Abstract

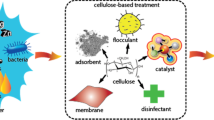

Water safety and security are global problems. Indeed, researchers have taken this matter seriously and have begun to find alternative ways of treating wastewater. The conventional method for treating wastewater has been found to be uneconomical, and the polymeric materials used were not environmentally friendly. Biosorption techniques and mechanisms have been shown to be an effective alternative to replace conventional technologies. As agricultural waste is abundantly available, it has been chosen as the best starting material to produce biosorption material. Also, the hydroxyl functional groups in cellulose act as important parts to produce better absorbent materials. This review has explored the role of natural fibres as adsorbents for wastewater treatment while at the same time, for the removal of adsorbates such as oil, dyes, heavy metals, ionic compounds, and others as reported in the literature. Also investigated in this study, were the different modification types used to enhance the fibres and the mechanism of contaminant removal by the absorbents. Lastly, the physical forms of adsorbates and common types of effluents treated using natural fibres were examined and discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Water is one of the primary necessities to sustain life. As reported by the United Nations, in 2017, the estimated world population of 7.6 billion is placing increasing pressure on the world’s limited water resources. However, while more water is being consumed, the quality of water is declining due to the significant amounts of pollutants being discarded into the world’s river systems, lakes and oceans each day. Accordingly, there are both point- and non-point sources of pollutants that contain different types of effluent. Therefore, different approaches must be employed for wastewater treatment.

Point source pollution originates from a single, specific site such as municipal or industrial waste. Since it originates from a specific location, it is easily monitored, identified and regulated. Municipal wastewater frequently contains pathogens and oxygen-depleting nutrients, both of which may cause serious health complications. Industrial point sources contribute heavy metals, toxic contaminants, and oils while non-point source pollution may result from urban and agricultural run-off and run-off from construction and mining sites. Therefore, since pollutants originate from many different sources, they are often difficult to identify. Contaminants can include sediment, organic matter, nutrients, and other toxic matter.

Wastewater treatment technology was initially designed to treat and clean up wastewater depending on the types and the extent of contamination while at the same time providing low-cost consumption. Over the years, innovation surrounding water treatment systems has intensified, beginning with conventional media filters to high-efficiency centrifuge filters, disk filters, membrane filtration (including micro and ultra-filtration) and non-membrane filtration systems (Karen 2014). However, the traditional materials employed, and conventional wastewater treatments have been unable to meet the environmental standards and hence, have been ineffective in addressing the removal of heavy metals at low concentrations in some instances (Demirbas 2008). This also includes the broad spectrum of toxic chemicals found in wastewater. Moreover, most of the materials used to produce the absorbents were produced from polymeric materials (Ji et al. 2012; Wang et al. 2011) and industrial by-products (Tripathi and Ranjan 2015) which are quite expensive.

Many studies, as a result, are now focusing on cost-effective approaches utilising natural fibres as the main material to produce absorbents. Notably, plant-based materials such as agricultural waste have been considered as promising materials to remove most contaminants from wastewater as they are inexpensive, readily available in large quantities, stable, eco-friendly, and non-toxic (Das 2010; Won et al. 2014). The benefits of using natural fibres include; high porosity, superior adsorption ability (Gaballah et al. 1997; Nakajima and Sakaguchi 1990; Tripathi and Ranjan 2015), low specific gravity (Dharmarathne et al. 2013) and regenerability (Sud et al. 2008).

This review focuses on the use and advantages of natural fibres as starting materials in wastewater treatment. Most natural fibres originate from agriculturally-based materials such as cotton, kenaf fibre, wheat straw, banana trunks and oil palm empty fruit bunches (Wang et al. 2012a). Accordingly, this paper is structured into four main sections; an overview of natural fibres, fibre treatments, physical forms of absorbent materials and the types of effluents treated using natural fibres.

Overview of natural fibres

The interest in using natural fibres as raw materials has been growing rapidly due to the increasing awareness towards sustainability of the environment (Chandramohan and Marimuthu 2011). Recently, over the last few years, bio-based materials have secured high demand in the market and industries (Faruk et al. 2012). The common natural fibres produced worldwide are listed in Table 1.

Natural fibres are defined as materials derived from plants and animals source (Ticoalu et al. 2010). Further, they are hydrophilic because lignocellulose contains strongly polarised hydroxyl groups. Therefore, these fibres are inherently incompatible with the hydrophobic polymer matrices. Before starting any treatments or modifications, it is important to understand the chemistry of natural fibres. Natural fibre is composed of cellulose, hemicelluloses, lignin, extractives, and inorganics.

Many studies have concentrated more on cellulose as it possesses unique properties such as its hydrophilic capabilities, processability, is insoluble in many solvents due to the hydrogen bonds and crystallinity, and is non-toxic (Suhas et al. 2016). Notwithstanding, cellulose is commonly made up of glucose units (French 2017) that bind together by many glycosidic linkages (see Fig. 1). Linking just two of these sugar units produces a disaccharide called cellobiose (Kalia et al. 2011).

The hydroxyl groups (−OH) in these glucose units are important in fibre modifications since they are the most reactive. Therefore, detecting the reactive hydroxyl groups is very important for optimising the modification process of natural fibres (He et al. 2012). Table 2 displays the chemical compositions of some common natural fibres.

Fibre treatments

To enhance and manipulate natural fibres as adsorbents, some modifications are required, usually by physical and chemical means.

Physical treatments

Physical adsorption is one of the most convenient methods of attaching compounds to fibre surfaces. The fundamental objectives of physical treatment are to remove surface contamination or impurities on the fibre and simultaneously, to provide better contact between the fibre surface (Mukhopadhyay and Fangueiro 2009). Physical approaches have been claimed as clean, fast and environmentally friendly (Cho et al. 2013). The process may involve size reduction by cutting or grinding, or via heat treatment. Usually, by physical treatment, the surface of the fibre will be roughened to enhance the contact area and provide mechanical interlocking between the fibre surface (Mukhopadhyay and Fangueiro 2009). Due to this reason, the surface area and porosity of the fibres would be increased while at the same time removing any impurities. Thus, the surface functional groups not accessible previously to the adsorbate could be exposed (Loganathan et al. 2013a). However, these types of treatments do not alter the chemical composition of the fibres (Adekunle 2015; Adekunle et al. 2010) and are not widely used due to their low effectiveness (Nguyen et al. 2013).

Physical adsorption

Physical adsorption typically occurs with the presence of weak van der Waals forces of attraction and occurs at low temperature with the formation of a multilayer of adsorbate on the adsorbent which decreases with increasing temperature. One of the most common techniques via electrostatic adsorption is applied to fibre that has undergone carbonisation under certain conditions. In this case, during carbonisation, the fibre is exposed to the selected gas at a certain temperature, which causes the fibre to loosen its crystal packaging and may lead to the formation of pores (Rombaldo et al. 2014). However, since fibre is negatively charged due to the carboxylic group on the fibre surface, it is possible for the cationic ion to be adsorbed onto the surface. Also, the adsorption is not selective, and the mechanism involves outer sphere surface complexation (Loganathan et al. 2013b) which means that it involves ion migration and does not involve electron transfer in a redox reaction (Ru et al. 2011; Song et al. 2016; Welgemoed 2005). Thus, the adsorption is not effective.

Due to this reason, the researcher invented activated carbon which is more effective in capturing effluent especially dye and heavy metals. In this case, the carbon was converted into activated carbon by a heating process without the presence of air. As a result, fine pores were created in the carbon particles (O’Connell et al. 2008) with the extended surface area, high adsorption capacity, more micro-pore structures and a higher degree of surface reactivity (Bharathi and Ramesh 2013).

