Abstract

Use of reactive dyes of red, blue and yellow colours for exhaustion dyeing of cotton conventional water-based dyeing method and PEG-based solvent-assisted reverse micelle dyeing method was investigated. Calibration curves of both dyeing approaches were established. The calibration results show that red dye can achieve higher absorbance value than yellow and blue dyes and the R-square of the curves can reach a value above 0.99 which indicates the curves are linear in structure and suitable for subsequent measurement. The values of substantivity factor (S), exhaustion factor (E), rate of fixation (R) and fixation factor (F) (SERF) are measured in percentage. The results reveal that using reverse micelle method can achieve higher dye absorption in both exhaustion and fixation processes, resulting in higher final exhaustion of dye in fibre than with the conventional water-based method. Therefore, the reverse micellar dyed samples generally can obtain higher dye absorption, lower reflectance percentage and darker shade in appearance than conventional water-based dyeing.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Textile dyeing has long been regarded as a process which consumes a significant amount of water and generates substantial amounts of effluents (Dong et al. 2007; Hickman 1993). In conventional water-based textile reactive dyeing process, due to low affinity of reactive dyes to cotton fibre, large amounts of salts are required to eliminate the repulsion force between dye molecules and fibre surface, to enhance dye affinity and accelerating dye absorption (Perkins 1996).

With the aim to investigate the possibility of switching the dyeing medium from aqueous to non-aqueous condition and establishing a more environmentally-friendly dyeing system with the absence of electrolytes, minimal dye hydrolysis and water consumption, some new methodologies have been used for dyeing of cotton fibres (Parvinzadeh Gashti et al. 2013; Sumithra 2018; Teklemedhin 2018). Several attempts have been made to use reverse micelles in the solvent-assisted dyeing system with anionic surfactants such as Aerosol-OT (De and Maitra 1995; Sawada and Ueda 2003). However, the use of anionic surfactants has adverse effects on water-pool polarity as it produces an uneven micro-environment unfavorable to the application of reverse micelles (Sawada and Ueda 2004a, b). Thus, efforts have been made to apply reverse micelles by using non-ionic surfactants in the solvent-assisted dyeing system so as to obtain a stable environment in the water-pool (Sawada et al. 2004). Experiments have been conducted to dye cotton with non-ionic Triton X-100 reverse micelles (Yi et al. 2012, 2014) and non-ionic Triton X-100/Span40 mixed reverse micelles (Yi et al. 2015). Our previous work has also studied the optimized condition of poly(ethylene glycol) (PEG)-based reverse micellar alkane reactive dyeing of cotton fibre (Wang et al. 2016). In addition, a series of works have been conducted to analyze the feasibility of applying computerised colour matching for colour communication and industrial application using decamethylcyclopentasiloxane (D5) solvent (Tang et al. 2017b) and assessing dyeing properties of fabrics dyed with use of alkane solvents (heptane, octane and nonane) (Tang et al. 2017a, 2018a, c). However, the reactive dye compatibility matrix (RCM) for exhaust dyeing of cotton fibre using reverse micelle is still unknown and has not yet been studied.

The reactive dye compatibility matrix (RCM) has several functions including: (a) it defines the optimum dyeing profile for exhaust dyeing with reactive dyes; (b) quantifies dye migration properties; (c) defines the degree of process control required to achieve shade reproducibility and level dyeing performance; and (d) serves as an index of dye reactivity. By understanding the RCM, properties of dyes during the exhaustion and fixation phase of the dyeing process, reactivity and level of performance required to achieve right-first-time production can be defined (Bradbury et al. 1995; Collishaw et al. 1993).

The purpose of the present study is to examine the RCM of reactive dyes (Red, Blue and Yellow) for dyeing of cotton fibre in alkane solvent-assisted PEG-based reverse micelle dyeing system and compare it with cotton fibre dyed by conventional water-based dyeing method using similar reactive dyes. The RCM study involves: (a) establishment of calibration curves for both conventional and reverse micelle dyeing system; and (b) measurement of individual values of substantivity factor (S), exhaustion factor (E), rate of fixation (R) and fixation (F) in percentage.

