Abstract

Cross-linked cellulose nanofibril (CNF) aerogel with positive and negative surface charge was prepared. For the surface charge modification of CNF from its intrinsic negative charge to positive charge, glycidyltrimethylammonium chloride was used. To stabilize the network structure of CNF aerogel in aqueous condition, maleic acid and sodium hypophosphite cross-linking treatment was applied. The ion adsorption properties of positive and negative charged cross-linked CNF aerogels were evaluated using the Langmuir adsorption model, and it was affected by pH of the ion solution. The maximum ion adsorption capacity of negatively charged cross-linked CNF aerogel was 0.79 mmol/g for the nickel cation while that of the positively charged cross-linked aerogel was 0.62 mmol/g for the permanganate anion.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cellulose is the most abundant and renewable biopolymer which can be derived from biomass. Its annual production is estimated to be 1010–1011 tons (Samir et al. 2005). Obviously, plant biomass is the most important source of cellulose, and cellulose is the principal component to form the cellular structure and allow plants to stand upright. Cellulose is an excellent material for this purpose because it is a water-insoluble polymer with strong mechanical properties. Thanks to the renewable nature and high strength of cellulose, much attention has been given to find a new industrial application of cellulose.

CNF is defined as a nano-scale fibrous material which can be obtained from cellulose fiber by means of a mechanical shearing action. CNF is composed of an aggregation of 10–50 cellulose elemental fibrils. Its diameter ranges from 5 to 50 nm and it length is typically several micrometers. Due to its high specific surface area and strong mechanical properties, many studies has been made to find various applications of CNF, including reinforcing agents for biocomposite materials (Shibata and Nakai 2010) and building material for translucent sheets (Iwamoto et al. 2005). One of the most promising applications of CNF is to use it as a starting material for the preparation of cellulose aerogels.

Aerogels are highly porous, ultra-lightweight materials that are formed by the removal of the liquid dispersion medium from a gel without collapse of the network structure (Hüsing and Schubert 1998). In contrast to conventional aerogels made from silica, nanoclay, or carbon nanofiber, CNF aerogel is considered to be more environmentally friendly because it is not necessary to employ multiple solvent-exchange stages or a supercritical drying process. Preparation of aerogel by freeze drying of CNF hydrogel was firstly reported by Pääkkö et al. (2008). CNF is a nano-sized flexible fibrous material which can build a complex three-dimensional fiber network structure by mechanical entanglement in aqueous media. As a result, the CNF suspension forms a hydrogel structure at a very low concentration above 1 wt%. During the freeze-drying process, the volume of the CNF suspension is maintained without collapse of the three-dimensional fiber network; thereby, CNF aerogel is produced. Since Pääkkö et al. (2008) reported CNF hydrogel, a large number of studies about the preparation and characterization of CNF aerogel have been made (Aulin et al. 2010; Sehaqui et al. 2010; Cervin et al. 2012; Chen et al. 2011; Zheng et al. 2014). The inherent high modulus and strength of the native cellulose and its biodegradability, biocompatibility, availability, renewability, and capacity for chemical modification (Syverud and Stenius 2009; Yano and Nakahara 2004) are important advantages of cellulose aerogels.

However, the wide application of CNF aerogel is inhibited by its poor structural stability in aqueous condition. The fiber network structure of the CNF aerogel relies on the interfibril hydrogen bonding and mechanical entanglement that is easily destroyed by water and swelling of fiber. Cross-linking treatment is regarded as the most effective way to overcome this limitation of CNF aerogel. In previous study, we have shown that the structural stability of the CNF aerogel in a wet state can be significantly improved by cross-linking treatment. Cross-linking treatment consists of surface modification of CNF with maleic acid and formation of interfibril covalent bonding by the reaction between grafted maleic acid and hypophosphite ions. Cross-linked CNF aerogel maintained its original shape after compressive deformation in a wet state while the porous aerogel intra-structure was maintained (Kim et al. 2015). Zhang et al. (2012) have also shown the cross-linked CNF aerogel with shape recovery characteristics by treatment with polyamide-epichlorohydrine, while Syverud et al. (2015) have reported the preparation of CNF hydrogel using an aldehydecontaining cross-linking agent.