The mechanism of adsorption occurs in several stages (see Fig. 2) and involves the transportation of adsorbates to the external surface of the absorbent. The adsorbates will then be transported within the pores of the adsorbent, and finally, some of the adsorbates will be adsorbed on the interior surface of the adsorption either by monolayer or multilayer adsorption (Bharathi and Ramesh 2013; Sivakumar and Palanisamy 2010).

(reproduced with permission from Sivakumar and Palanisamy 2010)

Mechanism of dye absorption

A number of natural fibres such as oil palm fibre (Hameed and El-Khaiary 2008), coir pith (Namasivayam and Sureshkumar 2008; Parab et al. 2009), sugarcane fibre (Parab et al. 2009), rice husk (Malik 2003), and banana peel (Annadurai et al. 2002) have been used to study the removal of different dyes from aqueous solutions at different conditions (Bharathi and Ramesh 2013). Inyang et al. (2012), found the removal efficiency of heavy metal using biochar made from sugar beet root. The results indicated that the sorption capacity of activated carbon made from natural fibres is comparable to those that are commercially available.

Modifications using ionic liquids

Ionic liquids are known as environmentally friendly solvents. Their unique properties such as low toxicity, non-volatile, high ionic conductivity and non-flammable have received intense scrutiny as green media in various chemistry processes (Mallakpour and Rafiee 2011). A study by Wendler et al. (2009) found that direct dissolution of cellulose and dry, wet shaping in ionic liquid provided regenerated fibres with high tenacity with the versatile application.

According to Takada and Kadokawa (2015), during the dissolution of cellulose in the ionic liquid, the crystalline structure of cellulose was loosened, and the excess water surrounding the cellulose was absorbed into the ionic solution. The cellulose crystalline parts then started to aggregate and possibly acted as a crosslinking point for the formation of ion gel (Fig. 3).

(reproduced with permission from Takada and Kadokawa 2015)

The mechanism of the formation of cellulose ionic gel

In a separate study by Sun et al. (2009) they used ionic liquid to form cellulose and chitin composite biosorbents for heavy metal adsorption. However, there are some drawbacks using ionic liquid modification. For instance, the high cost of ionic liquid prompted the researchers to reconsider using it as a media for cellulose dissolution. Moreover, the recovery and recycling process of the ionic liquid was entirely new to the researchers, and some of the ionic liquid may have been lost during the recycling process.

Plasma treatment

Plasma treatment has also been considered as an option for water treatment which involves electrical gas discharges and free radicals (Mukhopadhyay and Fangueiro 2009; Wang et al. 2012b). There are two types of plasma treatments available; vacuum plasma treatment and atmospheric treatment. The differences are explained further by Mukhopadhyay and Fangueiro (2009)in their review that follows.

Theoretically, this treatment was believed to bring physical modification on the surface of the fibre. Further, it may help to promote surface cleaning (Cho et al. 2004; Han et al. 2014; Mukhopadhyay and Fangueiro 2009), an etching effect, grafting and a functionalisation effect (Yang et al. 2015; Fig. 4). Basically, for surface cleaning and etching, it may result in promoting physical adhesion on the fibre surface whereas for grafting or crosslinking, it may help to strengthen the surface. On the other hand, for a functionalisation effect, it helps to modify the surface chemical structures and at the same time introduces free radicals (Mukhopadhyay and Fangueiro 2009).

(reproduced with permission from Yang et al. 2015)

Steps of atmospheric pressure plasma treatment

In wastewater treatment, this treatment was applied for the degradation of dyes (Jin et al. 2012; Kozáková et al. 2010; Yan et al. 2012), benzene derivatives (Kareem and Kaliani 2012), phenolic compound (Liu et al. 2010; Liimatainen et al. 2012), algae (Liu et al. 2015) and other ionic material (Ran et al. 2014).

In another study by Kim et al. (2017) they used a green and simple approach to synthesise hierarchical nanoporous MnO2 by applying plasma in a liquid precursor using three types of sugar as an inducer. Based on the findings, they found that more than 99% for an initial dye concentration of 10 mg L−1 was removed within 2 min. Therefore, this demonstrates that the technique could be effective in treating wastewater.

Accordingly, plasma treatments have their own advantages such as being reliable, reproducible and can be monitored accurately using a plasma diagnostic device (Mukhopadhyay and Fangueiro 2009). Moreover, plasma treatments may help in altering the variety of surface characteristics as needed depending on their application. However, the disadvantages of these treatments are that only one side of the material, directly facing the plasma jet, can be altered (Mukhopadhyay and Fangueiro 2009; Qiu et al. 2002).

Chemical treatments

Chemical modifications improve the adsorption capacity and stability of biosorbents (Demirbas 2008). As reported previously by Hokkanen et al. (2016), cellulose cannot be effectively used as absorbent first, without undergoing modification. The modification can be carried out by functionalising the cellulose functional groups according to the preferences either by esterification, oxidation, alkaline treatment, silylation, grafting or by other processes.

Esterification

Cellulose modification, especially esterification, has attracted widespread attention among researchers especially in homogeneous conditions (El Hamdaoui et al. 2016). During esterification, the ester functional groups (O–C=O group) are attached to hydroxyl groups of cellulose via precursor condensation (Missoum et al. 2013). Notably, cellulose modification by esterification can affect the fibres depending on the reagents used. The chemical route to form ester bonds with the hydroxyl of cellulose can be performed by either using carboxylic acid, alkydes, alketonedimers or acid chloride as described by Hubbe et al. (2015). Ma et al. (2014), also used betaine hydrochloride as a cationic agent to modify the cellulose to produce cationic adsorbent. In this case, the cationic cellulose absorbent acts to adsorb the anionic dyes due to the electrostatic attraction between the modified cellulose and the dyes. Esterification has also been found to increase the hydrophobicity nature of cellulose surface (Ashori et al. 2014; Bourbonnais and Marchessault 2010; Hubbe et al. 2015; Lackinger et al. 2012; Li et al. 2011; Pan et al. 2013) which may assist towards improving oil absorbency. Asadpour et al. (2016) reported that viscosity of oil has an important role in sorption. In this case, low viscosity oil penetrates the acetylated oil palm empty fruit bunch (OPEFB) fibres faster than the high viscosity oil. Asadpour et al. (2016) also reported that the oil concentration equilibrium fitted the Langmuir, isotherm model. However, in some cases, several disadvantages have been observed as the cellulosic surface may need to be oxidised before the esterification, in order to achieve a satisfactory degree of substitution (Hubbe et al. 2015).

Oxidation of cellulose

Oxidation of cellulose can be referred to as a condition where the functional groups of cellulose are attacked by the oxidising media. Usually, before oxidation occurs, the natural fibres are generally bleached to expose more hydroxyl functional groups. Notwithstanding, this could help to create further opportunities for functionalisation by the oxidising materials (Collinson and Thielemans 2010). The two main oxidants customarily used are superoxide anion (O2−) and hydrogen peroxide (H2O2).

During oxidation, the hydroxyl groups of cellulose can be converted to dialdehyde groups using sodium periodate (NaIO4; Kim et al. 2000). Those aldehyde groups, later on, can be further oxidised to carboxyl groups by sodium chlorite (NaClO2) under heterogeneous conditions (Kim et al. 2000; Liimatainen et al. 2012). In contrast, some researchers have preferred to use a catalyst such as 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO) and azide modification to carboxylate the cellulose (Okita et al. 2010; Takaichi and Isogai 2013).

