.

Leung, J., & Chan, K. Y. K. (2017). Microplastics reduced posterior segment regeneration rate of the polychaete Perinereis aibuhitensis. Marine Pollution Bulletin. https://doi.org/10.1016/j.marpolbul.2017.10.072.

Lwanga, E. H., Vega, J., Quej, V., Chi, J., del Cid, L., Chi, C., et al. (2017). Field evidence for transfer of plastic debris along a terrestrial food chain. Scientific Reports, 7(1), 14071.

Manojlovic, B. (1988). Influence of food and temperature on post-embryonal survival of yellow mealworm Tenebrio molitor L. (Coleoptera: Tenebrionidae). Zastita bilja, 183(39), 43–53.

Martin, W., & Scott, L. (2017). Freshwater microplastics: Emerging environmental contaminants? The handbook of environmental chemistry (Vol. 58). Frankfurt: Springer.

McNeill, I. C., Zulfiqar, M., & Kousar, T. (1990). A detailed investigation of the products of the thermal degradation of polystyrene. Polymer Degradation and Stability, 28(2), 131–151.

Moon, J., & Jeon, Y. (2008). Characterization of superlattices of monodisperse Fe3O4 nanoparticles in a polystyrene matrix with TEM and XRD. Superlattices and Microstructures, 43(2), 141–145.

Morales-Ramos, J., & Rojas, M. (2015). Effect of larval density on food utilization efficiency of Tenebrio molitor (Coleoptera: Tenebrionidae). Journal of Economic Entomology, 108(5), 2259–2267.

Nishizaki, H., & Yoshida, K. (1981). Effect of molecular-weight on various TGA methods in polystyrene degradation. Journal of Applied Polymer Science, 26(10), 3503–3504.

Parthasarathy, V., Dhanalakshmi, V., & Anbarasan, R. (2013). Thermal, melting and crystallinity behavior of esters grafted LDPE by thermolysis method. International Journal of Plastics Technology, 17(1), 61–74.

Phua, S. K., Castillo, E., Anderson, J., & Hiltner, A. (1987). Biodegradation of a polyurethane in vitro. Journal of Biomedical Materials Research, 21(2), 231–246.

Pielou, D., & Gunn, D. (1940). The humidity behaviour of the mealworm beetle, Tenebrio molitor L. I. The reaction to differences of humidity. Journal of Experimental Zoology, 17(3), 286–294.

Punzo, F., & Mutchmor, J. A. (1980). Effects of temperature, relative humidity and period of exposure on the survival capacity of Tenebrio molitor (Coleoptera: Tenebrionidae). Journal of the Kansas Entomological Society, 53(2), 260–270.

Reichert, J., Schellenberg, J., Schubert, P., & Wilke, T. (2017). Responses of reef building corals to microplastic exposure. Environmental Pollution. https://doi.org/10.1016/j.envpol.2017.11.006.

Roovers, J., & Toporowski, P. M. (1981). Preparation and characterization of H-shaped polystyrene. Macromolecules, 14(5), 1174–1178.

Sakai, W., Sadakane, T., Nishimoto, W., Nagata, M., & Tsutsumi, N. (2002). Photosensitized degradation and crosslinking of linear aliphatic polyesters studied by GPC and ESR. Polymer, 43(23), 6231–6238.

Satchwill, T., & Harrison, D. J. (1986). Synthesis and characterization of new polyvinylchloride membranes for enhanced adhesion of electrode surfaces. Journal of Electroanalytical Chemistry and Interfacial Electrochemistry, 202(1–2), 75–81.

Slichter, W. P., & Mandell, E. R. (1958). Molecular structure and motion in irradiated polyethylene. Journal of Physical Chemistry, 62(3), 334–340.

Sussarellu, R., Suquet, M., Thomas, Y., Lambert, C., Fabioux, C., Pernet, M., et al. (2016). Oyster reproduction is affected by exposure to polystyrene microplastics. Proceeding of the National Academy of Sciences of the United States of America, 113(9), 2430–2435.

Syberg, K., Nielsen, A., Khan, F. R., Banta, G. T., Palmqvist, A., & Jepsen, P. M. (2017). Microplastic potentiates triclosan toxicity to the marine copepod Acartia tonsa (Dana). Journal of Toxicology and Environmental Health-Part A-Current Issues, 80(23–24), 1369–1371.

Van Cauwenberghe, L., Vanreusel, A., Mees, J., & Janssen, C. R. (2013). Microplastic pollution in deep-sea sediments. Environmental Pollution, 182, 495–499.

Waller, C. L., Griffiths, H. J., Waluda, C. M., Thorpe, S. E., Loaiza, I., Moreno, B., et al. (2017). Microplastics in the Antarctic marine system: An emerging area of research. Science of the Total Environment, 598, 220–227.

Williams, P. T., & Williams, E. A. (1999). Fluidised bed pyrolysis of low density polyethylene to produce petrochemical feedstock. Pyrolysis, 51(1–2), 107–126.

Wooseok, L. (2017). A study of functionality and stability of LDPE-nano TiO2 composite film. Journal of Korea Society of Packaging Science & Technology, 23(2), 67–74.

Yang, S. S., Brandon, A. M., Flanagan, J., Yang, J., Ning, D. L., Cai, S. Y., et al. (2018). Biodegradation of polystyrene wastes in yellow mealworms (larvae of Tenebrio molitor Linnaeus): Factors affecting biodegradation rates and the ability of polystyrene-fed larvae to complete their life cycle. Chemosphere, 191, 979–989.

Yang, Y., Yang, J., Wu, W. M., Zhao, J., Song, Y. L., Gao, L. C., et al. (2015a). Biodegradation and mineralization of polystyrene by plastic-eating mealworms: Part 1. Chemical and physical characterization and isotopic tests. Environmental Science and Technology, 49(20), 12080–12086.

Yang, Y., Yang, J., Wu, W. M., Zhao, J., Song, Y. L., Gao, L. C., et al. (2015b). Biodegradation and mineralization of polystyrene by plastic-eating mealworms: Part 2. Role of Gut Microorganisms. Environmental Science and Technology, 49(20), 12087–12093.

Zhang, K., Hu, R. Q., Cai, M. M., Zheng, L. Y., Yu, Z. N., & Zhang, J. B. (2017). Degradation of plastic film containing polyethylene (PE) by yellow mealworms. Chemistry & Bioengineering, 34(4), 47–49.

Ziajahromi, S., Kumar, A., Neale, P., & Leusch, F. (2017). Impact of microplastic beads and fibers on Waterflea (Ceriodaphnia dubia) survival, growth, and reproduction: Implications of single and mixture exposures. Environmental Science and Technology, 51(22), 13397–13406.

Acknowledgements

The authors gratefully acknowledge the sponsorship from Shenzhen Municipal Development and Reform Commission (Discipline construction of watershed ecological engineering).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wu, Q., Tao, H. & Wong, M.H. Feeding and metabolism effects of three common microplastics on Tenebrio molitor L.. Environ Geochem Health 41, 17–26 (2019). https://doi.org/10.1007/s10653-018-0161-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10653-018-0161-5