Abstract

This study described a successful application of the Quality by Design (QbD) approach to pseudorabies virus (PRV) production process development in a fixed-bed bioreactor using the serum-free medium (SFM). The innovated tube-fixed-bed bioreactor was used as a scale-down model of the fixed-bed bioreactor for process development. Risk analysis was performed using Ishikawa diagram combined with failure mode effects analysis (FMEA). The comparative experiment was performed to screen proper medium for adherent African green monkey kidney (Vero) cells from three commercially available SFMs (VP-SFM, ProVERO-1 and Vero-A). The Vero-A medium showed as an outstanding one for further study. The PRV titer in harvest medium was consider as Critical Quality Attribute (CQA) and the Critical Process Parameters (CPPs) [time of infection (TOI), multiplicity of infection (MOI) and initial inoculation cell density] ranked high with risk priority number (RPN) were taken into design of experiment (DoE) methodology. Then prediction model of PRV production process was established and a robust PRV production process was explored. Under the robust setpoint conditions, the Xcell 1 L laboratory-scale fixed-bed bioreactor yielded PRV titer up to 7.87 log10 TCID50/mL at 3 dpi, which was comparable with that in the tube-fixed-bed bioreactor. Combination of the tube-fixed-bed bioreactor and QbD approach could further accelerate the development of a robust virus production process.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The pseudorabies virus (PRV), also known as Aujeszky’s disease virus (ADV), belongs to the family of herpesviridae and causes substantial economic losses to swine producer worldwide (Freuling et al. 2017). Vaccination with inactivated or attenuated live vaccines was the effective way to control PRV. The PRV Bartha-k61 was the first attenuated strain used for live vaccine production and still widely commercially used (McFerran and Dow 1975). Traditionally, PRV vaccine is produced in roller bottles, which led to batch-to-batch variation. Application of the fixed-bed bioreactor may provide a solution for vaccine production with high quality.

Large-scale bioreactors with carriers were usually used to propagate adherent cells for vaccine production (Barrett et al. 2009; Huang et al. 2015; Liu et al. 2018; Toriniwa and Komiya 2007). The stirred tank reactors (STRs) containing microcarriers or fixed-bed bioreactors packed with macrocarriers are the common choices. The fixed-bed bioreactors packed with macrocarriers are able to protect cells from stressful conditions, yielding cell concentration up to tenfold higher than that in STRs with microcarriers (Meuwly et al. 2007; Toriniwa and Komiya 2007). Given this, the fixed-bed bioreactors have been widely used for the cultivation of adherent mammalian cells to produce monoclonal antibody and vaccine (Toriniwa and Komiya 2007; Zhang et al. 2015).

During the adherent cell cultivation process, the bovine serum is usually used to supply growth factors, attachment factors and nutrients. However, the quality of this biological material varies between batches and the risk of contamination with viruses needs to be considered (Toriniwa and Komiya 2007). To solve those problems, the serum-free medium (SFM) with no component of animal origin was developed and used for vaccine production in STRs with microcarriers (Chen et al. 2011; Liu et al. 2018; Yuk et al. 2006). In contrast, vaccine production with SFM in the fixed-bed bioreactor was merely reported.

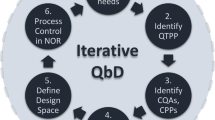

The pharmaceutical manufacturer should resubmit their application when production process parameters are changed. The application of QbD approach in pharmaceutical production process development could explore a robust design space, where working within could guarantee good quality of CQAs. This sound scientific and quality risk-based QbD approach which emphasizes product and process understanding and process control was already widely applied in the pharmaceutical industry (Pramod et al. 2016). As a statistical tool of QbD, the design of experiment (DoE) enables classification of process parameters based on their impact on product quality and enable prediction of a robust design space form the response surface (Abu-Absi et al. 2010; Pramod et al. 2016). To carry out the DoE approach, the experiments in design matrix should be conducted in parallel to narrow the batch-to-batch deviation. The traditional strategy way was carried out in the T-flask or the cell factory. However, this strategy may fail when scales-up to a fixed-bed bioreactor. Thus, a proper scale-down model is needed to reduce the cost and also in alignment with QbD guidance.