Zhu et al. (2015) successfully produced excellent coagulation-flocculation of the kaolin suspension with a turbidity removal of 99.5% using bamboo pulp via NaIO4 oxidation, urea grafting, and NaOH hydrolysis. In this case, the high anhydroglucosepyranose units’ oxidative cleavage of dicarboxyl cellulose led to excellent coagulation–flocculation by the mechanism of interaction between ionic polymer and mineral pigments via neutralisation or adsorption/bridging coagulation of metals salts. This was followed by the formation of large floc by a flocculation process. However, this method was claimed to be too complicated, expensive, and restricting the mass production of carboxylated cellulose.

Alkaline treatment

Alkaline treatment has been considered as one of the low cost and most effective surface treatments (Mohanty et al. 2001) which helps in removing the wax and lignin covering the surface of the fibre. Moreover, it creates greater potential of crystallisation, promotes interfacial bonding, and simultaneously increases the compatibility of the fibres. Therefore, it helps to enhance the mechanical properties of the fibres. According to Li et al. (2015), the mechanical properties of the alkaline treated bamboo fibre composites increased by more than 50% as compared to the untreated bamboo fibres.

Sodium hydroxide (NaOH) has also been used as an activating agent in the production of activated carbon. Coconut shell (Cazetta et al. 2011), olive husk (Michailof et al. 2008), and bamboo (Hameed et al. 2007) are among the fibres that have been used for the activation process.

According to Cazetta et al. (2011), NaOH helped to increase the micropores and diameter of the cavities. The presence of the capillaries with a large diameter increased the adsorption capacities especially for treating water effluent with large diameter molecules such as dyes, heavy metals, and pesticides.

Silylation

Silylation is another popular method in fibre modification involving the substitution of silyl groups to the fibres. Silane coupling agents have been used as they are bifunctional. Furthermore, there are many types of silane coupling agents with different functionalities. The most common types of silanes frequently used for natural fibres are gamma-aminopropyl trimethoxy silane (APS), gamma-diethylenetriaminopropyl trimethoxy silane (TAS), and gamma-Methacryloxypropyl trimethoxy silane (MPS; Abdelmouleh et al. 2002). Abdelmauleh et al. (2002) investigated the interaction between cellulose and silane coupling agent. In their study, they claimed that by heating up to 100 °C the covalent bond between the substrate, silane was formed via condensation reaction. Regarding the application as an adsorbent, Gebald et al. (2011) formed an amine-based absorbent using nano fibre cellulose for CO2 captured from air. Based on the result, following 12 h of exposure in normal air, 506 ppm of CO2 was successfully removed (Gebald et al. 2011). Indeed, a similar concept of the absorbency may also be applied in wastewater treatment.

Grafting

Graft polymerisation has attracted immense interest and attention as it has helped to alter the properties of cellulose and increase its functionality (Kang et al. 2007). Graft polymerisation allows for the combination of two or more polymers in one physical unit (Roy et al. 2009). The graft polymerisation of cellulose can be accomplished using various techniques, namely; ring-opening polymerisation (Hafren and Córdova 2005), free radical polymerisation (Srivastava et al. 2006), reversible addition fragmentation chain transfer (RAFT; Roy et al. 2005), nitroxide mediated polymerisation (NMP; Karaj-Abad et al. 2016), and atom transfer radical polymerisation (ATRP; Çankaya 2015).

In the application of wastewater treatment, Maimaiti et al. (2014) grafted cotton pulp cellulose with buthylmethacrylate via the homogeneous ATRP method. From the saturated adsorption rates using different oils, they found that the grafted cotton cellulose pulp adsorbent adsorbed three to six times better as compared to commercial polypropylene sorbate. Also, it was reported to have higher buoyancy recovery during oil clean-up over water (Maimaiti et al. 2014).

Types of physical forms of adsorbent materials

In general, the physical form of adsorbent material plays an important role in removing contaminants in wastewater. For adsorbent using natural fibres as starting materials, the types of physical form can be divided into four main categories (Table 3), namely; fibre form, powder or granule form, film or membrane form and hydrogel.

In fibre form, the fibre would typically be fabricated for easy handling following treatment. To develop renewable and sustainable adsorbent with high sorption capacity and selectivity, the fibre needs to undergo a modification process to modify the hydroxyl groups of the cellulose (Wang et al. 2016). Moreover, the fibre could also be processed and converted into a composite form. Wang et al. (2013b) synthesised polybutylmethacrylate/kapok fibre (PBMA/KF) composites to enhance the oil sorption capacities. The results indicated that the performance of the PBMA/KF with 8% kapok fibre loading exhibited higher oil sorption capacity compared to PBMA. Also, PBMA/KF composite had better oil retention capabilities and reusability (Wang et al. 2013b).

Activated carbon has continued to attract interest among researchers regarding its powder form. In this case, the process of producing activated carbon involves two steps; carbonisation followed by either physical (water steam or carbon dioxide) or chemical (acid or bases) activation (Rodríguez Correa et al. 2017). The mechanism of decomposition and char formation involves the release of hydrogen and an oxygen compound as well as a condensable volatile formed due to the cleavage weak inner bonds such as the C–O bond and β–O–4 structure (Britt et al. 1995; Rodríguez Correa et al. 2017; Shen et al. 2017) which leads to the formation of single and multi-phenolic compound (Faravelli et al. 2010; Rodríguez Correa et al. 2017). According to Dorrestijn et al. (2000), the secondary phase of reaction contributed to the formation of char. At this phase, the solid phase structure started to rearrange through the crosslinking of C–C bonds. Also, at a temperatures higher than 500 °C, the aromatic structures started to grow and rearrange into turbostratic graphene sheet (Kercher and Nagle 2003; Williams and Besler 1996).

Different treatment may produce different size and absorption effects. Granulated activated carbon (GAC) and powdered activated carbon (PAC) have been the most common types of activated carbon used to remove low molecular weight compounds (Phan et al. 2006). However, PAC was preferred since it provided higher and faster adsorption velocities (Van Oss 1990). This was due to the increase of porosity and higher surface area caused by the activation condition, such as temperature, time, and gas used during the preparation process (Oshida et al. 1995). According to Ashby et al. (2009), the relationship among porosity and pore size was the most important factor in producing adsorbent. However, commercial activated carbon is very expensive as far as the consumption cost and regeneration process are concerned (Bharathi and Ramesh 2013). Therefore, agricultural wastes have become popular raw materials for producing activated carbon.

The most common fibres used for making activated carbon are cotton (Liu et al. 2007), jute (Phan et al. 2006; Rombaldo et al. 2014), kenaf (Phan et al. 2006), rice husk (Chen et al. 2013) and oil palm shell (Ahmad et al. 2011). These adsorbents exhibit excellent adsorption capacities typically for pollutants such as phenol (Phan et al. 2006), dyes (Tan et al. 2008), and pesticides (Memon et al. 2008). Kulkarni et al. (2015), studied the efficiency of rice husk as cadmium sorbent and found that the adsorbency can reach up to 69% based on its original weight.

Adsorbents are also be used in membrane form. Membrane form filtration such as microfiltration, nanofiltration, ultrafiltration, and reverse osmosis have been considered as being highly effective in removing pollutants in wastewater treatment (Ahmad et al. 2004; Gebru and Das 2017a, b, 2018; Qin et al. 2007; Strathmann 2001; Van der Bruggen and Vandecasteele 2002; Walha et al. 2007). According to Owen et al. (1995), the membrane technique could be a better alternative in wastewater treatment compared to the traditional method due to more cost-effective and of higher efficiency. Moreover, the membrane technique is not capable of removing solid particles, and other inorganic contaminants such as heavy metals and ions. Juang and Shiau (2000) studied the removal of metal ions such as Cu (II) and Zn (II) from synthetic wastewater using chitosan enhanced membrane filtration.

