Abstract

We have designed an innovative protocol for the consolidation of waterlogged archaeological woods by using acetone mixtures of halloysite clay nanotubes and a chemically modified colophony (Rosin). Firstly, we have investigated the thermal properties of HNTs/Rosin nanocomposites, which have been prepared by means of the casting method from acetone. The HNTs content have been systematically changed in order to study the influence of the inorganic filler on the thermal stability and glass transition process of Rosin. We have observed that the thermal properties of the hybrids are affected by the specific HNTs/Rosin interactions. Then, acetone dispersions of HNTs/Rosin composites at variable filler content have been employed as consolidants for waterlogged archaeological woods. The quantitative analysis of the thermogravimetric curves have provided the amount of consolidants entrapped into the wood structure. These results have been successfully correlated to the consolidation efficiencies estimated from the analysis of the wood shrinkage volume upon drying. The attained knowledge represents the basic step to develop a green protocol for the long term protection of wooden art-works.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years Cultural Heritage studies have attracted a growing interest within several fields including the diagnostics (Mendoza Cuevas et al. 2015) as well as the protection (Giachi et al. 2011) of historical artefacts. In this regard, the conservation of waterlogged archaeological woods represents a challenging task in view of preventing the collapse of the wooden structure upon drying.

The degradation degree of the waterlogged woods is strongly dependent on the chemical and biological nature of the site. In general, low temperatures and anoxic conditions promote the wood conservation (Blanchette 2000), while the degradation of lignocellulosic polysaccharides and lignin is mostly due to the actions of bacteria (Bugg et al. 2011; Gelbrich et al. 2008) and fungi (Dedic et al. 2013). The degraded wood mainly consists of water and minerals, whereas the residual content of the organic components (lignin and holocellulose) is extremely low (Cavallaro et al. 2011a). Consequently, the wood porosity is strongly enhanced generating a relevant worsening (Riggio et al. 2014). Filling the cavities with a proper consolidant plays a crucial role to confer robustness and stability (Giachi et al. 2010). An effective consolidation of the waterlogged archaeological wood was achieved by using biocompatible polymers, such as colophonies (Donato et al. 2010) poly(ethylene) glycols (Cavallaro et al. 2013a; Cipriani et al. 2013; Christensen et al. 2012), poly(propylene) glycols (Donato et al. 2010), beeswax (Cavallaro et al. 2015a) and cellulose ethers (Walsh et al. 2017). Literature reports that highly volatile solvents are efficient for the wood impregnation because they are able to more favourably transport the consolidant polymers and quickly evaporate after the treatment (McKerrel et al. 1972). Within this, acetone dispersions of colophonies revealed as the most successful procedure for the conservation of waterlogged woods (Shamsi and Geckeler 2008). Both the natural and esterified colophonies are effective in the in the wood stabilization (in terms of shape and dimensions) with respect to the humidity variations (Giachi et al. 2011). Recently, inorganic nanomaterials were investigated for the conservation of art-works formed by lignin and cellulose, such as archaeological woods (Cavallaro et al. 2015a; Christensen et al. 2012) and papers (Cavallaro et al. 2014, 2016). It is reported that the combination of polymers and nanoparticles can generate an improvement on the consolidation of art-works based on lignocellulosic materials as consequence of the polymer adhesion to both the particles surfaces and the remaining wooden structure (Christensen et al. 2012). Among the nanoparticles, halloysite clay nanotubes (HNTs) were successfully employed for the protection of waterlogged archaeological woods (Cavallaro et al. 2015a). Chemically, the HNTs inner surface consists of a gibbsite octahedral sheet (Al–OH), whereas the shell is composed of siloxane groups (Si–O–Si) (Joussein et al. 2005). Halloysite is a promising nanofiller because of its hollow tubular morphology and tunable surface chemistry (Pasbakhsh et al. 2013). The length of HNTs is ca. 1 μm, while the external and internal diameters are 40–60 and 10–15 nm, respectively (Lvov et al. 2016). The peculiar surface chemistry endows a targeted modification driven by electrostatic interactions (Cavallaro et al. 2015b; Bertolino et al. 2017). Accordingly to their geometrical characteristics, HNTs are promising as fillers for the wood cavities. Moreover, HNTs are biocompatible as shown by several in vitro and in vivo studies (Fakhrullina et al. 2015; Kryuchkova et al. 2016; Fakhrullin and Lvov 2016) and their cavity can be can be easily loaded with functional molecules with magnetic (Vasilev et al. 2017) antimicrobial, (Aguzzi et al. 2013; Wei et al. 2014), antioxidant (Biddeci et al. 2016), surface active (Owoseni et al. 2014) and anticorrosion (Joshi et al. 2013; Abdullayev et al. 2012) activities. Due to these properties, HNTs are perspective as consolidants for a long term protection of art-works (Lvov and Abdullayev 2013). The addition of HNTs into polymer matrix induced an improvement of the mechanical perfomances (Cavallaro et al. 2011b; Arcudi et al. 2014) as well as the physical barrier properties (Sorrentino et al. 2007; Gorrasi et al. 2014). Within the cultural heritage applications, waterlogged woods treated by beeswax/HNTs composite exhibited a lower porosity degree with respect to those consolidated by pristine beeswax (Cavallaro et al. 2015a). Our work was focused on the development of an innovative green protocol for conservation of waterlogged archaeological woods. To this purpose, acetone dispersions of HNTs and Rosin were employed as consolidant mixtures. Specifically, Rosin100 (pentaerythritol ester of Colophony) was selected as polymer for the wood consolidation. The influence of HNTs on the thermal properties of the esterified colophony was investigated by Differential Scanning Calorimetry and Thermogravimetry. The thermal behaviour of the treated woods and the consolidation efficiency were determined by the shrinkage volume upon drying as well as by Thermogravimetry, which is a well-established technique for both the characterization of composites (Blanco et al. 2012, 2016; Belver et al. 2013; Rotaru et al. 2008) and the analysis of artwork materials (Duce et al. 2012; Sebestyén et al. 2015). The acquired knowledge represents the starting point for designing a green protocol to preserve the waterlogged archaeological woods using acetone dispersions of HNTs/Rosin hybrids.