In this study, the novel tube-fixed-bed bioreactor was used as a scale-down model of the fixed-bed bioreactor to develop the serum-free PRV vaccine production process according to the QbD approach. The Critical Process Parameters (CPPs) ranked high with risk priority number (RPN) were taken into DoE experiment. The robust setpoint and design space were explored based on prediction model and acceptable criteria. Reliability of the setpoints was confirmed in the tube-fixed-bioreactor and the Xcell 1 L laboratory-scale fixed-bed bioreactor. Finally, we successfully developed a robust serum-free PRV vaccine production process in fixed-bed bioreactor with the help of the tube-fixed-bed bioreactor and QbD approach.

Materials and methods

Medium, cells and virus

All SFMs in this study were prepared according to the user guides. The ProVERO-1 medium (Lonza, Cat. No. BEBF-02-030Q, Switzerland) was supplemented with EGF (Gibco, Cat. No. PHG0311L, USA) to a final concentration of 5 μg/L. The VP-SFM medium (Gibco, Cat. No. 11681020, USA) was supplemented with glutamine (Gibco, Cat. No. 25030149, USA) to a final concentration of 4 mM. The customized ready-to-use Vero-A medium was provided by TBD (TBD science, Cat. No. JNVAS001, China). All SFMs were supplemented with 0.75 mL/L Pluronic F68 (Gibco, Cat. No. 24040032, USA) when cells were cultured in bioreactors.

Adherent Vero cells were obtained from ATCC (CCL-81) and pre-cultured in T175-flasks (Thermo Scientific, Cat. No. 159910, USA) with DMEM (Hyclone, Cat. No. SH30243.01, USA) containing 10% FBS (BI, Cat. No. 04-001-1ACS, Israel) at 37 °C and 5% CO2 atmosphere. Subcultivation of cells in SFM was performed according to TrypLE Express Enzyme (GIBCO, Cat. No. 12605028, USA) user’s manual. The Vero cells continuously passaged three times in T-flask before inoculated to bioreactors.

Adaption of PRV (the Bartha-K61 strain) in serum free cultured Vero cells was recommended. The virus continuously passaged three times in T-flasks with SFM to produce working virus seeds. The titer of the virus seeds was determined by a TCID50 assay described below. Then the stocks were stored in aliquots (7.5 log10 TCID50/mL) at − 70 °C.

Cell culture and virus production in the fixed-bed bioreactors

The tube-fixed-bed bioreactor was used as a scale-down model and the Xcell 1 L laboratory-scale fixed-bed bioreactor was used to demonstrate the scalability of PRV production process (Nie et al. 2019). The medium screening experiment and DoE experiment were performed in tube-fixed-bed bioreactor, with 20 mL pre-warmed SFM and cells seed density of 0.2 × 106 cells/mL. Then the bioreactor was installed in a CO2 incubator shaker (S41i, New Brunswick, Germany) at 37 °C, 5% CO2 atmosphere and 180 rpm circular shaking. The Xcell bioreactor of 500 mL working volume was a 25-fold scaled-up model of the tube-fixed-bed bioreactor. The bioreactor temperature was maintained at 37 °C. The pH was controlled at 7.2 by injection of CO2 or addition of 7.5% (w/v) sodium bicarbonate. The pO2 was controlled at 50% air-saturation by injection of air or pure oxygen. Samples were taken every day to measure cell density and glucose concentration. When virus was inoculated into the in bioreactor at the time of infection, the medium was replaced with the fresh SFM. Samples were then taken daily to determine virus titer in the supernatant after inoculation.

