Abstract

The scientific publications on nanofibrillated cellulose (NFC) were reviewed in the light of recent developments in the field of characterization of NFC, and the evolving understanding of the material. This led to several insights, which challenged few of the established assumptions with regard to e.g. rheological properties of NFC suspensions, and factors affecting tensile strength and barrier properties of NFC films. The realizations may promote the wider application of nanofibrillated celluloses.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nanocellulosic materials have generated an immense interest from the research community, governmental bodies and the industry during several decades. This can be related to several exciting properties and the possibility of producing the materials from a multitude of sustainable resources. Nanocelluloses broadly include bacterial nanocellulose (BNC), nanocrystalline cellulose (NCC) and nanofibrillated cellulose (NFC). Even though BNC and NCC possess several unique properties, the advantage of NFC (to BNC and NCC) is that it can be produced at industrial scales, with a variety of functional groups, and by a multitude of industrially attractive processes. Consequently, NFC is today used in several industrial applications, e.g. as strengthening additive in the production of paper and cardboard products,Footnote 1 as rheological modifier in cosmeticsFootnote 2 and as an odour-eliminating agent in diapers.Footnote 3

The production, general characteristics and potential applications of NFC have been the subject of numerous reviews; see e.g. (Klemm et al. 2011; Dufresne 2013; Lindström et al. 2014). There are also several reviews that focus on specific properties and applications of NFC (Berglund 2005; Lavoine et al. 2012; Boufi et al. 2016; Nechyporchuk et al. 2016). However, these contributions often lack a more in-depth reviewing of the findings, which would be valuable to the reader. For example, there is still a lack of knowledge of the importance of the chemical pre-treatment process and the amount of mechanical shearing (in the NFC manufacturing process) on different NFC properties. There is also no clear understanding of the impact of parameters such as crystallinity index and degree of polymerization on barrier properties and mechanical strength of NFC films. Understandably, the knowledge is necessary for the efficient employment and the broadening of the areas of application of NFC.

This limitation may be related to the still growing understanding of the properties of the NFC, which complicates the reviewing work. However, a major reason is also the lack of universally accepted protocols for sample preparation and characterization of NFC-based systems, which hinders the effective comparison of different findings. It is noted that despite the urgency of the problem, there are very few contributions (Saarinen et al. 2009; Naderi and Lindström 2015; Olié 2016) that come close on the subject of developing characterization methods for NFC-based systems.

In this communication, the existing scientific publications on NFC, obtained through four different characterization methods (rheological measurements and centrifugation studies on NFC suspensions, together with tensile strength and oxygen permeability measurements on NFC films) are reviewed and the findings are re-evaluated by considering current understandings.

Rheological studies

Rheological measurements are highly sensitive to system differences. Hence, the employment of the method requires stringent protocols for sample handling and analysis. For example, Saarinen et al. (2009) reported that rheological studies on highly flocculated NFCs should be conducted with a concentric cylinders geometry and a gap size of at least 1 mm. Naderi and Lindström (2015) showed that pre-shearing of an unstable NFC (with phase-separation tendencies) is a pre-requisite for achieving reliable results. And Nechyporchuk et al. (2014) stressed the importance of using serrated geometries, instead of smooth geometries, in the study of concentrated NFCs as a mean to diminish slip effects.

The recording of the true rheological responses of NFC systems requires knowledge about the motion of the constituents of the systems and behaviour of the entire suspension, which is difficult to obtain. Nevertheless, an attempt was recently made by Nechyporchuk et al. (2014), by combining rheological measurements and a visualization device. These authors reported of shear banding phenomenon at certain shear rates in the study of enzymatically pre-treated (NFCEnz) and TEMPO-based (NFCTEMP) nanofibrillated celluloses.

A characteristic of NFC systems is the exponential increase of storage modulus (G′) of the NFC gels, which occurs beyond the critical network forming concentration of the systems. The theoretical work (on entangled semiflexible polymer systems) proposes an exponential value (α) of about 2.2, for the evolution of G′ as a function of concentration (MacKintosh et al. 1995). Tatsumi et al. (2002) reported an exponential value of about 2.2 for a presumably low-charged NFC. And, Naderi et al. (2014b) found α ≈ 2.4 for a carboxymethylated nanofibrillated cellulose (NFCCarb, 0.6 meq/g). There are, however, numerous contributions that have reported significantly higher α-values; see e.g. (Pääkkö et al. 2007; Agoda-Tandjawa et al. 2010; Shogren et al. 2011). The larger magnitudes of α may be related to different NFC structures, as proposed by e.g. Tatsumi et al. (2008). However, the high α-values could also be due to the incorrect selection of NFC suspensions (in the fitting process); that is the inclusion of NFC-concentrations that reside below or just above the critical network formation concentration.

The viscosity of NFCs also changes exponentially with concentration. Tatsumi et al. (2002) reported an exponential value (β) of about 2 for the evolution of shear stress (at constant shear rate) for a presumably low charged NFC; the value was proposed to be indicative of two-body collisions. Similar β-values have since been reported by Lasseuguette et al. (2008) for an NFCTEMP (presumably highly charged) and by Naderi et al. (2014b; 2015c) for an NFCCarb (0.6 meq/g) and a CMC-grafted nanofibrillated cellulose system (NFCCMC, 0.17 meq/g).

Another characteristic behaviour of NFC suspensions is their thixotropic behaviour. Lasseuguette et al. (2008) conducted several cycles of shear rate measurements on an NFCTEMP (presumably highly charged), and observed that the apparent viscosity did not change after the second cycle. These authors proposed different kinetics for the breaking and formation of fibril flocs as an explanation for their observation. Iotti et al. (2011) conducted a similar study as Lasseuguette et al. on an NFC (presumably low-charged); however, these authors did not observe a change in the magnitude of viscosity as a function of number of shear rate measurements. The observation of Iotti et al. proposes a very rapid network formation, which may find support in the studies of Naderi and Lindström (2016), who investigated the thixotropic properties of several NFC-grades (NFCCarb, NFCCMC, and NFCEnz) and found a rapid rebuilding of the NFC networks upon the scission of shearing of the systems.