Materials and methods

Materials

Rosin100 is from Bresciani srl. Halloysite nanotubes (HNTs) are from Sigma Aldrich. The deposit of HNTs is Dragon Mine (Utah, US). Acetone (99.5%, 0.791 g cm−3) is a Panreac reagent. The waterlogged archaeological woods are from the ship Chretienne C, (II century, BC), discovered over the coast of Provence and kindly provided by Prof. Patrice Pomey of C.N.R.S., Université de Provence (France). According to the procedure of the Italian standard (UNI 11205:2007), the archaeological woods were identified as Pinus Pinaster (Cavallaro et al. 2011a).

Preparation of the HNTs/Rosin composites

We prepared a 50 wt% rosin solution in acetone under stirring for 2 h at 25 °C. Then, appropriate amounts of HNTs were added to the rosin solution and kept under stirring overnight in order to obtain stable and homogenous mixtures. The well dispersed dispersions were poured into Petri dishes at 30 °C to evaporate the solvent until the weight was constant. The HNTs concentration (CHNTs) expressed as weight percent (grams of HNTs/100 g of the composite) was systematically changed within a wide range.

Consolidation of waterlogged archaeological wood

The waterlogged archaeological wood was consolidated through the immersion method as described elsewhere (Cavallaro et al. 2015a). HNTs/Rosin dispersions in acetone were employed as consolidant mixtures. The archaeological woods were kept in the Rosin/HNTs mixtures under stirring for three days. The efficiency of the treatment was evaluated by determining the shrinkage volume (∆VS) of treated and untreated wood samples. For each wood sample, the ∆VS values were calculated as difference between its initial volume (measured after exposure at ambient temperature for 24 h) and its final volume (measured after the exposure at 100 °C for 24 h).