Risk assessment and process characterization

Risk analysis was performed using Ishikawa diagram combination with failure mode effects analysis (FMEA). In this study, the PRV titer in supernatant was considered as Critical Quality Attribute (CQA). All process parameters correlated with the harvest titer were systematically grouped by function with the help of Ishikawa diagram. The severity, occurrence, and detectability of each parameter was quantified from 1 to 3 based on prior scientific knowledge and experience (Severity: 1, low; 2, moderate; 3, severe. Occurrence: 1, rare; 2 occasional; 3, frequent. Detectability: 1, very good; 2, moderate; 3 bad). The RPN of each parameter was calculated through multiplying their three scores and then ranked according to the FMEA approach. Only the process parameter with RPN higher than the limit was taken into DoE experiment for further study.

Reduced combinatorial design of experiment

Three CPPs of PRV production were investigated using DoE experiment, including time of infection (TOI), infection dose (calculated to multiplicity of infection (MOI) later) and inoculation cell density. The range of factors in DoE for PRV production process was shown in Table 1. The experiment was designed based on the model of Reduced combinatorial design recommend by MODDE software (MKS Data Analytics Solutions, Umea, Sweden) and the virus titers during 5 day post infection (dpi) were used as the responses of the model. In order to further estimate the effect of TOI on PRV titer, nine more experiments (experiment number from 17 to 21) were added to DoE experiment. The experimental matrix with 21 runs is shown in Table 2.

Measurement of cell density and glucose concentration

Cell density in the tube-fixed-bed bioreactor was measured using crystal violet staining method as described by Nie et al. (2019). Glucose concentration in the medium was quantified using commercially available enzymatic kit (Nanjing Jiancheng Bioengineering Institute, Cat. No. F006-1-1, China).

Determination of viral titer

First, the samples were centrifuged at 3000 rpm for 10 min to remove cellular debris. Then the PRV titer of samples were quantified in log10 TCID50/mL by the Reed–Muench method using the median endpoint of the tissue culture’s infectious dose (TCID50) as described by Liu et al. (2011) and Reed and Muench (1937).

Results

Risk assessment for PRV production process parameters

To develop the attenuated live vaccine (Bartha-k61) production process, the virus titer in harvest medium was considered as CQA and main process parameters in the virus production were shown in Ishikawa diagram (Fig. 1). The fixed-bed bioreactor was operated under the guidelines of user’s manual and properties such as shear force were determined. Though the process parameters, such as pH, DO, temperature, own high score of severity of impact, they could be well controlled and the alarm functions (such as failure connection and practical value over alarm limit) make those parameters with low scores of occurrence and detectability. The parameters list in Ishikawa diagram with low RPN was not evaluated in the further study. The parameters in PRV production process ranked based on the RPN were shown in Table 3. Four CPPs, the medium, initial cell density, TOI, and MOI (infection dose) ranked high with RPN were selected for DoE experiment.

Media screening for cell culture (comparative experiment)

Two rounds of experiment were usually needed when the DoE approach was applied. Firstly, factors significantly influenced the response were explored, then those factors were undergoing following optimization experiment. The commercial SFMs from supplier shows different abilities to sustain cell growth. In this study, comparative experiment was conducted in the fixed-bed bioreactor to choose a suitable SFM for adherent Vero cells. Very few kinds of SFM are available for adherent Vero cells, and we finally chose to test three available SFMs (VP-SFM, ProVERO-1, Vero-A) together with VPVA (the 1:1 mixture of VP-SFM and Vero-A). Though successful culture of Vero cells in ProVERO-1 medium was reported (Chen et al. 2011), the adaption of Vero cells in this medium was poor and the attempt to culture cells in this medium failed. As shown in Fig. 2a, Vero-A medium yielded highest cell density of 5.4 × 106 cells/mL at 7 days and cell growth profile in this medium was similar with that in 10% FBS containing medium. Cell density in VP-SFM medium was 4.8 × 106 cells/mL at 7 days, which was slightly lower than that in Vero-A medium. Thus the Vero-A medium was used in the following study. The slight shape changed of Vero cells was observed when cultured in T-flaks with Vero-A medium (Fig. 2b). Compact cell monolayer was formed at 3–4 days with few hole shape surface area without cells attached (shown with an arrow in Fig. 2b).