On a related note, Iotti et al. also observed a rheopectic effect in their shear rate measurement studies. The observations were proposed by these authors to occur through the formation of structures due to the “unique characteristics” of NFC. However, a review of the available literature reveals that the observed rheopectic behaviour may not be a general characteristic of NFCs. Rather, the review suggests that the effect is more often observed for lesser fibrillated NFCs; see e.g. (Karppinen et al. 2012; Naderi and Lindström 2016).

The viscosity measurements of Iotti et al. revealed another interesting phenomenon, in which the viscosity curve based on decreasing shear rates remained (in a wide shear rate interval) above the viscosity curve recorded on increasing shear rates. This observation was related (by these authors) to time-dependent reorganization processes.

On a related context, many reported shear viscosity measurements are characterized by a kink in the viscosity curves (Pääkkö et al. 2007; Besbes et al. 2011; Karppinen et al. 2012; Naderi et al. 2014b); the kinks have the character of a plateauing region. Karppinen et al. (2012), who combined rheological measurements and image-analysis of a presumably low-charged NFC, have related the origin of the kinks to the creation of large flocs and voids. However, it is pointed out that the conclusion is based on the study of the macro-sized constituents of the investigated NFC. Further reviewing of the literature may, however, provide an alternative explanation. For example, a closer examination of the contribution of Naderi et al. (2014b), in which the shear viscosity of an NFCCarb (0.6 meq/g) as a function of NFC concentration was investigated, reveals that the plateauing region appears at lower shear rates as a function of NFC concentration. Interestingly, the rheopectic effect in the report of Iotti et al. displayed a similar shift as a function of NFC concentration. Of interest to the discussions is also the report of Besbes et al. (2011), who investigated the impact of number of passes through a high pressure homogenizer on among others the rheological properties of an NFCTEMP (1 meq/g). From the results of Besbes et al., it can be discerned that the kinks in the curves are shifted to lower shear rate values with increasing number of passes (that is increasing degree of fibrillation). Similar observations can also be discerned from the publications of Naderi et al. (2015a; 2016b), who studied the impact of number of microfluidization passes on the properties of an NFCCarb (0.6 meq/g) and a phosphorylated NFC (NFCPhos, 0.7 meq/g). The apparent correlation between the NFC concentration in shear rate measurements and the degree of fibrillation, and the positioning of the kinks (and the rheopectic effects) suggests than there is a correlation between the kinks and the amount of the nanomaterials in the studied NFC systems. Furthermore, the results also indicate that the shift of the kinks to lower shear rates with the increasing degree of fibrillation is indicative of the formation of larger aggregates, as the characteristic shear rate is proportional to the inverse of the characteristic time of the system—which increases. The creation of larger aggregates may be rationalized by the formation of highly entangled entities, viz. fibril aggregates, when the number of nanofibrils is increased.

The impact of temperature on the viscosity of NFC was first studied by Herrick et al. (1983). These authors found that the viscosity of the studied NFC (presumably low-charged) decreased with increasing temperature. The observation was rationalized by the decreasing viscosity of water, in the NFC suspension, with temperature. Recently, Naderi and Lindström (2016) performed shear rate and oscillatory measurements on several nanofibrillated systems, among others a low charged (0.03 meq/g) NFCEnz. These authors made similar observations as Herrick et al.; however, a decrease in G’ and an increase in G′/G″ with increasing temperature were also observed. On the other hand, the impact of temperature was found to be lower for a medium charged (0.16 meq/g) NFCCMC and insignificant for a highly charged (0.6 meq/g) NFCCarb. Naderi and Lindström did not provide any explanation for these observations. However, these authors pointed out that dissolution of cellulose is known to decrease with increasing temperature, which has been proposed to be related to the amphiphilic nature of the material (Medronho et al. 2012). Hence, the trends in the results may be understood by the extent of the amphiphilicity of the fibrillated material, with the lowest charged systems NFC displaying the highest relative lowering in viscosity, due to a higher release of water.

Highly charged NFCs are obviously sensitive to changes in the ambient ionic strength. Fukuzumi et al. (2014) investigated the viscosity of a 0.1% (w/w) NFCTEMP (1.5 meq/g) as a function of NaCl concentration. These authors observed an increase in the viscosity of the NFC when the NaCl concentration was increased to 100 mM. At higher NaCl concentrations, the viscosity of the system decreased due to phase-separation. Jowkarderis and van de Ven (2014) used a capillary viscometer to investigate the impact of monovalent inorganic salts on a highly diluted (≤0.02% (w/w)) NFCTEMP (0.7 meq/g). These authors observed that the intrinsic viscosity decreased with increasing ionic strength of the system, if κd ≤ 1; κ denotes the inverse Debye length of the system and d denotes the diameter of the fibrils. However, at higher salt concentrations (κd > 1) the viscosity of the system increased, which was related to the flocculation of the nanofibrils. Naderi and Lindström (2014) investigated the impact of NaCl concentration (0.1–10 mM) on the rheological properties of a 1% (w/w) NFCCarb. These authors observed a noticeable decrease in the viscosity and G′/G″ of the NFC with increasing NaCl concentration. This observation is interesting, as Fall et al. (2011) have shown (by dynamic light scattering studies) that NFCCarb (0.6 meq/g) is stable in [NaCl] = 0.1–100 mM. The reasons behind the seemingly conflicting results are currently not understood.

The impact of multivalent ions on the rheological properties has also been studied. For example, Jowkarderis and van de Ven (2014) investigated the impact of CaCl2 on the intrinsic viscosity of an NFCTEMP (0.7 meq/g) and observed a similar trend as when the impact of NaCl was studied (see above). In another contribution Jowkarderis and van de Ven (2015) investigated the impact of CaCl2 on the creep-recovery of a 0.3% (w/w) NFCTEMP (0.7 meq/g) and observed an initial increase in the net-work deformation by the addition of small amount of salt ([CaCl2] < 0.2 mM), which was ascribed to the decrease of the double-layer thickness. The network deformation, however, decreased by further increase of the salt concentration, which these authors rationalized by fibril aggregation or the linking of the nanofibrils with calcium ions. Dong et al. (2013) investigated the impact of several di- and trivalent ions on the gel formation of an NFCTEMP (1.3 meq/g). These authors observed that G’ increased in the following order Fe3+ > Al3+ > Cu2+ > Zn2+ > Ca2+, which was proposed to reflect the strength of the metal-carboxylate bonding. However, the trend in the G′/G″ values did not match the G′-trend. These authors explained the observation by the acidity of some of the salt solutions, which led to the protonation of part of the carboxylate groups.