Experimental

Materials and reagents

Commercially ready-for-dyeing 100% cotton knitted interlock fabrics (40 wales/in. and 40 courses/in., fabric weight: 185 g/m2) were first cleaned in a laundering machine with detergent at temperature of 49 °C for 45 min. After cleaning, the fabrics were thoroughly tumble dried and conditioned at relative humidity of 65 ± 2% and 20 ± 2 °C for at least 24 h before subsequent experiments. Poly(ethylene glycol) (12) tridecylether (C13H27(OCH2CH2)12OH) and n-octanol, nonionic surfactant and co-surfactants respectively, were used to facilitate the formation of reverse micelles. Alkane solvents, including heptane, octane and nonane, were used as the non-aqueous medium for reverse micellar coloration of cotton. The chemicals used were of reagent grade. Three Levafix CA reactive dyes (Levafix Red CA, Levafix Blue CA and Levafix Yellow CA provided by Dystar, Shanghai, China) were directly used without further purification.

Establishment of calibration curves

Conventional water-based calibration

A stock solution of 1% was first prepared. A series of dye aqueous solutions were prepared by a simple injection method at room temperature. Controlled amounts of reactive dyes of different colours (red, blue and yellow) having different dye concentrations (0.1%, 0.2%, 0.4%, 0.6%, 0.8% and 1% dye conc.) were then mixed in deionized water to obtain 50 mL of dye liquor containing each dye. 35 g/L of sodium chloride was added to the dye solutions. The prepared dye solutions (with salt) of different dye concentrations were then diluted 5 times, injected into the cuvette (3 mL) and put into the UH5300 Spectrophotometer (Hitachi, Japan) for measurement. The absorbance values of the solutions were measured at wavelengths ranging from 400 to 700 nm. The Y-axis was between 0 and 1. The data interval was 1 nm and the scan speed was 400 nm/min. Maximum absorbance value λ of the curve peak of each solution was taken and calibration curves without the addition of soda ash were thus established.

Calibration curves with the addition of soda ash were established by adding a controlled amount of soda ash (5 g/L) into the prepared dye liquors. The dye liquors were then diluted 5 times, injected into the cuvette (3 mL) and put into the UH5300 Spectrophotometer (Hitachi, Japan) for measurement. The parameters of measurement were similar to those used for the curves without the addition of soda ash.

Non-aqueous alkane-based reverse micellar calibration

Series of PEG-based reverse micelles were prepared by a simple injection method at room temperature. The non-ionic surfactant and co-surfactant (n-octanol) were first premixed (with agitation). Then the surfactant/co-surfactant mixture was dissolved in heptane, octane and nonane respectively to obtain organic surfactant solutions for facilitating self-assembly of PEG-based reverse micelles (Solvent to cotton volume = 8 mL; surfactant to co-surfactant mole ratio = 1:8; surfactant to water mole ratio = 0.05:1; water-pool volume for dye = 0.5 mL; water-pool volume for soda ash = 0.3 mL).

Controlled amounts of reactive dye aqueous solutions of different colours (red, blue and yellow) and dye concentrations (0.1%, 0.2%, 0.4%, 0.6%, 0.8% and 1% dye conc.) were then applied into the reverse micellar system dropwise. After injection of the dye solution, the mixtures were vigorously stirred for 2 min until dye-encapsulated reverse micelle well-dispersed solution was obtained. The prepared reverse micellar dye solutions of different dye concentrations were then diluted 22 times, injected into the cuvette (3 mL) and put into the UH5300 Spectrophotometer (Hitachi, Japan) for measurement. The absorbance values of the solutions were measured at wavelengths ranging from 400 to 700 nm. The Y-axis was between 0 and 1. The data interval was 1 nm and the scan speed was 400 nm/min. The maximum absorbance value λ of the curve peak of each solution was taken and calibration curves without the addition of soda ash were thus established.

Calibration curves with addition of soda ash were established by adding a controlled amount of soda ash (colour fixation agent to cotton weight ratio 0.05 g/g) into the prepared reverse micellar dye solution. The solutions were then diluted 22 times, injected into the cuvette (3 mL) and put into the UH5300 Spectrophotometer (Hitachi, Japan) for measurement. The parameters of measurement were similar to those used for curves without the addition of soda ash.