In this case, the process of membrane synthesis involved the use of commercial membrane solution such as cellulose triacetate (Villalobos-Rodríguez et al. 2012) and cellulose nitrate (Soylak and Cay 2007). In order to make it porous, calcium carbonate was reacted with hydrochloric acid to form bubbles (Kellenberger et al. 2012). As illustrated in Fig. 5, the presence of calcium carbonate acted as a pore template to fabricate the polymeric membrane with tunable pore sizes (Kellenberger et al. 2012; Kaiser et al. 2017). The membrane also appeared to have a fine mesopore and micropore after heating the membrane in a hot water bath which helped in the rejection of the salt produced from the reaction of acid and calcium carbonate.

(reproduced with permission from Kaiser et al. 2017)

The production of the porous polymeric membrane using calcium carbonate as pore template

To remove the smallest component or charged solute, nanofiltration was used by reducing the pores on the membrane, and the membrane surface was modified by either ionic or cationic surface. Accordingly, this involved the adsorption process such as physical, chemical and ionic adsorption (Barakat 2011).

The most advanced form of adsorbent from amongst all the various types is a hydrogel which is produced from polysaccharide-based materials. Usually, the preparation of hydrogel involves crosslinking with other functional groups or coupling agents to form a water-insoluble crosslinked network. The nano-cellulose material may act as an additive, binder, or reinforcing agent (Carpenter et al. 2015). The high surface area to volume ratio allows for easier incorporation of chemical moieties, thus increasing the binding efficiency of the pollutants to the adsorbent. Wang et al. (2014) studied the effect of ultralight nanocomposite aerogel with graphite oxide that could absorb organic liquids such as cyclohexane and dimethylformamide (DMF). In separation technology, the transmission rate of solute is usually determined by the membrane pores and the relative size of solute (Liu et al. 2010). Liu and team also claimed that by increasing the concentration of regenerated cellulose made from cotton fibre in LiOH/urea/water solution, the membrane produced became denser with decreased pore structure.

Natural fibres for effluent treatment

Different types of agricultural waste can be treated using different approaches. Since the main components of agricultural waste and natural fibre are cellulose, hemicellulose and lignin with the hydroxyl functional group, they have a potential sorption capacity for various pollutants (Bhatnagar and Sillanpää 2010; Bhatnagar et al. 2015; De Gisi et al. 2016). However, the approach in removing the solute is different according to the effluent types either by removing physically, chemically or by adopting the ionic approach.

Oil-based effluent is categorised into two distinct types; free oil and emulsified oil. Free oil is easy to remove because it can be separated by gravitation and skimming off. However, for emulsified oil, it is more difficult to remove since it is more stable in the aqueous phase (Ibrahim et al. 2010; Nag 1995). As a solution, the functional groups on the surface of natural fibres are attached with a cationic surfactant such as hexadecylpyridinium chloride monohydrate (CPC, C21H88NCl) for oil adsorption (Ibrahim et al. 2010). As a result, a positive charge is formed on the fibre surface forcing the adsorption on the opposite surface charge to form a hydrophobic layer. This allows oil droplet partition into the surface layer (Ibrahim et al. 2010; Rawajfih and Nsour 2006).

Heavy metals are the most hazardous contaminants found among the chemical-intensive industries. Since they are highly soluble in the marine environment, these heavy metals can be easily absorbed by living organisms (Barakat 2011). Usually, the surface of natural fibres must be modified in order to function as an adsorbent. The charging effect on the heavy metal makes it easy to remove either by ion exchange, chemical precipitation, electrostatic removal or adsorption process. However, the capability to remove heavy metal depends on the pre-treatment method and the pH condition during the treatment process (Babel and Kurniawan 2003; Barakat 2011). For ionic effluent, a similar removal method for heavy metals is employed.

In dye removal, a different condition is observed as the dye characteristics, and the particle size are much larger as compared to heavy metal and other ions. Typically, the interaction between the absorbent and the dye particles are categorised under physisorption involving van der Waals attraction. Activated carbon is the most popular adsorbent that is used for the removal of dyes (Ahmad et al. 2011; Etim et al. 2016; Mondal and Islam 2014; Zhang et al. 2016).

Table 4 lists the various types of agricultural wastes used as adsorbents. The adsorbates are categorised according to their types. However, the percentage of effluent removal depends on the fibre treatments and physical forms of the adsorbents.

Conclusion

Many researchers continue working towards producing effective adsorbents having low cost and low energy consumption. The use of natural fibres as the adsorbent is an emerging trend in wastewater treatment technology as the fibres are abundant, readily available and are more environmentally friendly as compared to polymeric based materials. Many types of natural fibres, especially agricultural wastes have the potential to be utilised as absorbents.

To determine the best modification methods, the basic chemical properties of fibres need to be thoroughly understood. Cellulose possesses many desirable properties and is easily modified since it contains hydroxyl functional groups, thereby creating many active sites for adsorption. Based on the review, many researchers have preferred chemical modifications since they offered the greatest potential in adsorbing adsorbates. Furthermore, by chemical modifications, the hydroxyl functional groups can be modified according to the types of solutes and adsorbates to be removed.

However, after thorough observation, it was observed that almost none of these modified fibres could remove more than one type of contaminant at a time, as far as industrial and domestic relevant pollutants are concerned. Most researchers only focussed on removing one type of adsorbate each time, and only selective adsorbates could be removed. Therefore, further research is required on the practicality and durability of the adsorbents made from natural fibres.

References

Abdelmouleh M, Boufi S, Ben Salah A, Belgacem MN, Gandini A (2002) Interaction of silane coupling agents with cellulose. Langmuir 18:3203–3208

Abdul Khalil HPS, Siti Alwani M, Ridzuan R, Kamarudin H, Khairul A (2008) Chemical composition, morphological characteristics, and cell wall structure of malaysian oil palm fibers. Polym Plast Technol Eng 47:273–280

Adekunle KF (2015) Surface treatments of natural fibres—a review: part 1. Open J Polym Chem 5:41

Adekunle K, Åkesson D, Skrifvars M (2010) Biobased composites prepared by compression molding with a novel thermoset resin from soybean oil and a natural-fiber reinforcement. J Appl Polym Sci 116:1759–1765

Ahmad AL, Ooi BS, Mohammad AW, Choudhury JP (2004) Development of a highly hydrophilic nanofiltration membrane for desalination and water treatment. Desalination 168:215–221

Ahmad T, Rafatullah M, Ghazali A, Sulaiman O, Hashim R (2011) Oil palm biomass-based adsorbents for the removal of water pollutants—a review. J Environ Sci Health Part C 29:177–222

Anirudhan TS, Unnithan MR (2007) Arsenic(V) removal from aqueous solutions using an anion exchanger derived from coconut coir pith and its recovery. Chemosphere 66:60–66

Annadurai G, Juang RS, Lee DJ (2002) Use of cellulose-based wastes for adsorption of dyes from aqueous solutions. J Hazard Mater 92:263–274

Asadpour R, Sapari N, Hasnain Isa M, Kakooei S, Orji KU, Daneshfozoun S (2016) Esterification of corn silk fiber to improve oil absorbency. In: Paper presented at the advanced materials research