In a related context, the impact of pH on the rheological properties of NFCs has also been the subject of a handful of studies. The more interesting contribution (in the view of this author) is that of Jowkarderis and van de Ven (2014), in which a lowering in the intrinsic viscosity with decreasing pH of a highly charged NFCTEMP (0.7 meq/g) was observed.

Rheological studies on multi-component NFC-based systems are important for the evaluation of NFC in different applications. But, the number of publications in the field is relatively few (Lowys et al. 2001; Karppinen et al. 2011; Quennouz et al. 2016), and the conclusions are often not satisfactorily substantiated due to the inadequate investigation of the modes of interactions of NFC and other system components. The investigations are further complicated by the inadequate knowledge of the proper method of mixing of different components, which has been shown to have a major impact on the recorded rheological properties (Naderi et al. 2015b; de Kort et al. 2016). Rheological studies of multicomponent NFC-based systems should therefore be viewed as an immature field.

Barrier studies on NFC films

One of the more extraordinary properties of NFC is the ability to form highly impregnable layers—which can be designed to repel gas molecules. The capability of NFC to form dense layers can be rationalized by the strong cohesive forces among the nanofibrils, due to the higher surface area of the nano-sized materials as compared to larger entities. It is noted that the high crystalline content of NFC, which renders the material a denser character thanks to the highly compact structure of the crystalline cellulose (≈1.6 g/cm3, (Sugiyama et al. 1991; Nishiyama et al. 2002)), has also been proposed as an explanation for the attractive barrier properties of NFC.

Fukuzumi et al. (2013) investigated NFCTEMP with different degrees of crystallinity (crystallinity index = 56–64%). These authors found that at low humidity (RHFootnote 4 = 0%) the NFC with the highest degree of crystallinity displayed the lowest oxygen transmission rate (OTR); however, the barrier property of the different systems became comparable at ambient humidity conditions. Larsson et al. (2013) investigated the oxygen permeability (OP) of NFCs based on unmodified- and periodate oxidized pulps. The investigations revealed that periodate oxidation significantly decreased the crystallinity index (down to 21% from 73% for the unmodified pulp). However, the OP-values of the periodate-oxidized NFCs were about five times lower than the unmodified system at RH = 80%. The observations were rationalized by the ability of the oxidized nanofibrils to crosslink, and thereby hindering the swelling of the NFC film. In this context, it is of interest to also highlight the contribution of Belbekhouche et al. (2011), who found that the highly crystalline NCC has inferior barrier properties to NFC. These authors related their observation to the high porosity of the NCC-film. The reports combined, hence, indicate that barrier properties are more affected by the ability of the NFC to form dense and rigid films, rather than the degree of crystallinity of the nanocellulosic materials (at least in the investigated range).

Intuitively, NFCs with a higher degree of fibrillation should form denser NFC films, as they have a lower fibre fragment (which is detrimental to the integrity of the film) content. However, as it can be seen in Table 1, the impact of degree of fibrillation is not straightforward. Aulin et al. (2010) investigated the effect of the degree of fibrillation on the barrier property of a highly charged (0.5 meq/g) NFCCarb; these authors found that the property was not affected by the degree of fibrillation. This observation is in agreement with the findings of Siró et al. (2011), who studied an NFCCarb similar to that of Aulin et al., and the finding of Österberg et al. (2013) who studied a highly fibrillated and presumably low-charged NFC. The cited observations are, however, not supported by the investigations of Naderi et al. (2015c; 2016b), which showed that the barrier properties of NFCCMC (0.17 meq/g) and NFCPhos (0.7–1 meq/g) significantly improved when the degree of fibrillation of the NFCs increased (by increasing the number of microfluidization passes). In another contribution, Naderi et al. (2016a) compared the barrier properties of a low charged (0.03 meq/g) and low fibrillated NFCEnz and a highly charged (0.6 meq/g) and efficiently fibrillated NFCCarb, and observed a lower OP-value (≈0.04 cm3 μmm−2 d−1 kPa−1) for NFCEnz as compared to that of NFCCarb (≈0.2 cm3 μmm−2 d−1 kPa−1) at RH = 50%.

The compilation in Table 1 suggests that a critical, yet low, degree of fibrillation must be reached for producing dense NFC-layers. Beyond this critical point, little improvement is achieved by increasing the degree of fibrillation of NFC.

This realization can be useful for the employment of NFCs in barrier applications. Table 2 contains the tensile strength index (TSI) and the OP of a never-dried and fully dried and then redispersed NFCCarb (0.6 meq/g). As it can be seen, the lower magnitude of the TSI of the redispersed NFCCarb indicates that full redispersion has not been achieved; yet the OP-values of the never-dried and redispersed systems are comparable. In this context, it is noted that low-charged NFCs, viz. NFCEnz, have been shown to be incapable of regaining their never-dried barrier properties (Naderi et al. 2015b), which may be rationalized by that the degrees of fibrillation of the redispersed NFCs are below the critical values of the systems.

It is pointed out that the results (in Table 2) also suggest that a lower degree of fibrillation is required for making effective NFC-based gas barriers than for producing strong NFC films.

The barrier properties of NFCs may be expected to be highly influenced by the chemical pre-treatment process in their manufacturing. The summary of several contributions in Table 1 reveals, however, that the pre-treatment method has little influence on the gas barrier properties of NFCs—when a sufficient degree of fibrillation has been achieved. Furthermore, the results indicate that NFCs with a higher number of charged groups generally sorb more water, which increases the gas permeability.