SERF profile dyeing of cotton fibre

Conventional water-based SERF dyeing

The liquor-to-goods ratio was 50:1. The stock solution of 1% was first prepared. The reactive dye was applied to the prepared amount of deionized water to obtain the dye liquors. The dye concentration of the dye liquor was 1%. The amount of salt added, based on concentration of reactive dye used (percentage on weight of fibre, % owf), was 35 g/L. Figure 1 is the dyeing curve of conventional water-based dyeing of cotton. An example of conventional water-based SERF profile is shown in Fig. 2. To begin with, cotton fabrics were immersed in dye liquors (containing dye and salt) and put into the dye bath set at 30 °C. The dyeing temperature was then increased, at a rate of 1 °C/min, to 60 °C after 30 min (150 shakes/min). The dyeing time of 40 min was used. After dyeing, soda ash aqueous solution (5 g/L) was added into the dye bath (70 min). The fixation was conducted at 60 °C for 60 min. The total time required to finish the whole process was about 130 min. The fabrics were dyed for different durations of time (5 min, 10 min, 15 min, 30 min, 45 min, 60 min, 70 min, 75 min, 80 min, 85 min, 100 min, 115 min, and 130 min). After fixation, dyed cotton fabrics were rinsed in 50 mL of water per gram (without dye) for 2 min and air-dried. The dried fabrics were then conditioned at relative humidity of 65 ± 2% and 20 ± 2 °C for at least 24 h before subsequent measurement.

Reverse micellar SERF dyeing

Figure 3 presents the preparation of dye-encapsulated reverse micelle. The non-ionic surfactant and co-surfactant (n-octanol) were mixed (with agitation) to achieve surfactant to co-surfactant mole ratio of 1:8. Then the surfactant/co-surfactant mixture was dissolved in heptane, octane and nonane respectively to facilitate self-assembly of PEG-based reverse micelle. Reactive dye aqueous solution (1% dye conc.) was then applied into the reverse micellar system dropwise and the mixtures were vigorously stirred for 2 min until the well dispersed dye-encapsulated reverse micelle solution was obtained.

Figure 4 illustrates the profile of non-aqueous reverse micellar dyeing of cotton (Tang et al. 2018b; Wang et al. 2016). The cleaned cotton fabrics were first immersed in the dye encapsulated reverse micelle solution and poured into the shaking water bath at 30 °C. The dyeing temperature was then increased at a rate of 1 °C/min to 70 °C (150 shakes/min) in 35 min. The dyeing time was 40 min. After 75 min, soda ash aqueous solution was added into the dye liquor to facilitate fixation of reactive dyes on cotton fibre. The soda ash to cotton weight ratio (g/g) was 0.05. The fixation was conducted at 70 °C for 60 min. The total time required to finish the whole process was about 135 min and the fabrics were dyed for different durations of time (5 min, 10 min, 15 min, 30 min, 35 min, 50 min, 65 min, 75 min, 80 min, 85 min, 90 min, 105 min, 120 min, and 135 min). Dyed cotton fabrics were then rinsed in reverse micelle solution (without dye) for 2 min, air-dried and conditioned at relative humidity of 65 ± 2% and 20 ± 2 °C for at least 24 h before subsequent measurements. An example of PEG-reverse micellar SERF profile is shown in Fig. 5.

SERF measurement

Absorbance of solutions of conventional water-based dyeing system and alkane assisted reverse micellar dyeing system were measured by UH5300 Spectrophotometer (Hitachi, Japan). They were first diluted 5 times and 22 times respectively to ensure the absorbance value is within the range from 0 to 1. They were then injected into the cuvette for measurement. The baseline samples were prepared by using the reverse micelle solutions (without dye). After that, the dyed and rinsed reverse micellar solutions were measured. Absorbance values of the solutions were measured at wavelengths ranging from 400 to 700 nm. The Y-axis was between 0 and 1. The data interval was 1 nm and the scan speed was 400 nm/min. The lambda λ, maximum absorbance value of the curve peak, of each solution was taken and the SERF values were then obtained by calculation.

Fastness to laundering test

Colourfastness to laundering of dyed cotton fabrics was assessed according to AATCC Test Method 61-2013 (Colourfastness to Laundering: Accelerated) with test condition No. 2A.

Results and discussion

Calibration curves

The calibration curves of conventional water-based dyeing and reverse micellar dyeing of cotton fibre were established according to the Laws of Lambert and Beer (Eq. 1) (Swinehart 1962). The laws are normally combined in the relation

where A = absorbance, formerly called the optical density, P = radiant power, formerly called the intensity, a = absorptivity, formerly called the extinction coefficient, b = length of the beam in the absorbing medium, c = concentration of the absorbing species.