Ashby MF, Ferreira PJSG, Schodek DL (2009) Nanomaterials, nanotechnologies and design: an introduction for engineers and architects. Butterworth-Heinemann, Amsterdam

Ashori A, Babaee M, Jonoobi M, Hamzeh Y (2014) Solvent-free acetylation of cellulose nanofibers for improving compatibility and dispersion. Carbohydr Polym 102:369–375

Asim M, Abdan K, Jawaid M, Nasir M, Dashtizadeh Z, Ishak MR, Hoque ME (2015) A review on pineapple leaves fibre and its composites. Int J Polym Sci 2015:16

Babel S, Kurniawan TA (2003) Low-cost adsorbents for heavy metals uptake from contaminated water: a review. J Hazard Mater 97:219–243

Barakat MA (2011) New trends in removing heavy metals from industrial wastewater. Arab J Chem 4:361–377

Bazargan A, Tan J, Hui CW, McKay G (2014) Utilization of rice husks for the production of oil sorbent materials. Cellulose 21:1679–1688

Bharathi K, Ramesh S (2013) Removal of dyes using agricultural waste as low-cost adsorbents: a review. Appl Water Sci 3:773–790

Bhatnagar A, Sillanpää M (2010) Utilization of agro-industrial and municipal waste materials as potential adsorbents for water treatment—a review. Chem Eng J 157:277–296

Bhatnagar A, Sillanpää M, Witek-Krowiak A (2015) Agricultural waste peels as versatile biomass for water purification—a review. Chem Eng J 270:244–271

Bledzki AK, Gassan J (1997) Handbook of engineering polymeric materials. Marcel Dekker, New York

Bledzki AK, Reihmane S, Gassan J (1996) Properties and modification methods for vegetable fibers for natural fiber composites. J Appl Polym Sci 59:1329–1336

Bourbonnais R, Marchessault RH (2010) Application of polyhydroxyalkanoate granules for sizing of paper. Biomacromolecules 11:989–993

Brandão PC, Souza TC, Ferreira CA, Hori CE, Romanielo LL (2010) Removal of petroleum hydrocarbons from aqueous solution using sugarcane bagasse as adsorbent. J Hazard Mater 175:1106–1112

Britt PF, Buchanan Iii A, Thomas KB, Lee SK (1995) Pyrolysis mechanisms of lignin: surface-immobilized model compound investigation of acid-catalyzed and free-radical reaction pathways. J Anal Appl Pyrol 33:1–19

Çankaya N (2015) Cellulose grafting by atom transfer radical polymerization method. In: Cellulose-fundamental aspects and current trends. InTech

Carpenter AW, De Lannoy CF, Wiesner MR (2015) Cellulose nanomaterials in water treatment technologies. Environ Sci Technol 49:5277–5287

Cazetta AL, Vargas AMM, Nogami EM, Kunita MH, Guilherme MR, Martins AC, Silva TL, Moraes JCG, Almeida VC (2011) NaOH-activated carbon of high surface area produced from coconut shell: kinetics and equilibrium studies from the methylene blue adsorption. Chem Eng J 174:117–125

Chandramohan D, Marimuthu K (2011) A review on natural fibers. Int J Recent Res Appl Stud 8:194–206

Chen Y, Zhai SR, Liu N, Song Y, An QD, Song XW (2013) Dye removal of activated carbons prepared from NaOH-pretreated rice husks by low-temperature solution-processed carbonization and H3PO4 activation. Biores Technol 144:401–409

Cho D, Yun SH, Kim J, Lim S, Park M, Lee SS, Lee GW (2004) Influence of silane coupling agents on the interlaminar and thermal properties of woven glass fabric/nylon 6 composites. Macromol Res 12:119–126

Cho D, Kim HJ, Drzal LT (2013) Surface treatment and characterization of natural fibers: effects on the properties of biocomposites. Polym Compos 3:133–177

Collinson SR, Thielemans W (2010) The catalytic oxidation of biomass to new materials focusing on starch, cellulose and lignin. Coord Chem Rev 254:1854–1870

Das N (2010) Recovery of precious metals through biosorption—a review. Hydrometallurgy 103:180–189

David NSH (1992) Chemical modification of lignocellulosic material. Marcel Dekker, New York

De Gisi S, Lofrano G, Grassi M, Notarnicola M (2016) Characteristics and adsorption capacities of low-cost sorbents for wastewater treatment: a review. Sustain Mater Technol 9:10–40

Demirbas A (2008) Heavy metal adsorption onto agro-based waste materials: a review. J Hazard Mater 157:220–229

Dharmarathne N, Sato N, Kawamoto K, Sato H, Tanaka N (2013) Evaluation of wastewater treatment efficiency using coconut fiber biofilm reactor system with synthetic leachate. In: 3rd international conference on engineering and applied science, Osaka, Japan

Dorrestijn E, Laarhoven LJJ, Arends IWCE, Mulder P (2000) The occurrence and reactivity of phenoxyl linkages in lignin and low rank coal. J Anal Appl Pyrol 54:153–192

El Hamdaoui L, El Moussaouiti M, Gmouh S (2016) Homogeneous esterification of cellulose in the mixture N-butylpyridinium chloride/dimethylsulfoxide. Int J Polym Sci 2016:7

Etim U, Umoren S, Eduok U (2016) Coconut coir dust as a low cost adsorbent for the removal of cationic dye from aqueous solution. J Saudi Chem Soc 20:S67–S76

Faravelli T, Frassoldati A, Migliavacca G, Ranzi E (2010) Detailed kinetic modeling of the thermal degradation of lignins. Biomass Bioenergy 34:290–301

Faruk O, Bledzki AK, Fink HP, Sain M (2012) Biocomposites reinforced with natural fibers: 2000–2010. Prog Polym Sci 37:1552–1596

French AD (2017) Glucose, not cellobiose, is the repeating unit of cellulose and why that is important. Cellulose 24:4605–4609

Gaballah I, Goy D, Allain E, Kilbertus G, Thauront J (1997) Recovery of copper through decontamination of synthetic solutions using modified barks. Metall Mater Trans B 28:13–23

Gebald C, Wurzbacher JA, Tingaut P, Zimmermann T, Steinfeld A (2011) Amine-based nanofibrillated cellulose as adsorbent for CO2 capture from air. Environ Sci Technol 45:9101–9108

Gebru KA, Das C (2017a) Removal of bovine serum albumin from wastewater using fouling resistant ultrafiltration membranes based on the blends of cellulose acetate, and PVP-TiO2 nanoparticles. J Environ Manag 200:283–294

Gebru KA, Das C (2017b) Removal of Pb(II) and Cu (II) ions from wastewater using composite electrospun cellulose acetate/titanium oxide (TiO2) adsorbent. J Water Process Eng 16:1–13

Gebru KA, Das C (2018) Removal of chromium (VI) ions from aqueous solutions using amine-impregnated TiO2 nanoparticles modified cellulose acetate membranes. Chemosphere 191:673–684

Gönen F, Serin DS (2012) Adsorption study on orange peel: removal of Ni (II) ions from aqueous solution. Afr J Biotech 11:1250–1258

Hafren J, Córdova A (2005) Direct organocatalytic polymerization from cellulose fibers. Macromol Rapid Commun 26:82–86

Hameed B, El-Khaiary M (2008) Batch removal of malachite green from aqueous solutions by adsorption on oil palm trunk fibre: equilibrium isotherms and kinetic studies. J Hazard Mater 154:237–244

Hameed BH, Din ATM, Ahmad AL (2007) Adsorption of methylene blue onto bamboo-based activated carbon: kinetics and equilibrium studies. J Hazard Mater 141:819–825