The deterioration of the barrier properties of NFC films at high humidity conditions is a major impediment to the employment of NFCs in barrier applications. This inadequacy has led to the investigation of the feasibility of several approaches, which can be broadly divided into: (a) Alteration of the chemistry of the nanofibrils prior to film formation. (b) Combination of NFC with different materials. (c) Post-modification of NFC films by the attachment of amphiphilic/hydrophobic moieties. (d) Crosslinking of the nanofibrils in the NFC film. Generally, (a–c) do not lead to significantly improved properties as introduction of “alien” groups through chemical modification onto the nanofibrils only changes a fraction of the surface of the nanofibrils. Furthermore, the creation of nanocomposites by the mixture of NFC and other nano-sized materials requires high amounts of the latter and the employment of complicated mixing processes for the efficient dispersion of the different system components (Liu et al. 2011). And finally, the surface modification of the NFC films by e.g. attachment of amphiphilic moieties onto the NFC films does at the best change the surface properties of parts of the outermost NFC-layer (Lozhechnikova et al. 2014).

Today, crosslinking of the nanofibrils seems as the most viable route for producing effective barriers at high humidity conditions. It is noted that OTR-values in the order of 10–20 cm3 m−2 d−1 have been suggested (Parry 1993) to fulfil the requirement for atmospheric packaging. Hence, contributions viz. that of Shimizu et al. (2016), showing that OP-values in the order of 0.1 cm3 μmm−2 d−1 kPa−1 at RH = 80% can be obtained through the crosslinking of NFCTEMP films by multivalent ions, are of particular interest—as the calculatedFootnote 5 OTR-values (≈1 cm3 m−2 d−1) are an order of magnitude lower than the above-mentioned threshold.

Tensile strength measurements on NFC films

Nanofibrillated cellulose films are probably the strongest fabricated cellulosic materials, which makes them potentially interesting for several applications. Tensile strength measurements are an integral part in the quality control of paper and cardboard products, and can therefore potentially be used for the evaluation of NFC-based materials. As it can be expected, the measured mechanical properties of NFC films are highly affected by the sample preparation and measuring protocols. However, contributions in the field are scarce (Olié 2016). The problem is further amplified by the inadequate documentation of the experimental set-ups in the available literature. Nevertheless, the following may be discerned.

An example of the importance of the sample preparation protocol may be distinguished by the comparison of the significantly different TSI values on NFCEnz-based films reported by Henriksson et al. (2008) and Naderi et al. (2016a); see Table 3. It is noted that Henriksson et al. employed microfluidization (which is a high shearing process) for dilution of the investigated NFCEnz (0.03 meq/g), prior to film formation, while Naderi et al. employed gentle magnetic stirring to dilute their system. The importance of the dilution process, may find support in Fig. 1, which shows that the magnitude of pulp concentration (in the mechanical fibrillation step) that leads to the maximum fibrillation of a carboxymethylated pulp is shifted to higher values when microfluidization is employed in the dilution process. Hence, if unnoticed, the employment of high shear dilution protocols leads to erroneous conclusions.

Shear viscosities of NFCCarb systems that have been produced by microfluidization (1 pass) of different concentrations of a carboxymethylated pulp (0.6 meq/g). In each series, the rheological measurements have been conducted at the same NFC concentration, by diluting concentrated NFCs by either microfluidization (to 1% (w/w), Naderi et al. 2014b) or magnetic stirring (to 0.1% (w/w), Naderi et al. 2016a). The aim of the studies was to find the pulp concentration that leads to maximum fibrillation. The lines are to guide the eye

The gathered knowledge, from the paper industry (Borch 2002), proposes that the mode of drying may affect the mechanical properties of NFC films; however, the available literature on the subject with relation to NFCs is contradictory. Sehaqui et al. (2010) reported that free-standing films (based on an NFCEnz) that were prepared by solvent evaporation, had inferior strength compared to films that were prepared by filtration and drying under restrained conditions. These results are, however, contradicted by the comparison of the mechanical properties of films based on an NFCCarb (ca 0.6 meq/g) that have been produced by solvent evaporation (Aulin et al. 2012) or filtration and drying (Naderi et al. 2016a).

Another important parameter (based on the accumulated knowledge in the paper industry; see e.g. Brännvall 2007) in the analysis of the strength of NFC films is the grammage of the films. It is well-known that below a critical grammage the strength of the NFC films rapidly decreases, which may be understood by the increasing impact of film defects. Bessonoff and Paltakari (2015) investigated the impact of grammage of NFC films on the tensile properties of different NFCs. The studies showed that the strength of the NFC films rapidly decreased below a grammage-value of about 40 g/m2. Similar findings were recently reported by Olié (2016), who investigated the impact of grammage on TSI of films based on an NFCEnz (0.03 meq/g) and an NFCcarb (0.6 meq/g). In passing, it is noted that this author also investigated the impact of several other measuring parameters in tensile strength studies. It is interesting to note that NFC films that have been prepared by solvent evaporation have reported grammage values that are considerably lower than 40 g/m2. Hence, these notions may provide an explanation for the contradictory results of Sehaqui et al. (2010) and those of Aulin et al. (2012) and Naderi et al. (2016a).

It may be perceived that the tensile strength of NFC films is defined by the chemical pre-treatment method in the NFC manufacturing process. For example, Naderi et al. (2016a) found that films based on NFCCarb (0.6 meq/g) displayed a high tensile strength index (TSI ≈ 170 kNm/kg), while films based on NFCEnz (0.03 meq/g) and NFCCMC (0.17 meq/g) displayed significantly lower TSI-values (≈110 kNm/kg, when evaluated at the same amount of shearing). However, the summarized contributions in Table 3 reveal that sufficiently fibrillated NFCs display about the same tensile strength (TSI ≈ 170 kNm/kg), which incidentally has been proposed by Lindström (2016) to be the highest theoretical value for the strength of NFC films. The exception to this observation is perhaps periodate oxidation (Table 3), which is known to significantly reduce e.g. the degree of polymerization (D.P.) of cellulosic materials (Hou et al. 2007). The importance of D.P. on TSI will be elaborated in the following section.