Characterization

Thermogravimetry (TG) measurements were performed by means of a Q5000 IR apparatus (TA Instruments) under the nitrogen flow of 25 cm3 min−1 for the sample and 10 cm3 min−1 for the balance. The weight of each sample was ca. 5 mg. The experiments were carried out by heating the sample from room temperature to 900 °C with a rate of 10 °C min−1. The temperature calibration was carried out by means of the Curie temperatures of standards (nickel, cobalt, and their alloys). The measurements were repeated three times, and the average values with the corresponding standard deviation are reported for all the thermogravimetric parameters.

Differential scanning calorimetry (DSC) experiments were conducted by using the differential scanning calorimeter TA Instrument DSC (2920 CE). The calorimeter was calibrated using the melting enthalpy of standard indium (28.71 J g−1). Each sample (ca. 3 mg) was heated according to a temperature program of 20 °C min−1 in the temperature range comprised between −20 and 120 °C. The measurements were performed under a nitrogen flow rate of 60 cm3 min−1.

A microscope-mounted digital camera (Digitus-DA-70351) was used to capture the optical images of both the untreated and treated archaeological wood samples. The images were analyzed by ImageJ software in order to estimate the DVS values.

Results and discussion

Thermal properties of Rosin/HNTs composites

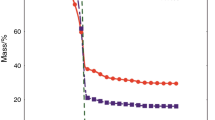

Figure 1 shows the thermogravimetric (TG) and differential thermogravimetric (DTG) curves of both pristine Rosin and HNTs/Rosin nanocomposites.

All materials exhibited a weight loss in the temperature range between 25 and 150 °C (ML150), which is related to their physically adsorbed water content. The mass loss occurring at ca. 350–450 °C is due to the thermal degradation of the organic molecules. Accordingly, the Rosin degradation temperature (Td) was estimated from the maximum of DTG peak centered at ca. 400 °C. The composite materials evidenced an additional DTG peak centered at ca. 500 °C, which can be attributed to the expulsion of the water molecules confined in the HNTs interlayer (Duce et al. 2015; Cavallaro et al. 2011b).

The Rosin thermal stability was strongly altered by the HNTs addition (Fig. 2). In particular, the Td versus CHNTs function showed a decreasing trend (Fig. 2) indicating that the HNTs/Rosin interactions induce a thermal destabilization of the esterified colophony. Interestingly, the composite with a very large HNTs content (ca. 50 wt%) evidenced a Td reduction of ca. 100 °C with respect to that of pure Rosin. Similarly, a decrease of the polymer resistance to the thermal degradation was detected in PEG20000/HNTs containing a large filler content (Cavallaro et al. 2013b). The Td decrease could be due to the partial deterioration of the Rosin structure induced by the filling with HNT. Consequently, the diffusion of the volatile products of the polymer degradation is favored in the nanocomposite materials.

Furthermore, TG curves endowed to determine the experimental HNTs/Rosin composition of the hybrid materials by the residual masses at 800 °C (MR800). The CHNTs values were calculated by using the rule of mixtures (Cavallaro et al. 2011b) once the mass loss of the pure components were known and by taking into account their water contents (ML150). Mathematical details concerning the determination of the HNTs/Rosin composition for the nanocomposites is presented in the Supplementary material. Table 1 highlights that a good agreement between the experimental and stoichiometric composition was observed. On this basis, we can conclude that the casting method from acetone was successful to obtain composites with HNTs homogeneously dispersed into the Rosin matrix.

The specific matrix/filler interactions influenced the Rosin glass transition, which was studied by DSC measurements in terms of glass transition temperature (Tg) and heat capacity change (∆Cp). It should be noted that ∆Cp values were normalized to the Rosin weight fraction by considering the experimental composition of the investigated materials (Table 1). A step change in the heat flow curves was observed at ca. 60 °C (Fig. 3) whose inflection point can be attributed to the Tg of Rosin.