Han SH, Oh HJ, Kim SS (2014) Evaluation of fiber surface treatment on the interfacial behavior of carbon fiber-reinforced polypropylene composites. Compos B Eng 60:98–105

Haussard M, Gaballah I, Kanari N, De Donato P, Barrès O, Villieras F (2003) Separation of hydrocarbons and lipid from water using treated bark. Water Res 37:362–374

He L, Li X, Li W, Yuan J, Zhou H (2012) A method for determining reactive hydroxyl groups in natural fibers: application to ramie fiber and its modification. Carbohydr Res 348:95–98

Hokkanen S, Bhatnagar A, Sillanpää M (2016) A review on modification methods to cellulose-based adsorbents to improve adsorption capacity. Water Res 91:156–173

Hubbe MA, Rojas OJ, Lucia LA (2015) Green modification of surface characteristics of cellulosic materials at the molecular or nano scale: a review, vol. 10

Ibrahim S, Wang S, Ang HM (2010) Removal of emulsified oil from oily wastewater using agricultural waste barley straw. Biochem Eng J 49:78–83

Igwe JC, Abia AA (2007) Adsorption isotherm studies of Cd (II), Pb(II) and Zn (II) ions bioremediation from aqueous solution using unmodified and EDTA-modified maize cob. Eclética Química 32:33–42

Inyang M, Gao B, Yao Y, Xue Y, Zimmerman AR, Pullammanappallil P, Cao X (2012) Removal of heavy metals from aqueous solution by biochars derived from anaerobically digested biomass. Biores Technol 110:50–56

Jayaprabha J, Brahmakumar M, Manilal V (2011) Banana pseudostem characterization and its fiber property evaluation on physical and bioextraction. J Nat Fibers 8:149–160

Ji F, Li C, Tang B, Xu J, Lu G, Liu P (2012) Preparation of cellulose acetate/zeolite composite fiber and its adsorption behavior for heavy metal ions in aqueous solution. Chem Eng J 209:325–333

Jin G, Pingdao G, Li Y, Fangchuan Z (2012) Degradation of dye wastewater by ns-pulse DBD plasma. Plasma Sci Technol 15:928–934

Juang RS, Shiau RC (2000) Metal removal from aqueous solutions using chitosan-enhanced membrane filtration. J Membr Sci 165:159–167

Kaiser A, Stark WJ, Grass RN (2017) Rapid production of a porous cellulose acetate membrane for water filtration using readily available chemicals. J Chem Educ 94:483–487

Kalia S, Dufresne A, Cherian BM, Kaith BS, Avérous L, Njuguna J, Nassiopoulos E (2011) Cellulose-based bio- and nanocomposites: a review. Int J Polym Sci 2011:2011

Kang PH, Jeun JP, Chung BY, Kim JS, Nho YC (2007) Preparation and characterization of glycidyl methacrylate (GMA) grafted kapok fiber by using radiation induced-grafting technique. J Ind Eng Chem Seoul 13:956

Karaj-Abad SG, Abbasian M, Jaymand M (2016) Grafting of poly [(methyl methacrylate)-block-styrene] onto cellulose via nitroxide-mediated polymerization, and its polymer/clay nanocomposite. Carbohydr Polym 152:297–305

Kareem TA, Kaliani AA (2012) Glow discharge plasma electrolysis for nanoparticles synthesis. Ionics 18:315–327

Karen (2014) Trends in industrial wastewater treatment. Retrieved 14 February 2018, from http://www.uswaterservices.com/news/2014/08/trends-in-industrial-wastewater-treatment/

Kellenberger CR, Luechinger NA, Lamprou A, Rossier M, Grass RN, Stark WJ (2012) Soluble nanoparticles as removable pore templates for the preparation of polymer ultrafiltration membranes. J Membr Sci 387–388:76–82

Kercher A, Nagle D (2003) Microstructural evolution during charcoal carbonization by X-ray diffraction analysis. Carbon 41:15–27

Kim UJ, Kuga S, Wada M, Okano T, Kondo T (2000) Periodate oxidation of crystalline cellulose. Biomacromolecules 1:488–492

Kim H, Watthanaphanit A, Saito N (2017) Simple solution plasma synthesis of hierarchical nanoporous MnO for organic dye removal. ACS Sustain Chem Eng 5:5842–5851

Kong W, Ren J, Wang S, Chen Q (2014) Removal of heavy metals from aqueous solutions using acrylic-modified sugarcane bagasse-based adsorbents: equilibrium and kinetic studies 9:3184–3196

Kozáková Z, Nejezchleb M, Krčma F, Halamová I, Čáslavský J, Dolinová J (2010) Removal of organic dye direct red 79 from water solutions by DC diaphragm discharge: analysis of decomposition products. Desalination 258:93–99

Kucharyov MS (1993) Properties and modification methods for vegetable fibers for natural fiber composites. Tekst Prom 23:8–9

Kulkarni SJ, Kaware JP (2015) Analysis of packed bed adsorption column with low cost adsorbent for cadmium removal. Int J Therm Environ Eng 9:17–24

Lackinger E, Sartori J, Potthast A, Rosenau T (2012) Novel and green ASA-type paper sizing agents based on renewable resources: from model experiments over lab trials to paper machine and large-scale production. In: Jin Y, Wang Z, Wu W (eds) Proceeding of the 4th international conference on pulping, papermaking and biotechnology (ICPPB’12), pp 435–439

Li H, Liu H, Fu S, Zhan H (2011) Surface hydrophobicity modification of cellulose fibers by layer-by-layer self-asssembly of lignosulfonates. BioResources 6:1681–1695

Li Y, Jiang L, Xiong C, Peng W (2015) Effect of different surface treatment for bamboo fiber on the crystallization behavior and mechanical property of bamboo fiber/nanohydroxyapatite/poly(lactic-co-glycolic) composite. Ind Eng Chem Res 54:12017–12024

Liimatainen H, Visanko M, Sirviö JA, Hormi OEO, Niinimaki J (2012) Enhancement of the nanofibrillation of wood cellulose through sequential periodate-chlorite oxidation. Biomacromolecules 13:1592–1597

Liu R, Ma W, Jia CY, Wang L, Li HY (2007) Effect of pH on biosorption of boron onto cotton cellulose. Desalination 207:257–267

Liu S, Zeng J, Tao D, Zhang L (2010) Microfiltration performance of regenerated cellulose membrane prepared at low temperature for wastewater treatment. Cellulose 17:1159–1169

Liu S, Zhao Y, Ma F, Ma L, O’Shea K, Zhao C, Hu X, Wu M (2015) Control of Microcystis aeruginosa growth and associated microcystin cyanotoxin remediation by electron beam irradiation (EBI). RSC Adv 5:31292–31297

Loganathan P, Vigneswaran S, Kandasamy J (2013a) Enhanced removal of nitrate from water using surface modification of adsorbents—a review. J Environ Manag 131:363–374

Loganathan P, Vigneswaran S, Kandasamy J, Naidu R (2013b) Defluoridation of drinking water using adsorption processes. J Hazard Mater 248–249:1–19

Ma W, Yan S, Meng M, Zhang S (2014) Preparation of betaine-modified cationic cellulose and its application in the treatment of reactive dye wastewater. J Appl Polym Sci 131:40522

Maimaiti H, Arken K, Wumaier M, Wushuer L (2014) Oil absorbency of cellulose/butylmethacrylate graft polymer fibers. Iran Polym J 23:671–678