Mathematical model of PRV production process

Response surface analysis of DoE data was conducted to obtain the quantitative relationship between CQA (harvest titer) and CPPs (TOI, MOI and initial cell density). Though MOI was usually used as a process parameter for virus inoculation, the virus dose for infection was used as a factor instead during DoE approach. The PRV titer during 5 dpi of each run were collected (Table 2). The PRV titer obtained at 3 dpi was relatively high and used as the response of model. The model was fit with multiple linear regression (MLR) and slightly modified with non-significant terms removed manually.

The model well explains the response variation with R2 = 0.83 (adjusted R2 = 0.72), Q2 = 0.47, validity = 0.68, reproducibility = 0.85 (Fig. 3a). The replicated experiments in replicate plot (blue point connected by a line) show low spread (Fig. 3b). The residual plot shows no outliers and the points closed to a straight line means residual are normally distributed (Fig. 3c). The significance of each factor on PRV production is shown in the coefficient plot (Fig. 3d, coefficients were scaled and centered) and their analysis of variance (ANOVA) results is shown in Table 4. The TOI and ID were significant model terms (P < 0.05) with positive and negative effect on PRV production respectively. The P value of lack of fit was 0.28 indicated no lack of fit was found in this model.

Model analysis of DoE in tube-fixed-bioreactor with MODDE software. a Summary of fit for PRV production. R2 = 0.83 (adjusted R2 = 0.72), Q2 = 0.47, validity = 0.68, reproducibility = 0.85. b Replicate plot for PRV production with experiment number labels. The replicated experiment in replicate plot shows in blue point connected by a line. c Residual plot for PRV production. The red dash lines indicated fourfold standard deviation. d The coefficient (scaled and centered) plot for PRV production

According to the predictive model, the contour plot of PRV yield was obtained (Fig. 4). As the infection dose and initial cell density increased in the defined range, the PRV titer first increased and then decreased. The virus infection at relative high cell density would improve the PRV titer. However, the PRV titer shown sharply decreased at TOI of 11 days, which may be due to the “Cell density effect” (Wood et al. 1982).

Design space development

Once the predictive model was established, the design space can be explored according to acceptable criteria. In this study, criteria were set as PRV titer higher than 7.4 log10 TCID50/mL and probability of failure less than 1%. Then, factor range was divided into 16 sections and 5000 Monte Carlo simulations were performed in each section by design space explorer function of MODDE software. The robust setpoint obtained was TOI of 8.47 days, infection dose of 6.92 log10 TCID50 (coded 0.0538) and initial cell density of 0.21 × 106 cells/mL (Fig. 5). The design space hypercube was TOI from 8.2 to 9.0 days, infection dose from 6.78 to 7.01 log10 TCID50, and initial cell density from 0.15 to 0.23 × 106 cells/mL. With initial cell density of 0.21 × 106 cells/mL, the tube-fixed-bed bioreactor yielded cell density of 8.3 × 106 cells/mL at 8.47 days, then the actual MOI was 0.035.