Applications of CNF as a loading matrix for chemicals have been reported. Dong et al. (2013) reported the loading of silver+ nanoparticles in a CNF suspension. Due to their positive charge, the silver nanoparticles were adsorbed onto the surface of the CNF by electrostatic attraction force, and strong gelation of the CNF was induced. Kolakovic et al. (2011) also reported the application of CNF films as a loading matrix for drug chemicals. They demonstrated that active pharmaceutical ingredients (APIs) can be loaded onto CNF aerogel by a simple filtration method with a loading rate of 40%. They also showed that the drug release rate of the API-loaded CNF film was sustained for 3 months. Valo et al. (2013) reported the application of CNF aerogel as a drug delivery material as well. However, in their research, model chemicals were loaded by means of a simple mixing process with the CNF in a suspension state. Therefore, controlling the chemical loading rate was difficult and the loaded chemicals may be lost during the aerogel preparation process. More efficient loading of ionic chemicals onto the cross-linked CNF aerogel can be obtained by employing an ion adsorption process. It was reported that chemically modified cellulose materials exhibited good ion adsorption performance. For instance, Karnitz et al. (2007) prepared succinic-acid-modified sugarcane bagasse, while de Melo et al. (2009) prepared maleic-anhydride-treated microcrystalline cellulose. In both studies, carboxylic moieties were grafted onto cellulose fibers and the anionic charge of the cellulose was enhanced by the added carboxyl groups. These chemically modified fibrous cellulose samples exhibit superior cation exchange performance levels. Studies showed that surface modification of the CNF with anionic and cationic functional groups would provide more specific application and efficient use of CNFs. Combining the chemical modification with aerogel structuring of CNF would allow more specific and interesting application of the CNF.

In this study, negatively and positively surface charged cross-linked CNF aerogels were prepared in the same way as our previous report except for the addition of positive surface charge modification of CNF. Prepared surface charge-controlled, cross-linked CNF aerogels showed identical structural and physical characteristics and their ion adsorption characteristics were investigated using metal cation or anion solutions. The effects of contact time and pH of the ion solutions on the ion adsorption characteristics of the cross-linked CNF aerogel were examined, and the theoretical adsorption capacities were determined.

Materials and methods

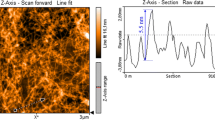

Preparation of CNF

CNF was prepared as described in the literature (Sim et al. 2015). Once-dried, commercial bleached eucalyptus kraft pulp was used as a raw material. Pulp sheets were dispersed in deionized water and refined using a laboratory Valley beater to get a freeness value of 450 mL CSF. The solids content of pulp slurry was then adjusted to 2 wt%. Pulp slurry was mechanically processed using a grinder (Super Masscollider MKCA6-3, Masuko Sanguo Co.). The rotation speed of the grinding stone was 1500 rpm and the stone gap was adjusted −60 µm. After grinding 40 times, CNF suspension was prepared.

Surface charge modification of CNF

The esterification process using maleic acid (MA) described in the literature (Kim et al. 2015) was employed for negative surface charge modification of cellulose. MA and sodium hypophosphite supplied by Sigma-Aldrich were added to CNF suspension. The molar ratio of MA to anhydroglucose unit (AGU) was 10, and the dosage of hypophosphite was 10 wt% of MA. After vigorous mixing for 30 min, the CNF suspension was kept at 120 °C for 30 min using an autoclave for esterification between MA and cellulose to obtain MA-treated CNF (CNF-MA). For the positive surface charge modification of cellulose, an esterification process using GTMAC described in literature was employed (Khalil-Abad et al. 2009; Kavaliauskaite et al. 2008). Since hydroxylation of GTMAC occurs more favorably than esterification of alkali activated cellulose (Zaman et al. 2012), the water content of the reaction mixture was reduced by employing dry, semi-dry, and organic solvent reaction systems (Bendoraitiene et al. 2006). In this study, pressurized dewatering equipment (Quro) was used to adjust the water content of the reaction mixture to around 7.5 wt%. Prepared CNF pad was put into a plastic bag and mixed well with 50 wt% NaOH solution by intensive hand kneading. The dosage of NaOH was 5 wt% of the dry mass of CNF. This mixture was heated to 70 °C for 30 min using a hot water bath. The GTMAC was then added to the reaction mixture. The dosage of GTMAC was 0.5, which was calculated as the molar ratio of GTMAC to AGU of CNF under the assumption that the CNF was composed of only cellulose. The mixture was reacted at 70 °C for 4 h in a hot water bath. During the reaction, the mixture was hand-kneaded every 15 min. At the end of the reaction, the mixture was cooled down by adding deionized water. The unreacted chemicals and by-products were removed by centrifugal washing at 3000g for 10 min. Precipitated GTMAC-treated-CNF (CNF-GTMAC) pad was redispersed in deionized water and the subsequent centrifugal washing steps were carried out. This washing procedure was repeated six times.