Figures 6, 7, 8 and 9 show calibration curves of the three reactive dyes (Levafix Red CA, Levafix Yellow CA, Levafix Blue CA) conducted in conventional water-based dyeing system and PEG-based reverse micellar dyeing system in heptane, octane and nonane medium with or without the addition of soda ash. The calibration curves are plotted with absorbance against concentration of dye (% owf). The slope and R square of each calibration curve are shown. The higher the slope, the larger is the absorbance difference proportional to dye concentration. The higher the R-square value, the more linear is the calibration curve. Generally speaking, the absorbance value is directly proportional to the dye concentration. When dye concentration increases, the absorbance value increases.

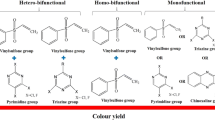

From Figs. 6, 7, 8 and 9, calibration results show that Levafix Red CA reactive dye has the highest absorbance value, followed by Levafix Yellow CA and Levafix Blue CA in both conventional water-based dyeing system and reverse micellar dyeing system. Although both are warm-type reactive dyes, difference in chemical structure and constitution may lead to the difference in absorbance. In addition, it is observed that the absorbance value did not vary too much, with and without soda ash addition. This indicates that the influence of soda ash is not very significant when no fabric is added into the dye liquor for fixation.

When compared with conventional water-based calibration curves of reactive dyes, calibration curves of reactive dyes in solvent-assisted reverse micellar systems exhibit higher absorbance. The reactive dyes in conventional water-based dyeing system can achieve absorbance values of Red: 0.807; Yellow: 0.661 and Blue: 0.573 only while reactive dyes in reverse micellar dyeing system can achieve absorbance values as high as Red: 0.994, Yellow: 0.798 and Blue: 0.647 (heptane dyeing). The possible reason is the minimization of the effect of dye hydrolysis in the reverse micellar dyeing system (Li et al. 2006; Makowski et al. 2010; Rjiba et al. 2007).

The linearity of the calibration curves is expressed as R-square (R2), a widely used method to measure the goodness-of-fit of a regression (Israeli 2007). R2 values are between 0 and 1, in which 0 means non-linear in structure and 1 means linear in structure. From Table 1, R squares of calibration curves of reactive dyes in both conventional water-based method and reverse micellar methods with or without the addition of soda ash are between 0.9900 and 0.9998. This indicates that the influence of soda ash is small on R-square values of the calibration curves and the calibration curves are linear in structure, which is suitable as a reference for subsequent SERF measurements.

The SERF values

Table 2 shows SERF values in per cent for conventional water-based and PEG-based reverse micellar dyeing of cotton in three primary colours. E represents exhaustion factor which is divided into two stages: (a) Exhaustion process before the addition of alkali which is from zero to S (the start of colour fixation); and (b) Fixation process which is the stage after alkali addition. F represents fixation which is from S to final fixation stage. R represents the value 5 min after alkali addition (the highest rate of fixation) (Figs. 2, 5).

With regard to the exhaustion process before the addition of alkali (S), conventional water-based dyeing system can achieve exhaustion as low as between 15 and 19% for the three reactive dyes whereas exhaustion of reverse micellar dyeing systems can reach from a low of 16% to as high as 59%. Among the three reactive dyes, reactive yellow dye can achieve the highest exhaustion, followed by red and blue in heptane, octane and nonane medium. This indicates that reactive yellow dye can achieve more effective and efficient exhaustion than the other two dyes even though there is no addition of electrolyte and soda ash.

The final exhaustion of dye in fibre (E) is obtained by counting the total dye exhaustion in fibre in the exhaustion and fixation processes. From Table 2, the results reveal that more than 90% (91–97%) of the dye was absorbed in cotton fabrics when PEG-based solvent-assisted reverse micelle dyeing method was used while conventional water-based dyeing method can only achieve 50–70% of final dye exhaustion in fibre. This indicates that less dye residuals would be left in the dye liquors after the reverse micellar dyeing process, thus achieving better dyeing effectiveness, efficiency and efficacy than the conventional water-based method. It is also observed that reactive red dye can achieve slightly higher final exhaustion than the other two dyes since optimization work has been conducted by using reactive red dye (Wang et al. 2016).

Regarding the rate of fixation (R) measured after 5 min of alkali addition, conventional water-based dyeing method basically has a lower rate of fixation (15–27%) than that of the reverse micellar systems (26–72%). It means that after addition of alkali, reverse micellar dyeing system can achieve faster fixation than the conventional one, indicating that reverse micellar dyeing systems have the potential to shorten the time for dyeing and fixation in the dyeing profile (Fig. 4). However, caution is called for when fixation rate is above 60% since there is a higher chance of encountering unlevelness when the fixation is too high and a certain degree of process control may be needed prevent the problem of unlevelness which may adversely affect the aesthetic appearance of the dyed fabrics.