We observed that Tg is not significantly affected by the presence of HNTs (Fig. 4a). Contrary to this, ∆Cp linearly reduces with the filler content (Fig. 4b) according to the Rosin immobilization onto the HNTs surfaces. Similarly, the addition of silica into poly(dimethylsiloxane) (Fragiadakis and Pissis 2007) and polyimide (Bershtein et al. 2002) generated a systematic ∆Cp decrease because of the reduced mobility of the polymer adsorbed onto the nanoparticles surfaces. Namely, the polymer chain mobility is constrained due to interaction with the surface of the particles.

Consolidation of waterlogged archaeological wood

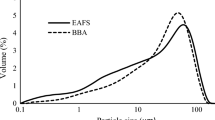

The HNTs/Rosin mixtures were investigated as consolidant for waterlogged archaeological wood by using the immersion procedure described for HNTs/Beeswax hybrids (Cavallaro et al. 2015a). According to the TG data, the nanotubes are uniformly dispersed into the Rosin making these dispersions promising for the treatment of porous materials, such as the archaeological woods. We studied the influence of HNTs/Rosin weight ratio (R) on the wood consolidation efficiency, which was estimated from TG experiments. Some examples of TG curves for untreated and treated archaeological woods are reported in the Supplementary material.

As shown in Table 2, the presence of the consolidant caused a decrease of the water content in agreement with the entrapment of the Rosin/HNT system into the wood pores.

DTG curves of the treated wood samples (Fig. 5) evidenced a sharp peak centered at ca. 400 °C that can be ascribed to the Rosin degradation.

This finding proves the successful penetration of Rosin into the wood structure. On this basis, we determined the amount of Rosin entrapped into the wood by the analysis of the mass losses occurring between 200 and 460 °C (ML200–460), in which the esterified colophony completely degrades. Table 2 collects the ML200–460 for treated and untreated wood samples. In order to estimate the consolidation efficiency the ML200–460 values were normalized to the water content (ML150) of the investigated samples by using the equation

Being that the wood partially degrades at 200–460 °C, the ML200–460 of the pure wood was taken into account. Accordingly, the weight fraction of Rosin in the consolidated wood (\( \upchi_{\text{R}} \)) was calculated as

where \( \left( {{\text{ML}}^{*}_{200-460} } \right)_{\text{T}} \), \( \left( {{\text{ML}}^{*}_{200-460} } \right)_{\text{T}} \) and \( \left( {{\text{ML}}^{*}_{200-460} } \right)_{\text{R}} \) are the mass losses normalized to the water contents for treated wood, untreated wood and pristine Rosin, respectively.

Figure 6 shows that the amount of Rosin entrapped into the wood structure is affected by the HNTs/Rosin weight ratio (R) of the consolidant mixture.

We observed that the presence of small amounts of HNTs favors the penetration of Rosin in the wood. In particular, the \( \upchi_{\text{R}} \) versus R function shows an increasing trend for consolidant mixtures with R ≤ 0.43. A further HNTs addition induced a strong decrease of the \( \upchi_{\text{R}} \) values because the wood pores are largely and preferentially filled by the nanotubes. The successful entrapment of the nanotubes into the wood structure was clearly evidenced by the DTG peak centered at ca. 500 °C (Fig. 5), which allowed us to calculate the HNTs weight fractions (\( \upchi_{\text{HNTs}} \)) by using an approach described elsewhere (Cavallaro et al. 2011b). The integration of the DTG peaks provided an accurate estimation of the mass losses (0.428 and 1.31 wt% for R = 0.66 and 1, respectively) caused by the expulsion of the two interlayer water molecules of halloysite. According to the corresponding mass loss of pristine HNTs (12.7 wt%) (Cavallaro et al. 2011b), we determined the \( \upchi_{\text{HNTs}} \) values in the consolidated woods (0.034 and 0.103 for R = 0.66 and 1, respectively). These results highlight that a preferential penetration of the nanotubes occurs for consolidant mixtures with a very large HNTs content. For R ≤ 0.66 the DTG curves of the treated wood samples did not show any reliable peak at ca. 500 °C (Fig. 5) and, therefore, the determination of the HNTs penetrated amount was not conducted. Nevertheless, we can conclude that that the entrapment of HNTs is negligible compared with that of Rosin. As shown in Fig. 6, the Rosin/HNTs interactions promote the penetration of the esterified colophony for consolidant mixture with low HNTs content. Based on the TG data, we calculated the pore volume of the wood filled by the consolidant materials (Vc) by considering the density values for HNTs and Rosin (2.65 and 1.073 g cm−3, respectively) and assuming that the specific filler/matrix interactions did not affect the volume of both components. Regarding the composite mixtures with a low HNTs content, the Vc are underestimated because the weight fraction of HNTs in the wood was not taken into account. As reported in Table 3, the addition of small amounts of HNTs induces a reliable increase of Vc compared to that of pure Rosin. It is noteworthy to note that a Vc enhancement of 30% was detected for HNTs/Rosin with R = 0.43. On the contrary, a significant Vc reduction was observed for HNTs/Rosin mixtures with a large filler content. We calculated a Vc decrease of 65% for HNTs/Rosin with R = 1.