The ease of fibrillation of the cellulosic materials is, however, highly affected by the pre-treatment process. For example, the low-charged NFCEnz (0.03 meq/g) is very difficult to fibrillate (Naderi et al. 2016a), but highly charged NFCs viz. NFCTEMP, NFCCarb and NFCPhos are more easily fibrillated (Fukuzumi et al. 2013; Naderi et al. 2015a, 2016b). The more interesting revelation from the survey in Table 3 is that introduction of charges in the fibrous system (irrespective of their mode of addition) is beneficial for the fibrillation process. For example, Naderi et al. (2015c) found that the degree of fibrillation of NFCCMC could be significantly improved by increasing the energy consumption in the mechanical fibrillation process. It is noted that NFCCMC is produced by physical grafting of CMC chains onto the outer layers of the cellulosic materials (Laine et al. 2000) prior to fibrillation. On the other hand, the pre-treatment processes of NFCCarb, NFCTEMP and NFCPhos are based on the chemical grafting of charged groups onto the nanofibrils.

Saito et al. (2009) studied the impact of D.P. on the tensile properties of NFCTEMP (≤0.8 meq/g), and found that decreasing the D.P. of the NFC lowered the strength of the corresponding film (Fig. 2). Fukuzumi et al. (2013) investigated the impact of D.P. of NFCTEMP (1.5 meq/g) on the tensile properties of the corresponding films and observed that the tensile strength of the NFC films decreased with the lowering of the D.P. (Fig. 2). On a similar note, Henriksson et al. (2008) observed that the strength of films based on an NFCEnz (presumably low charged) decreased when the D.P. of the pulp decreased (Fig. 2). Interestingly, Landmér (2015) observed that the TSI-values of films based on an NFCCarb (0.6 meq/g) remained unaffected when D.P. of the pulp exceeded a value of about 1000. However, a significant lowering of the tensile strength of films was observed when D.P. decreased below 1000 (Fig. 2). It is interesting to note that a similar criticalFootnote 6 D.P. value has been proposed for the strength of cellulose fibres (Gurnagul et al. 1992), which affects the strength of fibrous structures viz. paper sheets.

The impact of D.P. on TSI of NFC films. (filled square) NFCCarb (ca 0.6 meq/g), reproduction from (Landmér 2015). (open square) NFCEnz (0.03 meq/g), reproduction from Henriksson et al. (2008). (filled rectangle) NFCTEMP (≤0.8 meq/g), reproduction from Saito et al. (2009). (open triangle) NFCTemp (1.5 meq/g), reproduction from Fukuzumi et al. (2013). The results of Henriksson et al., Saito et al., and Fukuzumi et al. have been estimated by dividing the reported stress values by the assumed density (1.5 g/cm3) of the NFC films. The lines are to guide the eye

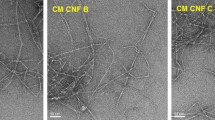

Centrifugation of NFC suspensions

The ability to estimate the NFC content is highly desirable for quality control purposes, and for process development. However, the highly-entangled state of most NFCs makes the estimation of the nano-fraction of NFCs a virtually insurmountable task. Hence, in the waiting for the development of efficient analytical methodologies the research community has resorted to engineering tools viz. centrifugation. This method assumes that the nanofibril content (NC) in the supernatant (after centrifugation of the highly-diluted sample) increases with the increasing efficiency of the fibrillation process. It is noted that higher charged entities can more effectively resist the centrifugal force than lower charged entities. Hence, care should be taken when comparing NFCs with different charge densities, by centrifugation. In these instances, centrifugation studies must be combined with other analytical methods (viz. tensile strength measurements on NFC films). This point has been raised by Naderi et al. (2016a), who compared the degrees of fibrillation of NFCEnz (0.03 meq/g), NFCCMC (0.17 meq/g) and NFCCarb (0.6 meq/g), by combining several methodologies.

Fall et al. (2011) applied centrifugation on NFCCarb with different charge densities and observed the highest NC for the highest charged system. A similar trend was also observed by Tanaka et al. (2012) who investigated NFCTEMP. Fall et al. (2014) investigated NFC systems based on different wood species and observed a higher NC (by centrifugation of 0.2% (w/w) suspensions) for the species that had a higher hemicellulose content.

The high NFC concentration (0.2% (w/w)) in the centrifugation process of Fall et al. (2014) is noteworthy, as it resides beyond the critical network forming concentration of several NFC systems (Pääkkö et al. 2007; Tanaka et al. 2014). Implications of this notion can be observed in the report of Naderi et al. (2014a), who showed that the suspension concentration should be well below the critical network forming concentration of the system, for the effective separation of the nanofibrils from lesser fibrillated system constituents (Fig. 3).

The impact of NFCCarb (0.6 meq/g) suspension concentration on the apparent nanofibril content as obtained by centrifugation; reproduction from (Naderi et al. 2014a). The line is to guide the eye

Naderi et al. (2015a) studied an NFCCarb (0.6 meq/g) that was produced by different amount of shearing, and observed a correlation between NC and shear viscosity (Fig. 4). A correlation between TSI and the nanofibril content was also observed (Fig. 4) for NC up to about 50% (w/w), beyond which TSI plateaued at about 170 kNm/kg. This observation indicates that a very high degree of fibrillation is not required for achieving optimum NFC properties, at least with respect to TSI (and OP, Table 1). It is postulated that a similar conclusion can also be drawn for the rheological properties of NFCs, by e.g. considering the studies of Naderi et al. (2016a). These authors showed that a continued shearing of NFCs beyond their optimum degree of fibrillation results in the deterioration of the rheological properties (due to the proposed shortening of the nanofibrils).