Preparation of cross-linked CNF aerogel

To the washed and re-dispersed CNF-GTMAC suspension, a 10 molar ratio of MA and 10 wt% of sodium hypophosphite were added and the same mixing and autoclave treatment were carried out as described in 2.2 for CNF-MA to make CNF-GTMAC-MA. After that, 20 wt% of sodium hypophosphite was added to CNF-MA and CNF-GTMAC-MA suspensions, and the total solids content was adjusted to 3.5 wt%. After that, the suspensions were transferred to polystyrene cuvettes as molds. Before rapid freezing, CNF hydrogels in the cuvette were placed in a refrigerator at 4 °C for overnight. The precooled CNF hydrogels were rapidly frozen at −196 °C using liquid nitrogen, and the frozen samples were subjected to freeze-drying using a freeze dryer (FD8518, Ilshin Lab) for 3 days. The cold trap temperature was −80 °C and the vacuum level was maintained at 5 mmHg during the freeze-drying process. After three days of freeze-drying, rectangular CNF-MA and CNF-GTMAC-MA aerogels with a density of 36 kg/m3 were prepared. Thereafter, aerogels were cured in a convection oven to form cross-linking between cellulose fibrils. The curing temperature was 170 °C and the time was 10 min. Cross-linked CNF-MA and CNF-GTMAC-MA aerogels were cut into cubes with a size of 10 × 10 × 10 mm.

Zeta potential of CNF-MA and CNF-GTMAC-MA

The zeta potential of CNF-MA and CNF-GTMAC-MA were measured using a Nanosizer ZS (Malvern) based on the laser Doppler electrophoresis technique. Small amounts of CNF-MA and CNF-GTMAC-MA suspension were diluted with deionized water. The pH of the suspensions wwere adjusted to 3–11 with 0.1 N NaOH and 0.1 N HCl solutions. The NaCl solution was then added to the CNF suspensions in order to equalize the conductivity of the CNF suspensions to 0.9 ± 0.1 mS/cm. Prepared CNF suspension was injected into a folded capillary zeta potential measurement cell. The zeta potential was calculated by measuring the electrophoretic mobility using Smoluchwski’s approximation. The temperature of the CNF suspension was controlled at 25 °C.

Characterization of the ion adsorption property of CNF aerogels

For the determination of the ion adsorption performance of the cross-linked CNF aerogel, metal ions were used. For the cation adsorption of the negatively charged cross-linked CNF-MA aerogel, nickel nitrate [Ni(NO3)2] was used. For the anion adsorption of the positively charged cross-linked CNF-GTMAC-MA aerogel, potassium permanganate (KMnO4) was used. These chemicals were purchased from Sigma-Aldrich. All solutions were prepared with deionized water.

The ion adsorption process was carried out in a batch process. Aqueous solutions of a metal ion with different concentrations ranging from 0.1 to 5 mmol/L were prepared; 25 mL of each solution was placed in a conical tubes. A cross-linked CNF aerogel cube was immerged into each metal ion solution. The oven-dried weight of a cube of the cross-linked CNF aerogel sample was 0.036 g (Fig. 1). During the ion adsorption process, the conical tubes containing the ion solutions were shaken using a conical tube mixer. After the adsorption process, the CNF aerogels were removed from the metal ion solutions and the concentrations of the remaining metal ions in the solution were determined by inductively coupled plasma optical emission spectrometry (ICP-OES, ICP-730 ES, Varian). The adsorption capacity (n f ) was calculated by the following equation (Eq. 1):

In this equation, n i is the initial molar number of ions, n s denotes the remaining molar number of ions in the solution, and m is the weight of the CNF aerogel.