Demonstration of scalability

To demonstrate the scalability of PRV production process established in scale-down model, the profile of glucose consumption rate (GCR) curve and virus production curve of the tube-fixed-bed bioreactor and the Xcell fixed-bed bioreactor were compared. As a proper scale-down model, the performance indicators and quality attributes should be comparable with those of the large-scale production bioreactor (Abu-Absi et al. 2010; Nagashima et al. 2013). The macrocarriers were packed in the fixed-bed bioreactor and samples taken from bioreactor for cell counting were not available. The GCR profile, which as an indicator of cell concentration, was compared at both scale. The GCR profile in Xcell fixed-bed bioreactor shown similar trend with that in tube-fixed-bed bioreactor (Fig. 6a). During the cell cultivation in tube-fixed-bed bioreactor, the glucose concentration was higher than 7.3 mM and no growth inhibition was found. The cell density of 5.8 × 106 cells/mL was reached in the Xcell bioreactor at 7 days, which indicated the cell cultivation process scale-up successfully (data not shown). The PRV production profile in the tube-fixed-bed bioreactor and Xcell fixed-bed bioreactor under robust setpoint conditions was tested (Fig. 6b). The PRV titer in Xcell fixed-bed bioreactor reached peak of 7.87 log10 TCID50/mL at 3 dpi, which was comparable with that in the tube-fixed-bed bioreactor. The titer decreased as the culture process extended, and the harvest process was conducted at 3 dpi. Those results indicated that the novel tube-fixed-bed bioreactor worked well as a scaled-down model for vaccine process development.

Discussion

The Bartha-K61 strain is widely used to produce attenuated modified live PRV vaccine. The PRV was usually produced in T-flasks, roller bottles or STRs with the serum-containing medium (Slivac et al. 2006). A previous study reported the PRV production process optimization using the multiple harvest process (Srcek et al. 2004). In this study, a robust serum-free PRV production process was developed with the help of the QbD approach. The fixed-bed bioreactor with SFM yielded PRV titer of 7.87 log10 TCID50/mL, which was 7.4-fold higher than that obtained in Wave Bioreactor with suspension BHK cell line (Slivac et al. 2006).

Nowadays, most commercial viral vaccine production processes still rely on anchorage-dependent continuous cell lines such as Vero, MDCK, and MRC-5 (Gallo-Ramirez et al. 2015). Usually, the serum was added into the medium to supply growth factors and attachment factors for cells. However, the disadvantages of using serum should be concerned, which includes batch-to-batch variation and the risk of contamination. Reducing or eliminating the use of raw materials of animal origin in biologic manufacture processes has been encouraged by the Food and Drug Administration (FDA) of United States and the European Agency for the Evaluation of Medicinal Products (EMEA) of Europe (Yuk et al. 2006). The several vaccines, such as rabies, influenza, yellow fever, were successfully produced by serum-free methods (Chen et al. 2011; Frazatti-Gallina et al. 2004; Souza et al. 2009). However, only few commercially available SFMs were available for adherent Vero cells. Previous reports mainly focused on microcarriers-based virus production with VP-SFM medium in STR. The maximum cell density was no more than 2 × 106 cells/mL, which was obviously lower than that in serum-containing medium (Liu et al. 2007; Souza et al. 2009). The medium blending or mixture strategy was successfully used to develop SFM for CHO cells to further improve cell density (Jordan et al. 2013; Rouiller et al. 2013). However, no improvement of Vero cell density was observed by using this strategy (data not shown). Under serum-free condition, cells were more sensitive to shear force induced by the sparging and stirred agitator of STR (Ozturk and Palsson 1991). Due to the low share force and high surface area, the fixed-bed bioreactors have gained growing attention in the cultivation of adherent mammalian cells in SFM. However, few studies about serum-free Vero cell cultivation in fixed-bed bioreactor were reported.

During the virus production process development, scale-down model was needed to mimic and optimize the performance of the large-scale bioreactor. In this study, the tube-fixed-bed bioreactor was used as a scale-down model of a fixed-bed bioreactor. The CO2 incubator equipped with shaker platform was required to provide an appropriate physical environment. The Vero cells in tube-fixed-bed bioreactor with SFM yielded cell density of 5.4 × 106 cells/mL at 7 days, which was twofold higher than that in STR (Chen et al. 2011; Liu et al. 2011, 2018; Rourou et al. 2007; Silva et al. 2008). Under the same condition, the cell density of 5.8 × 106 cells/mL was obtained in Xcell bioreactor, which indicated successful scale-up of Vero cell cultivation process. Similar trend of GCR profile and the PRV production profile in both bioreactors with SFM further confirmed the applicability of tube-fixed-bed bioreactor as scale-down model.

