Abstract

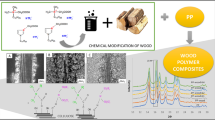

A previous study on consolidation of waterlogged archaeological wood (WAW) via surface initiated ARGET ATRP of the cell walls has shown its potential of maintaining the dimensional stability. But the defects lie in the unsuitable initiator immobilization methods and polymerization conditions, which impedes its application. Therefore, we are proposing a novel functionalization method for initiator immobilization in water or water/ethanol solution and an improved thermo-initiated ARGET ATRP system. First, mercaptoethylamine (MEA) was used to functionalize WAW with amino groups in water under circumneutral conditions. Then, quinone-based initiators reacted with those amino groups realizing its immobilization. Finally, by using less active reductants such as ascorbic acid 2-glucoside and glucose, monomer, catalyst, and reductant were able to permeate into the WAW samples at room temperature and polymerization was initiated by heating to 60 °C (for ascorbic acid 2-glucoside) or 80 °C (for glucose). Both satisfying uniformity and dimensional stability (77.0–85.1% ASE) can be achieved through the described approach. Moreover, the described functionalization methods may also provide reference for WAW consolidation material designs and applications in other lignocellulosic materials in the future.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The consolidation and dehydration of waterlogged archaeological wood (WAW) has been an everlasting research focus in conservation. One of the major objective of consolidation is to prevent cracking and shrinkage and thus maintain the dimension of WAW during the drying process. Recent developments in consolidants include natural resins (Cavallaro et al. 2015, 2017), halloysite nanotubes loaded with calcium hydroxide (Cavallaro et al. 2018, 2020), polysaccharides (Mohamed and Lotfy 2019; Walsh et al. 2015; Christensen et al. 2015), sugars (Babiński 2015; Liu et al. 2019; Tahira et al. 2017; Kennedy and Pennington 2014), melamine (Cesar et al. 2016), feather keratin (Endo et al. 2008, 2010), lignin-like oligomers (Mchale et al. 2016, 2017), supramolecule (Walsh et al. 2014), organosilicon compounds (Broda and Mazela 2017; Broda et al. 2019a, b), etc. Generally speaking, water soluble materials are preferred in application due to their convenience despite that their hygroscopic property of different level and potential instability may arise concerns. As high-molecular-weight materials are low in permeability, in situ polymerization and various oligomers are selected as the next-generation candidates for consolidation of WAW. Among the recent developed materials, organosilicon compounds seem most fit the criteria of WAW consolidation, i.e. high dimensional stability, high permeability, low hygroscopicity, anti-microbial property, retreatability, acceptable appearance, etc. But solvent replacement process during the organosilicon treatment may still bring inconvenience in large-scale application. Although some of the existing methods for consolidating WAW are quite practical yet with some defects and others are still in the research stages with promising outcomes, it is still necessary to explore more possibility in consolidation method.

One of the most widely used materials in conservation is acrylate polymer. But porous structures of wood impede polymer penetration and retreatability if monomers were introduced first and polymerized in situ. This makes polymers such as poly-acrylates lose their edges in WAW conservation. So, what if we are able to let monomers penetrate into WAW first and exclusively polymerized to the decayed cell walls?

Our preliminary attempt to consolidate WAW using surface-initiated ARGET ATRP has demonstrated that the cell walls can be exclusively consolidated to maintain dimensional stability and the cell lumens can be retained for future retreatments (Zhou et al. 2019). But two unsolved critical problems concerning real applications are the reaction conditions for immobilization of initiators in WAW and the ability to control the uniformity of the polymerization process. In terms of functionalization of WAW for ARGET ATRP process, the most widely used and efficient way is to use relatively toxic acyl halide, e.g. 2-bromoisobutyryl bromide, to react with hydroxyl groups mainly from cellulose. Additionally, this reaction requires aprotic solvents, such as dichloromethane or acetonitrile, which is also considered toxic and should be avoided in conservation practices because of potential health risks for conservators and additional costs in protection and recycling. Therefore, a much safer and more applicable approach for functionalization of WAW using low-toxic functionalizing reagents in non-toxic solvents, such as water and ethanol, is a must to promote the ARGET ATRP method for treating WAW and also provide a chemical basis for other potential methods. Apart from that, specific reaction conditions should be carefully selected to ensure the uniformity as much as possible.