The impact of amount of shearing (expressed as energy consumption) on the properties of NFCCarb (0.6 meq/g). The shearing was achieved by the repeated microfluidization of a 1.2% (w/w) carboxymethylated system at 400 bar. Reproduction from (Naderi et al. 2015a). The lines are to guide the eye

Concluding remarks

In this report, the literature on the properties of NFC was reinvestigated in the light of recent developments in the field of characterization of NFC, and current understandings. The following findings are highlighted:

The success of rheological investigations is dependent on the employment of proper sample handling and measuring protocols. The shear viscosity curves of NFC networks display often a more complex behaviour than highly fibrillated equivalents.

Barrier properties of NFC film, at ambient conditions, are less affected by the crystallinity of the nanofibrils than the ability of the nanofibrils to form dense and rigid structures. Furthermore, the nature of the pre-treatment process has little impact on the property. Interestingly, attractive barrier properties can be obtained by low-fibrillated NFCs, if the degree of fibrillation of the system is above a critical value.

Incorporation of charges in fibrous systems enhances the fibrillation process. Nanofibrillated celluloses based on different pre-treatment processes (except for possibly periodate oxidation) display about the same optimum strength, if the degrees of fibrillation of the NFCs are sufficiently high.

The literature survey proposes the existence of a critical D.P., below which the tensile strengths of NFC films are highly dependent on the magnitude of the D.P. of the fibrillated system.

Change history

13 October 2017

In the original publication of the article, the co-author name Tom Lindström was mistakenly missed out. Also the affiliation of the corresponding author was provided incorrectly. It has been updated in this erratum.

Notes

Relative humidity.

OTR can be estimated by knowing the OP and film thickness (that was given by the authors): OTR ~ OP/film-thickness.

The critical value applies for systems in which the degradation process of D.P. is homogeneous and random.

References

Agoda-Tandjawa G, Durand S, Berot S, Blassel C, Gaillard C, Garnier C, Doublier JL (2010) Rheological characterization of microfibrillated cellulose suspensions after freezing. Carbohydr Polym 80(3):677–686. doi:10.1016/j.carbpol.2009.11.045

Aulin C, Gällstedt M, Lindström T (2010) Oxygen and oil barrier properties of microfibrillated cellulose films and coatings. Cellulose 17:559–574

Aulin C, Salazar-Alvarez G, Lindström T (2012) High strength, flexible and transparent nanofibrillated cellulose-nanoclayt biohybrid films with tunable oxygen and water vapor permeability. Nanoscale 4:6622–6628

Belbekhouche S, Bras J, Siqueira G, Chappey C, Lebrun L, Khelifi B, Marais S, Dufresne A (2011) Water sorption behavior and gas barrier properties of cellulose whiskers and microfibrils films. Carbohydr Polym 83(4):1740–1748. doi:10.1016/j.carbpol.2010.10.036

Berglund LA (2005) Cellulose-based nanocomposites. In: Mohanty A, Misra M, Drzal L (eds) Natural fibres, biopolymers and biocomposites. Taylor & Francis, Abingdon, pp 807–832

Besbes I, Alila S, Boufi S (2011) Nanofibrillated cellulose from TEMPO-oxidized eucalyptus fibres: effect of the carboxyl content. Carbohydr Polym 84(3):975–983. doi:10.1016/j.carbpol.2010.12.052

Bessonoff M, Paltakari J (2015) A rapid method for the production of fibrillar cellulose films and an insight on their properties. Nord Pulp Pap Res J 30(1):142–148

Borch J (2002) Handbook of physical testing of paper, vol 2, 2nd edn. Marcel Dekker, New York

Boufi S, González I, Delgado-Aguilar M, Tarrès Q, Pèlach MÀ, Mutjé P (2016) Nanofibrillated cellulose as an additive in papermaking process: a review. Carbohydr Polym 154:151–166. doi:10.1016/j.carbpol.2016.07.117

Brännvall E (2007) Aspects on strength delivery and higher utilisation of the strength potential of softwood kraft pulp fibres. Doctoral thesis, Royal Institute of Technology, Stockholm

de Kort DW, Veen SJ, Van As H, Bonn D, Velikov KP, van Duynhoven JPM (2016) Yielding and flow of cellulose microfibril dispersions in the presence of a charged polymer. Soft Matter 12(21):4739–4744. doi:10.1039/c5sm02869h

Dong H, Snyder JF, Williams KS, Andzelm JW (2013) Cation-Induced hydrogels of cellulose nanofibrils with tunable moduli. Biomacromol 14(9):3338–3345. doi:10.1021/bm400993f

Dufresne A (2013) Nanocellulose: a new ageless bionanomaterial. Mater Today 16(6):220–227. doi:10.1016/j.mattod.2013.06.004

Fall AB, Lindström SB, Sundman O, Ödberg L, Wågberg L (2011) Colloidal stability of aqueous nanofibrillated cellulose dispersions. Langmuir 27:11332–11338

Fall AB, Burman A, Wågberg L (2014) Cellulosic nanofibrils from eucalyptus, acacia and pine fibers. Nord Pulp Pap Res J 29(1):176–184

Fukuzumi H, Saito T, Isogai A (2013) Influence of TEMPO-oxidized cellulose nanofibril length on film properties. Carbohydr Polym 93(1):172–177. doi:10.1016/j.carbpol.2012.04.069

Fukuzumi H, Tanaka R, Saito T, Isogai A (2014) Dispersion stability and aggregation behavior of TEMPO-oxidized cellulose nanofibrils in water as a function of salt addition. Cellulose 21(3):1553–1559. doi:10.1007/s10570-014-0180-z

Ghanadpour M, Carosio F, Larsson PT, Wågberg L (2015) Phosphorylated cellulose nanofibrils: a renewable nanomaterial for the preparation of intrinsically flame-retardant materials. Biomacromol. doi:10.1021/acs.biomac.5b01117

Gurnagul N, Page DH, Paice MG (1992) The effect of cellulose degradation on the strength of wood pulp fibres. Nord Pulp Pap Res J 07(3):152–154. doi:10.3183/NPPRJ-1992-07-03-p152-154

Henriksson M, Berglund LA, Isaksson P, Lindström T, Nishino T (2008) Cellulose nanopaper structures of high toughness. Biomacromol 9:1579–1585