The design space in International Conference on Harmonization (ICH) Q8 guidance document was defined as “the multi dimensional combination and interaction of input variables and process parameters that have been demonstrated to provide assurance quality”. The process parameters working within the design space is not considered as a change. The QbD approach is already widely applied in pharmaceutical production process development to establish a design space. The CQAs for antibody production process including titer, the main peak in CEX (cation-exchange chromatography) and glycan profiles (Abu-Absi et al. 2010; Bhatia et al. 2016; Nagashima et al. 2013). However, in vaccine production process, virus titer and antigenic titer are considered as the CQA (Li et al. 2019). When more than one CQA (response) are taken into account, all criteria of each CQA should be fulfilled so that consistent product quality can be achieved when those process parameters controlled in the range of design space.

The CPPs of TOI and MOI obtained from Risk analysis were the key parameter for virus production. Those two parameters were usually optimized step by step in a traditional way (Yuk et al. 2006). During the microcarrier-based virus production process, the cells were infected with virus until the highest cell density reached. Thus, the TOI varied from 3 to 5 days, depending on the microcarrier concentration used (Rourou et al. 2009). The fixed-bed bioreactor packed with macrocarriers could supply high surface thus the cell density will increase with the culture time prolongs. However, when cells were infected at a higher cell density (at 11 days), the PRV titer in supernatant decreased obviously.

Compared with traditional one-factor-at-a-time (OFAT) approach, the DoE approach is a systematically methodology to evaluate critical parameters and optimize processes parameters. Using the prediction model established based on experimental result, the optimal setpoint of each factor at which the response reached maximum or minimum was obtained. The robust setpoint and design space of each factor were calculated using the Monte Carlo simulations method with criteria of accepted limit of CQA (response) and probability of failure. The prediction model generated by DoE should be good enough to explain the experimental results and to predictive the unknown data. The Q2 greater than 0.7 means the small deviation between the predicted data and the experiment data. The Q2 greater than 0.1 can be considered as a significant model and Q2 greater than 0.5 can be consider as a good model (Bhatia et al. 2016). The Q2 could be improved with non-significant term removed from model manually in a hierarchical manner (Islam et al. 2007; Nie et al. 2018). The robust setpoint may not be found when the acceptable limit is too closed to the highest yield predicted. In this case, the PRV titer higher than 7.4 log10 TCID50/mL was used as the criteria so that higher virus titer and more flexible design space are obtained.

Conclusion

In summary, a PRV production process guided by QbD approach was developed efficiently with the help of tube-fixed-bed bioreactor. The Vero-A medium was selected through medium screening experiment. The initial cell density, TOI, and MOI (infection dose) ranked high with RPN were selected for DoE experiment. The robust setpoint calculated was TOI of 8.47 days, infection dose of 6.92 log10 TCID50 and initial cell density of 0.21 × 106 cells/mL. The robust PRV production process was evaluated in Xcell fixed-bed bioreactor. This study could be used as a generic platform for the production of vaccines of human usage.

References

Abu-Absi SF, Yang L, Thompson P, Jiang C, Kandula S, Schilling B, Shukla AA (2010) Defining process design space for monoclonal antibody cell culture. Biotechnol Bioeng 106:894–905. https://doi.org/10.1002/bit.22764

Barrett PN, Mundt W, Kistner O, Howard MK (2009) Vero cell platform in vaccine production: moving towards cell culture-based viral vaccines. Expert Rev Vaccines 8:607–618. https://doi.org/10.1586/erv.09.19

Bhatia H, Read E, Agarabi C, Brorson K, Lute S, Yoon S (2016) A design space exploration for control of Critical Quality Attributes of mAb. Int J Pharm 512:242–252. https://doi.org/10.1016/j.ijpharm.2016.08.046