Protic solvents such as water and ethanol, however, are highly competitive if hydroxyl groups in cellulose are the target reactants. As a result, reactions such as esterification are unable to be carried out effectively in these solvents. Lignin is an alternative reactant in wood and relatively more aboundant in WAW due to cellulose and hemicellulose consumptions by bacteria (Björdal et al. 1999; Björdal 2012; Blanchette 2000), which makes it more suitable for functionalization. A simple method to functionalize lignin in WAW has already been hidden in WAW itself. Enlightened from recent findings of organic sulfur (thiol, thioether, etc.) in WAW resulted from the reaction between lignin and hydrogen sulfide produced by sulfate reducing bacteria (Fors et al. 2006; Fors et al. 2012; Fors et al. 2015), thiol-lignin based reaction is thus proposed as a promising way to introduce functional groups to WAW. The mechanism of thiol-lignin reaction has been deeply studied in Kraft pulping process (Gierer 1980, 1985). To put it simply, phenolic units firstly undergo an initial transformation into intermediates of the quinone methide type if there is an eliminable α-substituent (e.g. a hydroxyl or aroxyl group). This step is followed by an addition of hydrosulfide ions attacking Cα of phenolic arylpropane units and giving benzyl mercaptide structures. If thiol is used as the initial reactant instead of sodium sulfide, the reaction will cease at benzyl sulfide structures and there will be no subsequent depolymerization of lignin like in Kraft pulping. This mechanism can be also classified as the thiol-Michael addition click reaction (Nair et al. 2014) in some way, which is a simple, robust and highly effective reaction to obtain C-S bonds under relative facile conditions.

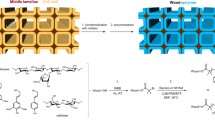

With such a theoretical basis supporting the possibility and feasibility, here we are attempting to use mercaptoethylamine (MEA, also known as cysteamine) to functionalize WAW with amino groups in circumnuetral aqueous solution. MEA is an essential source for bio-synthesis of coenzyme A1 and medically used to treat acute heavy metal poisoning and radiation syndrome, which demonstrate its low toxicity. Then, non-volatile α-bromoisobutyric acid (BIBA) can be applied to form amide bonds with amine from MEA moiety in ethanol, giving the C–Br bonds in WAW. Furthermore, two o-quinone based molecules are designed and synthesized which are able to link to amino group from MEA moiety in aqueous solution. Thereafter, the ARGET ATRP process developed in our previous research is modified to a thermo-triggered system to acquire more desirable uniformity. The reaction scheme is depicted in Fig. 1.

Materials and methods

materials and reagents

Waterlogged archaeological pine wood (Pinus massoniana) were cut into blocks of 10 mm(longitudinal) × 5 mm (tangential) × 5 mm (radial) approximately in size. The archaeological wood used was obtained from the Nanhai I shipwreck lying on the bottom of South China Sea for around 800 years with a maximum moisture content of around 517% and density of 0.171 g/cm3. Iron related compounds in these samples were removed by soaking in 3% citric acid for 1 week and washed in distilled water. Copper(II) bromide(Cu(II)Br2, 99%) from Macklin Biochemical, 2-bromoisobutyryl bromide (BIBB, 98%) from Aladdin, 4-(aminomethyl)-2-methoxyphenol hydrochloride, 4-(aminoethyl)-2-methoxyphenol hydrochloride (98%), N-hydroxysuccinimide (98%) from Energy Chemical, 2-bromoisobutyl acid (97%), L-Ascorbic acid 2-glucoside (97%) from Bide Pharmatech, pyridine (99%) from Xilong Scientific, tris(2-dimethylaminoethyl)amine (Me6TREN, 99%) from HEOWNS Biochem Technologies, 1-ethyl-3(3-dimethylpropylamine) carbodiimide chloride (EDC) from MREDA, ethanol (AR) from Tongguang Fine Chemicals were used as received. Butyl methacrylate (97% with 10 ppm MEHQ) were purchased from Aladdin and purified through an alkaline aluminum oxide column to eliminate inhibitors before use.