When comparing the fixation percentage (F) in the fixation process, conventional water-based dyeing approach can obtain 35–53% of fixation while reverse micellar dyeing approaches can obtain fixation ranging from 32 to 77%. Among the three reactive dyes, blue dye has the highest fixation, followed by red and yellow. This indicates that reactive blue dye is more alkali-dependent than the other two dyes for dye exhaustion in fibre. It is predicted that if the whole reverse micellar dyeing system is conducted without the addition of alkali, blue-dyed fabrics may result in low exhaustion of dye in fibre.

Comparison between water-based dyeing and reverse micellar dyeing

The individual SERF values of reverse micellar dyeing approach are generally higher than those of the conventional water-based approach. It indicates that the use of reverse micellar dyeing approach can facilitate gain higher exhaustion of dye. More than 90% of dye could be absorbed in the cotton substrates when reverse micellar dyeing method was used while the conventional dyeing method scored lower dye percentage in fibre, only 50–70%. This implies that less dye residuals would be left in dye liquor and less hydrolysis of the dye would occur after the reverse micellar dyeing process, indicating better dyeing efficiency, effectiveness and efficacy of reverse micellar dyeing system when compared with the conventional water-based method.

The reverse micellar dyeing method required at least 80 min to reach the dyeing equilibrium because the colour fixation agent (soda ash) was applied at 75 min and no substantial fixation occurred before the alkali addition. In the conventional dyeing method there is a tendency for increased dye uptake and no equilibrium was found even at 130 min which means the percentage of dye in the fibre may have the tendency to increase if the dyeing process continues after 130 min. This indicates that reverse micellar dyeing method is more time saving and energy saving than the conventional water-based dyeing method.

Colourfastness to washing

Tables 3 and 4 represent the colour change and colour staining ratings of the dyed fabrics and the multi-fibre strips after the test of colourfastness to washing respectively. The test results show that the ratings for colour change and staining are between 4–5 and 5 for both water-dyed and reverse micellar dyed samples. It indicates that the fabric samples were thoroughly rinsed, and the SERF results obtained when measuring the absorption value of dye liquors, after dyeing and rinsing, are reliable to a large extent.

Conclusion

The reactive dye compatibility matrix (RCM) of red, blue and yellow colours for exhaust dyeing of cotton was investigated through the use of conventional water-based dyeing method and PEG-based solvent-assisted reverse micelle dyeing method. Calibration curves of the two dyeing methods were established. The calibration results show that red dye can achieve higher absorbance value than yellow and blue dyes. The SERF values are presented in the form of percentage. The results reveal that using reverse micelle method can achieve higher dye absorption in both exhaustion and fixation processes, resulting in higher final exhaustion of dye in fibre than the conventional water-based method.

References

Bradbury M, Collishaw P, Moorhouse S (1995) Reactive dye selection and process development for exhaust dyeing of cellulose. Text Chem Color 27:19–23

Collishaw PS, Phillips DAS, Bradbury MJ (1993) Controlled coloration: a success strategy for the dyeing of cellulosic fibres with reactive dyes. J Soc Dye Colour 109:284–292. https://doi.org/10.1111/j.1478-4408.1993.tb01577.x

De TK, Maitra A (1995) Solution behaviour of Aerosol OT in non-polar solvents. Adv Colloid Interface Sci 59:95–193

Dong Y, Chen J, Li C, Zhu H (2007) Decoloration of three azo dyes in water by photocatalysis of Fe(III)–oxalate complexes/H2O2 in the presence of inorganic salts. Dyes Pigments 73:261–268

Hickman WS (1993) Environmental aspects of textile processing. J Soc Dye Colour 109:32–37. https://doi.org/10.1111/j.1478-4408.1993.tb01499.x

Israeli O (2007) A Shapley-based decomposition of the R-square of a linear regression. J Econ Inequal 5:199–212. https://doi.org/10.1007/s10888-006-9036-6

Li Z, Singh S, Woodward W, Dang L (2006) Kinetics study of OH radical reactions with n-octane, n-nonane, and n-decane at 240 − 340 K using the relative rate/discharge flow/mass spectrometry technique. J Phys Chem A 110:12150–12157

Makowski W, Leżańska M, Mańko M, Włoch J (2010) Porosity and surface properties of mesoporous silicas and their carbon replicas investigated with quasi-equlibrated thermodesorption of n-hexane and n-nonane. J Porous Mater 17:737–745