Result and discussion

The zeta potential of CNF-MA and CNF-GTMAC-MA

The changes in zeta potential of CNF-MA and CNF-GTMAC-MA at five different pHs of the suspension are shown in Fig. 2. CNF-GTMAC-MA showed the highest positive charge at pH 3, and the surface charge decreased as pH increased. At pH 12, the surface charge of CNF-GTMAC-MA was almost neutral. In contrast, untreated CNF and CNF-MA showed a higher negative charge in alkaline conditions. Similar surface charge behavior of untreated CNF and CNF-MA suggested that the grafting of MA onto the cellulose did not contribute significantly to the overall increase in the number of carboxyl groups of CNF-MA. As reported by Abbott et al. (2006), most of the reactant is not able to reach the cellulose hydroxyl groups of intra-CNF; therefore, chemical modification of CNF is limited to the surface and swelling region of CNF. Ho et al. (2011) calculated the theoretical ratio of the surface hydroxyl groups, and the bulk hydroxyl group is only 0.0002 when the diameter of CNF is 7.5 nm.

The cross-linking of CNF using MA and sodium hypophosphite occurs in two reactions, i.e. grafting of MA onto the surface of CNF and cross-linking of the grafted MA by hypophosphite. In this study, the cross-linking of MA by hypophosphite occurred in a solid state after the freeze drying of the CNF aerogel. Therefore, some part of the MA reacted with hypophosphite while the rest of the MA remained intact. As a result, the cross-linked CNF aerogel contains free carboxylic acid groups on the surface of the CNF, as the scheme in Fig. 3 shows. In CNF-GTMAC-MA aerogel, not only cationic quaternary ammonium groups of GTMAC but also anionic carboxyl groups are present. Dissociation of carboxylic acid increases with an increase of pH and this caused a reduction of CNF-GTMAC-MA at high pH conditions. That is, the presence of carboxylic groups means that the surface charge of the cross-linked CNF is influenced by the pH of the aqueous media for both positively (CNF-GTMAC-MA) and negatively (CNF-MA) charged aerogels.

Effect of pH of solution on ion adsorption of CNF aerogel

Because the surface charge of the cross-linked CNF was affected by the pH of the aqueous media, it was expected that the adsorption of metal ions would also depend on pH. An experiment to assess the adsorption performance of the cross-linked CNF aerogel was carried out with 1 mM of metal ion solutions at different pH conditions ranging from 3 to 11. Nickel nitrate solution and potassium permanganate solution were prepared and used to investigate the adsorption property of negatively and positively charged CNF aerogel, respectively. The adsorption capacities (n f ) for the two aerogels after 3 h of adsorption are presented in Fig. 4. The negatively charged CNF-MA aerogel showed the maximum adsorption of Ni2+ at pH 11, while the positively charged CNF-GTMAC-MA aerogel showed the maximum adsorption of MnO4 − at pH 3. This agrees well with the result of the surface charge.

Contact time for adsorption equilibrium

An experiment to assess the adsorption kinetics was performed in a batch process by varying the adsorption time from 10 min to 3 h. Nickel nitrate and potassium permanganate solutions at 1 mM were used as adsorbates. The pH was adjusted to 11 for the nickel nitrate solution and to 3 for the potassium permanganate solution. Figure 5 shows the kinetics of adsorption onto the negatively and positively charged CNF aerogels. This showed that a state of adsorption equilibrium was reached after 60 min for both the negatively and positively charged aerogels.

Maximum adsorption capacity of cross-linked CNF aerogel

To study the adsorption isotherm of the negatively charged CNF aerogel, cobalt, cadmium, and nickel ion solutions were prepared. For the positively charged CNF aerogel, permanganate and dichromate anions were used. The concentration of both cation and anion solutions was varied from 0.1 to 5 mM/L. After 3 h of adsorption, the remaining metal ion concentration was determined to derive the equilibrium adsorption isotherm. The Langmuir adsorption model (de Melo et al. 2009; Abo-Farha et al. 2009) was employed to evaluate the adsorption performance of the cross-linked CNF aerogel. The Langmuir adsorption model assumes that each of the adsorbed ions is held by a definite point of attachment on the surface. Given this assumption, the maximum adsorption capacity corresponding to complete monolayer coverage was estimated according to Abo-Farha et al. (2009). During the adsorption process, a state of dynamic equilibrium exists between the solved ions in the aqueous phase and ions adsorbed onto the solid. The ratio between the number of moles in solution and that of the ions adsorbed on the CNF surface can be expressed as Eq. (2).