Synthesis of the initiators 2-bromo-N-[(4-hydroxy-3-methoxyphenyl)methyl]-2-methylpropanamide and 2-bromo-N-[(4-hydroxy-3-methoxyphenyl)ethyl]-2-methylpropanamide

The synthesis of 2-bromo-N-[(4-hydroxy-3-methoxyphenyl)methyl]-2-methylpropanamide was carried out by interfacial reaction between vanillylamine hydrochloride and 2-bromoisobutyryl bromide in biphase H2O/CHCl3 system according to the synthetic procedure provided in reference (Wang et al. 2009) with some modifications. Specifically, 1.00 g (5.27 × 10–3 mol) 4-(aminomethyl)-2-methoxyphenol hydrochloride were dissolved in 10 ml water and 1.33 g (0.0158 mol) NaHCO3 were added to the solution. After stirring the mixture for 30 min at 20 °C, 15 ml of chloroform were added. The mixture was stirred for another 15 min and then 1 ml CHCl3 solution of 2-bromoisobutyryl bromide (5.27 × 10–3 mol) was added dropwise. The mixture was stirred for 30 min at 20 °C, and clear the organic layer was separated. The water layer was extracted by chloroform (1 × 5 ml). The combined organic layers were washed with 2% HCl solution and dried with anhydrous MgSO4. The solvent was removed under reduced pressure and the crude product was recrystallized in absolute ethanol, giving 1.30 g white crystals. Yield: 82%; 1H NMR (500 MHz, CDCl3, δ in ppm): 6.89–6.87 (d, 1H, Ar), 6.77–6.80 (m, 2H, Ar), 4.37–4.38 (d, 2H, CH2), 3.88 (s, 3H, OCH3), 1.99 (s, 6H, CH3). The same procedure was carried out to synthesize 2-bromo-N-[(4-hydroxy-3-methoxyphenyl)ethyl]-2-methylpropanamide. Yield: 67% pale white crystals; 1H NMR (500 MHz, CDCl3, δ in ppm): 6.87–6.85 (d, 1H, Ar), 6.69–6.72 (m, 2H, Ar), 3.89 (s, 3H, OCH3), 3.51–3.47 (m, 2H, N-CH2), 2.76–2.79 (t, 2H, CH2), 1.92 (s, 6H, CH3).

Functionalization of WAW with amino groups

The reaction between MEA and WAW samples were carried out in 0.3 M aqueous solution of MEA in circumneutral conditions (pH 6.0, 7.0 and 8.0) at 20 °C, 50 °C and 80 °C for 1, 2, 3, 4 and 5 days. For the subsequent treatments in this paper, the optimal conditions of pH8.0, 80 °C and 5 days are adopted.

Immobilization of initiators

Generation of o-quinones and reaction with WAW samples

A typical preparation of 7.5 ml 0.02 mol/L o-quinone solution (labeled as Quinone A) is as follows. 45.3 mg (0.15 mmol) of 2-bromo-N-[(4-hydroxy-3-methoxyphenyl)methyl]-2-methylpropanamide were dissolved in 3.75 ml ethanol and 164.5 mg (0.30 mmol) ceric ammonium nitrate in 0.6 ml water were added dropwise to the solution with stirring. After stirring for 1 min, 136.9 mg (0.60 mmol) dipotassium phosphate in 3.15 ml water were added to the solution to remove cerium cations by precipitating ceric phosphate. The mixture was stirred for 10 min and filtered. The pH of the filtrate was adjusted by NaOH to 8.0. The same procedures were used to prepare the solution of Quinone B from 2-bromo-N-[(4-hydroxy-3-methoxyphenyl)ethyl]-2-methylpropanamide. The amino functionalized WAW samples were soaked in the as-prepared solutions of Quinone A and Quinone B for 5 days at 20 °C and 50 °C respectively. After the reaction, the samples were washed in 50% ethanol/water at 50 °C for 5 days, during which the solution was repetitively changed with new one for at least 5 times.

Immobilization of BIBB and BIBA

For comparison purpose, BIBB was used to react with hydroxyl groups in WAW samples and BIBA with amino groups in MEA treated WAW samples. The immobilization of BIBB was carried out in CH2Cl2 with WAW sample (CH2Cl2 saturated), BIBB and pyridine at the volume ratio of 4:3:2 at 50 °C for 1 h.