Herrick FW, Casebier RL, Hamilton JK, Sandberg KR (1983) Microfibrillated cellulose: morphology and accessibility. Appl Polym Sci Symp 37:797–813

Hou QX, Liu W, Liu ZH, Bai LL (2007) Characteristics of wood cellulose fibers treated with periodate and bisulfite. Ind Eng Chem Res 46:7830–7837. doi:10.1021/ie0704750

Iotti M, Gregersen ØW, Moe S, Lenes M (2011) Rheological studies of microfibrillar cellulose water dispersions. J Polym Environ 19(1):137–145. doi:10.1007/s10924-010-0248-2

Jowkarderis L, van de Ven TM (2014) Intrinsic viscosity of aqueous suspensions of cellulose nanofibrils. Cellulose. doi:10.1007/s10570-014-0292-5

Jowkarderis L, van de Ven TGM (2015) Rheology of semi-dilute suspensions of carboxylated cellulose nanofibrils. Carbohydr Polym 123:416–423. doi:10.1016/j.carbpol.2015.01.067

Karppinen A, Vesterinen A-H, Saarinen T, Pietikäinen P, Seppälä J (2011) Effect of cationic polymethacrylates on the rheology and flocculation of microfibrillated cellulose. Cellulose 18(6):1381–1390. doi:10.1007/s10570-011-9597-9

Karppinen A, Saarinen T, Salmela J, Laukkanen A, Nuopponen M, Seppälä J (2012) Flocculation of microfibrillated cellulose in shear flow. Cellulose 19(6):1807–1819. doi:10.1007/s10570-012-9766-5

Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed 50(24):5438–5466

Laine J, Lindström T, Nordmark GG, Risinger G (2000) Studies on topochemical modification of cellulosic fibers. Part 1. Chemical conditions for the attachment of carboxymethyl cellulose onto fibers. Nord Pulp Pap Res J 15:520–526. doi:10.3183/NPPRJ-2000-15-05-p520-526

Landmér A (2015) Sambandet mellan cellulosakedjans polymerisationsgrad och styrkan i nanofibrillerad cellulosafilm. KTH, Stockholm

Larsson PA, Kochumalayil JJ, Wågberg L (2013) Oxygen and water vapour barrier films with low moisture sensitivity fabricated from self-cross-linking fibrillated cellulose. In: 15th fundamental research symposium: advances in pulp and paper research, Cambridge. The pulp and paper fundamental research society, pp 851–866

Larsson PA, Berglund LA, Wagberg L (2014) Ductile all-cellulose nanocomposite films fabricated from core-shell structured cellulose nanofibrils. Biomacromol 15(6):2218–2223. doi:10.1021/bm500360c

Lasseuguette E, Roux D, Nishiyama Y (2008) Rheological properties of microfibrillar suspension of TEMPO-oxidized pulp. Cellulose 15(3):425–433. doi:10.1007/s10570-007-9184-2

Lavoine N, Desloges I, Dufresne A, Bras J (2012) Microfibrillated cellulose—its barrier properties and applications in cellulosic materials: a review. Carbohydr Polym 90(2):735–764. doi:10.1016/j.carbpol.2012.05.026

Lindström T (2016) From microfibrillar cellulose to nanocellulose applications—an account of the evolutionary developments. In: Paper presented at the 9th international paper and coating chemistry symposium/international paper physics conference Tokyo, Japan, October 29-November 1

Lindström T, Aulin C, Naderi A, Ankerfors M (2014) Microfibrillated cellulose. Encyclopedia of Polymer Science and Technology. Wiley, New York

Liu A, Walther A, Ikkala O, Belova L, Berglund LA (2011) Clay nanopaper with tough cellulose nanofiber matrix for fire retardancy and gas barrier functions. Biomacromol 12(3):633–641. doi:10.1021/bm101296z

Lowys M-P, Desbrières J, Rinaudo M (2001) Rheological characterization of cellulosic microfibril suspensions. Role of polymeric additives. Food Hydrocolloid 15:25–32

Lozhechnikova A, Dax D, Vartiainen J, Willfor S, Xu C, Osterberg M (2014) Modification of nanofibrillated cellulose using amphiphilic block-structured galactoglucomannans. Carbohydr Polym 110:163–172. doi:10.1016/j.carbpol.2014.03.087

MacKintosh FC, Kas J, Janmey PA (1995) Elasticity of semiflexible biopolymer networks. Phys Rev Lett 75:4425–4428. doi:10.1103/PhysRevLett.75.4425

Medronho B, Romano A, Miguel M, Stigsson L, Lindman B (2012) Rationalizing cellulose (in)solubility: reviewing basic physicochemical aspects and role of hydrophobic interactions. Cellulose 19(3):581–587. doi:10.1007/s10570-011-9644-6

Naderi A, Lindström T (2014) Carboxymethylated nanofibrillated cellulose: effect of monovalent electrolytes on the rheological properties. Cellulose 21(5):3507–3514. doi:10.1007/s10570-014-0394-0

Naderi A, Lindström T (2015) Rheological measurements on nanofibrillated cellulose systems: a science in progress. In: Monda HI (ed) Cellulose and cellulose derivatives: synthesis, modification and applications. Biochemistry research trends. Nova Science Publishers Inc, New York, pp 187–202

Naderi A, Lindström T (2016) A comparative study of the rheological properties of three different nanofibrillated cellulose systems. Nord Pulp Pap Res J 31(3):354–363

Naderi A, Lindström T, Pettersson T (2014a) The state of carboxymethylated nanofibrils after homogenization-aided dilution from concentrated suspensions: a rheological perspective. Cellulose 21(4):2357–2368. doi:10.1007/s10570-014-0329-9

Naderi A, Lindström T, Sundström J (2014b) Carboxymethylated nanofibrillated cellulose: rheological studies. Cellulose 21(3):1561–1571. doi:10.1007/s10570-014-0192-8

Naderi A, Lindström T, Sundström J (2015a) Repeated homogenization, a route for decreasing the energy consumption in the manufacturing process of carboxymethylated nanofibrillated cellulose? Cellulose 22(2):1147–1157. doi:10.1007/s10570-015-0576-4