Parvinzadeh Gashti M, Rashidian R, Almasian A, Badakhshan Zohouri A (2013) A novel method for colouration of cotton using clay nano-adsorbent treatment. Pigment Resin Technol 42:175–185

Perkins WS (1996) Dyes. Textile coloration and finishing. Carolina Academic Press, Durham, pp 138–144

Rjiba N, Nardin M, Dréan J-Y, Frydrych R (2007) A study of the surface properties of cotton fibers by inverse gas chromatography. J Colloid Interface Sci 314:373–380

Sawada K, Ueda M (2003) Adsorption and fixation of a reactive dye on cotton in non-aqueous systems. Color Technol 119:182–186

Sawada K, Ueda M (2004a) Characteristics of aqueous microenvironments in non-ionic surfactant reverse micelles and their use for enzyme reactions in non-aqueous media. J Chem Technol Biotechnol 79:369–375

Sawada K, Ueda M (2004b) Enzyme processing of wool fabrics in a non-ionic surfactant reverse micellar system. J Chem Technol Biotechnol 79:376–380

Sawada K, Ueda M, Kajiwara K (2004) Simultaneous dyeing and enzyme processing of fabrics in a non-ionic surfactant reverse micellar system. Dyes Pigments 63:251–258

Sumithra M (2018) Dyeing of cotton fabric using herbs. J Text Sci Eng 8:344. https://doi.org/10.4172/2165-8064.1000344

Swinehart D (1962) The beer-lambert law. J Chem Educ 39:333

Tang AYL, Lee CH, Wang Y, Kan CW (2017a) Octane-assisted reverse micellar dyeing of cotton with reactive dyes. Polymers 9:678

Tang AYL, Wang YM, Lee CH, Kan CW (2017b) Computer color matching and levelness of PEG-based reverse micellar decamethyl cyclopentasiloxane (D5) solvent-assisted reactive dyeing on cotton fiber. Appl Sci 7:682

Tang AYL, Lee CH, Wang Y, Kan CW (2018a) Dyeing properties of cotton with reactive dye in nonane nonaqueous reverse micelle system. ACS Omega 3:2812–2819

Tang AYL, Lee CH, Wang YM, Kan CW (2018b) Effect of hydrophilic–lipophilic balance (HLB) values of PEG-based non-ionic surfactant on reverse micellar dyeing of cotton fibre with reactive dyes in non-aqueous medium. Fiber Polym 19:894–904. https://doi.org/10.1007/s12221-018-8061-y

Tang AYL, Wang Y, Lee CH, Kan CW (2018c) Comparison of computer colour matching of water-based and solvent-based reverse micellar dyeing of cotton fibre. Color Technol 134:258–265. https://doi.org/10.1111/cote.12333

Teklemedhin B (2018) Cationization of cotton using extracted keratin from ethiopian sheep wool waste for salt free dyeing with reactive dye. J Text Sci Eng 8:365. https://doi.org/10.4172/2165-8064.1000365

Wang Y, Lee CH, Tang YL, Kan CW (2016) Dyeing cotton in alkane solvent using polyethylene glycol-based reverse micelle as reactive dye carrier. Cellulose 23:965–980

Yi S, Dong Y, Li B, Ding Z, Huang X, Xue L (2012) Adsorption and fixation behaviour of CI Reactive Red 195 on cotton woven fabric in a nonionic surfactant Triton X-100 reverse micelle. Color Technol 128:306–314

Yi S, Deng Y, Sun S (2014) Adsorption and dyeing characteristics of reactive dyes onto cotton fiber in nonionic Triton X-100 reverse micelles. Fiber Polym 15:2131–2138

Yi S, Tong X, Sun S, Dai F (2015) Dyeing properties of CI reactive violet 2 on cotton fabric in non-ionic TX-100/Span40 mixed reverse micelles. Fibers Polym 16:1663–1670

Acknowledgments

Authors are grateful for the financial support from The Hong Kong Polytechnic University for this work (Grant Nos. RUV7, 4-ZZGK, G-UADU).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tang, A.Y.L., Lee, C.H., Wang, Y.M. et al. Dyeing cotton with reactive dyes: a comparison between conventional water-based and solvent-assisted PEG-based reverse micellar dyeing systems. Cellulose 26, 1399–1408 (2019). https://doi.org/10.1007/s10570-018-2150-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-2150-3