The immobilization of BIBA was carried out in ethanol with MEA treated WAW samples (ethanol saturated), 0.1 mol/L BIBA, 0.12 mol/L EDC, 0.1 mol/L NHS (or without) and 0.1 mol/L TEA (or without) at 20 °C for 24 h.

Also, the immobilization of BIBA was carried out in aqueous solutions. Equal volume of 0.2 mol/L BIBA and 0.24 mol/L EDC ethanol solution and 0.2 mol/L dipotassium phosphate water solution were mixed together, giving 0.1 mol/L BIBA/EDC solution with initial pH 6.2. 0.1 mol/L BIBA/EDC/NHS solutions with initial pH 7.2 and 8.2 (by adding NaOH) were also prepared. MEA treated WAW samples were soaked in the above solutions for 24 h.

After the immobilization, the samples were washed in ethanol at 20 °C for 5 days, during which the solution was repetitively changed with new one for at least 5 times.

Surface-initiated ARGET ATRP of acrylate polymer

The WAW sample, ethanol, water and monomer (BMA) were mixed in the volume ratio of 1:8:3:3, giving 20% BMA solution. The addition of water is to increase the solubility of reductants being used here. The catalyst (CuBr2), ligand (Me6TREN), and reductants (sodium ascorbate, ascorbic acid 2-glucoside, or glucose) were added to the solution in the molar ratio of 1:5:40 and Cu2+ concentration is fixed at 30 μg/ml. The over excess addition of reductants was due to possible consumption of reductants by oxidized wood components and oxygen. Among the three reductants, ascorbic acid 2-glucoside and glucose are inert at room temperature and active at elevated temperatures, which allows all the reactants to permeate into WAW samples for any period of time (24 h in this research) before heating to initiate the polymerization. The heating temperature of the polymerization using ascorbic acid 2-glucoside is 60 °C and glucose 80 °C. However, sodium ascorbate is a strong reductant and active at room temperature. When using sodium ascorbate, the catalyst was added after soaking the WAW in the mixture of the rest reactants for 24 h (only for comparison purpose). The vessels for the reactions were selected according to the solution volume to leave as little air as possible. After the polymerization, the sample were washed in ethyl acetate (if evident polymer precipitation was formed) and ethanol at 20 °C, each for 24 h.

Elemental analysis

The nitrogen contents of MEA treated samples were measured by elemental analyzer (vario EL) produced by Elementar Analysensysteme GmbH. The bromine contents of the initiator immobilized samples were measured by energy dispersive spectroscopy (EDS) attached to a scanning electron microscope (HITACHI TM3030). The EDS analysis was carried out under low vacuum mode with the working voltage of 15 kV. Both surface and inner sections of each sample was tested for 3 times and mean values were calculated.

Fourier transform infrared spectroscopy (FTIR)

Chemical composition of grinded specimens was determined by attenuated total reflection Fourier transform infrared spectroscopy (PerkinElmer Spectrum Spotlight 200) with a range from 4000 cm−1 to 650 cm−1 under 2 cm−1 resolution and 128 accumulation times.

Effectiveness of the treatment

The effectiveness of the treatment was measured by calculating weight percentage gain (WPG), radial shrinkage, tangential shrinkage, volume shrinkage and anti-shrinkage efficiency (ASE) according to the following three equations:

WPG:

where V0—initial volume of a sample in waterlogged conditions, mt –the mass of a specimen after air-drying, Vr—initial volume of an untreated reference sample in waterlogged conditions, mr –the mass of an untreated reference sample after air-drying.

Shrinkage:

where V0—initial volume of a sample in waterlogged conditions, Vt—the volume of a sample after air-drying, and V can be replaced by L (length) for calculating radial or tangential shrinkage.

Volumetric AES:

where Su—shrinkage of untreated sample, St—shrinkage of treated sample.

The volume of the samples were all determined by water displacement method.

Water contact angle measurement

The sessile drop method was used to determine the contact angle of water by placing distilled water droplets of 5.0 μm onto the surfaces and inner sections of the samples and images were taken at a certain frequency. WCA was measured by optical contact angle analyzer (DSA 30) with analyzing software produced by KRUSS.