Naderi A, Lindström T, Sundström J, Flodberg G (2015b) Can redispersible low-charged nanofibrillated cellulose be produced by the addition of carboxymethyl cellulose? Nord Pulp Pap Res J 30(4):568–577. doi:10.3183/NPPRJ-2015-30-04-p568-577

Naderi A, Lindström T, Sundström J, Pettersson T, Flodberg G, Erlandsson J (2015c) Microfluidized carboxymethyl cellulose modified pulp: a nanofibrillated cellulose system with some attractive properties. Cellulose 22(2):1159–1173. doi:10.1007/s10570-015-0577-3

Naderi A, Lindström T, Erlandsson J, Sundström J, Flodberg G (2016a) A comparative study of the properties of three nanofibrillated cellulose systems that have been produced at about the same energy consumption levels in the mechanical delamination step. Nord Pulp Pap Res J 31(3):364–371

Naderi A, Lindström T, Weise CF, Flodberg G, Sundström J, Junel K, Erlandsson J, Runebjörk A (2016b) Phosphorylated nanofibrillated cellulose: production and properties. Nord Pulp Pap Res J 31(1):22–31

Naderi A, Larsson PT, Stevanic JS, Lindström T, Erlandsson J (2017) Effect of the size of the charged group on the properties of alkoxylated NFCs. Cellulose 24(3):1307–1317. doi:10.1007/s10570-017-1190-4

Nechyporchuk O, Belgacem MN, Pignon F (2014) Rheological properties of micro-/nanofibrillated cellulose suspensions: wall-slip and shear banding phenomena. Carbohydr Polym 112:432–439. doi:10.1016/j.carbpol.2014.05.092

Nechyporchuk O, Belgacem MN, Pignon F (2016) Current progress in rheology of cellulose nanofibril suspensions. Biomacromol 17(7):2311–2320. doi:10.1021/acs.biomac.6b00668

Nishiyama Y, Langan P, Chanzy H (2002) Crystal structure and hydrogen bonding system in cellulose I-beta from X-ray and neutron fiber diffraction. JACS 124(31):9074–9082

Olié N (2016) Development of a protocol for measuring the tensile properties of nanofibrillated cellulose (NFC) films. Internship report, p 1–16, Polytech Grenoble (France)

Österberg M, Vartiainen J, Lucenius J, Hippi U, Seppala J, Serimaa R, Laine J (2013) A fast method to produce strong NFC films as a platform for barrier and functional materials. Appl Mater Interfaces 5:4640–4647

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O, Lindström T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromol 8(6):1934–1941

Parry RT (1993) Principles and applications of modified atmosphere packaging of foods, 1st edn. Springer, New York. doi:10.1007/978-1-4615-2137-2

Quennouz N, Hashmi SM, Choi HS, Kim JW, Osuji CO (2016) Rheology of cellulose nanofibrils in the presence of surfactants. Soft Matter 12(1):157–164. doi:10.1039/C5SM01803J

Saarinen T, Lille M, Seppälä J (2009) Technical aspects on rheological characterization of microfibrillar cellulose water suspensions. Annu Trans Nord Rheol Soc 17:121–128

Saito T, Hirota M, Fukuzumi H, Tamura N, Heux L, Kimura S, Isogai A (2009) Individualization of nano-sized plant cellulose fibrils by direct surface carboxylation using TEMPO catalyst under neutral conditions. Biomacromol 10(7):1992–1996

Sehaqui H, Liu A, Zhou Q, Berglund LA (2010) Fast preparation procedure for large, flat cellulose and cellulose/inorganic nanopaper structures. Biomacromol 11(9):2195–2198

Shimizu M, Saito T, Isogai A (2016) Water-resistant and high oxygen-barrier nanocellulose films with interfibrillar cross-linkages formed through multivalent metal ions. J Memb Sci 500:1–7. doi:10.1016/j.memsci.2015.11.002

Shogren RL, Peterson S, Evans KO, Kenar JA (2011) Preparation and characterization of cellulose gels from corn cobs. Carbohydr Polym 86:1351–1357

Siró I, Plackett D, Hedenqvist M, Ankerfors M, Lindström T (2011) Highly transparent films from carboxymethylated microfibrillated cellulose: the effect of multiple homogenization steps on key properties. J Appl Polym Sci 119(5):2652–2660. doi:10.1002/app.32831

Sugiyama J, Vuong R, Chanzy H (1991) Electron diffraction study on the two crystalline phases occurring in native cellulose from an algal cell wall. Macromolecules 24(14):4168–4175. doi:10.1021/ma00014a033

Tanaka R, Saito T, Isogai A (2012) Cellulose nanofibrils prepared from softwood cellulose by TEMPO/NaClO/NaClO(2) systems in water at pH 4.8 or 6.8. Int J Biol Macromol 51(3):228–234. doi:10.1016/j.ijbiomac.2012.05.016

Tanaka R, Saito T, Ishii D, Isogai A (2014) Determination of nanocellulose fibril length by shear viscosity measurement. Cellulose 21(3):1581–1589. doi:10.1007/s10570-014-0196-4

Tatsumi D, Ishioka S, Matsumoto T (2002) Effect of fiber concentration and axial ratio on the rheological properties of cellulose fiber suspensions. J Soc Rheol Jpn 30:27–32

Tatsumi D, Inaba D, Matsumoto T (2008) Layered structure and viscoelastic properties of wet pulp fiber networks. J Soc Rheol Jpn 36:235–239. doi:10.1678/rheology.36.235

Acknowledgments

Sundbladsfonden is acknowledged for its financial support. Professor Tom Lindström is thanked for insightful discussions.

Author information

Authors and Affiliations

Corresponding author

Additional information

An erratum to this article is available at https://doi.org/10.1007/s10570-017-1516-2.

Rights and permissions

About this article

Cite this article

Naderi, A. Nanofibrillated cellulose: properties reinvestigated. Cellulose 24, 1933–1945 (2017). https://doi.org/10.1007/s10570-017-1258-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1258-1