The consolidation efficiency results were related to the shrinkage volume (∆VS) values for untreated and treated wood samples. Figure 7a shows the shrinkage volume for the waterlogged archaeological wood consolidated by HNTs/Rosin (R = 1) mixture. Optical photos of untreated and treated wood samples are presented in the Supplementary material.

As general result, the ∆VS values of the treated samples are lower compared to that of the untreated one (Fig. 7b) confirming the successful consolidation of the waterlogged archaeological woods. As expected by the TG data (Fig. 6), the ∆VS of the wood samples consolidated by HNTs/Rosin mixture depends on the specific composition of the consolidant mixture. The lowest ∆VS value was estimated for the wood treated by HNTs/Rosin with R = 0.25, while the addition of a larger amount of HNTs (R = 1) induced a decrease of the consolidation efficacy with respect to that observed for pure Rosin (Fig. 7b). The ∆VS results confirm that the presence of small amounts of HNTs favors the entrapment of Rosin into the wood pores improving the impregnation efficacy. Contrary to this, the composite mixture with a large HNTs content exhibited a lower consolidation ability respect to that of pristine Rosin because the penetration of the esterified colophony is strongly reduced. The antishrink efficiencies of the HNTs/Rosin mixtures range between 36 and 65%. These results are comparable to those obtained by using several protocols for the treatment of the archaeological woods (Grattan et al. 2006) highlighting the suitability of the HNTs/Rosin dispersions as consolidants.

Conclusions

Acetone dispersions of HNTs/Rosin nanocomposites were investigated as potential consolidants for waterlogged archaeological woods. We observed that the thermal properties of Rosin are strongly affected by the addition of HNTs. TG experiments evidenced that the resistance to thermal degradation of Rosin is significantly reduced in the presence of HNTs, which are homogeneously dispersed into the polymer matrix. Regarding the Rosin glass transition, the nanocomposites exhibited a decrease of the heat capacity change according to the polymer immobilization onto the HNTs surfaces. The efficacy of the wood treatment by HNTs/Rosin hybrids was estimated by the quantitative analysis of TG curves as well as by the shrinkage volumes upon drying. We found that the consolidation efficiency of the archaeological woods can be controlled by the concentration of the inorganic filler. The presence of small amounts of HNTs favored the penetration of Rosin into the wooden structure and, consequently, the shrinkage volume of the treated archaeological woods showed a relevant decrease compared to that consolidated by the pristine esterified colophony. Contrary to these results, a worsening of the consolidation efficiency was detected for nanocomposites with a very large HNTs content because of a strong reduction of the Rosin amount entrapped into the wood pores. The HNTs/Rosin mixtures can be considered perspective as consolidants for the conservation of waterlogged archaeological woods. The encapsulation of antimicrobial compounds into the HNTs lumen might be strategic for future advances and long-term protection purposes.