Results and discussion

Amino functionalization

It has been mentioned in the Introduction that organic sulfur such as thiols and thioethers were found in archaeological wood because of the reaction between hydrogen sulfide and archaeological wood (Fors et al. 2006; Fors et al. 2012; Fors et al. 2015). During the Kraft pulping process, the main reactant with lignin is also sodium sulfide (Gierer 1980, 1985). As mercapto groups are strong nucleophiles and show even better nucleophilicity than hydrogen sulfide, it is theoretically a promising linker for WAW functionalization. Because mercapto groups are also reactive with active alkyl halide, such as the most crucial part of the initiator for ATRP, a two-step procedure was adopted. First, MEA, a simple and safe bifunctional reagent, was used to introduce amino groups to the WAW samples. Due to the practical requirements of WAW conservation, circumneutral conditions (pH 6.0–8.0) were chosen for experiments. Elemental analysis in Fig. 2 shows that the highest nitrogen content of 1.31 wt% can be achieved at 80 °C, pH 8.0 for 5 days’ treatment. In a more milder conditions (50 °C, pH 8.0, 5 days), nitrogen content reached 1.10 wt%. Concluded from Fig. 2, a slightly alkaline condition and elevated temperature promoted the reaction between the lignin in WAW and MEA. As the samples treated at room temperature also showed increased nitrogen contents, heating might not be necessary if time is aboundant. Although the sample used here contained 0.56 wt% nitrogen, we cannot guarantee that amount of nitrogen in every piece of WAW and that they are in the form of reactive amino groups. In the FT-IR spectra in Fig. 3, the most reliable absorption of lignin at 1508 cm−1 are normalized in each figure. The absorptions related to alkyl aryl ethers at 1265, 1221, 1139, and 1028 cm−1 all show slight decreases after the treatments by MEA in both alkaline and acidic conditions. With increases of time, these absorptions decreased slightly, which indirectly demonstrates the occurrence of the reaction between MEA and the lignin in WAW. Additionally, lignin index can be applied to evaluate lignin degradation by normalizing the peak intensities of the lignin group at 1508 cm–1 with the C–H deformation of CH3 groups at 1368 cm–1 (Gupta et al. 2015). The estimated the lignin indexes from Fig. 3 are almost identical as the peaks at 1368 cm–1 from all the spectra overlap together, which suggests the lignin was barely degraded during the treatment.

Immobilization of the initiators

In most cases of functional material synthesis, BIBB is the most effective way to react with hydroxyl groups. But for WAW, a too effective way can lead to a significant difference of initiator content between the macro surface and the inner part. Experiment results in Fig. 4 show that the WAW sample treated by BIBB and pyridine presents 1.76 at% Br content on the surface and only 0.44 at% in the inner section. By treating the WAW with MEA, the WAW samples are functionalized with amino groups, making it possible for other effective and selective reactions. First, we tried EDC, a most widely used and highly effective amidation reagent, and BIBA in various conditions in absolute ethanol. The results in Fig. 4 show that about 0.5 at% Br content was achieved in both surfaces and inner sections of the samples treated in optimal conditions, suggesting effectiveness and uniformity in both amino functionalization and initiator immobilization. To confirm that the Br contents in WAW samples were acquired through chemical reactions instead of absorptions, MEA treated WAW samples were treated by BIBA alone and only 0.02 at% Br was detected, which can be also viewed as undetected considering EDS detection limits. However, it is more desired and applicable to immobilize the initiator in aqueous condition or at least with water-tolerant reagents. Several treatments by EDC and BIBA were carried out in 50% ethanol/water solution. Because of fast hydrolysis of the newly formed active esters, there is no sufficient time for them to permeate into the WAW samples, resulting in high Br contents on the surfaces and very low Br contents in the inner parts (lower than 0.10 at%). The reaction between amino groups and o-quinone is very common in biological processes in living creatures (Le Bourvellec and Renard 2012) and food processing (Lin et al. 2018), and the reaction rate between them is also relatively fast (Li et al. 2016). Therefore, we designed two water-tolerant compounds to react with amino groups, i.e. 4-((2-bromoisobutylcarbonyl)aminomethyl)-o-quinone (Quinone A) and 4-((2-bromoisobutylcarbonyl)aminoethyl)-o-quinone (Quinone B) and addition products have lignin-like catechol structure. After treating the amino-functionalized WAW samples with Quinone A and Quinone B at 50 °C, the Br content of the inner part increased to around 0.2 at% (Fig. 5). At room temperature, Quinone A are much less effective than Quinone B. One mild defect for both quinone treatments are that the Br contents on the surfaces are higher than the inner parts because of the instability of o-quinones and thus forming oligomers on the surface. Additional, to prove the occurrence of the reaction between the amino groups and quinones, WAW sample without MEA treatment underwent the optimal treatment with Quinone B, giving only 0.02 at% Br in the inner part. After the treatments at 50 °C, the samples treated by Quinone A are darker than those treated by Quinone B. Therefore, Quinone B is more suitable for application. Moreover, it will be shown in the polymerization part that 0.2% Br contant is adequate for polymerization and maintaining dimensional stability.