Chen A, Poh SL, Dietzsch C, Roethl E, Yan ML, Ng SK (2011) Serum-free microcarrier based production of replication deficient influenza vaccine candidate virus lacking NS1 using Vero cells. BMC Biotechnol 11:81. https://doi.org/10.1186/1472-6750-11-81

Frazatti-Gallina NM et al (2004) Vero-cell rabies vaccine produced using serum-free medium. Vaccine 23:511–517. https://doi.org/10.1016/j.vaccine.2004.06.014

Freuling CM, Muller TF, Mettenleiter TC (2017) Vaccines against pseudorabies virus (PrV). Vet Microbiol 206:3–9. https://doi.org/10.1016/j.vetmic.2016.11.019

Gallo-Ramirez LE, Nikolay A, Genzel Y, Reichl U (2015) Bioreactor concepts for cell culture-based viral vaccine production. Expert Rev Vaccines 14:1181–1195. https://doi.org/10.1586/14760584.2015.1067144

Huang D et al (2015) Serum-free suspension culture of MDCK cells for production of influenza H1N1 vaccines. PLoS ONE. https://doi.org/10.1371/journal.pone.0141686

Islam RS, Tisi D, Levy MS, Lye GJ (2007) Framework for the rapid optimization of soluble protein expression in Escherichia coli combining microscale experiments and statistical experimental design. Biotechnol Prog 23:785–793. https://doi.org/10.1021/bp070059a

Jordan M, Voisard D, Berthoud A, Tercier L, Kleuser B, Baer G, Broly H (2013) Cell culture medium improvement by rigorous shuffling of components using media blending. Cytotechnology 65:31–40. https://doi.org/10.1007/s10616-012-9462-1

Li X et al (2019) Quality by design-driven process development of cell culture in bioreactor for the production of foot-and-mouth veterinary vaccine. J Pharm Sci 108:2288–2295. https://doi.org/10.1016/j.xphs.2019.02.004

Liu CC, Lian WC, Butler M, Wu SC (2007) High immunogenic enterovirus 71 strain and its production using serum-free microcarrier Vero cell culture. Vaccine 25:19–24. https://doi.org/10.1016/j.vaccine.2006.06.083

Liu CC et al (2011) Purification and characterization of enterovirus 71 viral particles produced from vero cells grown in a serum-free microcarrier bioreactor system. PLoS ONE 6:e20005. https://doi.org/10.1371/journal.pone.0020005

Liu CC et al (2018) Enhancing enterovirus A71 vaccine production yield by microcarrier profusion bioreactor culture. Vaccine 36:3134–3139. https://doi.org/10.1016/j.vaccine.2017.02.042

McFerran JB, Dow C (1975) Studies on immunisation of pigs with the Bartha strain of Aujeszky’s disease virus. Res Vet Sci 19:17–22. https://doi.org/10.1016/s0034-5288(18)33548-3

Meuwly F, Ruffieux PA, Kadouri A, von Stockar U (2007) Packed-bed bioreactors for mammalian cell culture: bioprocess and biomedical applications. Biotechnol Adv 25:45–56. https://doi.org/10.1016/j.biotechadv.2006.08.004

Nagashima H, Watari A, Shinoda Y, Okamoto H, Takuma S (2013) Application of a quality by design approach to the cell culture process of monoclonal antibody production, resulting in the establishment of a design space. J Pharm Sci 102:4274–4283. https://doi.org/10.1002/jps.23744

Nie L, Hu M, Yan X, Guo T, Wang H, Zhang S, Qu H (2018) Optimization of a coupling process for insulin degludec according to a Quality by Design (QbD) paradigm. AAPS PharmSciTech 19:1–10. https://doi.org/10.1208/s12249-018-1032-1

Nie J et al (2019) Production process development of pseudorabies virus vaccine by using novel scale-down model of fixed-bed bioreactor. J Pharm Sci. https://doi.org/10.1016/j.xphs.2019.10.002

Ozturk SS, Palsson BO (1991) Examination of serum and bovine serum-albumin as shear protective agents in agitated cultures of hybridoma cells. J Biotechnol 18:13–28. https://doi.org/10.1016/0168-1656(91)90232-K