References

Abdullayev E, Joshi A, Wei W et al (2012) Enlargement of halloysite clay nanotube lumen by selective etching of aluminum oxide. ACS Nano 6:7216–7226. doi:10.1021/nn302328x

Aguzzi C, Viseras C, Cerezo P et al (2013) Release kinetics of 5-aminosalicylic acid from halloysite. Coll Surf B Biointerfaces 105:75–80. doi:10.1016/j.colsurfb.2012.12.041

Arcudi F, Cavallaro G, Lazzara G et al (2014) Selective functionalization of halloysite cavity by click reaction: structured filler for enhancing mechanical properties of bionanocomposite films. J Phys Chem C 118:15095–15101. doi:10.1021/jp504388e

Belver C, Aranda P, Ruiz-Hitzky E (2013) Silica–alumina/sepiolite nanoarchitectures. J Mater Chem A 1:7477–7487. doi:10.1039/C3TA01686B

Bershtein VA, Egorova LM, Yakushev PN et al (2002) Molecular dynamics in nanostructured polyimide–silica hybrid materials and their thermal stability. J Polym Sci Part B Polym Phys 40:1056–1069. doi:10.1002/polb.10162

Bertolino V, Cavallaro G, Lazzara G, Milioto S, Parisi F (2017) Biopolymer-targeted adsorption onto halloysite nanotubes in aqueous media. Langmuir 33:3317–3323. doi:10.1021/acs.langmuir.7b00600

Biddeci G, Cavallaro G, Di Blasi F et al (2016) Halloysite nanotubes loaded with peppermint essential oil as filler for functional biopolymer film. Carbohydr Polym 152:548–557. doi:10.1016/j.carbpol.2016.07.041

Blanchette RA (2000) A review of microbial deterioration found in archaeological wood from different environments. Int Biodeterior Biodegrad 46:189–204. doi:10.1016/S0964-8305(00)00077-9

Blanco I, Abate L, Bottino FA, Bottino P (2012) Thermal degradation of hepta cyclopentyl, mono phenyl-polyhedral oligomeric silsesquioxane (hcp-POSS)/polystyrene (PS) nanocomposites. Polym Degrad Stab 97:849–855. doi:10.1016/j.polymdegradstab.2012.03.041

Blanco I, Abate L, Bottino FA (2016) Preparation and thermal characterization of three different series of novel polyhedral oligomeric silsesquioxanes/polystyrene nanocomposites. J Macromol Sci Part B 55:1111–1123. doi:10.1080/00222348.2016.1242531

Bugg TD, Ahmad M, Hardiman EM, Singh R (2011) The emerging role for bacteria in lignin degradation and bio-product formation. Curr Opin Biotechnol 22:394–400. doi:10.1016/j.copbio.2010.10.009

Cavallaro G, Donato DI, Lazzara G, Milioto S (2011a) A comparative thermogravimetric study of waterlogged archaeological and sound woods. J Therm Anal Calorim 104:451–457. doi:10.1007/s10973-010-1229-3

Cavallaro G, Lazzara G, Milioto S (2011b) Dispersions of nanoclays of different shapes into aqueous and solid biopolymeric matrices. Extended physicochemical study. Langmuir 27:1158–1167. doi:10.1021/la103487a

Cavallaro G, Donato DI, Lazzara G, Milioto S (2013a) Determining the selective impregnation of waterlogged archaeological woods with poly(ethylene) glycols mixtures by differential scanning calorimetry. J Therm Anal Calorim 111:1449–1455. doi:10.1007/s10973-012-2528-7

Cavallaro G, Lisi R, Lazzara G, Milioto S (2013b) Polyethylene glycol/clay nanotubes composites. J Therm Anal Calorim 112:383–389. doi:10.1007/s10973-012-2766-8

Cavallaro G, Lazzara G, Milioto S, Parisi F (2014) Halloysite nanotubes as sustainable nanofiller for paper consolidation and protection. J Therm Anal Calorim 117:1293–1298. doi:10.1007/s10973-014-3865-5