Surface initiated ARGET ATRP

Although amidation by EDC/BIBA can immobilize more initiators on the MEA-treated WAW sample in ethanol, the efficiency decreased when water presents. On the contrary, quinone based initiators are able to react with amino groups in water/ethanol solution, which are more applicable in practice. Therefore, Quinone B modified WAW samples were selected for ARGET ATRP. Previous study (Zhou et al. 2019) has shown that ARGET ATRP can cause surface expansion when polymerization time increases. As ARGET ATRP was carried out at room temperature in that research, there was no enough time for all the reactants to permeate into the samples. Consequently, initiators on the surface have more chances to react with mononers and uniformity could not be guarenteed. Therefore, less active reductants such as ascorbic acid 2-glucoside and glucose are proposed to be used here and stronger reductant sodium ascorbate are served as comparison. Ascorbic acid 2-glucoside and glucose are both inert to the ARGET ATRP system at room temperature, allowing all the reactants to permeate into the samples first, and become active at 60 °C and 80 °C respectively to start the ATRP process. The polymerization results are shown in Table 1 and Fig. 6. Sample 1 using sodium ascorbate as redcutant presents incredible expansion of 47.3% volume and 210% WPG because of its strong reducibility and thus fast initiation rate of ARGET ATRP. The surface of sample 1 also featured with excessive polymer brushes (Fig. 6). Although such a result is dissatisfying, it can be served as an effective way to confirm the successful immobilization of the initiators. By replacing the reductant with ascorbic acid 2-glucoside or glucose, the ARGET ATRP process can be additionally controlled by temperature to acquire the uniformity. Sample 2, 3, and 4 all show no excessive polymer on the surface and appear almost the same as unpolymerized sample except evident shrinkage. The radial shrinkages of sample 2, 3 and 4 reduced to 3.1%, 3.3%, 2.6% respectively and the tangential shrinkages to 6.7%, 7.5%, 2.9% respectively. The volume shrinkages of sample 2, 3 and 4 reduced to 11.0%, 12.1% and 7.8% respectively and ASE increased to 79.0%, 77.0% and 85.1% respectively. Additionally, the WPG of sample 4 polymerized for 24 h shows no evident expansion and polymer brushes on the surface, completely different from sample 1 despite the WPG are close. Owing to more evenly distributed initiators, less active reductants and thermal initiated process, the main defect of ARTP has been overcome. The polymerization uniformity can also be displayed by the hydrophobicity of the samples in Figs. 6 and Fig. 7. Both surface and inner sections of sample 2, 3, and 4 display hydrophobicity with contact angles from 103 to 135° depending on surface roughness and contact time. Also, with the increase of contact time, the contact angle only decreased very slightly and the water drops were barely absorbed by the samples. By contrast, the contact angle of the unpolymerized sample cannot be measured because of its instant absorption of water. It appears that the contact angles of the surfaces are slightly smaller than those of the corresponding inner sections. This might be caused by the removal of ungrafted polymer chains from the surface during the washing process as those precipitated initiator oligomers might not be completely washed away and form free polymer chains in the solution during the polymerization.