Here, C s (mol/L) is the concentration of the remaining metal ions in the solution in an equilibrium state, and n f (mol/g) is the number of moles adsorbed. From the linearized adsorption isotherm, by considering C s /n f versus C s , the remaining parameters n s (mol/g; the maximum amount of adsorbed metal ions per mass of CNF aerogel) and b (L/mol, constant value) were determined using the least squares method. The adsorption isotherm and linearized Langmuir adsorption for nickel and permanganate ion are shown in Figs. 6 and 7, respectively. From the Langmuir adsorption isotherm, the adsorption parameters were obtained and listed in Table 1.

The n s value, the maximum ion adsorption capacity of the negatively charged cross-linked CNF aerogel, was 0.79 mmol/g for Ni2+ ion, while that of the positively charged case was 0.62 mmol/g for MnO4 −. These values were rather low compared to reported results of chemically modified micro-particular cellulose absorbent materials. For instance, de Melo et al. (2009) reported that 1.8–2.5 mmol/g and Karnitz et al. (2007) showed 1.74–2.78 mmol/g as adsorption capacity of cellulose absorbents. However, the adsorption capacity of CNF aerogels was appreciably higher than purolite C100, which is a commercial strong acid ion-exchange resin reported by Abo-Farha et al. (2009; 0.05 mmol/g toward Pb2+ cation). Because of the good ionic chemical loading capability and highly porous aerogel structure, the cross-linked CNF aerogel is expected to be a good chemical loading and carrier media.

Conclusions

In this study, negative surface-charged and positive surface-charged cross-linked CNF aerogels were prepared with CNF grafted by MA (CNF-MA) and CNF grafted with MA and GTMAC (CNF-GTMAC-MA), respectively. The zeta potentials of CNF-MA and CNF-GTMAC-MA were affected by the pH of the aqueous media. CNF-MA showed a weak negative charge at pH 3, and this negative charge became stronger as pH was increased due to the dissociation of the carboxyl groups. On the other hand, the zeta potential of CNF-GTMAC-MA exhibited the strongest positive charge at pH 3, though the strength decreased with an increase in pH.

The ion adsorption of cross-linked CNF aerogels was influenced by pH due to the surface charge. The negatively charged cross-linked CNF aerogel showed the highest adsorption performance of nickel cation at pH 11, whereas the positively charged cross-linked CNF aerogel showed the highest adsorption of permanganate anion at pH 3.

Both cross-linked CNF aerogels reached an equilibrium adsorption state after 1 h. Isotherm adsorption was carried out, and the theoretical maximum adsorption performance levels of the cross-linked CNF aerogels were determined using the Langmuir adsorption model. The maximum ion adsorption capacity of the negatively charged cross-linked CNF aerogel was 0.79 mmol/g for the nickel cation while that of the positively charged cross-linked aerogel was 0.62 mmol/g for the permanganate anion.

References

Abbott AP, Bell TJ, Handa S, Stoddard B (2006) Cationic functionalization of cellulose using a choline based ionic liquid analoge. Green Chem 8:784–786

Abo-Farha SA, Abdel-Aal AY, Ashour IA, Garamon SE (2009) Removal of some heavy metal cations by synthetic resin purolite C100. J Hazard Mater 169:190–194

Aulin C, Netrval J, Wågberg L, Lindström T (2010) Aerogels from nanofibrillated cellulose with tunable oleophobicity. Soft Matter 6:3298–3305

Bendoraitiene J, Kavaliauskaite R, Klimaviciute R, Zemaitaitis A (2006) Peculiarities of starch cationization with glycidyltrimethylammonium chloride. Starch 58:623–631

Cervin NT, Aulin C, Lasson PT, Wågberg L (2012) Ultra porous nanocellulose aerogels as separation medium for mixtures of oil/water liquids. Cellulose 19:401–410

Chen W, Haipeng Y, Qing L, Yixing L, Jian L (2011) Ultralight and highly flexible aerogels withl ong cellulose I nanofibers. Soft Matter 7:10360–10368

de Melo JCP, da Silva Filho EC, Santana SAA, Airoldi C (2009) Maleic anhydride incorporated onto cellulose and thermodynamics of cation-exchange process at the solid/liquid interface. Colloids Surf A 346:138–145

Dong H, Snyder JF, Tran DT, Leadore JL (2013) Hydrogel, aerogel and film of cellulose nanofibrils functionalized with silver nanoparticles. Carbohydr Polym 95:760–767