Cavallaro G, Lazzara G, Milioto S et al (2015a) Thermal and dynamic mechanical properties of beeswax-halloysite nanocomposites for consolidating waterlogged archaeological woods. Polym Degrad Stab 120:220–225. doi:10.1016/j.polymdegradstab.2015.07.007

Cavallaro G, Lazzara G, Milioto S, Parisi F (2015b) Hydrophobically modified halloysite nanotubes as reverse micelles for water-in-oil emulsion. Langmuir 31:7472–7478. doi:10.1021/acs.langmuir.5b01181

Cavallaro G, Lazzara G, Milioto S, Parisi F (2016) Halloysite nanotubes with fluorinated cavity: an innovative consolidant for paper treatment. Clay Miner 51:445. doi:10.1180/claymin.2016.051.3.01

Christensen M, Kutzke H, Hansen FK (2012) New materials used for the consolidation of archaeological wood–past attempts, present struggles, and future requirements. J Cult Herit 13:S183–S190. doi:10.1016/j.culher.2012.02.013

Cipriani G, Salvini A, Fioravanti M et al (2013) Synthesis of hydroxylated oligoamides for their use in wood conservation. J Appl Polym Sci 127:420–431. doi:10.1002/app.37678

Dedic D, Iversen T, Ek M (2013) Cellulose degradation in the Vasa: the role of acids and rust. Stud Conserv 58:308–313

Donato D, Lazzara G, Milioto S (2010) Thermogravimetric analysis. J Therm Anal Calorim 101:1085–1091

Duce C, Ghezzi L, Onor M et al (2012) Physico-chemical characterization of protein–pigment interactions in tempera paint reconstructions: casein/cinnabar and albumin/cinnabar. Anal Bioanal Chem 402:2183–2193. doi:10.1007/s00216-011-5684-x

Duce C, Vecchio Ciprioti S, Ghezzi L et al (2015) Thermal behavior study of pristine and modified halloysite nanotubes. J Therm Anal Calorim 121:1011–1019. doi:10.1007/s10973-015-4741-7

Fakhrullin RF, Lvov YM (2016) Halloysite clay nanotubes for tissue engineering. Nanomedicine 11:2243–2246. doi:10.2217/nnm-2016-0250

Fakhrullina GI, Akhatova FS, Lvov YM, Fakhrullin RF (2015) Toxicity of halloysite clay nanotubes in vivo: a Caenorhabditis elegans study. Environ Sci: Nano 2:54–59. doi:10.1039/C4EN00135D

Fragiadakis D, Pissis P (2007) Glass transition and segmental dynamics in poly(dimethylsiloxane)/silica nanocomposites studied by various techniques. J Non Cryst Solids 353:4344–4352. doi:10.1016/j.jnoncrysol.2007.05.183

Gelbrich J, Mai C, Militz H (2008) Chemical changes in wood degraded by bacteria. Int Biodeterior Biodegrad 61:24–32. doi:10.1016/j.ibiod.2007.06.007

Giachi G, Capretti C, Macchioni N et al (2010) A methodological approach in the evaluation of the efficacy of treatments for the dimensional stabilisation of waterlogged archaeological wood. J Cult Herit 11:91–101. doi:10.1016/j.culher.2009.04.003

Giachi G, Capretti C, Donato ID et al (2011) New trials in the consolidation of waterlogged archaeological wood with different acetone-carried products. J Archaeol Sci 38:2957–2967. doi:10.1016/j.jas.2011.06.012

Gorrasi G, Pantani R, Murariu M, Dubois P (2014) PLA/halloysite nanocomposite films: water vapor barrier properties and specific key characteristics. Macromol Mater Eng 299:104–115. doi:10.1002/mame.201200424

Grattan D, Bilz M, Grant T, Logan J (2006) Outcome determines treatment—an approach to the treatment of waterlogged wood. J Wetl Archaeol 6:49–63. doi:10.1179/jwa.2006.6.1.49

Joshi A, Abdullayev E, Vasiliev A et al (2013) Interfacial modification of clay nanotubes for the sustained release of corrosion inhibitors. Langmuir 29:7439–7448. doi:10.1021/la3044973