Malik PK (2003) Use of activated carbons prepared from sawdust and rice-husk for adsorption of acid dyes: a case study of acid yellow 36. Dyes Pigm 56:239–249

Mallakpour S, Rafiee Z (2011) Ionic liquids as environmentally friendly solvents in macromolecules chemistry and technology, part I. J Polym Environ 19:447–484

Marshall WE, Wartelle LH, Boler DE, Johns MM, Toles CA (1999) Enhanced metal adsorption by soybean hulls modified with citric acid. Biores Technol 69:263–268

Memon GZ, Bhanger M, Akhtar M, Talpur FN, Memon JR (2008) Adsorption of methyl parathion pesticide from water using watermelon peels as a low cost adsorbent. Chem Eng J 138:616–621

Michailof C, Stavropoulos GG, Panayiotou C (2008) Enhanced adsorption of phenolic compounds, commonly encountered in olive mill wastewaters, on olive husk derived activated carbons. Biores Technol 99:6400–6408

Missoum K, Belgacem MN, Bras J (2013) Nanofibrillated cellulose surface modification: a review. Materials 6:1745–1766

Mohanty AK, Misra M, Drzal LT (2001) Surface modifications of natural fibers and performance of the resulting biocomposites: an overview. Compos Interfaces 8:313–343

Mondal MIH, Islam MK (2014) Effect of pH on the dye absorption of jute fibre dyed with direct dyes. Orient J Chem 30:1571–1575

Mukhopadhyay S, Fangueiro R (2009) Physical modification of natural fibers and thermoplastic films for composites—a review. J Thermoplast Compos Mater 22:135–162

Nag A (1995) Utilization of charred sawdust as an adsorbent of dyes, toxic salts and oil from water. Process Saf Environ Prot Trans Inst Chem Eng Part B 73:299–306

Nakajima A, Sakaguchi T (1990) Recovery and removal of uranium by using plant wastes. Biomass 21:55–63

Namasivayam C, Sureshkumar M (2008) Removal of chromium (VI) from water and wastewater using surfactant modified coconut coir pith as a biosorbent. Biores Technol 99:2218–2225

Nguyen TAH, Ngo HH, Guo WS, Zhang J, Liang S, Yue QY, Li Q, Nguyen TV (2013) Applicability of agricultural waste and by-products for adsorptive removal of heavy metals from wastewater. Biores Technol 148:574–585

O’Connell DW, Birkinshaw C, O’Dwyer TF (2008) Heavy metal adsorbents prepared from the modification of cellulose: a review. Biores Technol 99:6709–6724

Okita Y, Saito T, Isogai A (2010) Entire surface oxidation of various cellulose microfibrils by TEMPO-mediated oxidation. Biomacromolecules 11:1696–1700

Oshida K, Kogiso K, Matsubayashi K, Takeuchi K, Kobayashi S, Endo M, Dresselhaus MS, Dresselhaus G (1995) Analysis of pore structure of activated carbon fibers using high resolution transmission electron microscopy and image processing. J Mater Res 10:2507–2517

Owen G, Bandi M, Howell JA, Churchouse SJ (1995) Economic assessment of membrane processes for water and waste water treatment. J Membr Sci 102:77–91

Pan Y, Xiao H, Song Z (2013) Hydrophobic modification of cellulose fibres by cationic-modified polyacrylate latex with core-shell structure. Cellulose 20:485–494

Parab H, Sudersanan M, Shenoy N, Pathare T, Vaze B (2009) Use of agro-industrial wastes for removal of basic dyes from aqueous solutions. Clean Soil Air Water 37:963–969

Phan NH, Rio S, Faur C, Le Coq L, Le Cloirec P, Nguyen TH (2006) Production of fibrous activated carbons from natural cellulose (jute, coconut) fibers for water treatment applications. Carbon 44:2569–2577

Qin JJ, Oo MH, Kekre KA (2007) Nanofiltration for recovering wastewater from a specific dyeing facility. Sep Purif Technol 56:199–203

Qiu Y, Hwang YJ, Zhang C, Bures BL, McCord M (2002) Atmospheric pressure helium + oxygen plasma treatment of ultrahigh modulus polyethylene fibers. J Adhes Sci Technol 16:449–457

Radetić MM, Jocić DM, Jovančić PM, Petrović ZL, Thomas HF (2003) Recycled wool-based nonwoven material as an oil sorbent. Environ Sci Technol 37:1008–1012

Ran J, Wu L, Zhang Z, Xu T (2014) Atom transfer radical polymerization (ATRP): a versatile and forceful tool for functional membranes. Prog Polym Sci 39:124–144

Rawajfih Z, Nsour N (2006) Characteristics of phenol and chlorinated phenols sorption onto surfactant-modified bentonite. J Colloid Interface Sci 298:39–49

Rezaee A, Godini H, Dehestani S, Khavanin A (2008) Application of impregnated almond shell activated carbon by zinc and zinc sulfate for nitrate removal from water. J Environ Health Sci Eng 5:125–130

Rodríguez Correa C, Stollovsky M, Hehr T, Rauscher Y, Rolli B, Kruse A (2017) Influence of the carbonization process on activated carbon properties from lignin and lignin-rich biomasses. ACS Sustain Chem Eng 5:8222–8233

Rombaldo CFS, Lisboa ACL, Mendez MOA, Coutinho AR (2014) Brazilian natural fiber (jute) as raw material for activated carbon production. An Acad Bras Ciênc 86:2137–2144

Rowell RM, Schultz TP, Narayan R (1992) Emerging technologies for materials and chemicals from biomass. In: ACS symposium series (USA), vol 476

Roy D, Guthrie JT, Perrier S (2005) Graft polymerization: grafting poly (styrene) from cellulose via reversible addition–fragmentation chain transfer (RAFT) polymerization. Macromolecules 38:10363–10372

Roy D, Semsarilar M, Guthrie JT, Perrier S (2009) Cellulose modification by polymer grafting: a review. Chem Soc Rev 38(7):2046–2064

Ru ZX, Chai LX, Liu YB (2011) Treatment of metallurgical comprehensive electroplating waste-water with oxidation-reduction method. China Nonferrous Metall 6:60–62

Shen Y, Ma D, Ge X (2017) CO2-looping in biomass pyrolysis or gasification. Sustain Energy Fuels 1:1700–1729

Sidik S, Jalil A, Triwahyono S, Adam S, Satar M, Hameed B (2012) Modified oil palm leaves adsorbent with enhanced hydrophobicity for crude oil removal. Chem Eng J 203:9–18

Sivakumar P, Palanisamy N (2010) Mechanistic study of dye adsorption on to a novel non-conventional low-cost adsorbent. Adv Appl Sci Res 1:58–65

Song Y, Lei S, Zhou J, Tian Y (2016) Removal of heavy metals and cyanide from gold mine waste-water by adsorption and electric adsorption. J Chem Technol Biotechnol 91:2539–2544

Soylak M, Cay RS (2007) Separation/preconcentration of silver(I) and lead(II) in environmental samples on cellulose nitrate membrane filter prior to their flame atomic absorption spectrometric determinations. J Hazard Mater 146:142–147

Srivastava A, Chaurasia A, Sharma S, Mishra G (2006) Kinetics and mechanism of polymerization of vinyl acetate using triphenyl stibonium 1, 2, 3, 4-tetraphenyl-cyclopentadiene ylide. J Sci Ind Res 65:514–517

Strathmann H (2001) Membrane separation processes: current relevance and future opportunities. AIChE J 47:1077–1087