Conclusion

Here we proposed a systematic approach to functionalize waterlogged archaeological wood with amino groups, ATRP initiators and poly-butyl methacrylate. The first step using MEA to increase amino groups in WAW samples can be carried out in absolute water solution under circumneutral conditions and here the nitrogen content of the samples increased by up to 0.75wt%. Then two o-quinone based initiators were designed to react with amino groups in WAW and successfully immobilized in water/ethanol solution, giving up to 0.2at% Br content of the sample. In comparison to widely used acyl halide such as BIBB, this method can achieve better uniformity and be carried out in water/ethanol solution instead of aprotic organic solvent. Also, amidation by carbodiimide such as EDC in ethanol raised the Br content to up to 0.5at%, which can be served as an alternative. Moreover, we found that two less active reductants, i.e., ascorbic acid 2-glucoside and glucose, are able to much better control the uniformity of polymerization because they turn the ARGET ATRP into thermo-initiated systems and the polymerization rates in those systems may also decrease. All of the above improvements make the ARGET ATRP method much more applicable to maintaining dimensional stability of WAW. The results in this paper show a maximum ASE of 85.1% and a minimum volume shrinkage of 7.8%, which can meet the requirement of WAW dehydration in most cases. Furthermore, the described functionalization methods may also provide reference and inspirations for WAW consolidation material designs other than ARGET ATRP and applications in other lignocellulosic materials. Future studies may have at least two focuses, i.e. developing even more convenient, applicable, robust methods for functionalization and screening the most suitable monomers and polymerization conditions for WAW consolidation by the existing methods.

Availability of the data and material

All the data are available upon reasonable requests.

References

Babiński L (2015) Dimensional changes of waterlogged archaeological hardwoods pre-treated with aqueous mixtures of lactitol/trehalose and mannitol/trehalose before freeze-drying. J Cult Herit 16:876–882

Björdal CG (2012) Microbial degradation of waterlogged archaeological wood. J Cult Herit 13:S118–S122

Björdal CG, Nilsson T, Daniel G (1999) Microbial decay of waterlogged archaeological wood found in Sweden applicable to archaeology and conservation. Int Biodeter Biodegr 43:63–73

Blanchette RA (2000) A review of microbial deterioration found in archaeological wood from different environments. Int Biodeter Biodegr 46:189–204

Broda M, Mazela B (2017) Application of methyltrimethoxysilane to increase dimensional stability of waterlogged wood. J Cult Herit 25:149–156

Broda M, Mazela B, Dutkiewicz A (2019a) Organosilicon compounds with various active groups as consolidants for the preservation of waterlogged archaeological wood. J Cult Herit 35:123–128

Broda M, Mazela B, Radka K (2019b) Methyltrimethoxysilane as a stabilising agent for archaeological waterlogged wood differing in the degree of degradation. J Cult Herit 35:129–139

Cavallaro G, Lazzara G, Milioto S, Parisi F, Sparacino V (2015) Thermal and dynamic mechanical properties of beeswax-halloysite nanocomposites for consolidating waterlogged archaeological woods. Polym Degrad Stabil 120:220–225

Cavallaro G, Lazzara G, Milioto S, Parisi F, Ruisi F (2017) Nanocomposites based on esterified colophony and halloysite clay nanotubes as consolidants for waterlogged archaeological woods. Cellulose 24:3367–3376

Cavallaro G, Milioto S, Lazzara G (2020) Halloysite nanotubes: interfacial properties and applications in cultural heritage. Langmuir 36:3677–3689

Cavallaro G, Milioto S, Parisi F, Lazzara G (2018) Halloysite nanotubes loaded with calcium hydroxide: alkaline fillers for the deacidification of waterlogged archeological woods. ACS Appl Mater Inter 10:27355–27364

Cesar T, Danevčič T, Kavkler K, Stopar D (2016) Melamine polymerization in organic solutions and waterlogged archaeological wood studied by ftir spectroscopy. J Cult Herit 23:106–110

Christensen M, Larnøy E, Kutzke H, Hansen FK (2015) Treatment of waterlogged archaeological wood using chitosan- and modified chitosan solutions. part 1: chemical compatibility and microstructure. J Am Inst Conserv 54:3–13

Endo R, Kamei K, Iida I, Kawahara Y (2008) Dimensional stability of waterlogged wood treated with hydrolyzed feather keratin. J Archaeol Sci 35:1240–1246