Joussein E, Petit S, Churchman GJ et al (2005) Halloysite clay minerals—a review. Clay Miner 40:383–426

Kryuchkova M, Danilushkina A, Lvov Y, Fakhrullin R (2016) Evaluation of toxicity of nanoclays and graphene oxide in vivo: a paramecium caudatum study. Environ Sci Nano 3:442–452. doi:10.1039/C5EN00201J

Lvov Y, Abdullayev E (2013) Functional polymer–clay nanotube composites with sustained release of chemical agents. Prog Polym Sci 38:1690–1719. doi:10.1016/j.progpolymsci.2013.05.009

Lvov Y, Wang W, Zhang L, Fakhrullin R (2016) Halloysite clay nanotubes for loading and sustained release of functional compounds. Adv Mater 28:1227–1250. doi:10.1002/adma.201502341

McKerrel H, Roger E, Varsaniy A (1972) The acetone/rosin method for conservation of waterlogged wood. Stud Conserv. doi:10.1179/sic.1972.011

Mendoza Cuevaz A, Bernardini F, Gianoncelli A, Tuniz C (2015) Energy dispersive X-ray diffraction and fluorescence portable system for cultural heritage applications. X-ray Spectrom 44:105–115. doi:10.1002/xrs.2585

Owoseni O, Nyankson E, Zhang Y et al (2014) Release of surfactant cargo from interfacially-active halloysite clay nanotubes for oil spill remediation. Langmuir 30:13533–13541. doi:10.1021/la503687b

Pasbakhsh P, Churchman GJ, Keeling JL (2013) Characterisation of properties of various halloysites relevant to their use as nanotubes and microfibre fillers. Appl Clay Sci 74:47–57. doi:10.1016/j.clay.2012.06.014

Riggio M, Sandak J, Sandak A et al (2014) Analysis and prediction of selected mechanical/dynamic properties of wood after short and long-term waterlogging. Constr Build Mater 68:444–454. doi:10.1016/j.conbuildmat.2014.06.085

Rotaru A, Nicolaescu I, Rotaru P, Neaga C (2008) Thermal characterization of humic acids and other components of raw coal. J Therm Anal Calorim 92:297–300. doi:10.1007/s10973-007-8816-y

Sebestyén Z, Czégény Z, Badea E et al (2015) Thermal characterization of new, artificially aged and historical leather and parchment. J Anal Appl Pyrolysis 115:419–427. doi:10.1016/j.jaap.2015.08.022

Shamsi MH, Geckeler DV (2008) The first biopolymer-wrapped non-carbon nanotubes. Nanotechnology 19:075604

Sorrentino A, Gorrasi G, Vittoria V (2007) Potential perspectives of bio-nanocomposites for food packaging applications. Trends Food Sci Technol 18:84–95. doi:10.1016/j.tifs.2006.09.004

Vasiliev AN, Shvanskaya LV, Volkova OS et al (2017) Magnetism of natural composite of halloysite clay nanotubes Al2Si2O5(OH)4 and amorphous hematite Fe2O3. Mater Charact 129:179–185. doi:10.1016/j.matchar.2017.04.028

Walsh Z, Janeček E-R, Jones M, Scherman OA (2017) Natural polymers as alternative consolidants for the preservation of waterlogged archaeological wood. Stud Conserv 62:173–183. doi:10.1179/2047058414Y.0000000149

Wei W, Minullina R, Abdullayev E et al (2014) Enhanced efficiency of antiseptics with sustained release from clay nanotubes. RSC Adv 4:488–494. doi:10.1039/C3RA45011B

Acknowledgments

The work was financially supported by the University of Palermo, PON-TECLA (PON03PE_00214_1). The authors have no conflicts of interest to declare.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Cavallaro, G., Lazzara, G., Milioto, S. et al. Nanocomposites based on esterified colophony and halloysite clay nanotubes as consolidants for waterlogged archaeological woods. Cellulose 24, 3367–3376 (2017). https://doi.org/10.1007/s10570-017-1369-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1369-8