Sud D, Mahajan G, Kaur MP (2008) Agricultural waste material as potential adsorbent for sequestering heavy metal ions from aqueous solutions—a review. Biores Technol 99:6017–6027

Suhas Gupta VK, Carrott PJM, Singh R, Chaudhary M, Kushwaha S (2016) Cellulose: a review as natural, modified and activated carbon adsorbent. Biores Technol 216:1066–1076

Sun X, Peng B, Ji Y, Chen J, Li D (2009) Chitosan (chitin)/cellulose composite biosorbents prepared using ionic liquid for heavy metal ions adsorption. AIChE J 55:2062–2069

Takada A, Kadokawa JI (2015) Fabrication and characterization of polysaccharide ion gels with ionic liquids and their further conversion into value-added sustainable materials. Biomolecules 5:244

Takaichi S, Isogai A (2013) Oxidation of wood cellulose using 2-azaadamantane N-oxyl (AZADO) or 1-methyl-AZADO catalyst in NaBr/NaClO system. Cellulose 20:1979–1988

Tan I, Ahmad AL, Hameed B (2008) Adsorption of basic dye on high-surface-area activated carbon prepared from coconut husk: equilibrium, kinetic and thermodynamic studies. J Hazard Mater 154:337–346

Teli MD, Valia SP (2013) Acetylation of banana fibre to improve oil absorbency. Carbohydr Polym 92:328–333

Telkapalliwar N, Shivankar V (2016) Adsorption of Pb(II) from aqueous solution onto microwave assisted activated carbon prepared from orange peel. Int J Appl Innov Eng Manag 5:76–82

Tian Y, Wu G, Tian X, Tao X, Chen W (2013) Novel erythrocyte-like graphene microspheres with high quality and mass production capability via electrospray assisted self-assembly. Sci Rep 3:3327

Ticoalu A, Aravinthan T, Cardona F (2010) A review of current development in natural fiber composites for structural and infrastructure applications. In: Paper presented at the southern region engineering conference 2010, SREC 2010—incorporating the 17th annual international conference on mechatronics and machine vision in practice, M2VIP 2010

Tripathi A, Ranjan MR (2015) Heavy metal removal from wastewater using low cost adsorbents. J Bioremed Biodeg 6:315

Ugbolue SCO (1990) Structure/property relationships in textile fibres. Text Prog 20:1–43

Van der Bruggen B, Vandecasteele C (2002) Distillation vs. membrane filtration: overview of process evolutions in seawater desalination. Desalination 143:207–218

Van Oss CJ (1990) A review of: “Active Carbon.” (1988) Bansal RC, Donnet JB, Stoeckli F (eds). Marcel Dekker, New York, pp. 482, $135.00. J Dispers Sci Technol 11:323

Villalobos-Rodríguez R, Montero-Cabrera ME, Esparza-Ponce HE, Herrera-Peraza EF, Ballinas-Casarrubias ML (2012) Uranium removal from water using cellulose triacetate membranes added with activated carbon. Appl Radiat Isot 70:872–881

Walha K, Amar RB, Firdaous L, Quéméneur F, Jaouen P (2007) Brackish groundwater treatment by nanofiltration, reverse osmosis and electrodialysis in Tunisia: performance and cost comparison. Desalination 207:95–106

Wang J, Xu L, Meng Y, Cheng C, Li A (2011) Adsorption of Cu2 + on new hyper-crosslinked polystyrene adsorbent: batch and column studies. Chem Eng J 178:108–114

Wang J, Zheng Y, Wang A (2012a) Effect of kapok fiber treated with various solvents on oil absorbency. Ind Crops Prod 40:178–184

Wang X, Zhou M, Jin X (2012b) Application of glow discharge plasma for wastewater treatment. Electrochim Acta 83:501–512

Wang J, Zheng Y, Wang A (2013a) Coated kapok fiber for removal of spilled oil. Mar Pollut Bull 69(1):91–96

Wang J, Zheng Y, Wang A (2013b) Preparation and properties of kapok fiber enhanced oil sorption resins by suspended emulsion polymerization. J Appl Polym Sci 127:2184–2191

Wang Y, Yadav S, Heinlein T, Konjik V, Breitzke H, Buntkowsky G, Schneider Jorg J, Zhang K (2014) Ultra-light nanocomposite aerogels of bacterial cellulose and reduced graphene oxide for specific absorption and separation of organic liquids. RSC Adv 4:21553–21558

Wang Z, Guo H, Shen F, Yang G, Zhang Y, Zeng Y, Wang L, Xiao H, Deng S (2015) Biochar produced from oak sawdust by lanthanum (La)-involved pyrolysis for adsorption of ammonium (NH4 +), nitrate (NO3 −), and phosphate (PO4 3−). Chemosphere 119:646–653

Wang J, Geng G, Liu X, Han F, Xu J (2016) Magnetically superhydrophobic kapok fiber for selective sorption and continuous separation of oil from water. Chem Eng Res Des 115:122–130

Welgemoed TJ (2005) Capacitive deionization technology TM development and evaluation of an industrial prototype system. Desalination 183:327–340

Wen T, Zhao Z, Shen C, Li J, Tan X, Zeb A, Wang X, Xu AW (2016) Multifunctional flexible free-standing titanate nanobelt membranes as efficient sorbents for the removal of radioactive 90Sr2+ and 137Cs+ ions and oils. Sci Rep 6:20920

Wendler F, Kosan B, Krieg M, Meister F (2009) Possibilities for the physical modification of cellulose shapes using ionic liquids. Macromol Symp 280:112–122

Williams PT, Besler S (1996) The influence of temperature and heating rate on the slow pyrolysis of biomass. Renew Energy 7:233–250

Won SW, Kotte P, Wei W, Lim A, Yun YS (2014) Biosorbents for recovery of precious metals. Biores Technol 160:203–212

Wong KK, Lee CK, Low KS, Haron MJ (2003) Removal of Cu and Pb by tartaric acid modified rice husk from aqueous solutions. Chemosphere 50:23–28

Xu X, Gao BY, Yue QY, Zhong QQ (2010) Preparation of agricultural by-product based anion exchanger and its utilization for nitrate and phosphate removal. Biores Technol 101:8558–8564

Yan Z, Liu Y, Ren W, Yuan Z (2012) Investigation of liquid plasma catalysis on Ti electrodes for the decolorization of a brilliant red B solution. J Electrostat 70:48–53

Yang YW, Wu JY, Liu CT, Liao GC, Cheng KY, Chiang MH, Wu JS (2015) An optimized two-step nitrogen-based plasma treatment procedure under atmospheric-pressure condition and its surface amination mechanism. Plasma Process Polym 12:678–690

Zhang X, Duan C, Jia X, Dai B (2016) Carboxylation kapok fiber as a low-cost, environmentally friendly adsorbent with remarkably enhanced adsorption capacity for cationic dyes. Res Chem Intermed 42:5069–5085

Zhu H, Zhang Y, Yang X, Liu H, Zhang X, Yao J (2015) An eco-friendly one-step synthesis of dicarboxyl cellulose for potential application in flocculation. Ind Eng Chem Res 54:2825–2829

Acknowledgments

The authors would like to acknowledge the Ministry of Higher Education and Universiti Sains Malaysia for their financial support in this research via 203.PHUMANITI.6711512 and the MyBrain15 scholarship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rahman, N.S.A., Yhaya, M.F., Azahari, B. et al. Utilisation of natural cellulose fibres in wastewater treatment. Cellulose 25, 4887–4903 (2018). https://doi.org/10.1007/s10570-018-1935-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-1935-8