Ho TTT, Zimmermann T, Hauert R, Caseri W (2011) Preparation and characterization of cationic nanofibrillated cellulose from etherification and high-shear disintegration process. Cellulose 18:1391–1406

Hüsing N, Schubert U (1998) Aerogels—airy materials: chemistry, structure, and properties. Angew Chem Int Ed 37:22–45

Iwamoto S, Nakagaito AN, Yano H, Nogi M (2005) Optically transparent composites reinforced with plant fiber-based nanofibers. Appl Phys A 81:1109–1112

Karnitz O Jr, Gurgel LVA, de Melo JCP, Botaro VR, Melo TMS, de Freitas Gil RP, Gil LF (2007) Adsorption of heavymetal ion fromaqueous singlemetal solution by chemically modified sugarcane bagasse. Bioresour Technol 98:1291–1297

Kavaliauskaite R, Klimaviciute R, Zemaitaitis A (2008) Factors influencing production of cationic starches. Carbohydr Polym 73:665–675

Khalil-Abad MS, Yazdanshenas MS, Nateghi MR (2009) Effect of cationization on adsorption of silver nanoparticles on cotton surfaces and its antibacterial activity. Cellulose 16:1147–1157

Kim CH, Youn HJ, Lee HL (2015) Preparation of cross-linked cellulose nanofibril aerogel with water absorbency and shape recovery. Cellulose 22:3715–3724

Kolakovic R, Peltonen L, Laaksonen T, Putkisto K, Laukkanen A, Hirvonen J (2011) Spray-dried cellulose nanofibers as novel tablet excipient. AAPS PharmSciTech 12:1366–1373

Pääkkö M, Vapaavuori J, Silvennoinen R, Kosonen H, Ankerfors M, Lindtsröm T, Berglund LA, Ikkala O (2008) Long and entangled native cellulose I nanofibers allow flexible aerogels and hierarchically porous templates for functionalities. Soft Matter 4:2492–2499

Samir A, Alloin F, Dufresne A (2005) Review of recent research into cellulosic whiskers, their properties and their application in nanocomposite field. Biomacromol 6:612–626

Sehaqui H, Salajková M, Zhou Q, Berglund LA (2010) Mechanical performance tailoring of tough ultra-high porosity foams prepared from cellulose I nanofiber suspensions. Soft Matter 6:1824–1832

Shibata M, Nakai K (2010) Preparation and properties of biocomposites composed of bio-based epoxy resin, tannic acid, and microfibrillated cellulose. J Polym Sci Part B Polym Phys 48:425–433

Sim K, Ryu J, Youn HJ (2015) Structural characteristics of nanofibrillated cellulose mats: effect of preparation conditions. Fibers Polym 16:294–301

Syverud K, Stenius P (2009) Strength and barrier properties of MFC films. Cellulose 16:75–85

Syverud K, Pettersen SR, Draget K, Chinga-Carrasco G (2015) Controlling the elastic modulus of cellulose nanofibril hydrogels-scaffolds with potential in tissue engineering. Cellulose 22:473–481

Valo H, Arola S, Laaksonen P, Torkkeli M, Peltonen L, Linder MB (2013) Drug release from nanoparticles embedded in four different nanofibrillar cellulose aerogels. Eu J Pharm Sci 50:69–77

Yano H, Nakahara S (2004) Bio-composites produced from plant microfiber bundles with a nanometer unit web-like network. J Mater Sci 39:1635–1638

Zaman M, Xiao H, Chibante F, Ni Y (2012) Synthesis and characterization of cationically modified nanocrystalline cellulose. Carbohydr Polym 89:163–170

Zhang W, Zhang Y, Lu C, Deng Y (2012) Aerogels from crosslinked cellulose nano/micro-fibrils and their fast shape recovery property in water. J Mater Chem 22:11642–11650

Zheng Q, Cai Z, Gong S (2014) Green synthesis of polyvinyl alcohol (PVA)–cellulose nanofibril (CNF) hybrid aerogels and their use as superabsorbents. J Mater Chem A 2:3110–3118a

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, C.H., Youn, H.J. & Lee, H.L. Preparation of surface-charged CNF aerogels and investigation of their ion adsorption properties. Cellulose 24, 2895–2902 (2017). https://doi.org/10.1007/s10570-017-1321-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1321-y