Pramod K, Tahir MA, Charoo NA, Ansari SH, Ali J (2016) Pharmaceutical product development: a quality by design approach. Int J Pharm Investig 6:129–138. https://doi.org/10.4103/2230-973X.187350

Reed LJ, Muench H (1937) A simple method of estimating fifty per cent endpoints. Am J Epidemiol 27:493–497

Rouiller Y, Perilleux A, Collet N, Jordan M, Stettler M, Broly H (2013) A high-throughput media design approach for high performance mammalian fed-batch cultures. MAbs 5:501–511. https://doi.org/10.4161/mabs.23942

Rourou S, van der Ark A, van der Velden T, Kallel H (2007) A microcarrier cell culture process for propagating rabies virus in Vero cells grown in a stirred bioreactor under fully animal component free conditions. Vaccine 25:3879–3889. https://doi.org/10.1016/j.vaccine.2007.01.086

Rourou S, van der Ark A, Majoul S, Trabelsi K, van der Velden T, Kallel H (2009) A novel animal-component-free medium for rabies virus production in Vero cells grown on Cytodex 1 microcarriers in a stirred bioreactor. Appl Microbiol Biotechnol 85:53–63. https://doi.org/10.1007/s00253-009-2064-y

Silva AC, Delgado I, Sousa MF, Carrondo MJ, Alves PM (2008) Scalable culture systems using different cell lines for the production of Peste des Petits ruminants vaccine. Vaccine 26:3305–3311. https://doi.org/10.1016/j.vaccine.2008.03.077

Slivac I, Srček VG, RadoŠević K, Kmetič I, Kniewald Z (2006) Aujeszky’s disease virus production in disposable bioreactor. J Biosci 31:363–368. https://doi.org/10.1007/bf02704109

Souza MC, Freire MS, Schulze EA, Gaspar LP, Castilho LR (2009) Production of yellow fever virus in microcarrier-based Vero cell cultures. Vaccine 27:6420–6423. https://doi.org/10.1016/j.vaccine.2009.06.023

Srcek VG, Cajavec S, Sladic D, Kniewald Z (2004) BHK 21 C13 cells for Aujeszky’s disease virus production using the multiple harvest process. Cytotechnology 45:101–106. https://doi.org/10.1007/s10616-004-2551-z

Toriniwa H, Komiya T (2007) Japanese encephalitis virus production in Vero cells with serum-free medium using a novel oscillating bioreactor. Biologicals 35:221–226. https://doi.org/10.1016/j.biologicals.2007.02.002

Wood HA, Johnston LB, Burand JP (1982) Inhibition of Autographa californica nuclear polyhedrosis virus replication in high-density Trichoplusia ni cell cultures. Virology 119:245–254. https://doi.org/10.1016/0042-6822(82)90085-x

Yuk IH et al (2006) A serum-free Vero production platform for a chimeric virus vaccine candidate. Cytotechnology 51:183–192. https://doi.org/10.1007/s10616-006-9030-7

Zhang Y, Stobbe P, Silvander CO, Chotteau V (2015) Very high cell density perfusion of CHO cells anchored in a non-woven matrix-based bioreactor. J Biotechnol 213:28–41. https://doi.org/10.1016/j.jbiotec.2015.07.006

Acknowledgements

This work was supported by the National Key Research and Development Program of China (No. 2018YFA0900804); the National Natural Science Foundation of China (No. 21878124; 31570034); the Collaborative Innovation Center of Jiangsu Modern Industrial Fermentation, the 111 Project (No. 111-2-06); TaiShan industrial Experts Programme (tscy20160307).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nie, J., Sun, Y., Han, F. et al. Rapid process development of serum-free pseudorabies virus production with the Quality by Design approach. Cytotechnology 72, 283–293 (2020). https://doi.org/10.1007/s10616-020-00377-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10616-020-00377-9