Endo R, Kamei K, Iida I, Yokoyama M, Kawahara Y (2010) Physical and mechanical properties of waterlogged wood treated with hydrolyzed feather keratin. J Archaeol Sci 37:1311–1316

Fors Y, Grudd H, Rindby A et al (2015) Sulfur and iron accumulation in three marine-archaeological shipwrecks in the Baltic Sea: The Ghost, the Crown and the Sword. Sci Rep 4:4222

Fors Y, Jalilehvand F, Risberg ED et al (2012) Sulfur and iron analyses of marine archaeological wood in shipwrecks from the Baltic Sea and Scandinavian waters. J Archaeol Sci 39:2521–2532

Fors Y, Sandström M (2006) Sulfur and iron in shipwrecks cause conservation concerns. Chem Soc Rev 35:399–415

Gierer J (1980) Chemical aspects of kraft pulping. Wood Sci Technol 14:241–266

Gierer J (1985) Chemistry of delignification. Wood Sci Technol 19:289–312

Gupta BS, Jelle BP, Gao T (2015) Wood facade materials ageing analysis by ftir spectroscopy. Construct Mater 168:219–231

Kennedy A, Pennington ER (2014) Conservation of chemically degraded waterlogged wood with sugars. Stud Conserv 59:194–201

Le Bourvellec C, Renard CMGC (2012) Interactions between polyphenols and macromolecules: quantification methods and mechanisms. Crit Rev Food Sci Nutr 52:213–248

Li Y, Jongberg S, Andersen ML et al (2016) Quinone-induced protein modifications: Kinetic preference for reaction of 1,2-benzoquinones with thiol groups in proteins. Free Radic Biol Med 97:148–157

Lin Y, Li L, Lund MN et al (2018) Reduction of Nε -(carboxymethyl) lysine by (−)-epicatechin and (−)-epigallocatechin gallate: The involvement of a possible trapping mechanism by catechin quinones. Food Chem 266:427–434

Liu L, Zhang L, Zhang B, Hu Y (2018) A comparative study of reinforcement materials for waterlogged wood relics in laboratory. J Cult Herit 36:94–102

McHale E, Braovac S, Steindal CC et al (2016) Synthesis and characterisation of lignin-like oligomers as a bio-inspired consolidant for waterlogged archaeological wood. Pure Appl Chem 88:969–977

Mchale E, Steindal CC, Kutzke H et al (2017) In situ polymerisation of isoeugenol as a green consolidation method for waterlogged archaeological wood. Sci Rep 7:46481

Mohamed HSAAK, Lotfy HM (2019) A new mixture of hydroxypropyl cellulose and nanocellulose for wood consolidation. J Cult Herit 35:140–144

Nair DP, Podgórski M, Chatani S et al (2014) The thiol-michael addition click reaction: a powerful and widely used tool in materials chemistry. Chem Mater 26:724–744

Tahira A, Howard W, Pennington ER, Kennedy A (2017) Mechanical strength studies on degraded waterlogged wood treated with sugars. Stud Conserv 62:223–228

Walsh Z, Janeček E, Hodgkinson JT et al (2014) Multifunctional supramolecular polymer networks as next-generation consolidants for archaeological wood conservation. Proc Nat Acad Sci USA 111:17743–17748

Walsh Z, Janeček E, Jones M, Scherman OA (2015) Natural polymers as alternative consolidants for the preservation of waterlogged archaeological wood. Stud Conserv 54:45–56

Wang B, Yang F, Shan YF et al (2009) Highly efficient synthesis of capsaicin analogues by condensation of vanillylamine and acyl chlorides in a biphase H2O/CHCl3 system. Tetrahedron 65:5409–5412

Zhou Y, Wang K, Hu D (2019) High retreatability and dimensional stability of polymer grafted waterlogged archaeological wood achieved by ARGET ATRP. Sci Rep 9:9879

Funding

The research is supported by National Social Science Foundation of China (Grant No. 19CKG032).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

There is no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, Y., Wang, K. & Hu, D. An aqueous approach to functionalize waterlogged archaeological wood followed by improved surface-initiated ARGET ATRP for maintaining dimensional stability. Cellulose 28, 2433–2443 (2021). https://doi.org/10.1007/s10570-020-03664-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-020-03664-y